Patents

Literature

30 results about "Mouse Tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

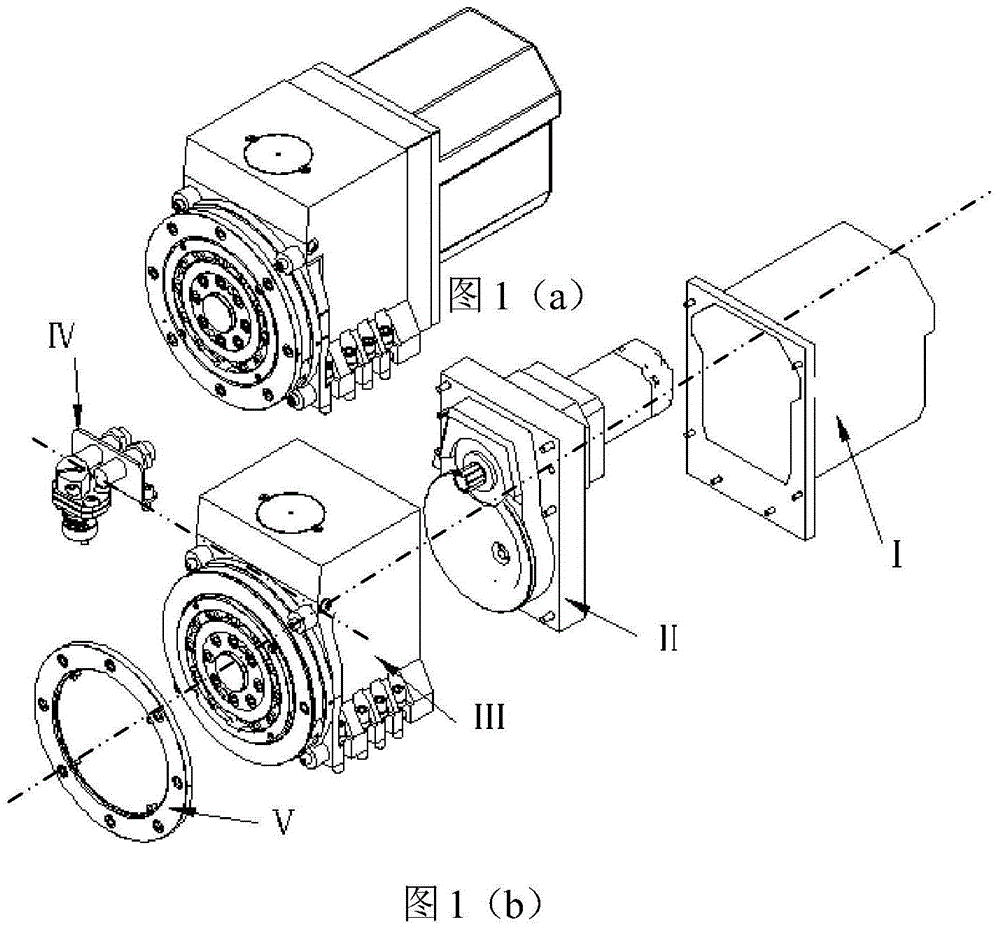

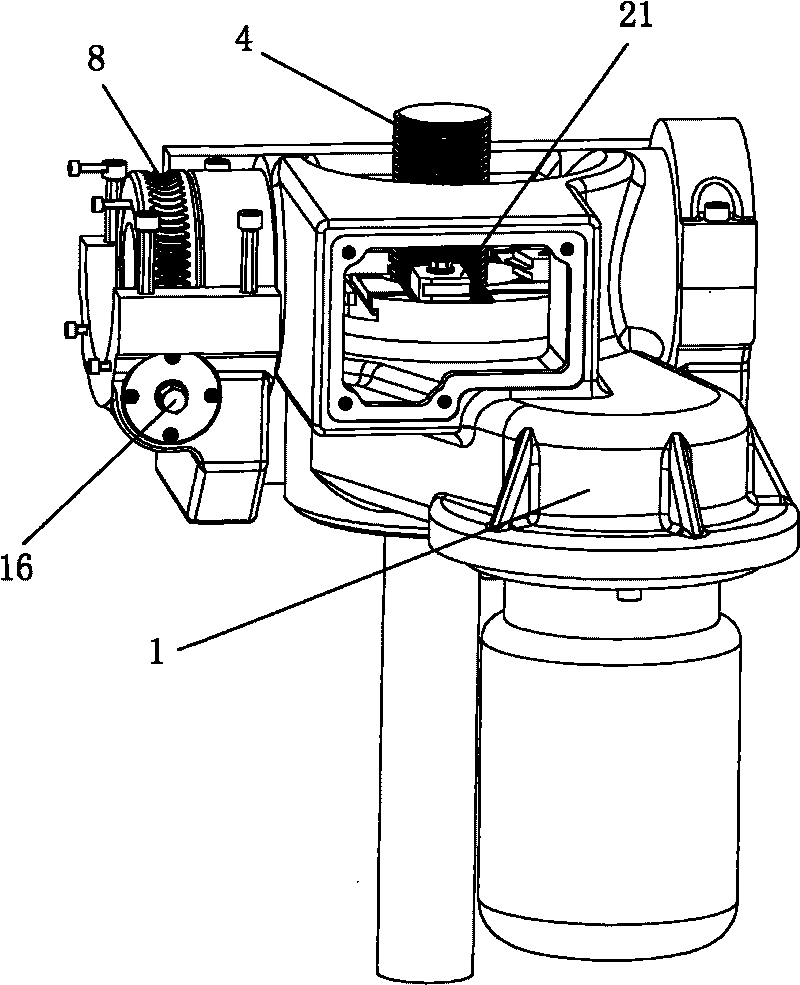

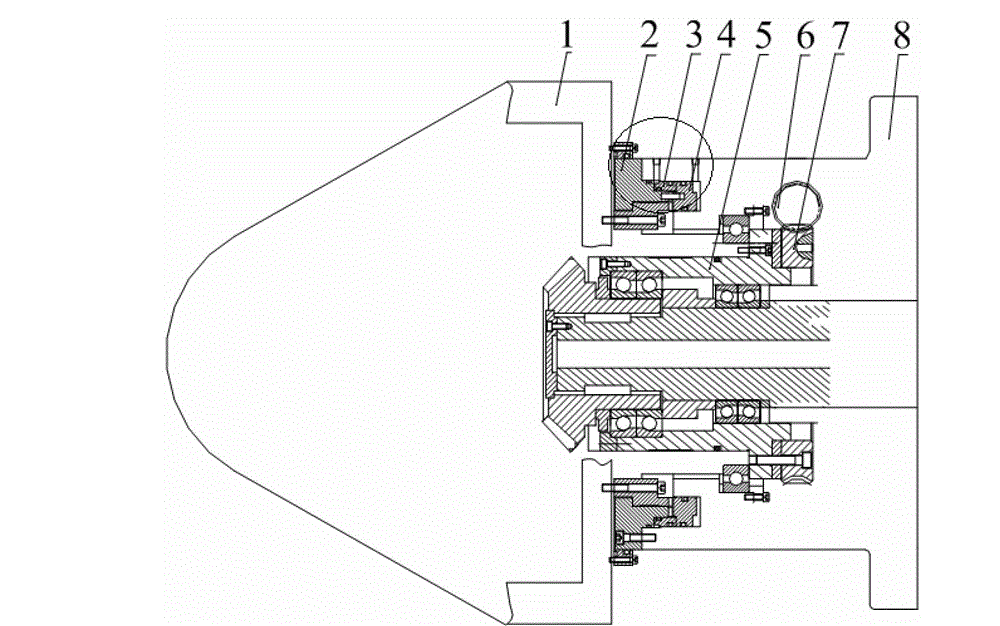

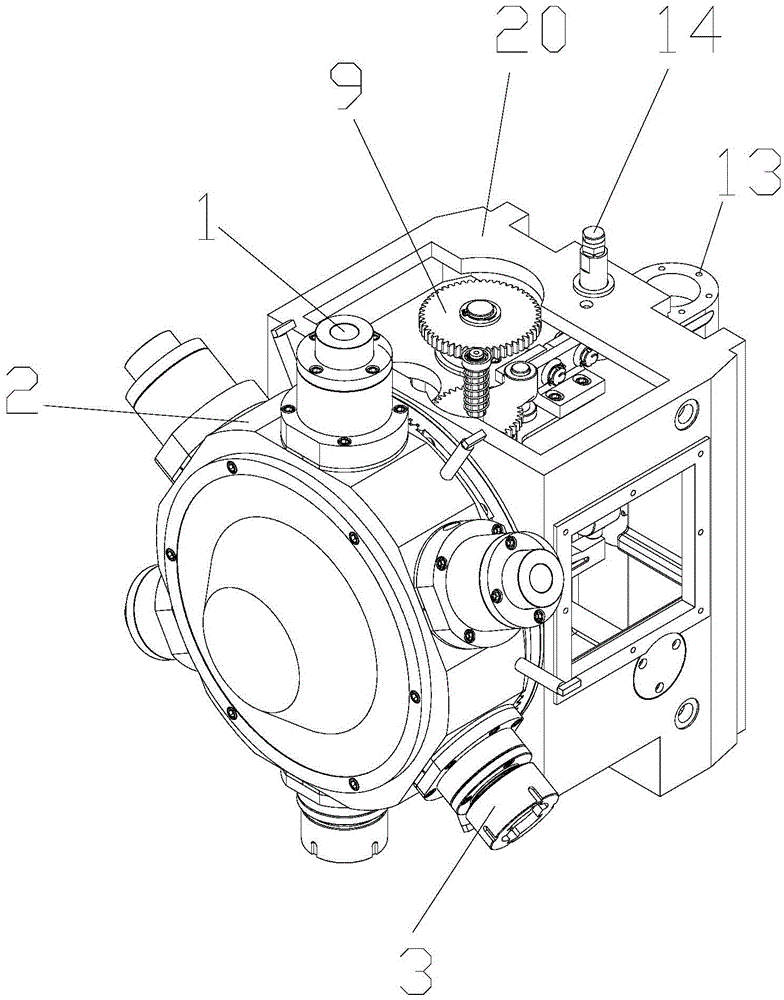

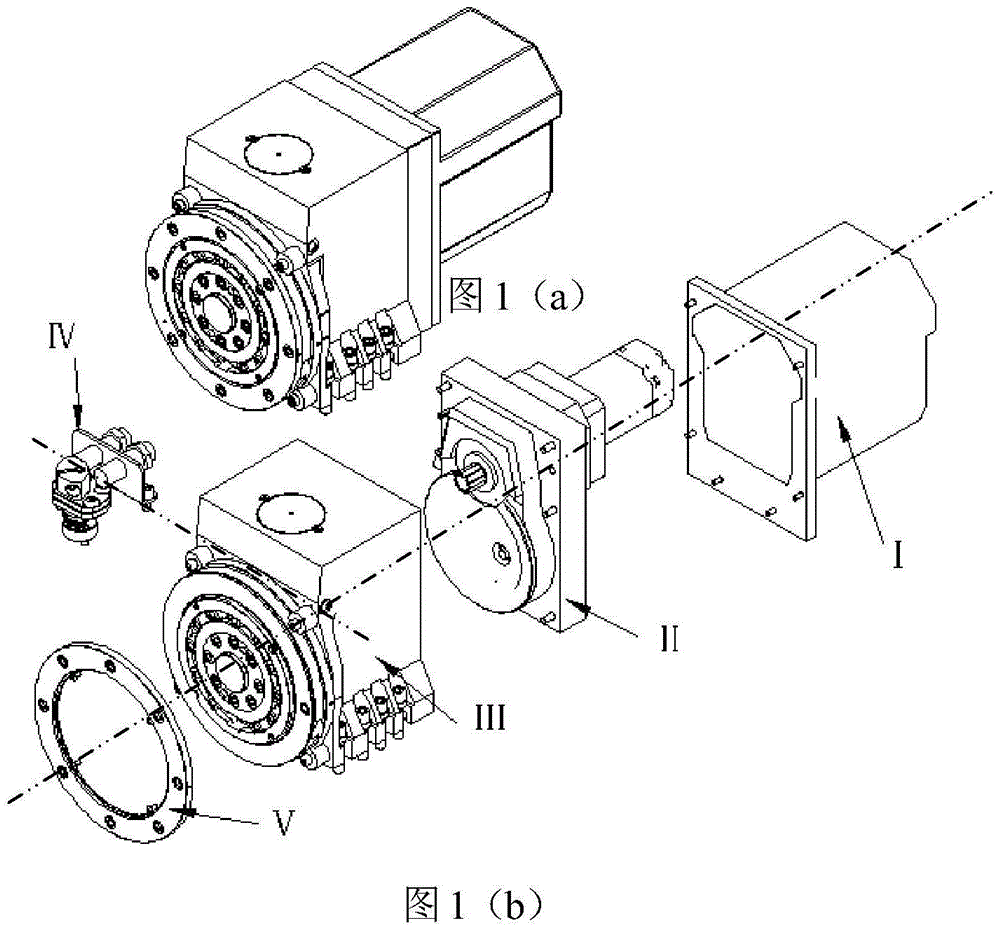

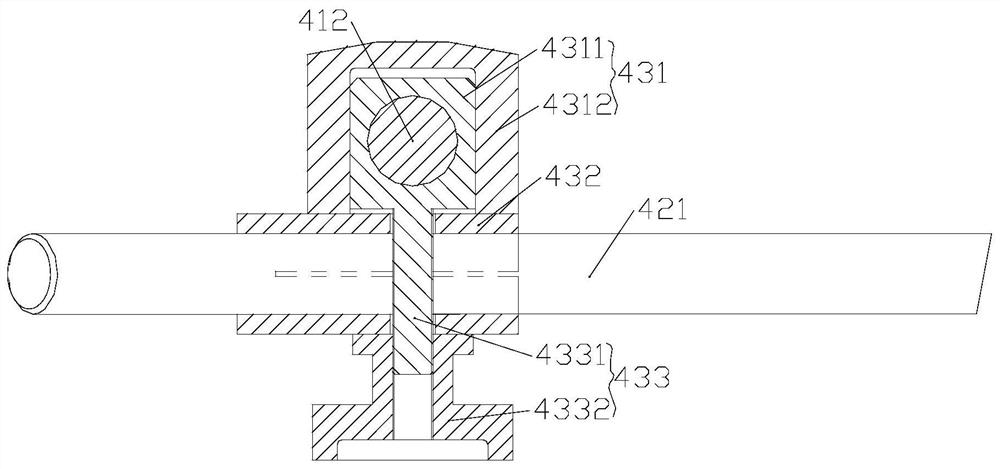

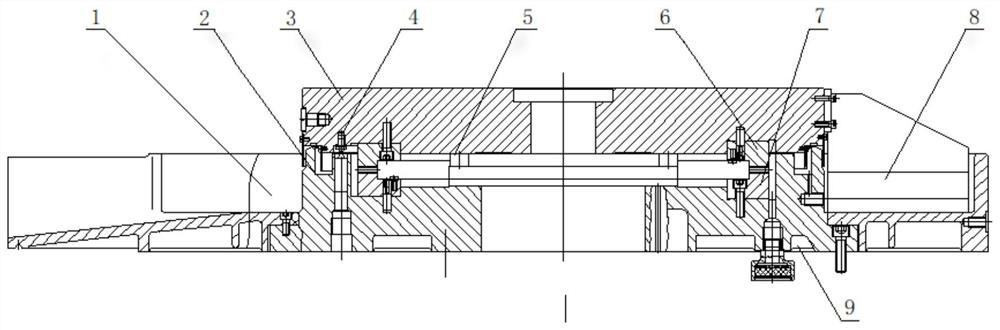

Servo tool rest structure and application method thereof

ActiveCN104815994AEasy to installEasy to debugPrecision positioning equipmentMachine tool componentsNumerical controlReduction drive

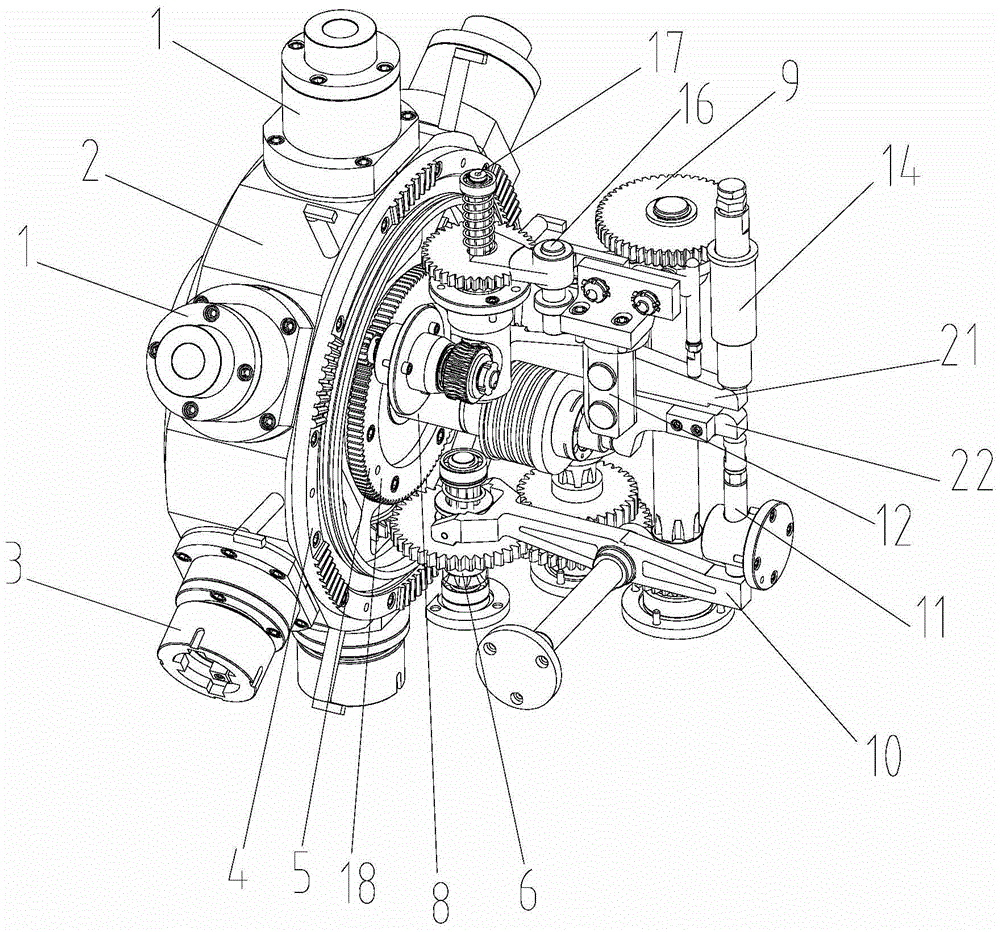

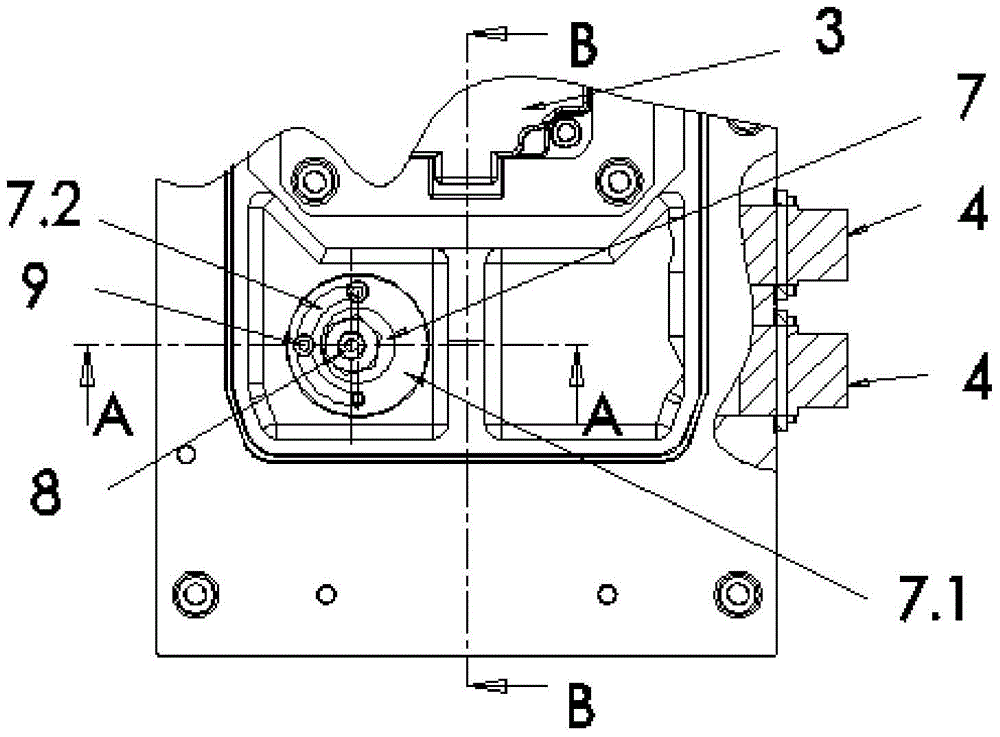

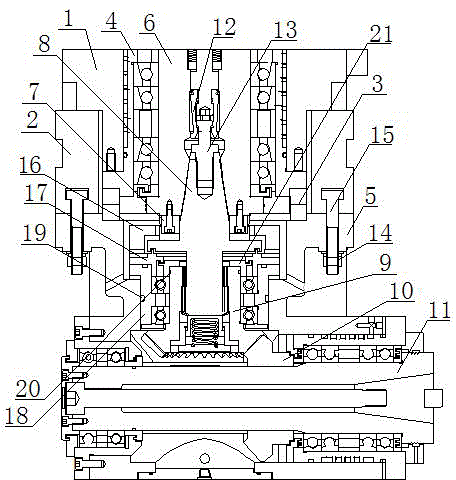

The invention relates to the field of tool rests for numerical control machine tools, in particular to a servo tool rest structure and an application method thereof. The servo tool rest is provided with a shell, a rear cover plate assembly, a box assembly, a proximity switch assembly and a water division disk, wherein the shell is installed at the tail of the rear cover plate assembly, the speed reducer end of the rear cover plate assembly is connected with the rear end of the box assembly, the proximity switch assembly is installed in the box of the box assembly, and the water division disk is installed on a moving gear disk of the box assembly. A motor and a speed reducer of the rear cover plate assembly are installed on a rear cover plate and are used as a power source; the box assembly is positioned with a three-mouse-tooth disk structure, and a cam structure is adopted in the proximity switch to detect the locking state of a tool rest. With the servo tool rest structure and the application method thereof, the problems that in the prior art, motion actions are complex and the structure is complex when a tool rest is positioned and translocated, and the difficulty degree of tool rest part manufacturing and complete machine assembly are increased are solved, and the servo tool rest structure and the application method thereof are applied to numerical control machine tools and numerical control turning centers to realize tool replacement.

Owner:SHENYANG MASCH TOOL CO LTD

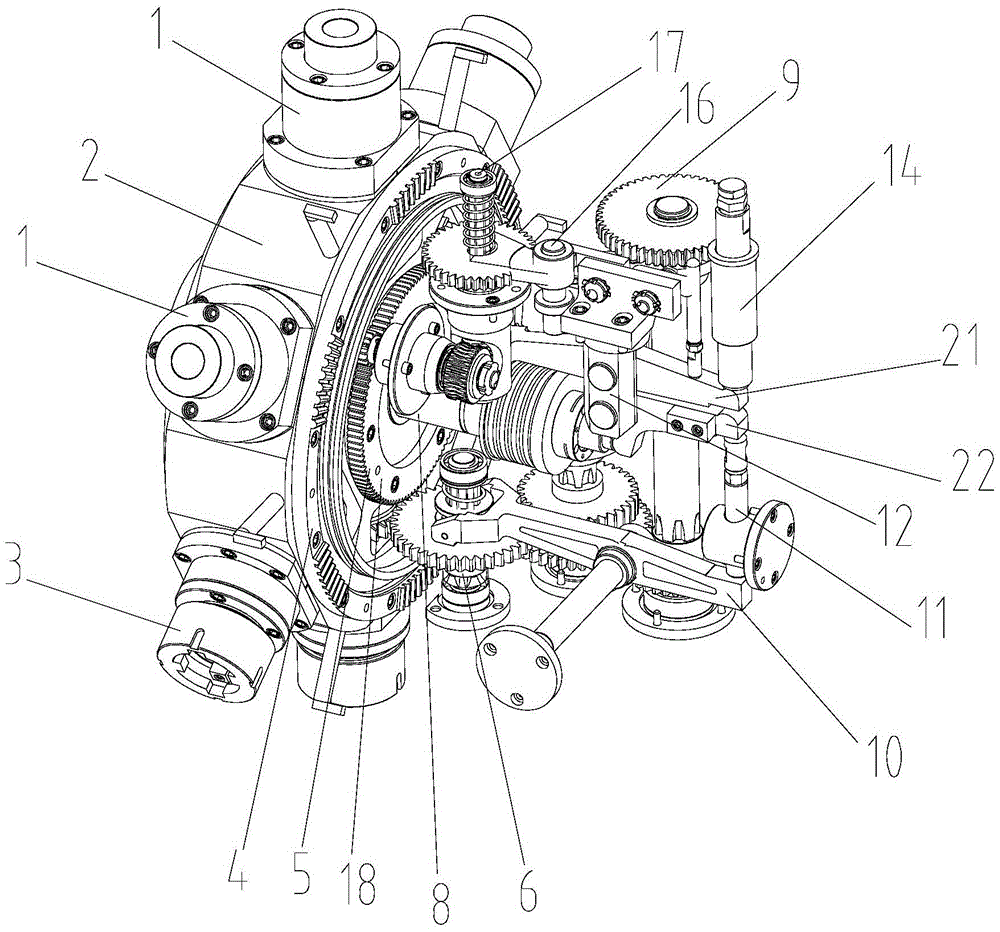

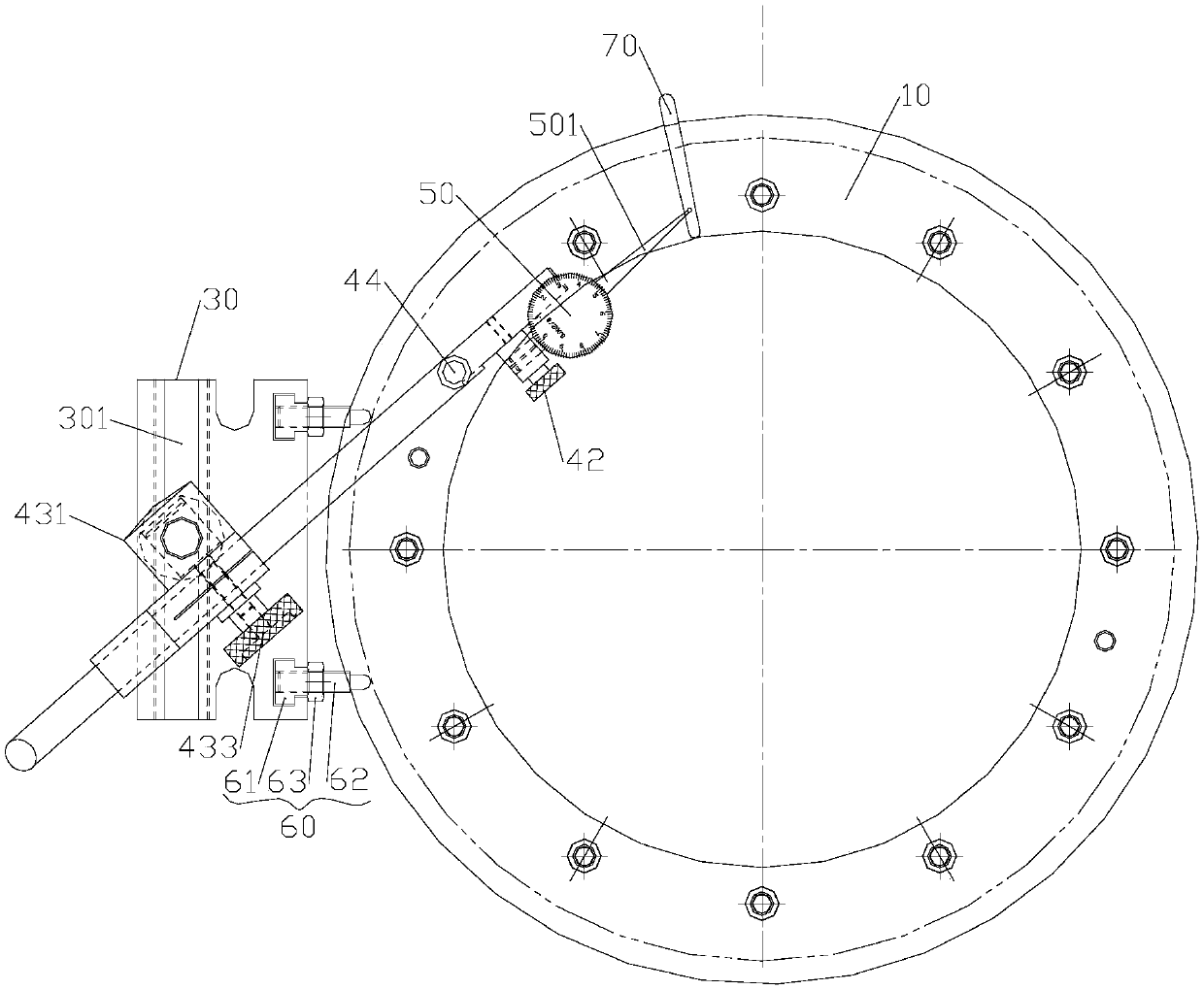

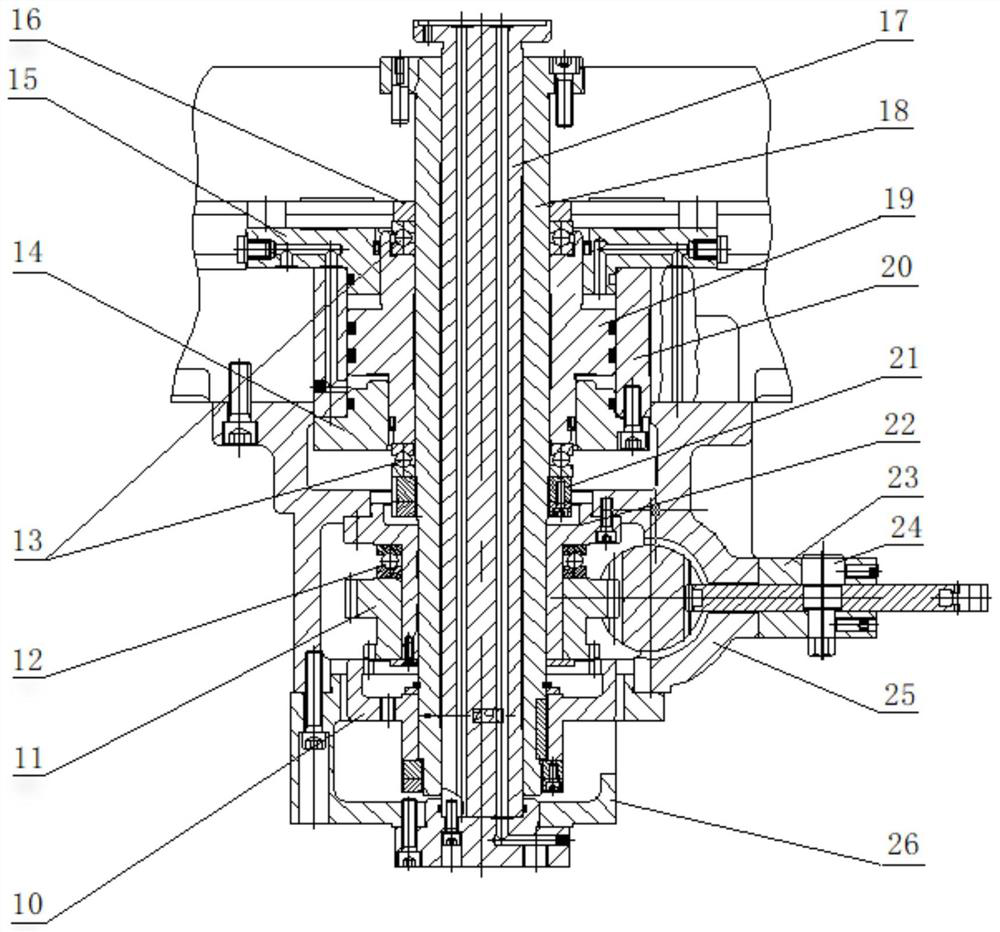

Multifunctional drilling and milling mechanism

ActiveCN103949887ARealize heavy cutting drilling and millingImprove machining accuracyOther manufacturing equipments/toolsLarge fixed membersMouse ToothEngineering

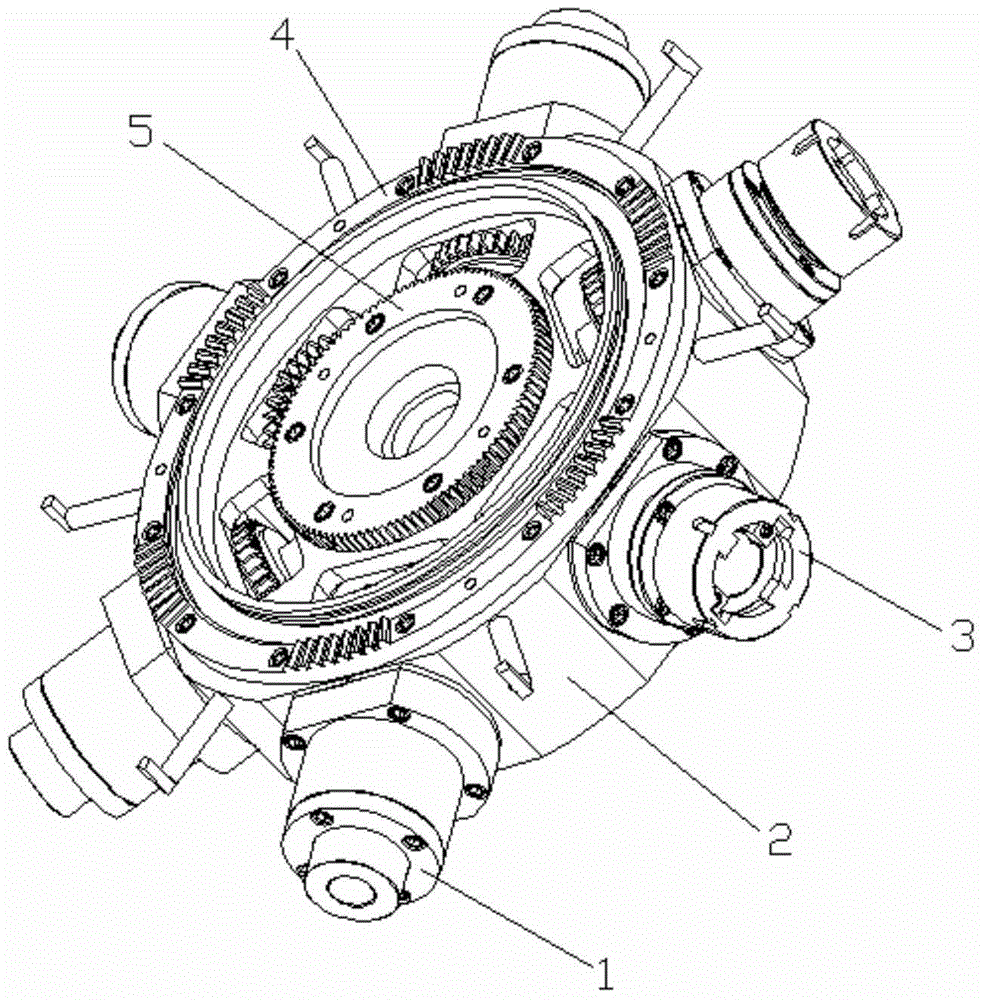

The invention discloses a multifunctional drilling and milling mechanism. The multifunctional drilling and milling mechanism comprises a main shaft head and a main shaft box, wherein the main shaft head comprises four drilling power heads, a main shaft box shell, two milling power heads, a mouse-tooth disc and a cutter disc gear, wherein the four drilling power heads and the two milling power heads are uniformly distributed along the circumferential direction of the cylindrical profile of the main shaft box shell, and are arranged on the main shaft box shell by rolling bearings; the mouse-tooth disc is arranged on the end surface of one side of the main shaft box shell, and the cutter disc gear is arranged on the center of the main shaft box shell; the main shaft head is connected to one end of the main shaft box by virtue of the mouse-tooth disc; the main shaft box comprises a shaft VIII, a shaft II, an indexing main shaft, a main transmission shaft, a shaft X, a shaft III, a shaft IV, a shaft IX, a worm shaft VI, a shaft VII and a turbine shaft which adopt the main shaft box body as support, as well as a lead-screw support, a connecting rod mechanism and a main driving clutch device. The multifunctional drilling and milling mechanism disclosed by the invention is applied on a machine tool and realizes drilling and milling processing of workpieces under the condition of once clamping, so that the accuracy of shapes and positions of holes or key grooves is ensured and the environment-friendly and energy-saving effects are achieved.

Owner:安阳市海之达新型建材有限公司

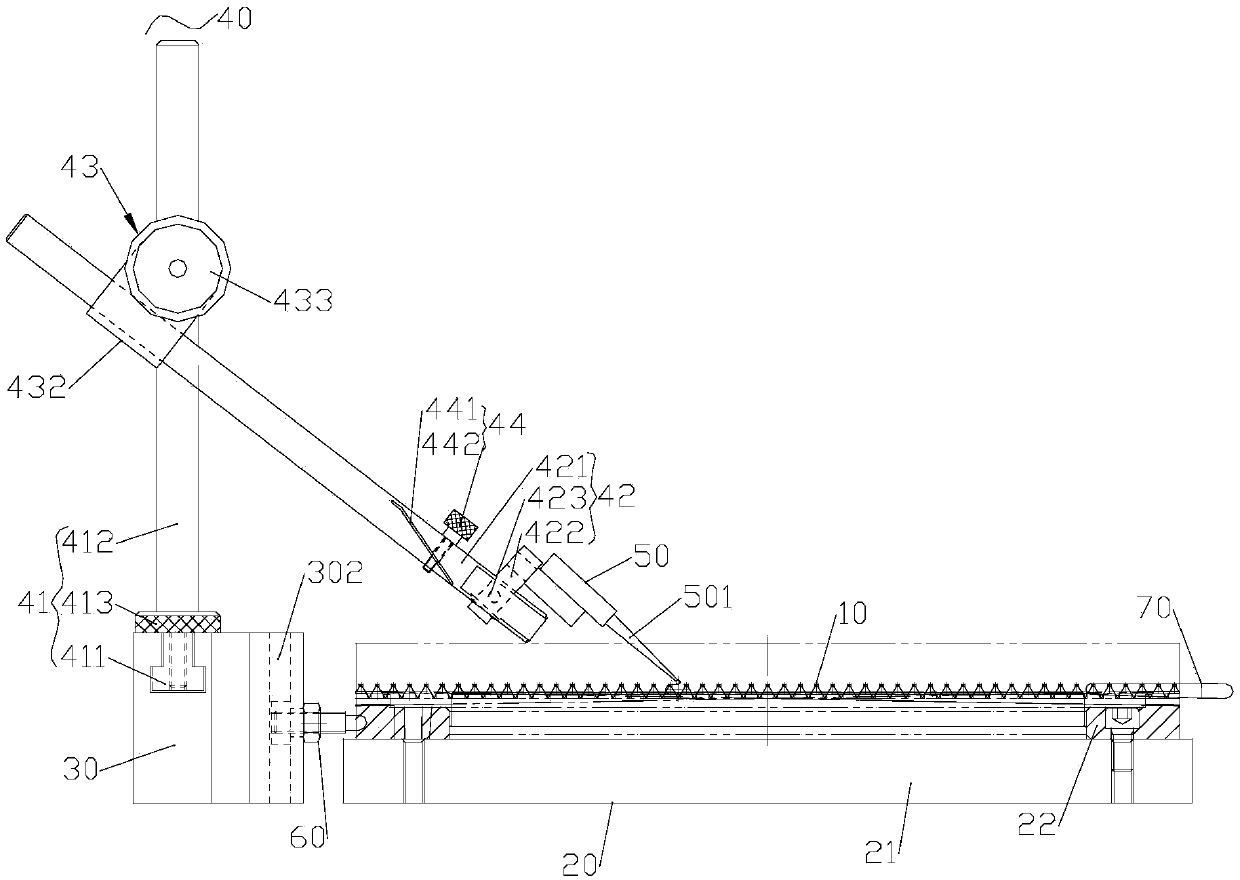

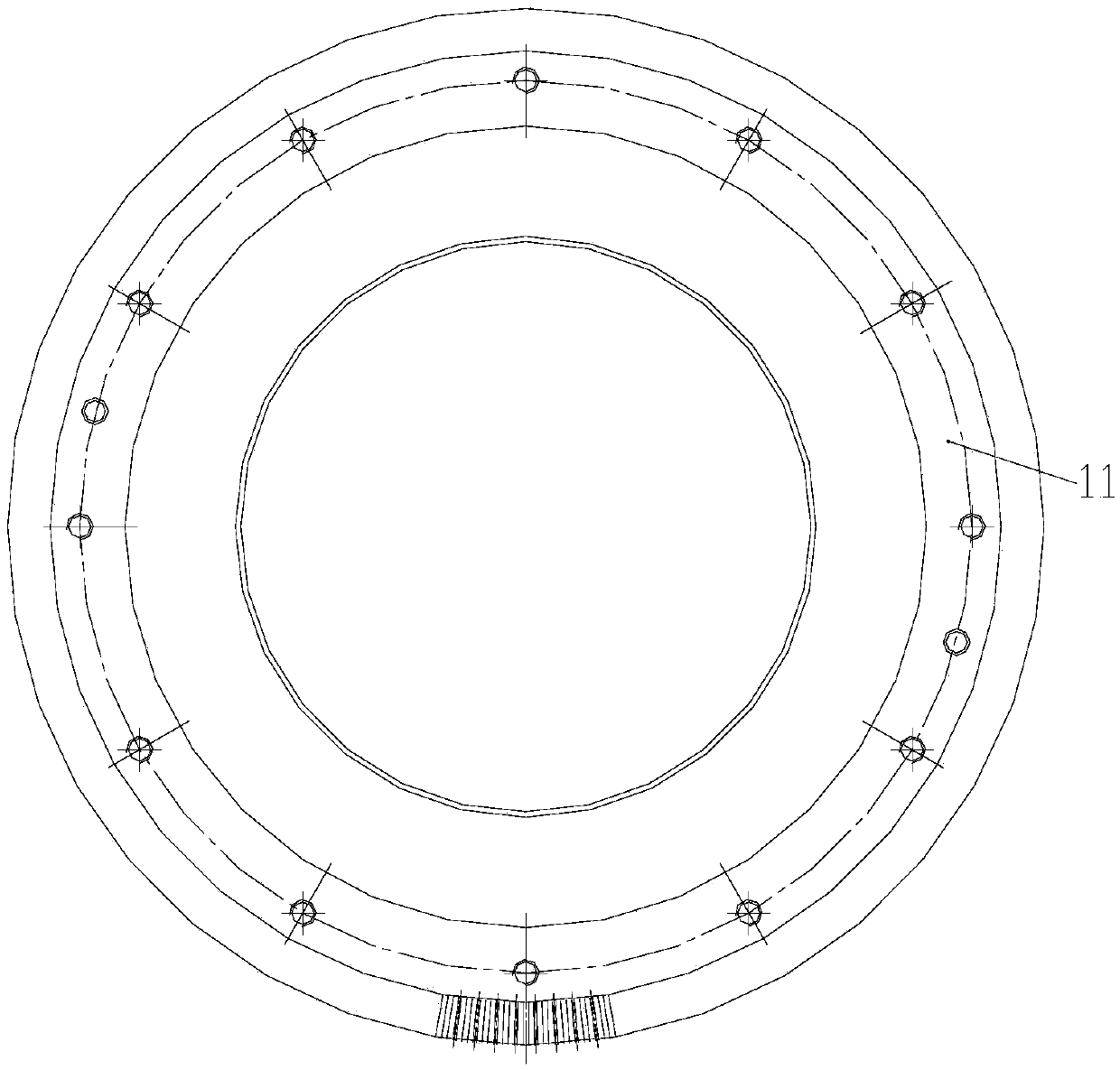

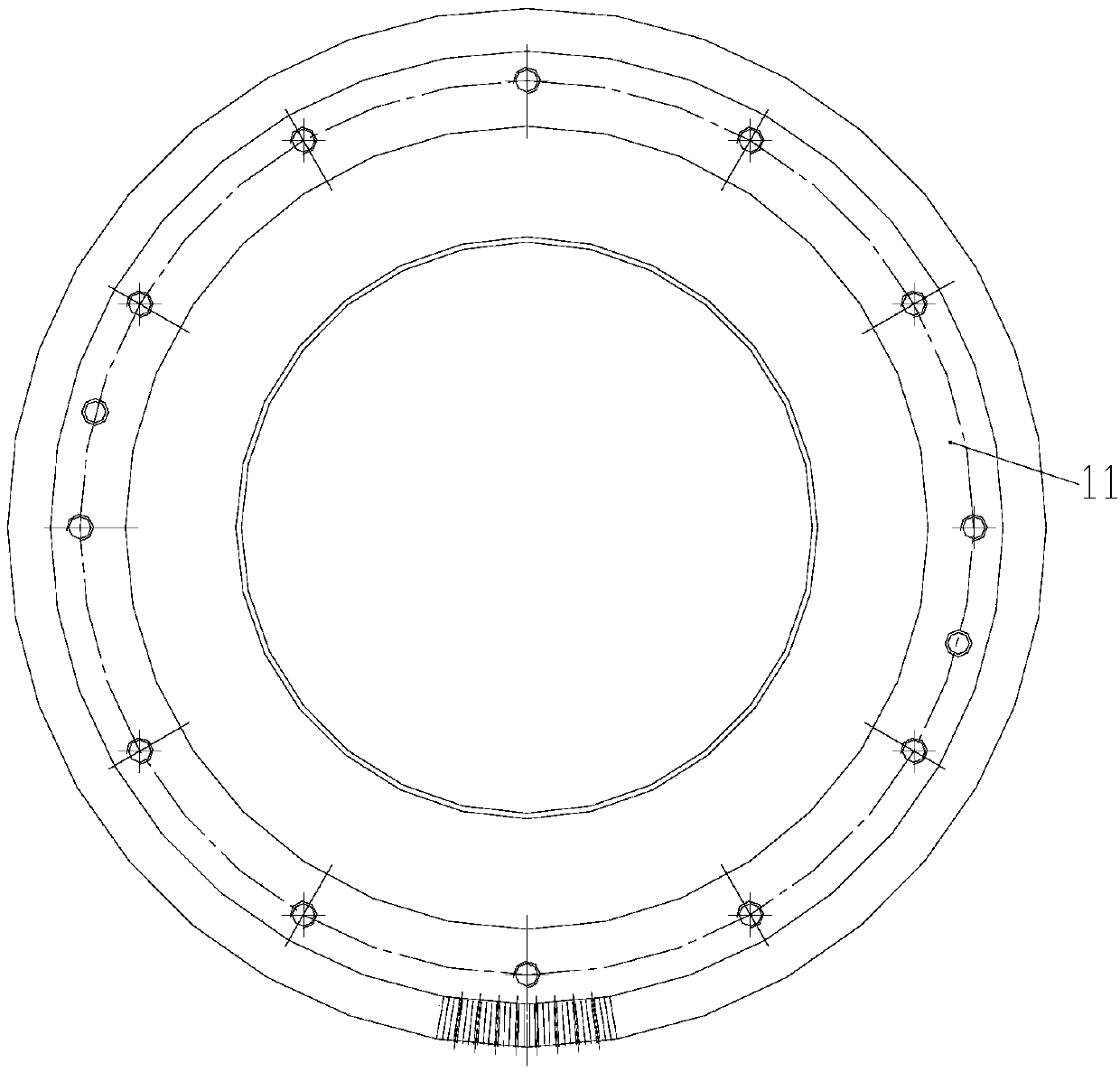

New high-efficiency whirling milling head

InactiveCN101745705AHigh precisionIncrease contact surfaceThread cutting toolsThread cutting machinesMilling cutterMouse Tooth

The invention discloses a new high-efficiency whirling milling head. Four cutter bars are fixedly arranged on four cutter installing grooves on a milling cutter disk, and the milling cutter disk is provided with mouse tooth-shaped gears meshed with the cutter bars, so that the cutter bars can be positioned more reliably and can be assembled and disassembled more conveniently. The positions of the cutter bars in the cutter installing grooves are adjusted by a vernier depth gauge to meet the condition that the center of the top edge of a cutter passes through the axle center of a workpiece. In the invention, the milling cutter disk and a pulley drive mechanism fixing cover are arranged in a whirling milling head cover body, and the lift angle of a milling head which is integrally connected with the whirling milling head cover body is adjusted through a set of screw bevel gear mechanism. After the cutter bars are worn, only the top surfaces of the obtuse parts of the cutter bars need to be ground, the tooth thickness and the cutting center line of the cutter bars can not be changed, the cutter bars can be reground for many times, and the dimensional accuracy and the positioning accuracy of the cutter bars can not be changed. The cutter which is ground by being vertically inclined for 13 degrees by the cutter bars is in a shortened tooth shape, still has very high strength and can be used for powerful high-speed milling.

Owner:南靖长青精密丝杆制造有限公司

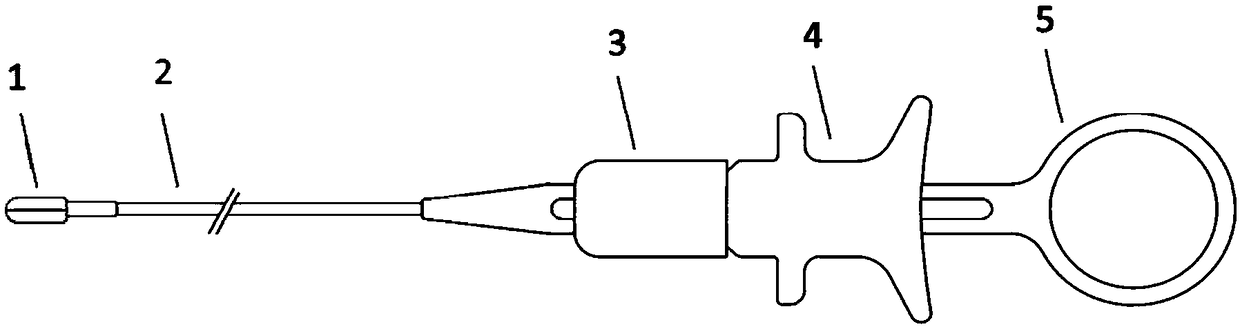

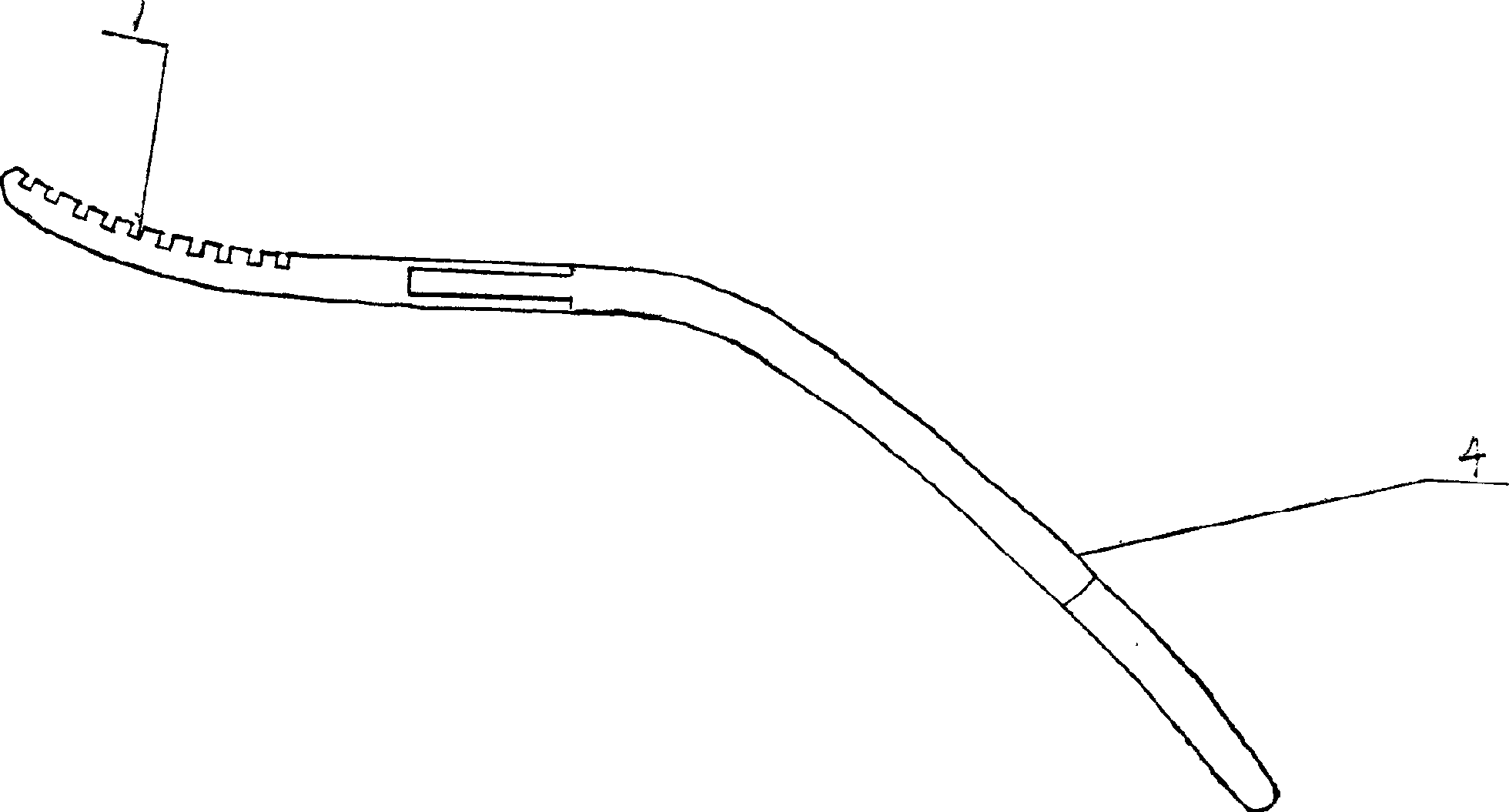

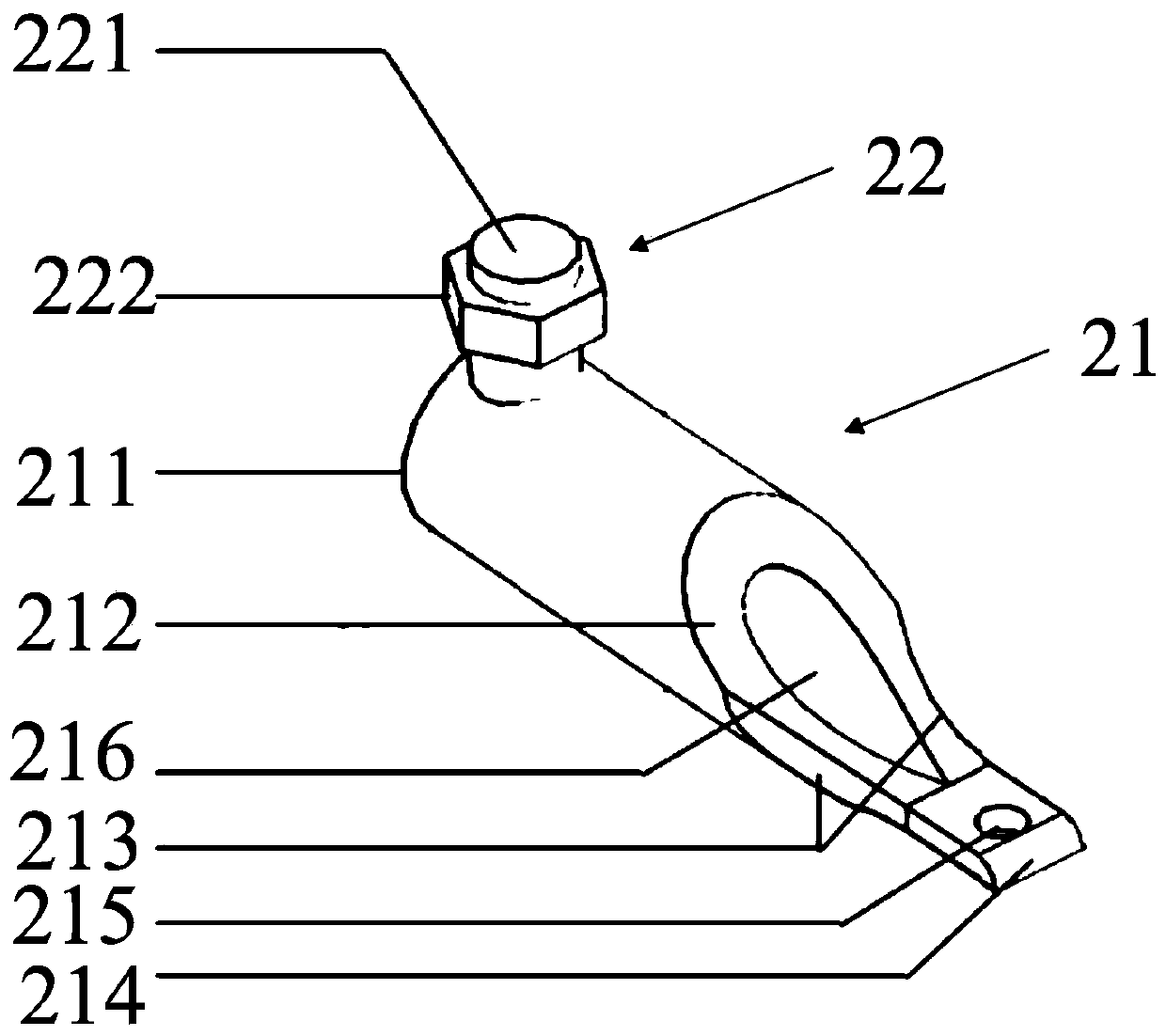

Special pushing device for completely degradable occluder and method for connection of special pushing device with occluder

The invention discloses a special pushing device for a completely degradable occluder. The special pushing device is characterized by comprising a spring steel cable, an inner core wire capable of moving back and forth is arranged in the spring steel cable, the front end of the spring steel cable is fixedly connected to the middle of a forcep head, the rear end of the forcep head is connected withthe front end of the inner core wire, the rear end of the inner core wire is connected with a slider which sleeves a pushing ring, a locking part sleeves the pushing ring, and the spring steel cableis arranged in the pushing ring. The joint position of the middle of the forcep head and the occluder is provided with a through hole, or the forcep head is a double-layer sleeve rope, or the forcep head is in a mouse tooth structure. The special pushing device is fittingly connected with the occluder and used with the occluder to solve problems of pulling the completely degradable occluder into asheath, pushing, releasing and the like in an interventional operation from the engineering point of view, and safety and effectiveness in application to transthoracic and percutaneous interventionalsurgeries.

Owner:SHANGHAI SHAPE MEMORY ALLOY

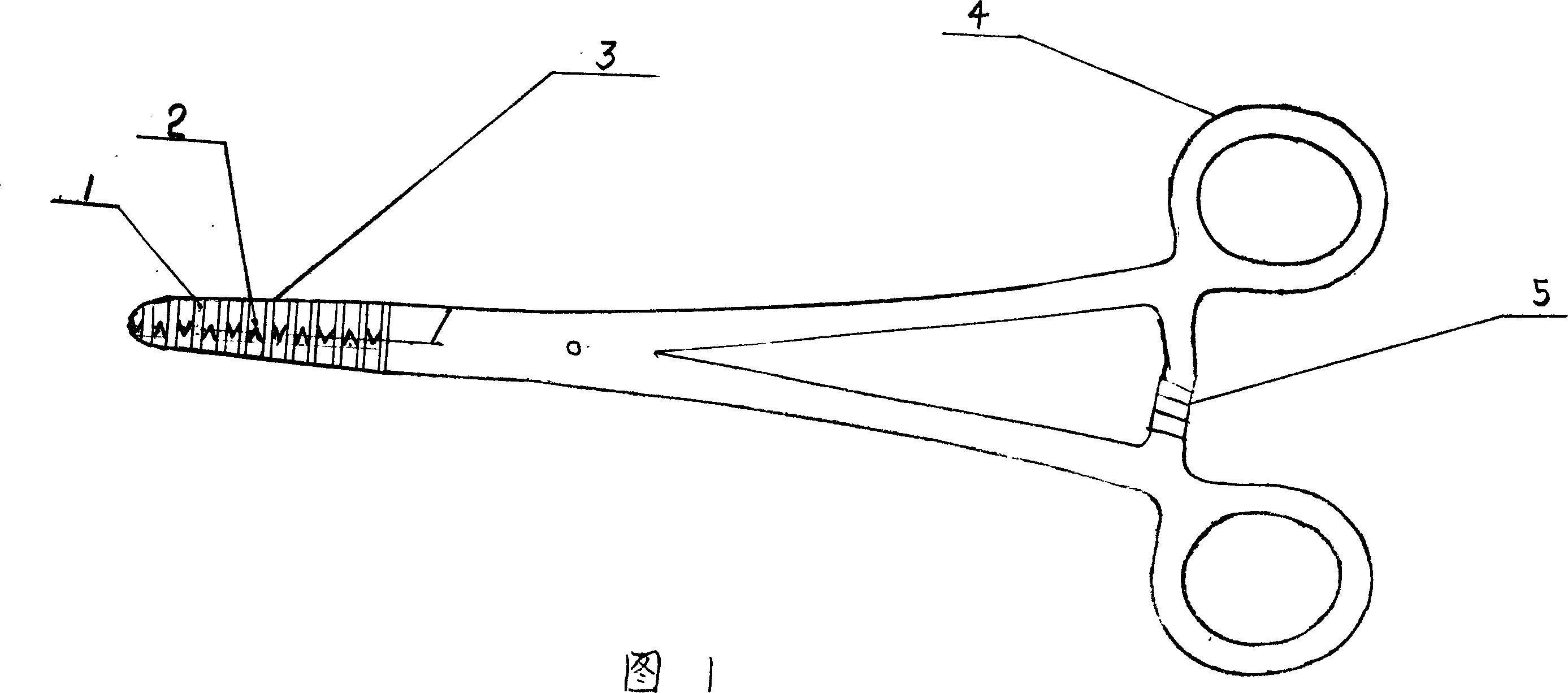

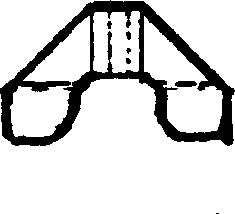

External pile excision stitch removal free stitching tong

InactiveCN1555766AFully and accurately determineAccurately determineSurgical staplesLocking mechanismLong axis

A suture forceps for excising external piles without removing silk features that the cross section of matched two teeth shows splayed shape, the contact surfaces are engaged in the mode of mouse teeth, upper tooth has needle slot, and its handle has self-locking mechanism.

Owner:龚希峰

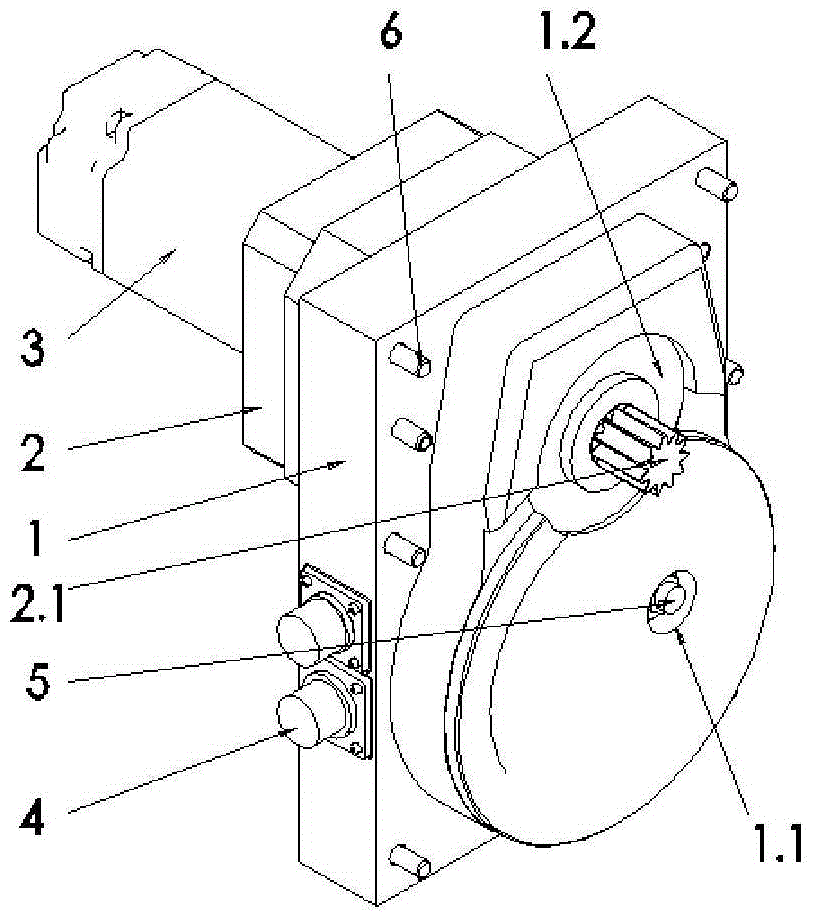

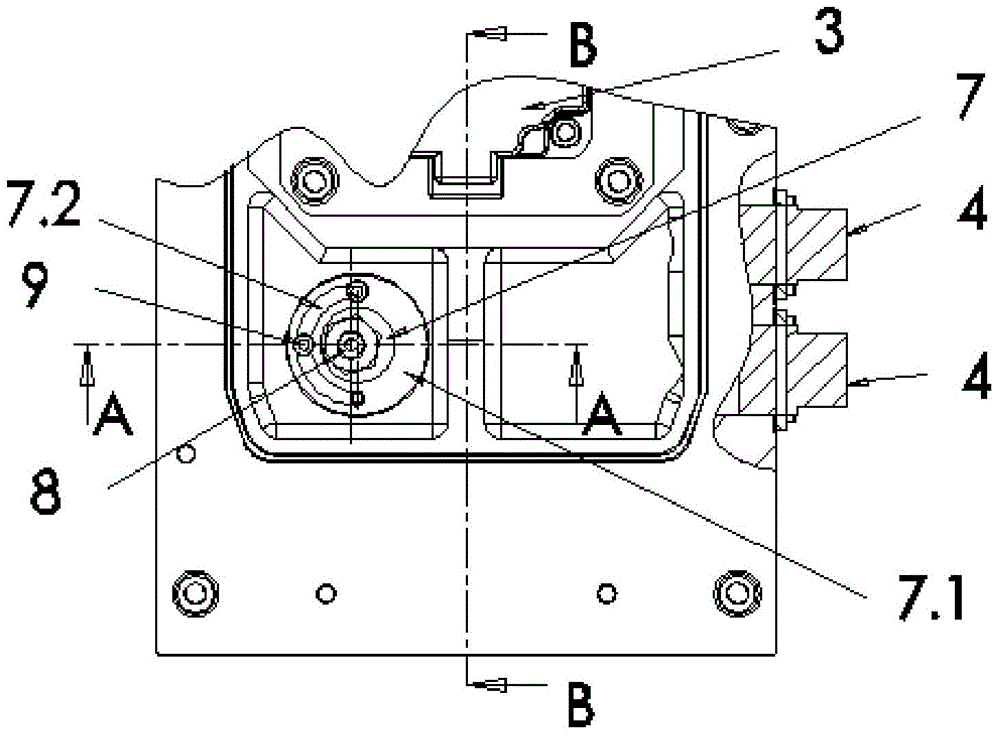

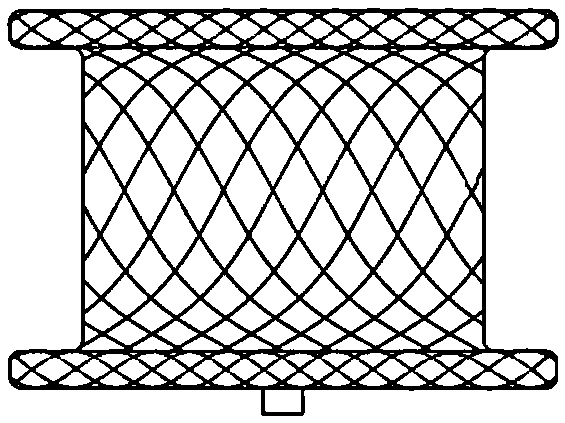

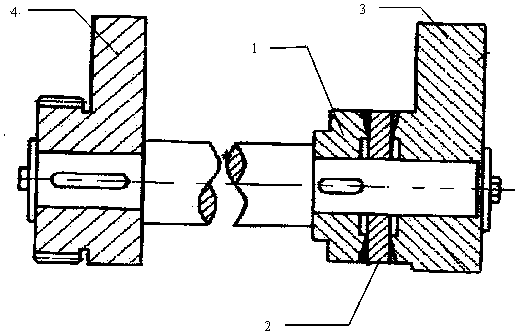

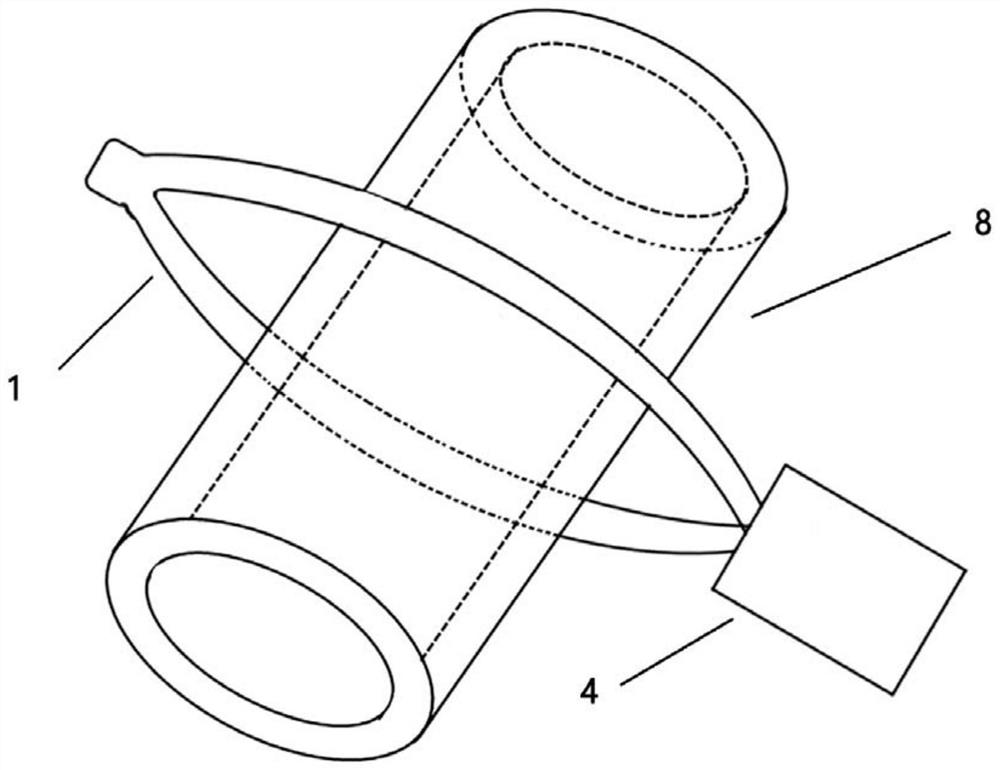

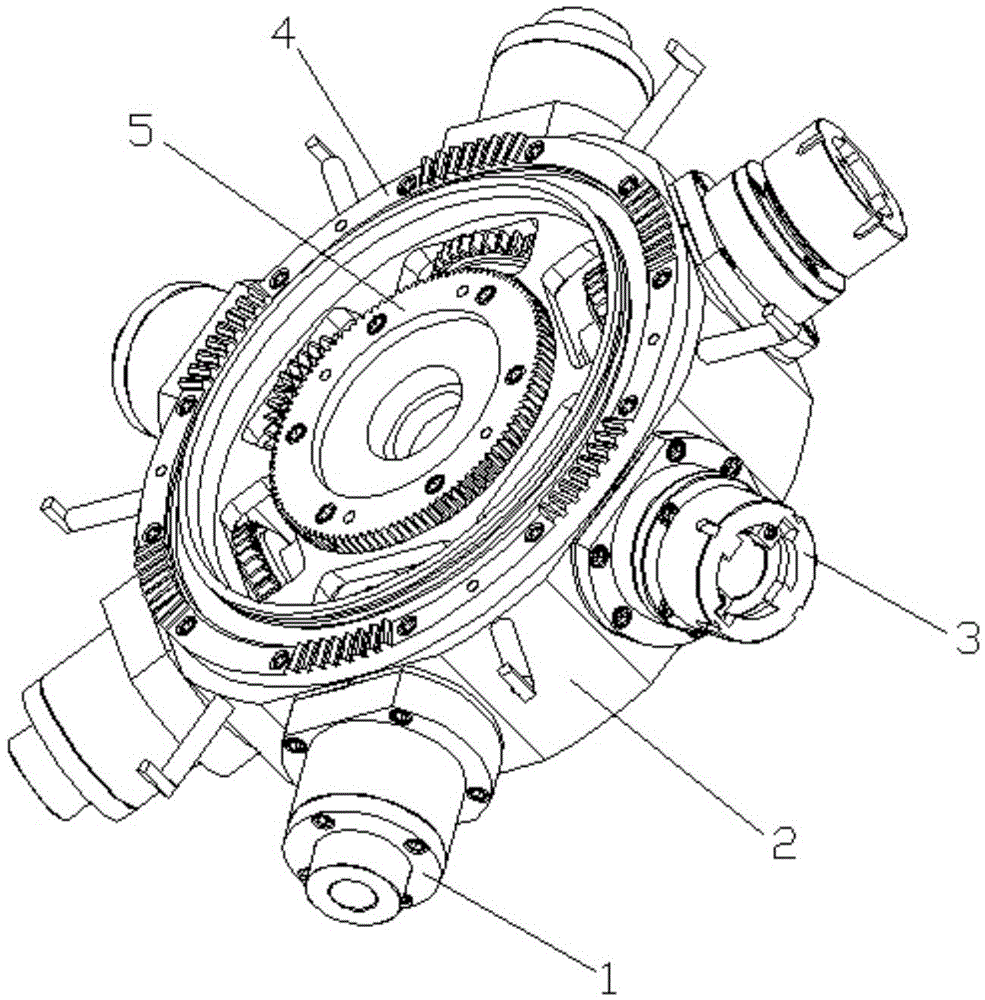

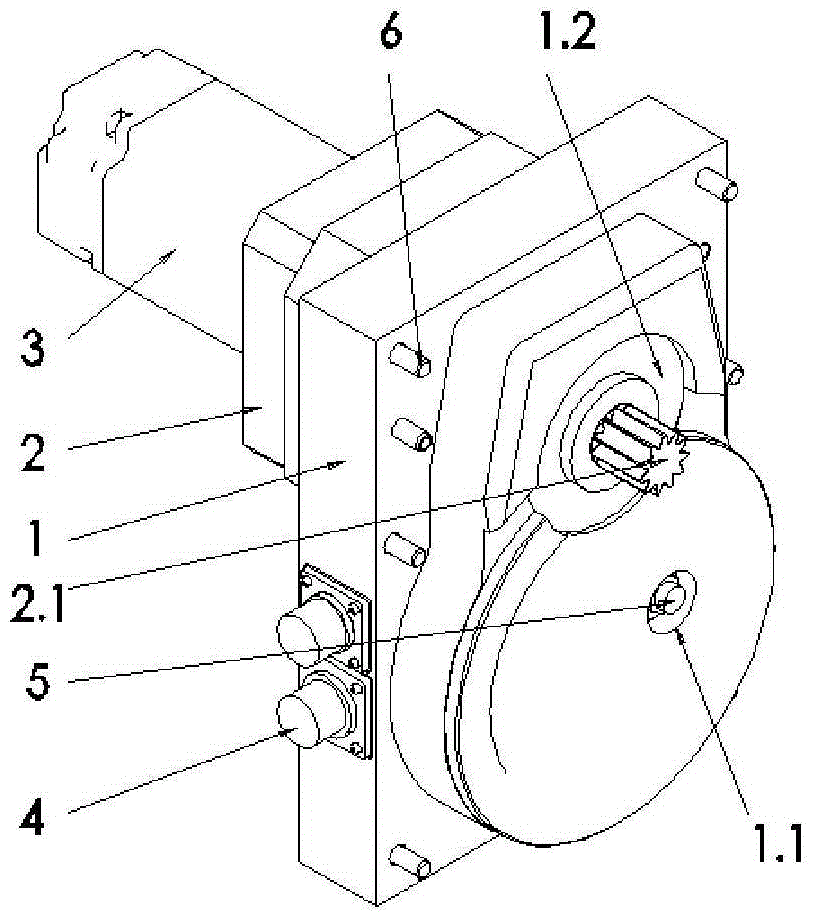

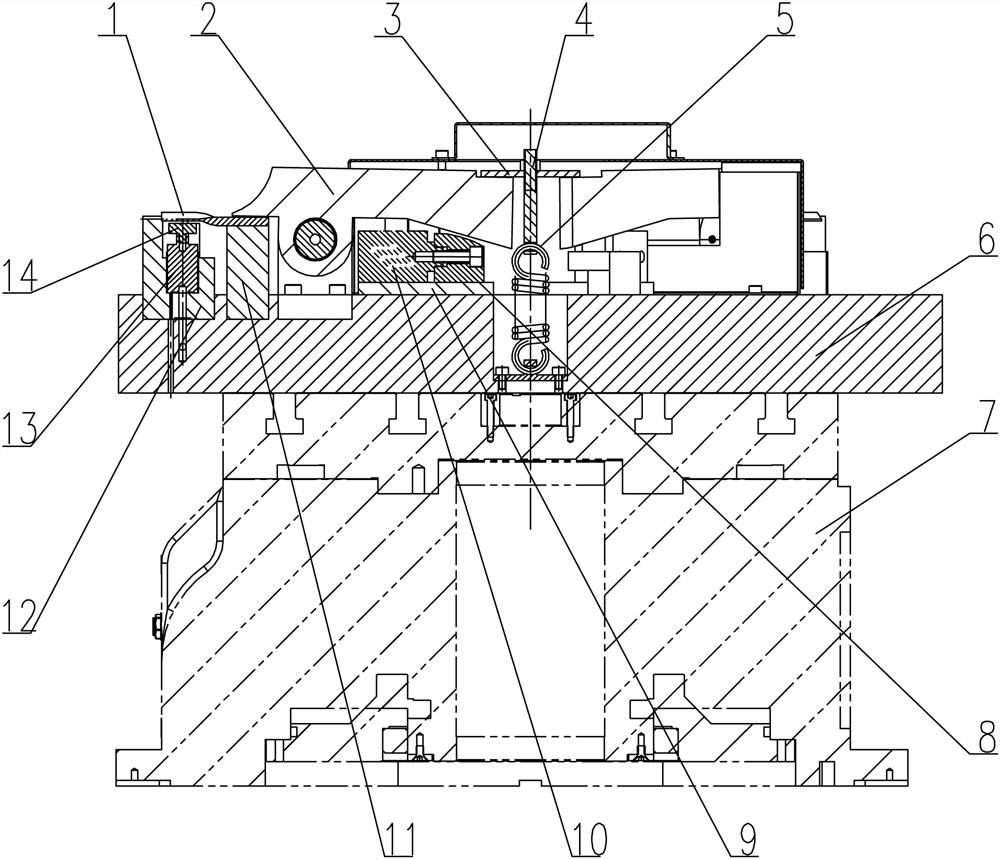

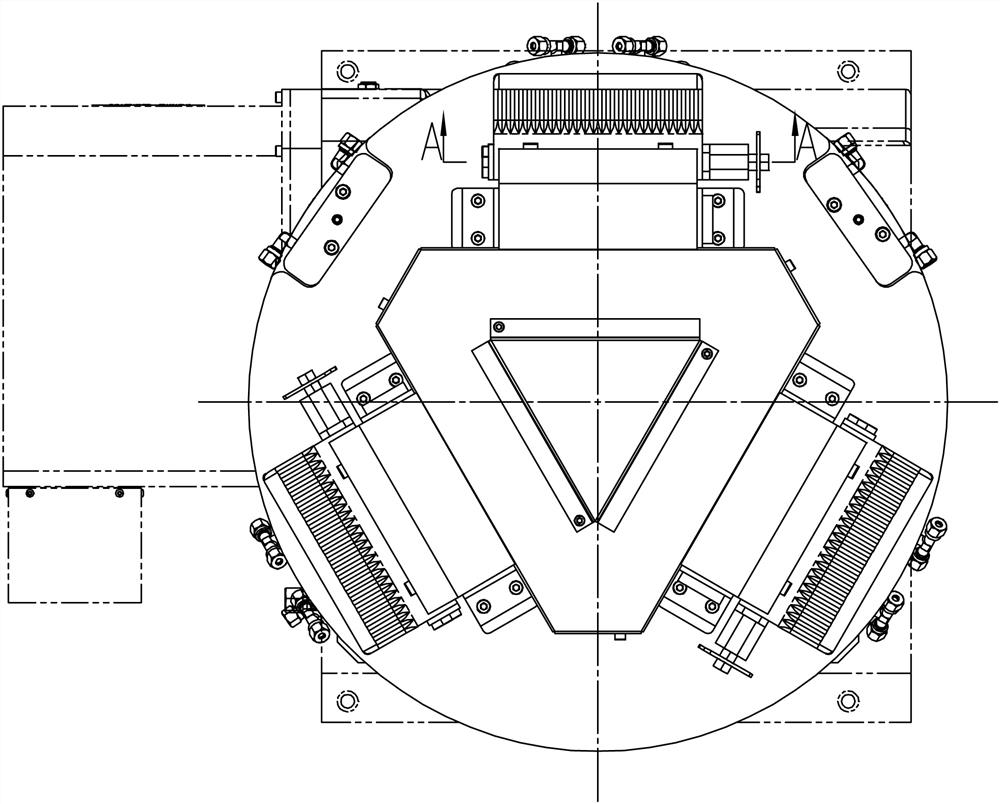

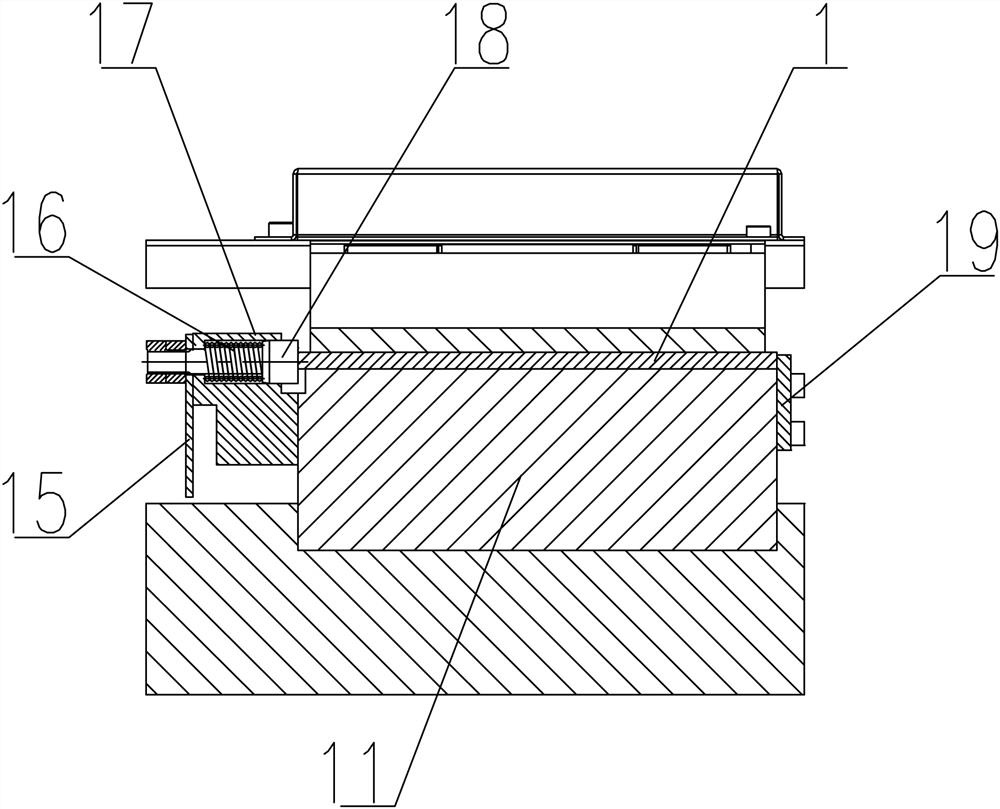

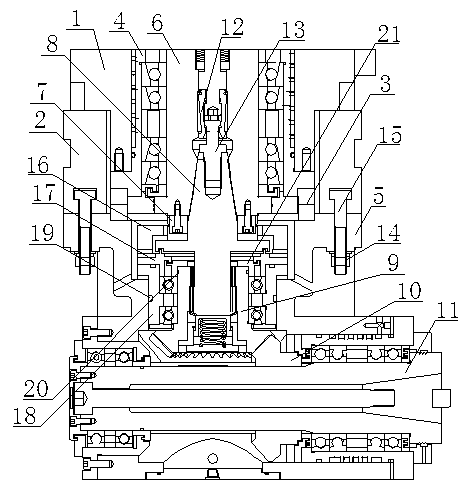

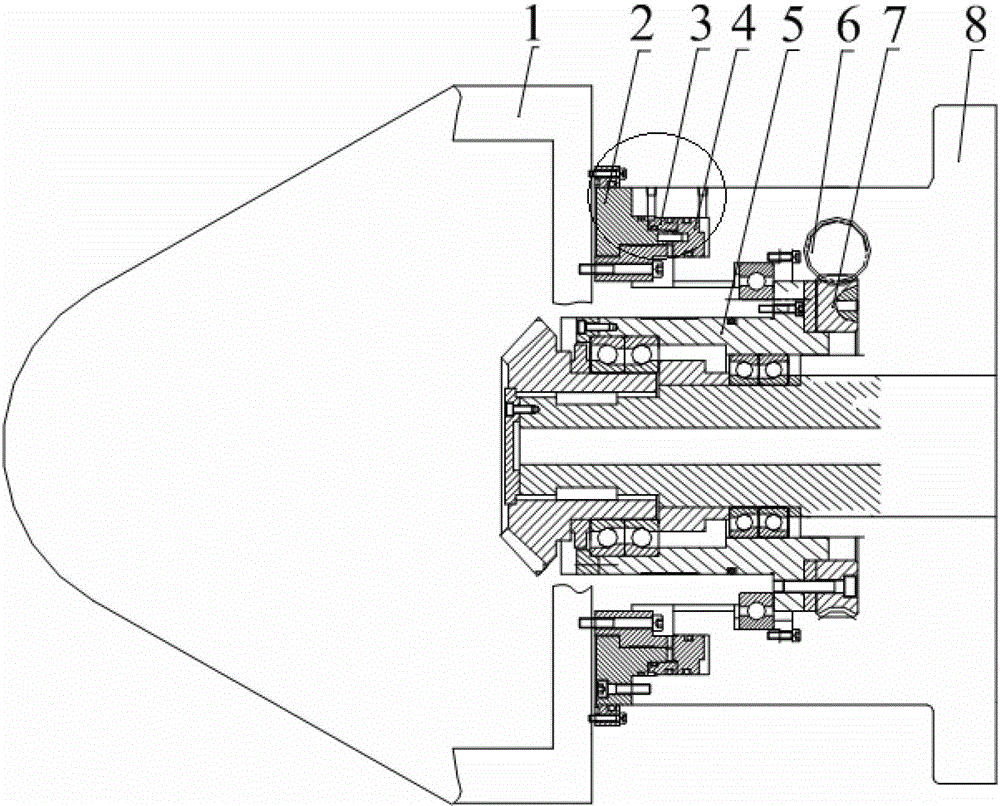

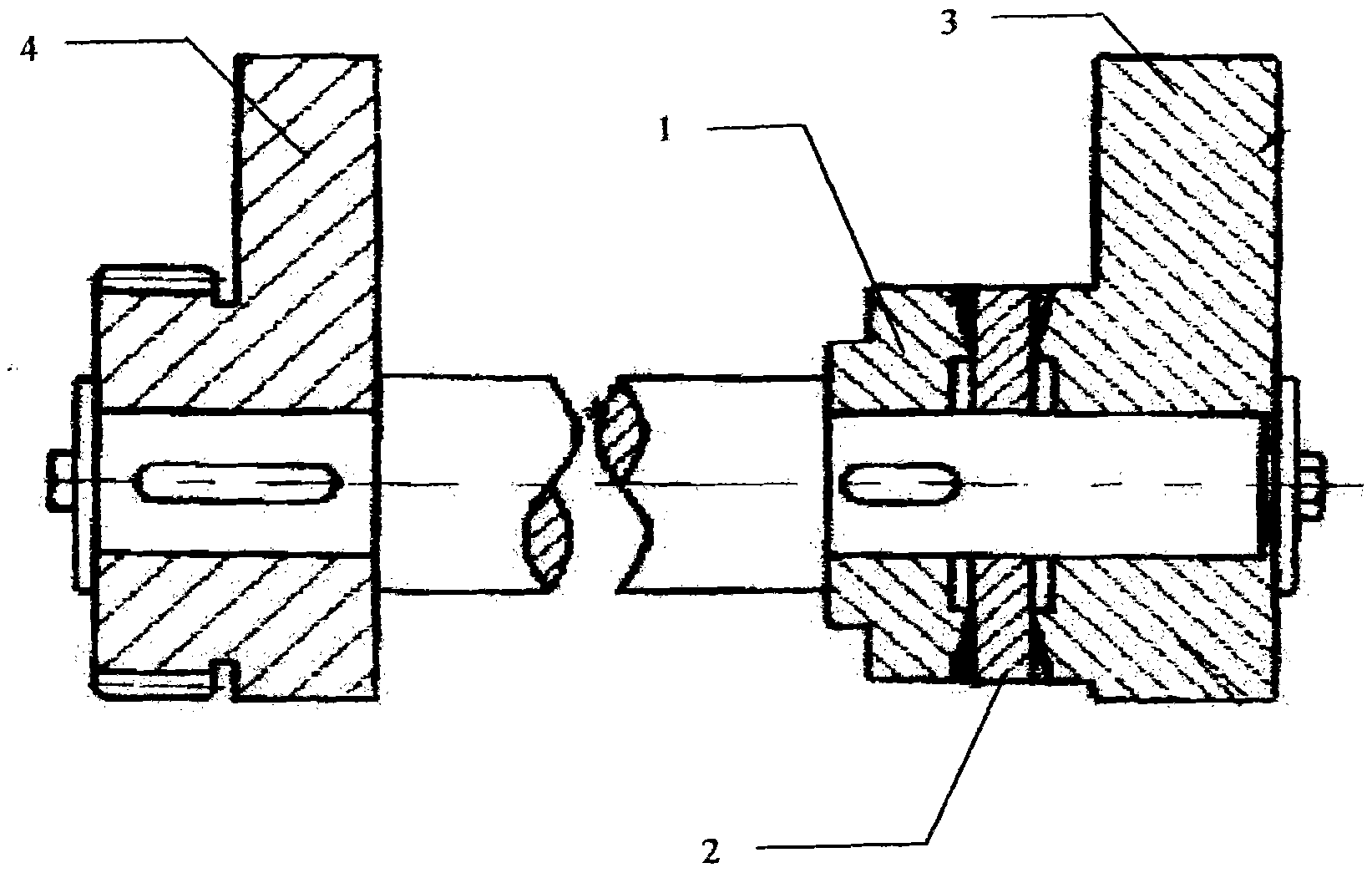

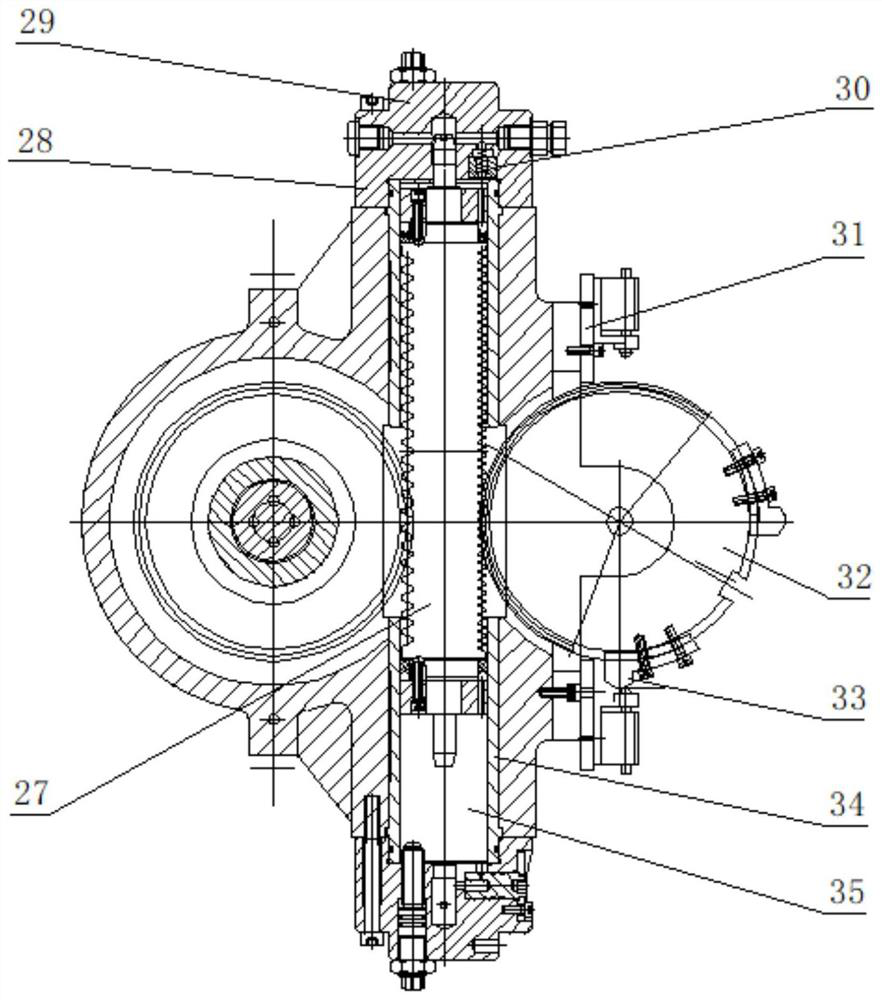

Mouse tooth disk locking mechanism for efficient and compound milling disk mill device of blisk

InactiveCN103143762ALarge locking torqueMeet the requirements of high rigidity and high torqueMilling equipment detailsMetal working apparatusLocking mechanismMouse Tooth

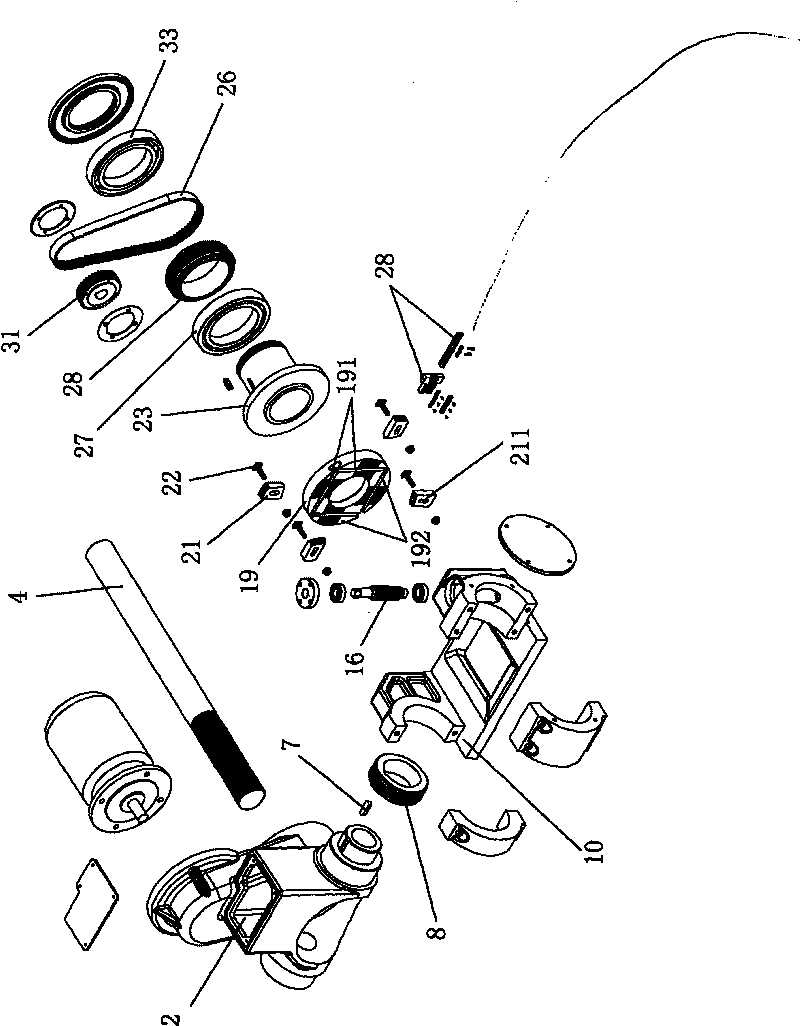

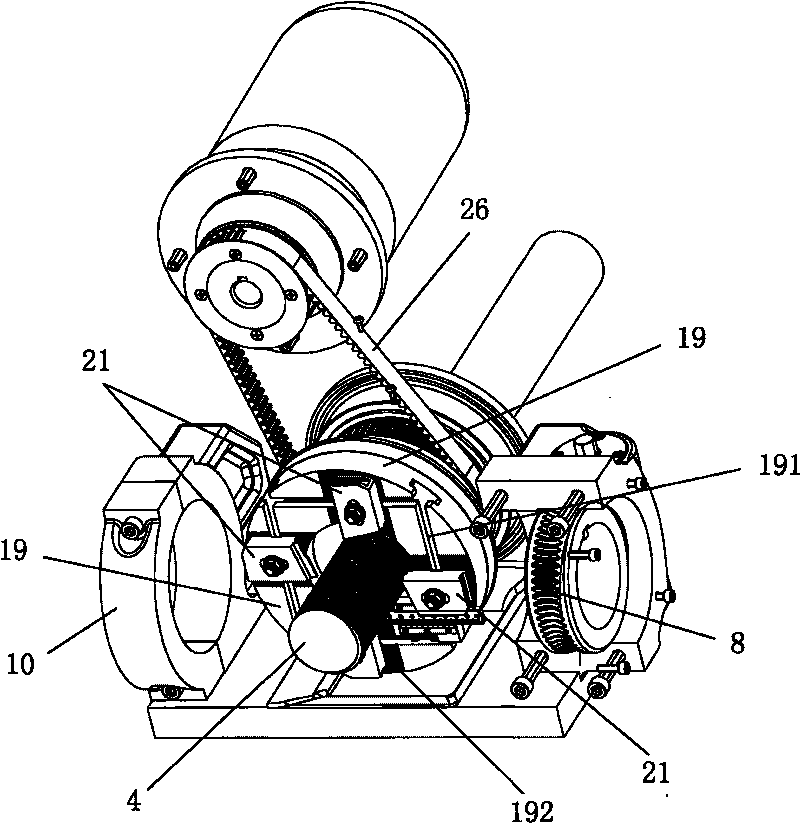

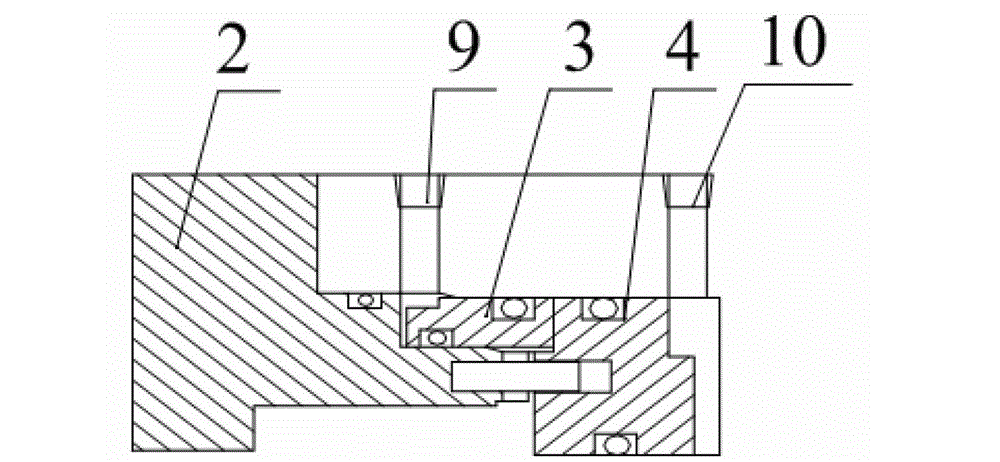

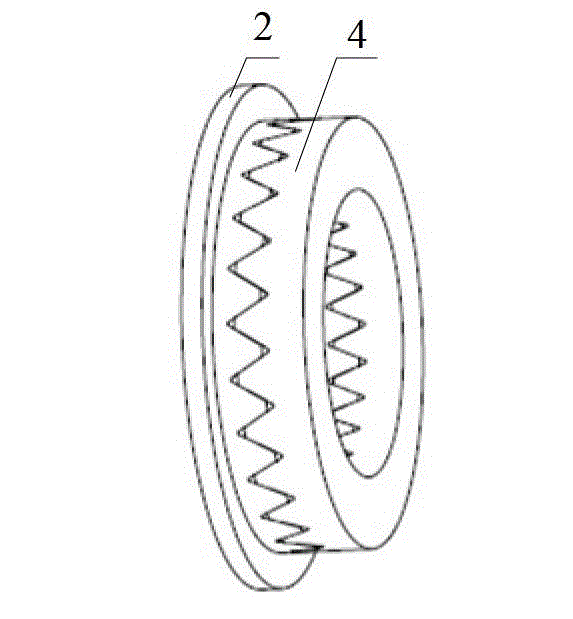

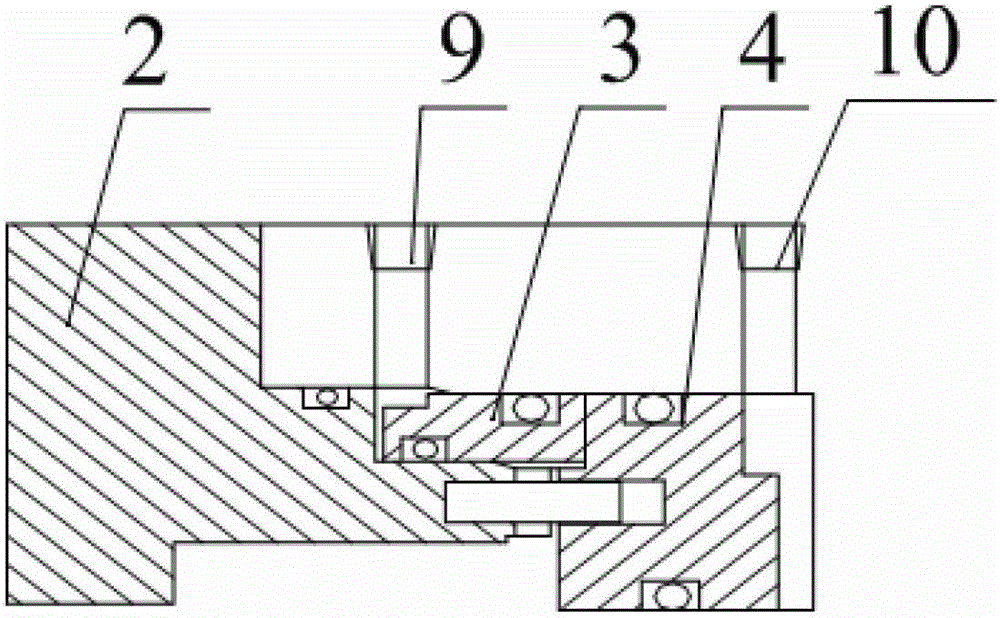

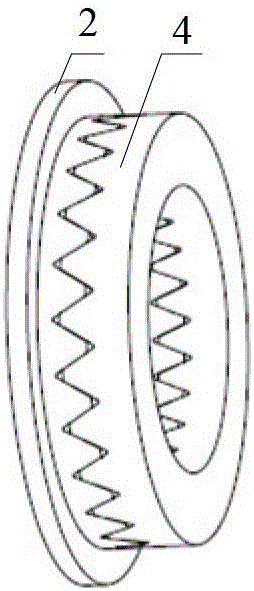

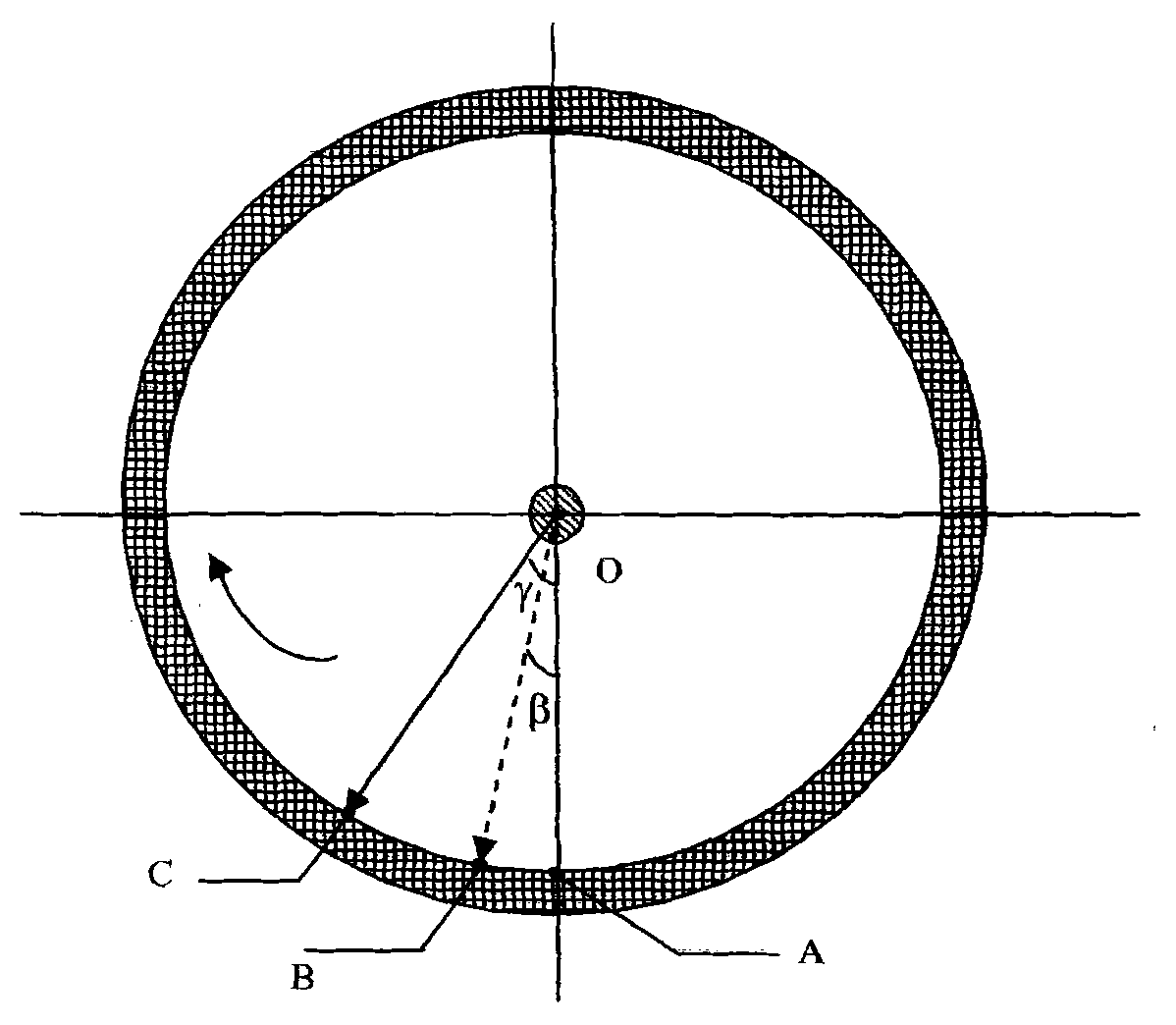

The invention discloses a mouse tooth disk locking mechanism for an efficient and compound milling disk mill device of a blisk. The mouse tooth disk locking mechanism is used for solving the technical problem that an existing hydraulic locking mechanism for the efficient and compound milling disk mill device of the blisk is poor in locking force. The technical scheme is that the mouse tooth disk locking mechanism comprises a disk mill box body (1), an inner box body (5), a worm (6), a worm gear (7), an outer box body (8), a serve motor (11), a left side fluted disk (2), a push ring (3) and a right side fluted disk (4). The left side fluted disk (2) and the right side fluted disk (4) are meshed, and two end faces of the push ring (3) are respectively matched with the left side fluted disk (2) and the right side fluted disk (4). The mouse tooth locking mechanism can generate locking force through mesh between tooth faces between mouse disk teeth so as to be large in locking torque and meet high-rigidity and large-torque requirements in a disk milling process. Furthermore, the minimum scale division of three piece type end face fluted disks of the mouse tooth disk is 1 degree so as to achieve accurate control of a swing angle of the disk mill device.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

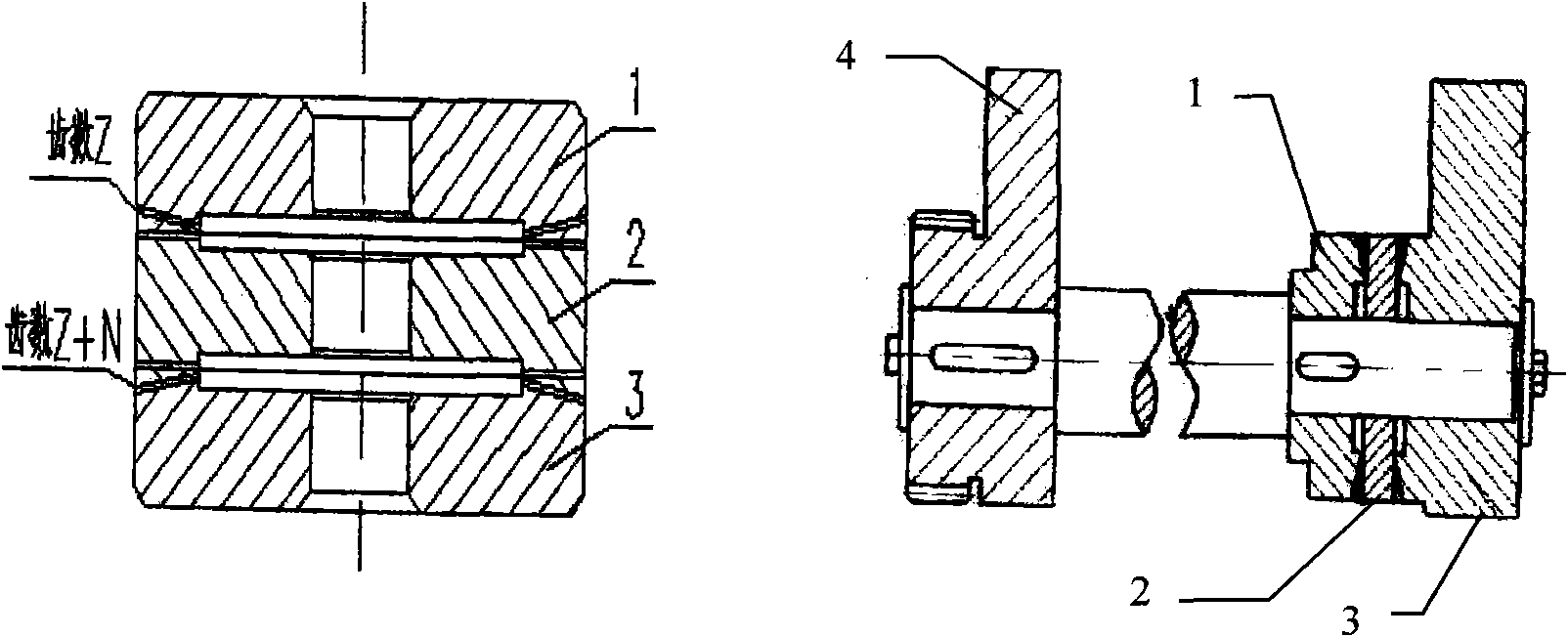

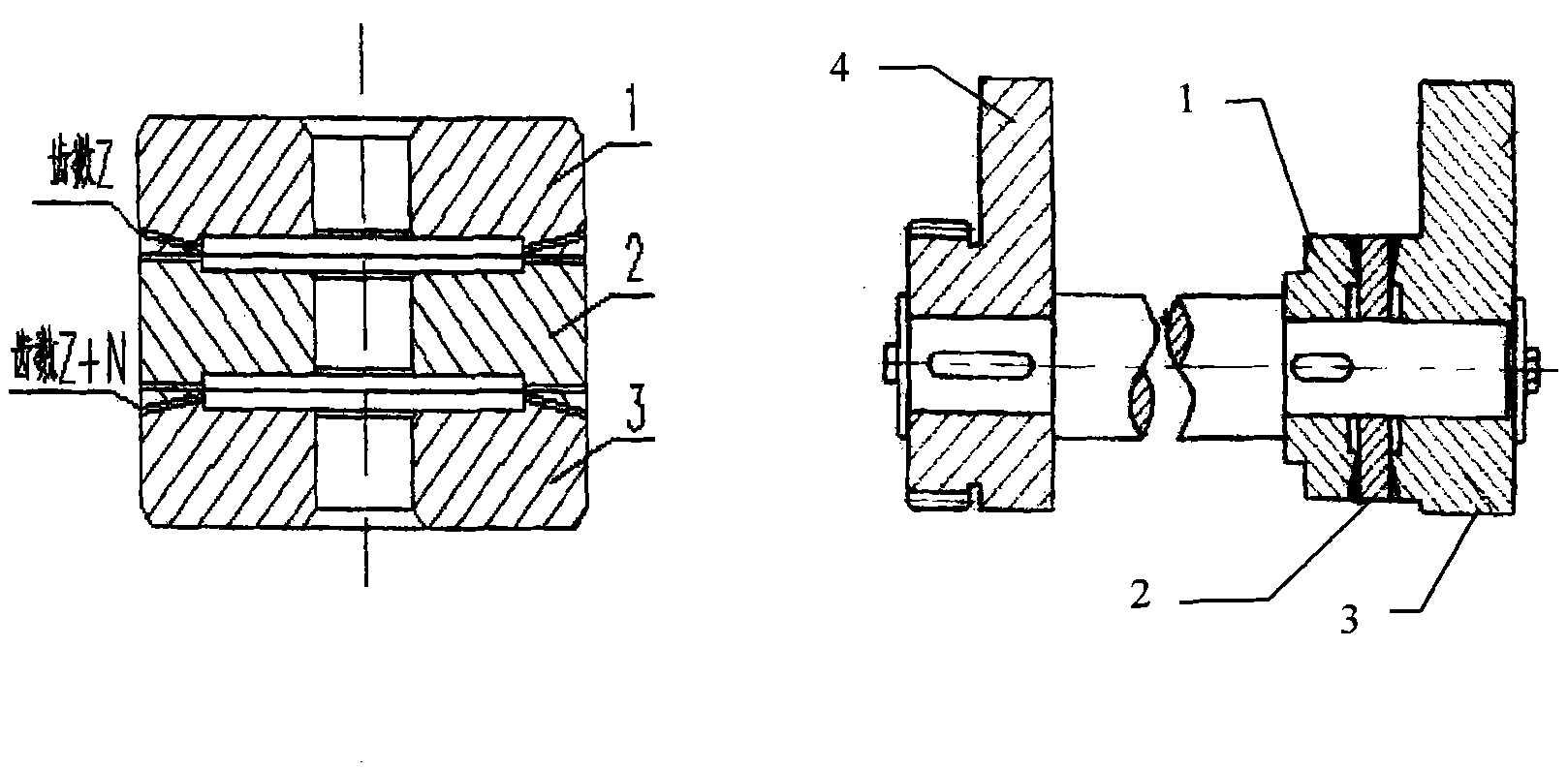

Mechanism and method for tooth difference rigidity dividing adjustment for thread spinners

ActiveCN101576127AEliminate biasArtificial thread manufacturing machinesInterengaging clutchesMouse ToothEngineering

The invention provides a mechanism for tooth difference rigidity dividing adjustment for thread spinners, which comprises an upper-layer part, a middle-layer part and a lower-layer part, wherein the layers are linked by mouse tooth type clutches; suppose that the number of the teeth between the upper-layer part and the middle-layer part is Z, the tooth difference between the upper-layer part and the lower-layer part can be 1, 2, 3 or N(N is an integer more than or equal to 1). During the adjustment of a gear transmission device, if the upper-layer part and the middle-layer part are needed to be rotated one tooth difference clockwise or counter-clockwise, the lower-layer part and the middle-layer part are rotated one or more tooth differences in the same direction. The structure can be used in design of coaxial mechanisms capable of transmitting a plurality of planes at the same time to ensure that the mechanisms keep precise synchronization or distribute at a certain fixed angle to eliminate machining or installation errors.

Owner:QINGDAO TEXTILE MACHINERY

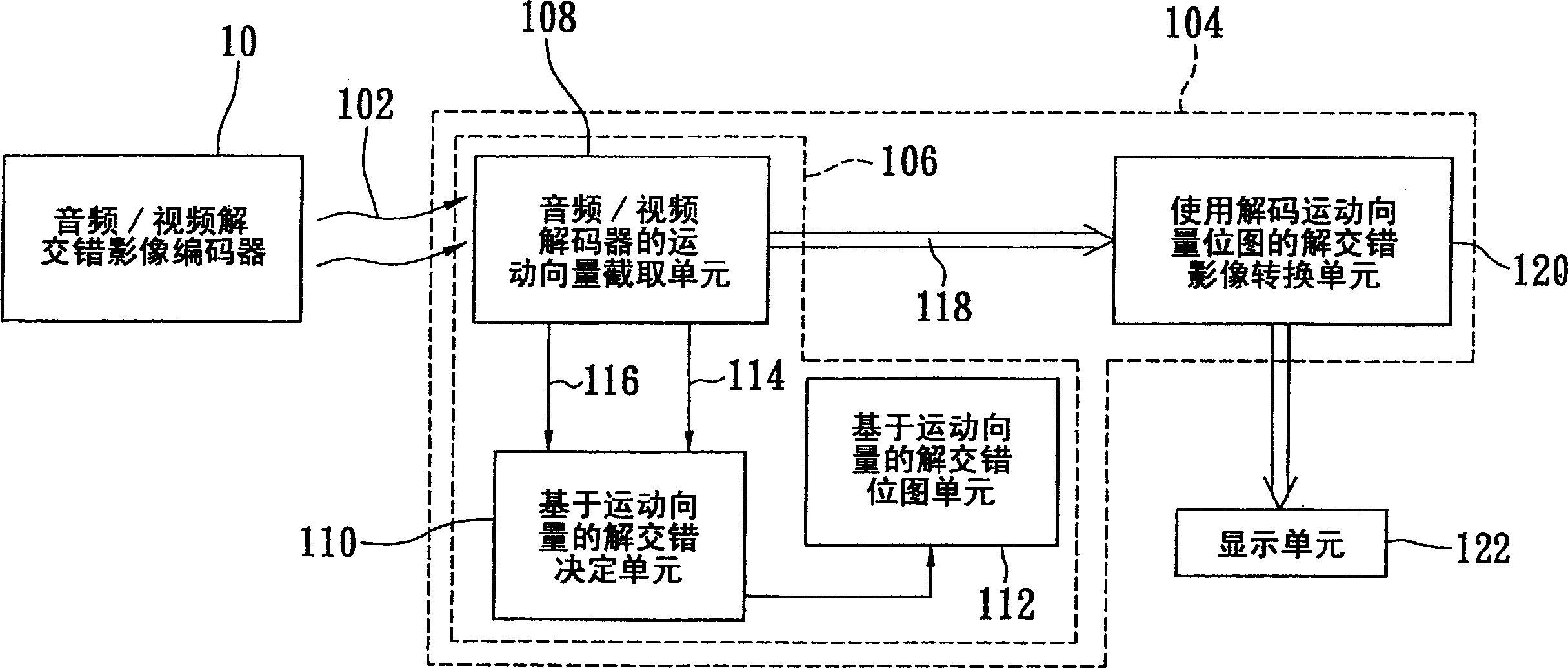

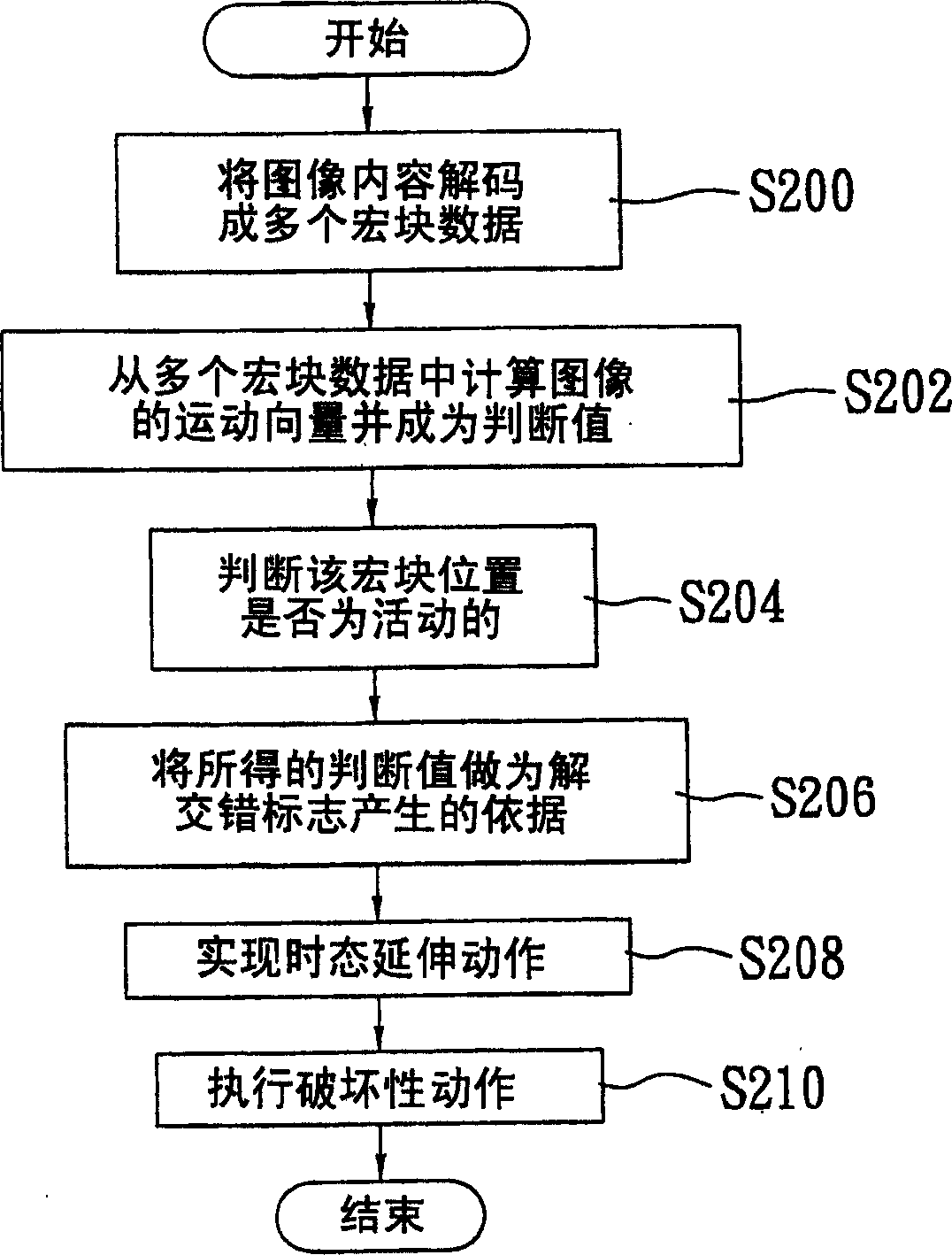

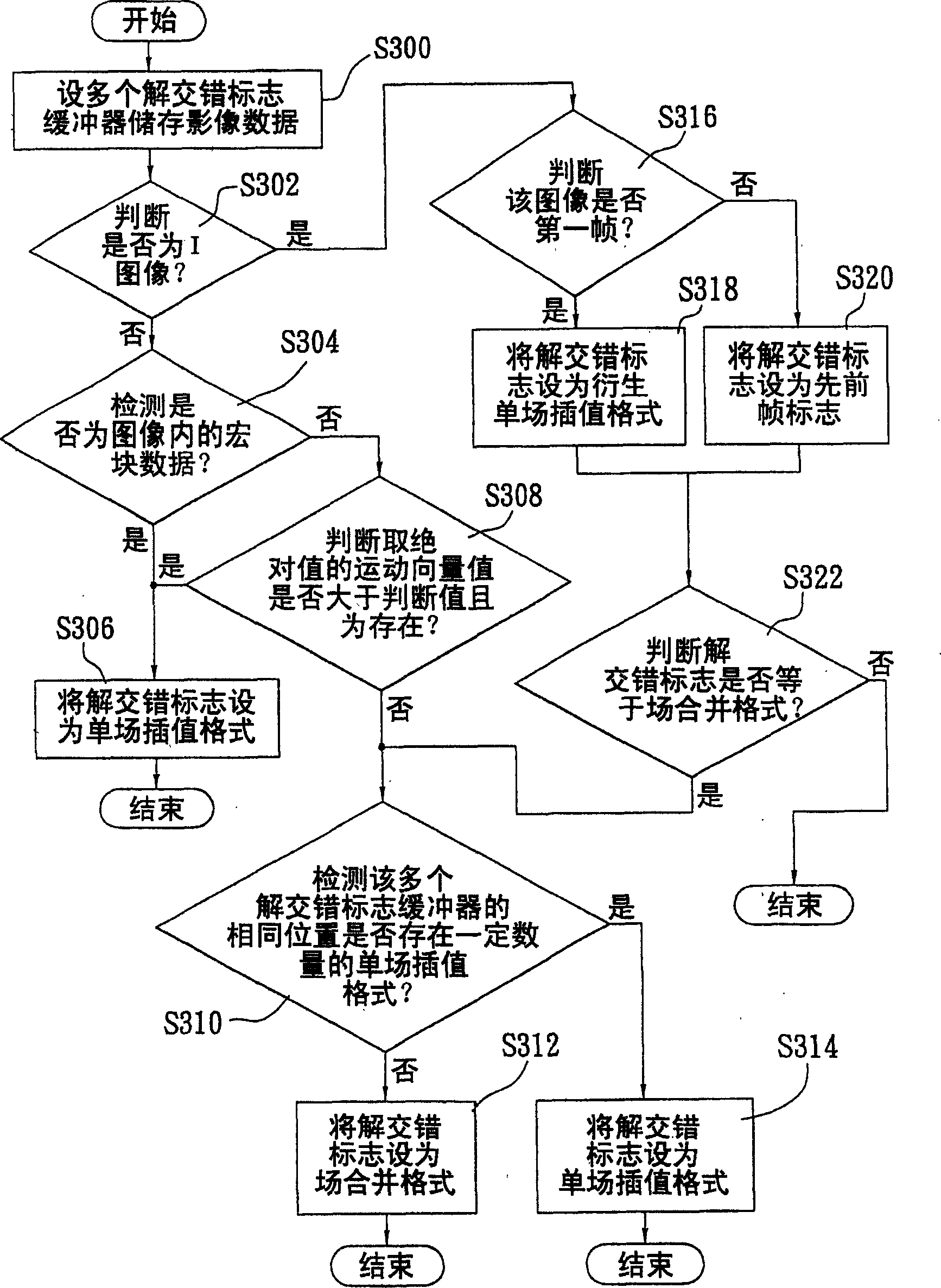

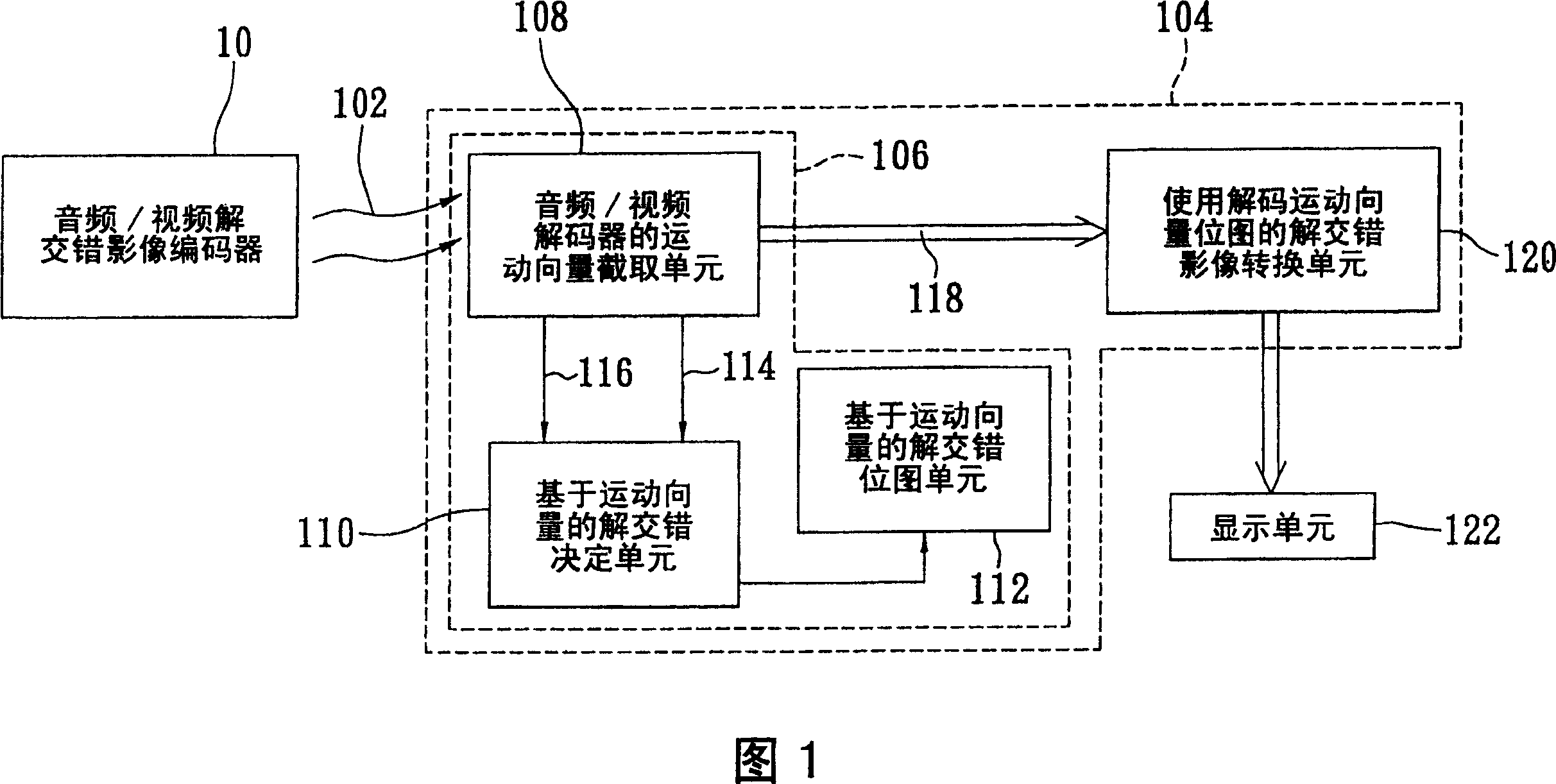

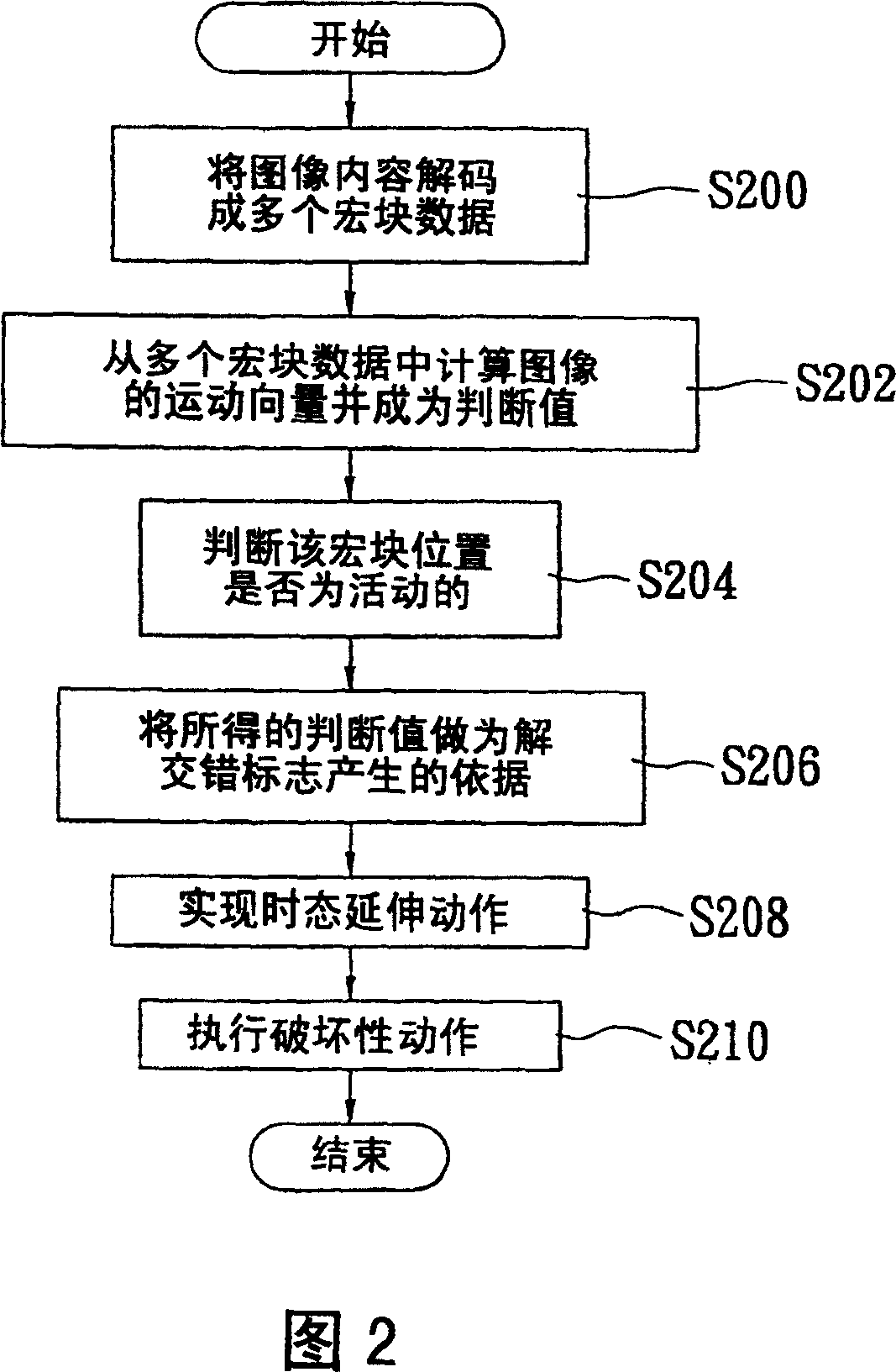

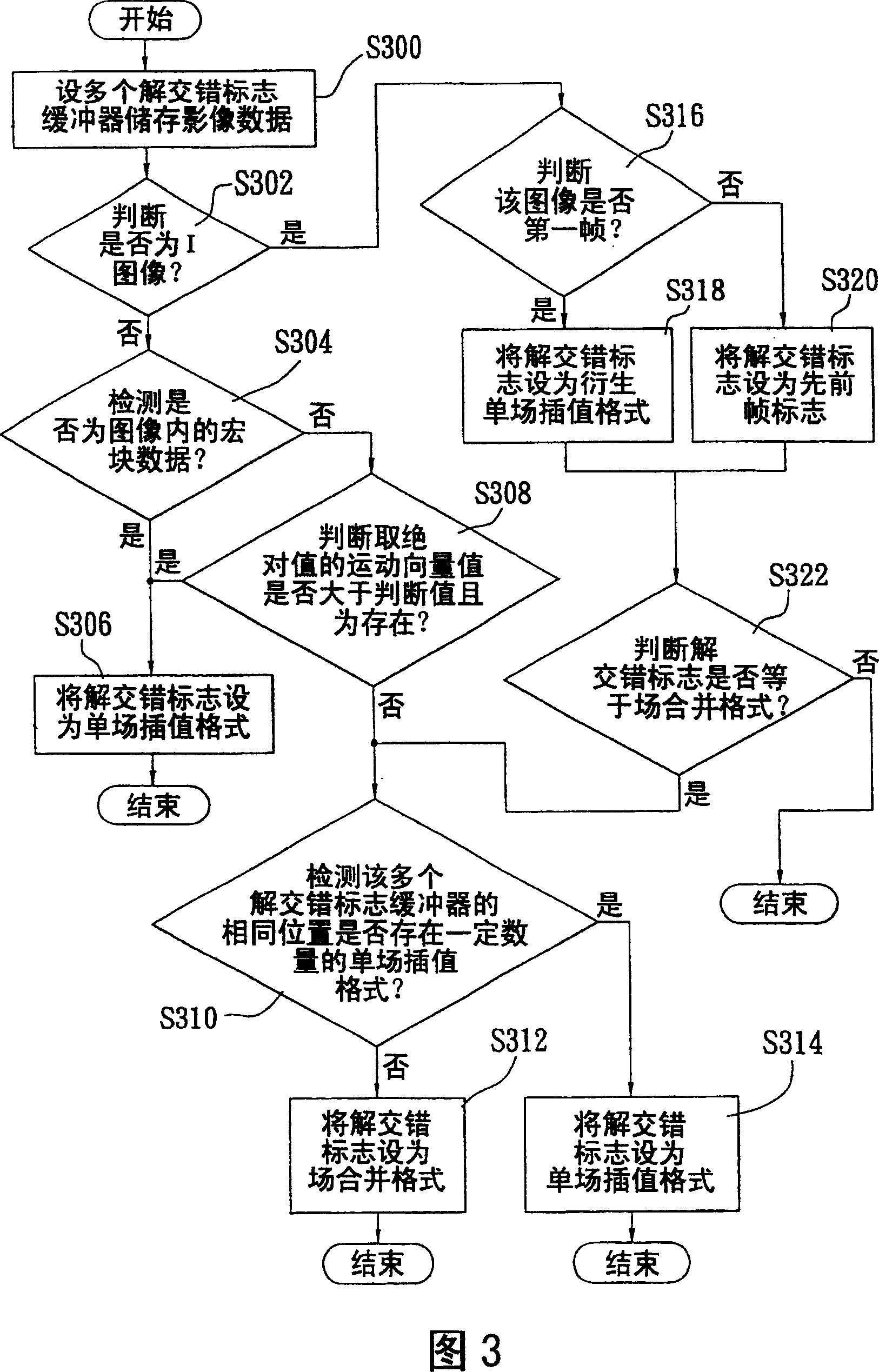

Motion vector de-interleaving method

InactiveCN1652598AConservative judgmentEliminate (Mice Teeth) PhenomenonStandards conversionComputer graphics (images)Motion vector

The method includes following steps: decoding a image content into multiple macro data pieces; from the multiple macro data pieces, calculating a motion vector, which is as a judgment value; from the said judgment value, generating multiple deinterleaved labels; implementing time stretching operation for generated deinterleaved labels. The time stretching operation includes following actions further: setting up multiple buffers of deinterleaved labels; determining whether current deinterleaved label is a field combination format (Weave); determining whether other buffers of deinterleaved labels are single field interpolation format (BOB); and setting up the deinterleaved labels as derived single field interpolation format (BOB 2); carrying out destructive operation to destroy multiple isolated deinterleaved labels, and making them possess correlativity in spatial motion. The invention prevents phenomena of mouse teeth in more degree.

Owner:ALICORP

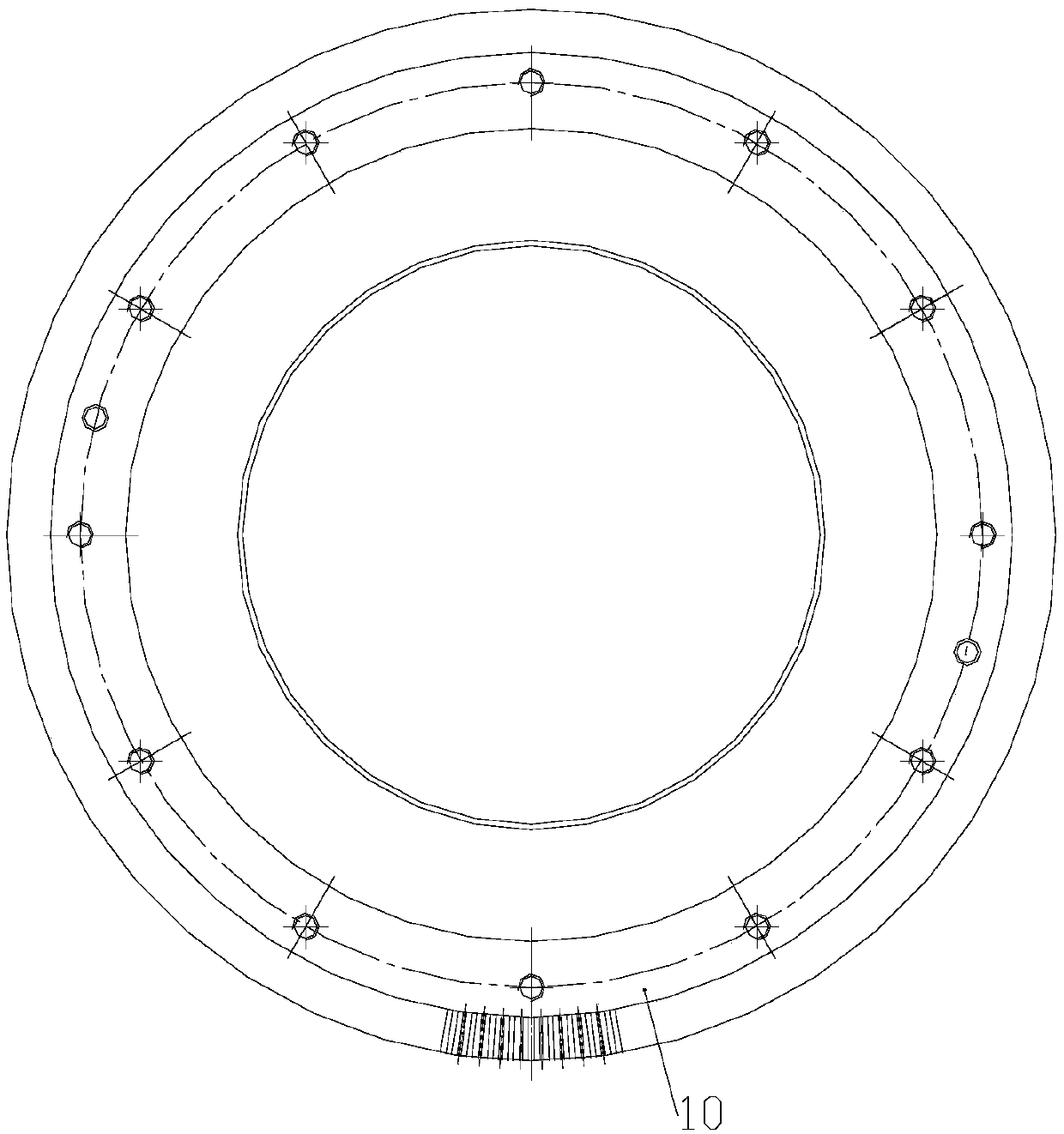

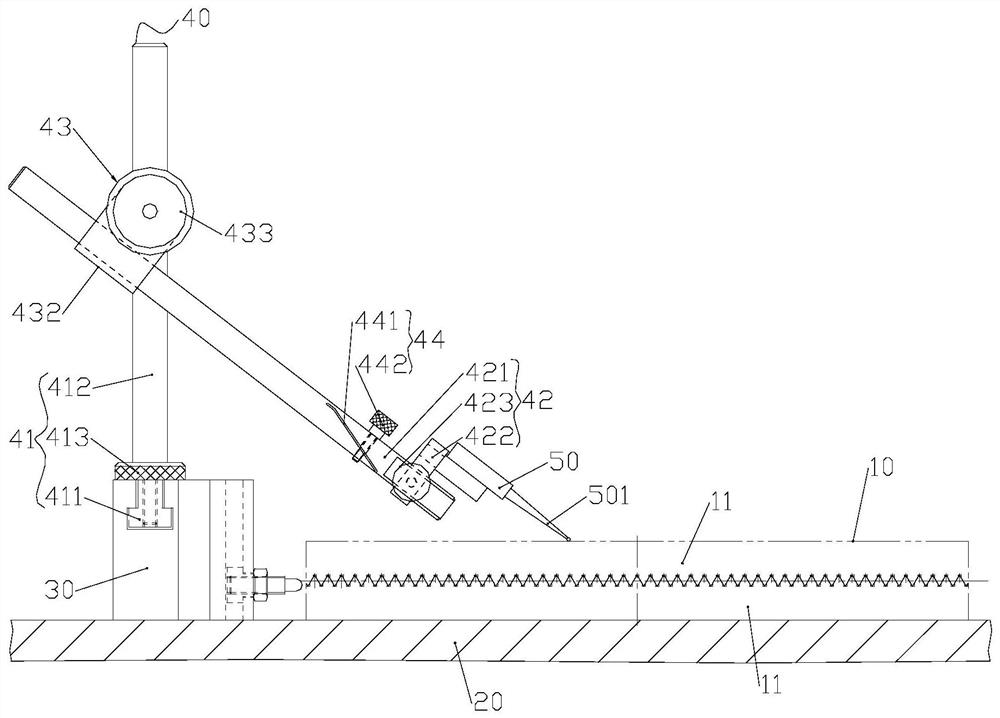

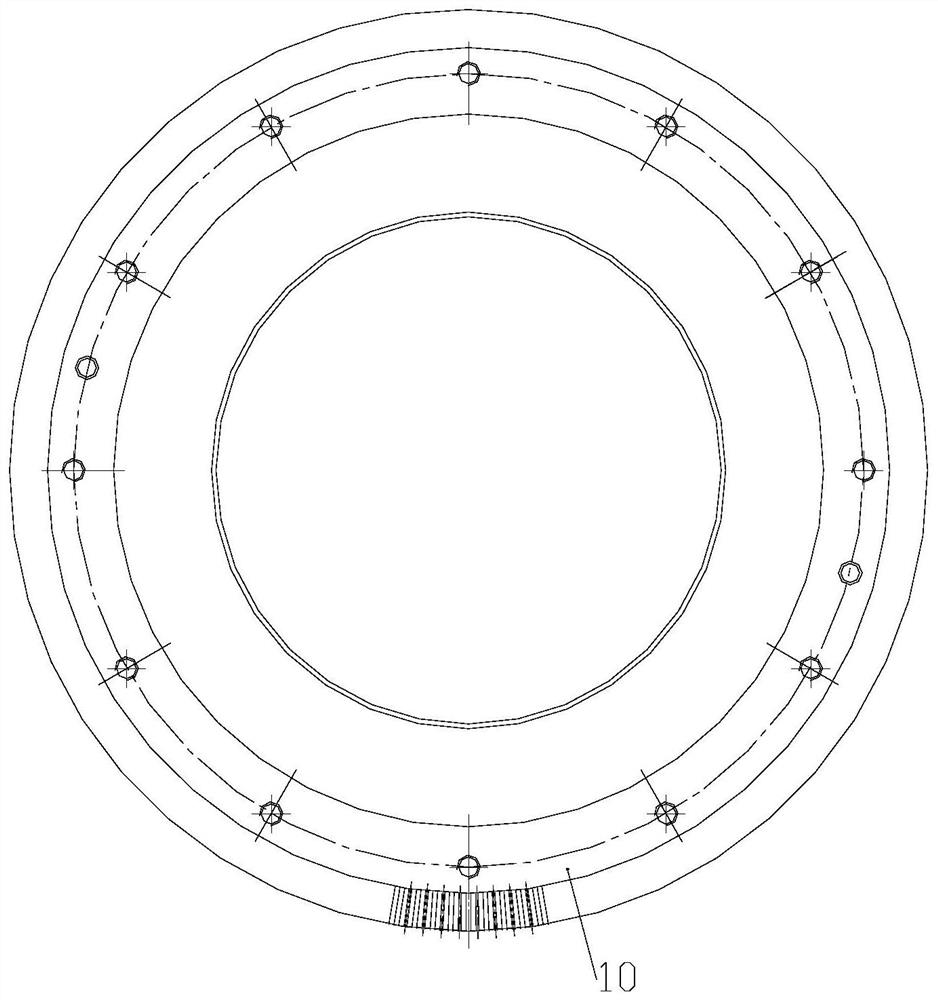

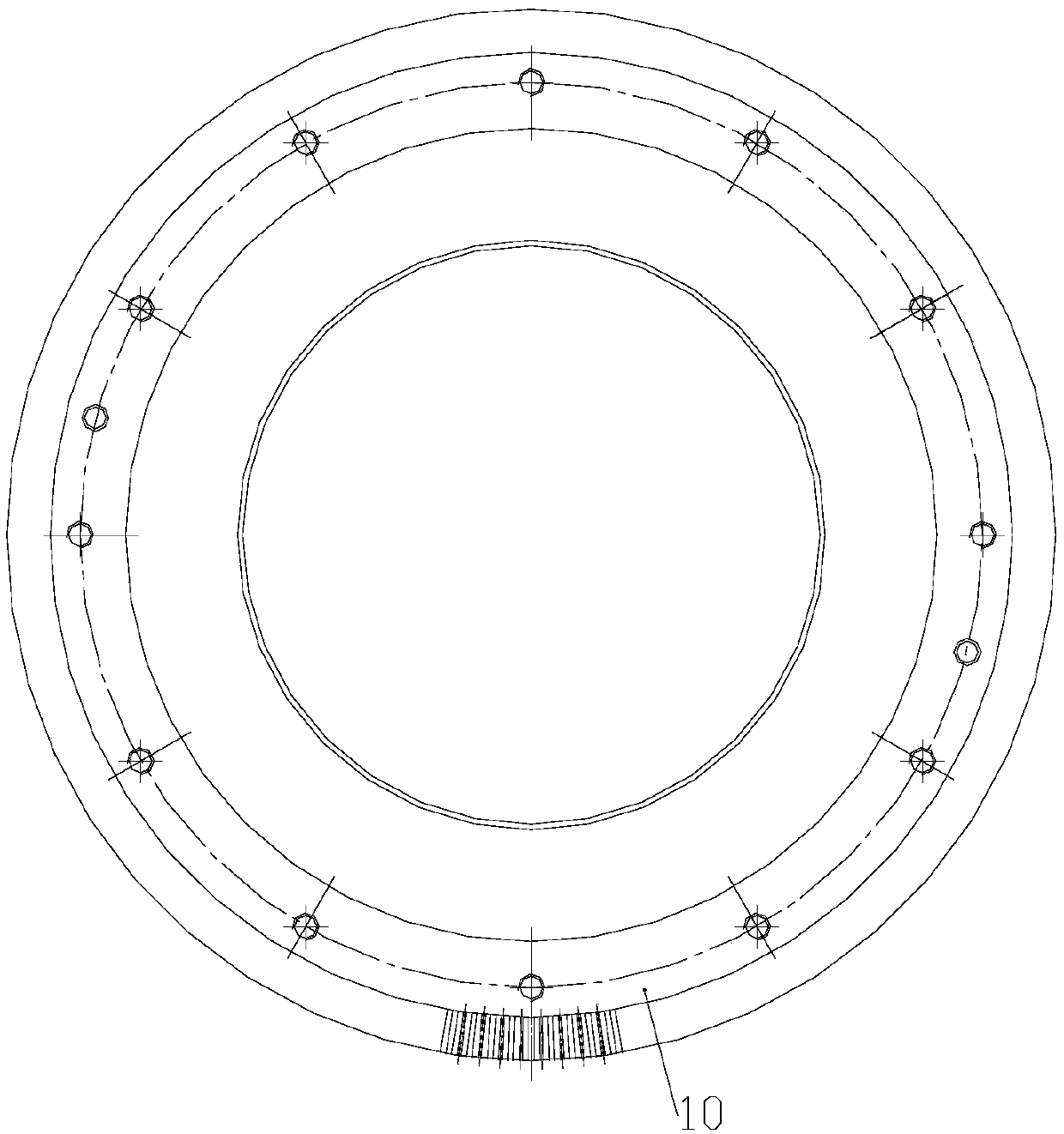

Method for detecting shape and depth error of tooth surface of mouse tooth disc

ActiveCN109654978ALower skill requirementsEasy to operateMechanical depth measurementsMouse ToothMaximum pressure

The invention discloses a method for detecting the shape and depth error of a tooth surface of a mouse tooth disc, which comprises the following steps of: the mouse tooth disc is installed and positioned. A measuring rod in the detection device is arranged and positioned on a tooth-shaped surface to be detected of the mouse tooth disc. A measuring gauge pressure gauge in the detection device is arranged on an outer circle of the measuring rod and moves along the outer conical circle generatrix of the measuring rod so as to display the maximum pressure gauge value of the outer conical circle generatrix. And the steps are sequentially repeated to obtain the maximum pressure gauge values of a plurality of outer conical circular generatrixes corresponding to a plurality of tooth-shaped surfaces to be measured, and the tooth surface shape and depth error of the mouse tooth disc is obtained according to the maximum pressure gauge values of the plurality of outer conical circular generatrixes. When the detection method is adopted, the operation steps are simple, and the detection period can be greatly shortened.

Owner:CHINA HANGFA SOUTH IND CO LTD

Rat and mouse gas anesthesia mask

The invention provides a rat and mouse gas anesthesia mask which comprises a support sleeve, an anesthesia nozzle and an anesthesia hose joint. The support sleeve comprises a support sleeve body, a sliding groove and a latex thin film, and one end of the support sleeve body is sealed by the latex thin film. The anesthesia nozzle is slidably arranged in the support sleeve in a sleeving manner and comprises a hollow pipeline unit and a fixed component, the hollow pipeline unit comprises a hollow pipeline body, a first tangent plane is obliquely arranged at one end of the hollow pipeline body, second tangent planes are arranged on two opposite sides of the first tangent plane, the first tangent plane and the front ends of the second tangent planes are enclosed to form a mouse tooth fixing plate, and a mouse upper incisor inserting hole is formed in the mouse tooth fixing plate. A fixing component is slidably arranged in the sliding groove and connected with the hollow pipeline body, the latex thin film and the mouse tooth fixing plate are arranged on the same side, an eccentric circular hole is formed in the latex thin film and corresponds to a sliding position of the mouse tooth fixing plate, and mouth and nose of a mouse and the mouse tooth fixing plate penetrate the eccentric circular hole. The mask has the advantages that the mask is open, covering area is less, and anestheticconsumption is low.

Owner:湖北锐影科技有限公司

Teeth-difference rigidity scaling adjusting mechanism and method for spinning machine

The invention provides a teeth-difference rigidity scaling adjusting mechanism for a spinning machine. The teeth-difference rigidity scaling adjusting mechanism comprises an upper part, an intermediate part and a lower part which are connected by a mouse tooth clutch, the number of teeth between the upper part and the intermediate part is Z, and teeth difference between the upper part and the lower part is 1, 2, 3 or N which is an integer larger than or equal to 1. When a gear transmission device is adjusted and if the upper part and the intermediate part rotate clockwise or anticlockwise by one teeth difference, the lower part and the intermediate part rotate by one or more teeth differences according to the same sequence. The teeth-difference rigidity scaling adjusting mechanism can be used on a same shaft and transmit to multiple planes, thereby being capable of accurately synchronizing or distributing according to a certain fixed angle. Accordingly, error in machining or mounting is eliminated.

Owner:QINGDAO KANGWEILONG COMMODITY COMPANY

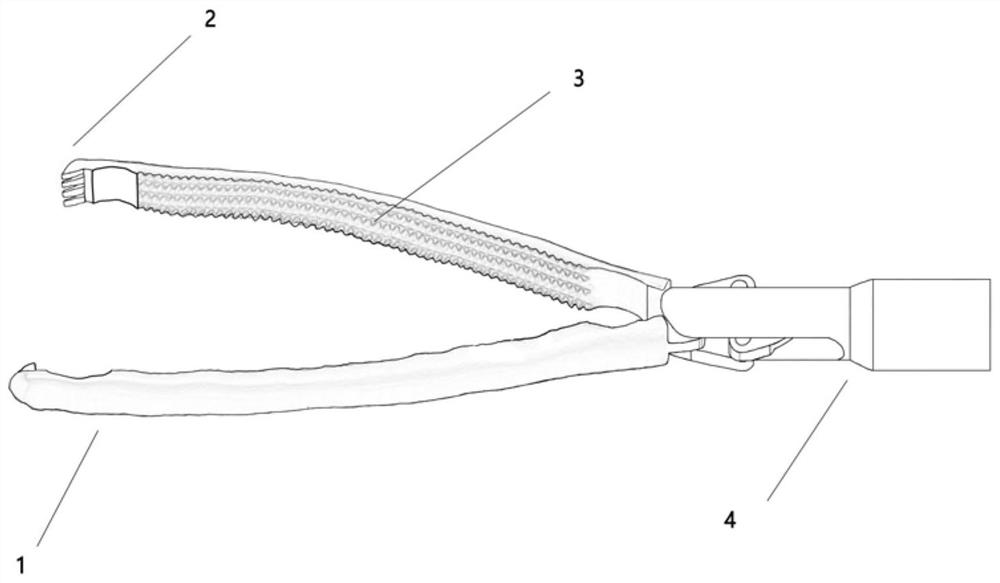

Thoracoscope esophageal grasping forceps

The invention relates to thoracoscope esophageal grasping forceps, and belongs to the technical field of medical instruments. The forceps comprise a forceps head, a rotating shaft and a forceps handle, wherein the forceps head is connected with the forceps handle through the rotating shaft; and the forceps head comprises two arc-shaped forceps supports, one ends of the two arc-shaped forceps supports are jointly connected with the rotating shaft, and mouse teeth are arranged at the other ends of the two arc-shaped forceps supports. By aiming at the situation that an existing laparoscope instrument cannot meet the requirement for thoracoscope esophageal dissociation, the thoracoscope esophageal grasping forceps are provided. The thoracoscope esophageal grasping forceps are reasonable in structure, convenient to clinically popularize, economical, practical and easy to operate.

Owner:丁新宇 +2

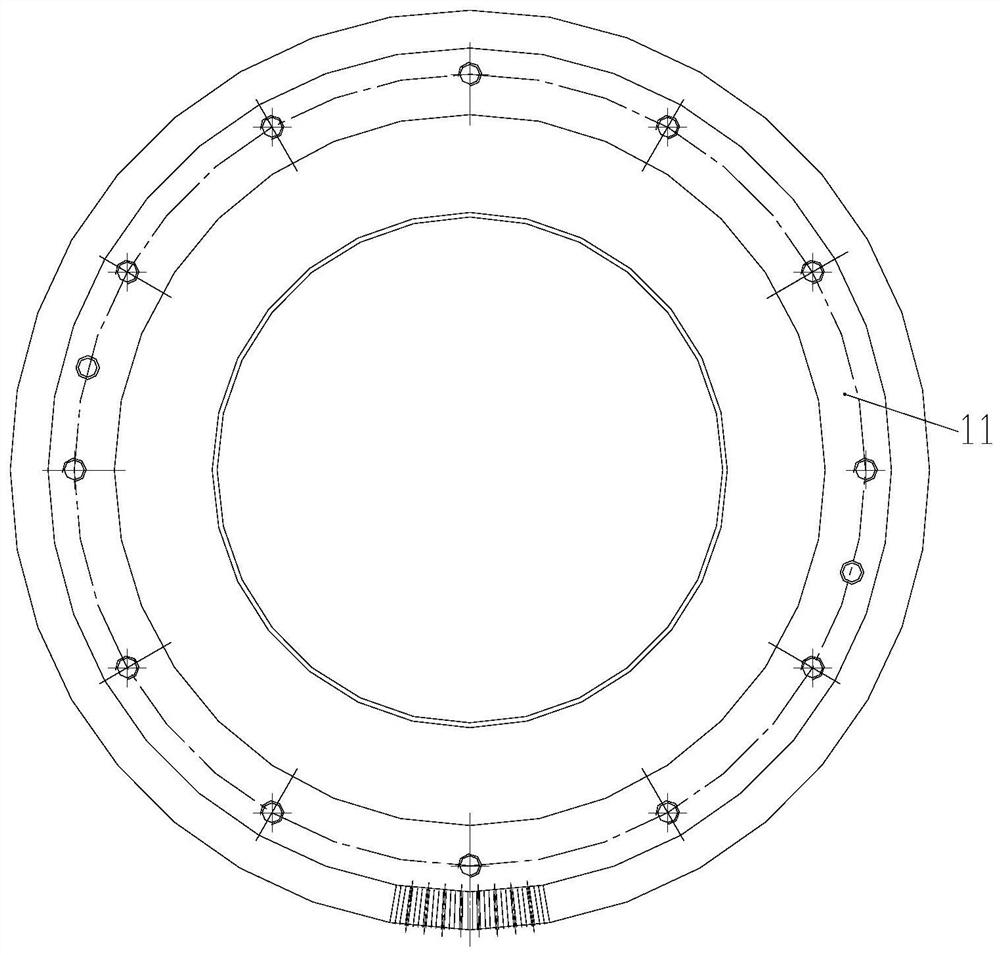

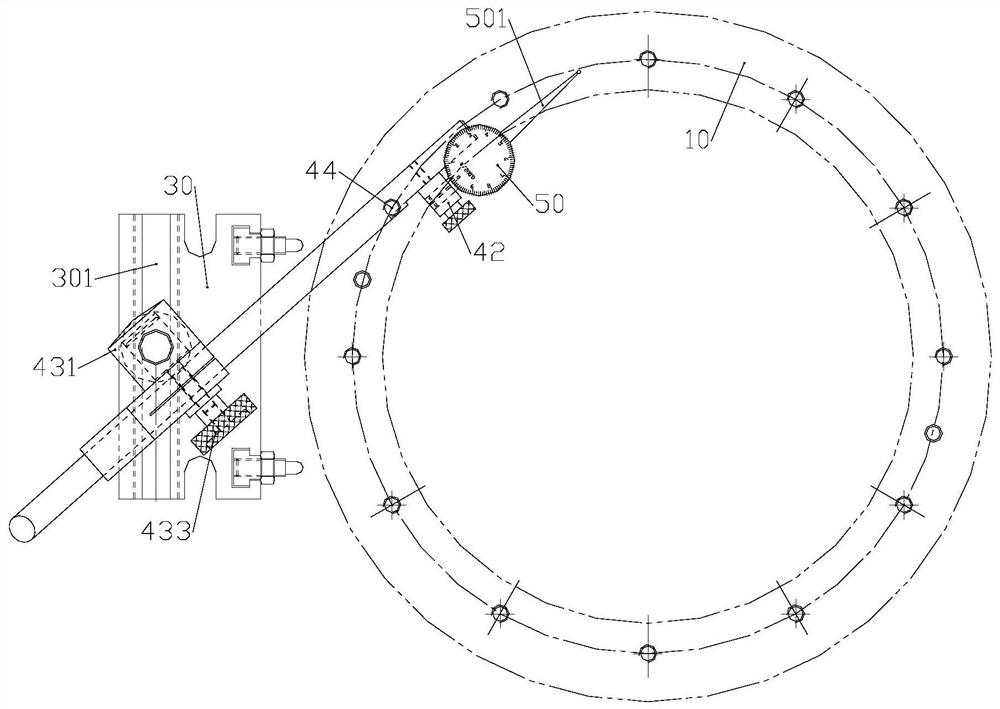

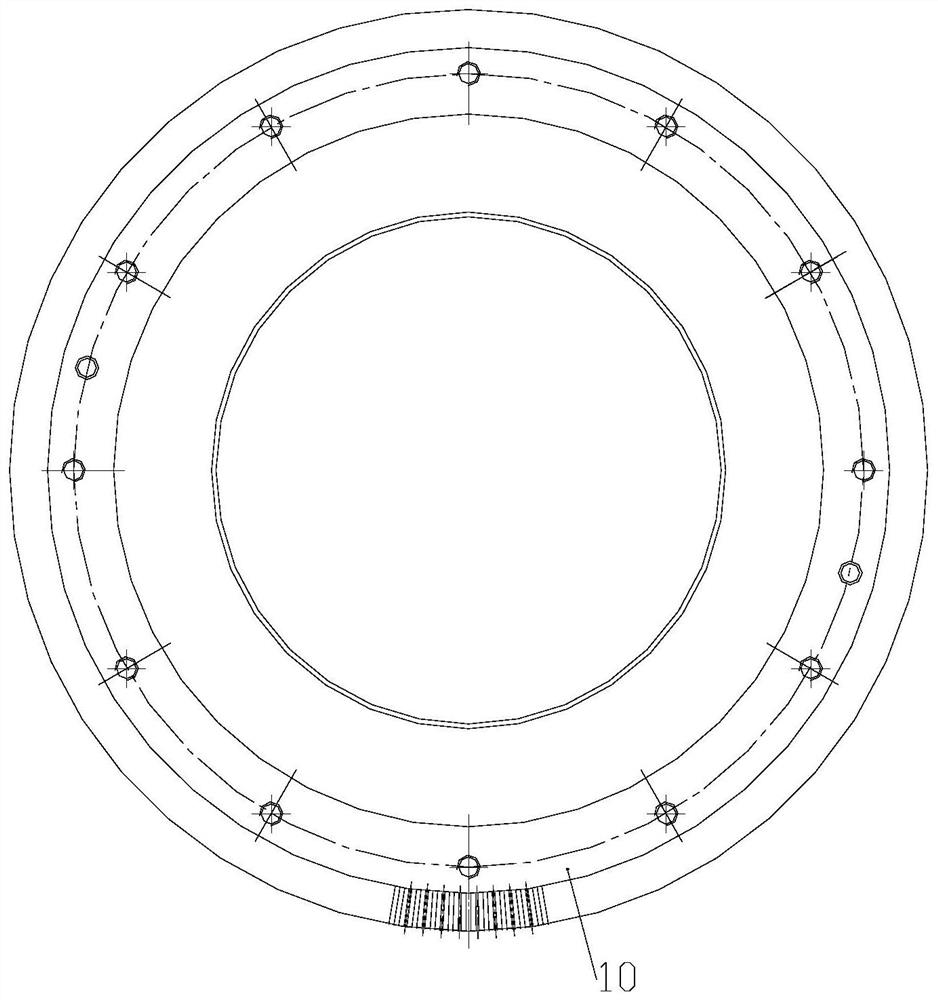

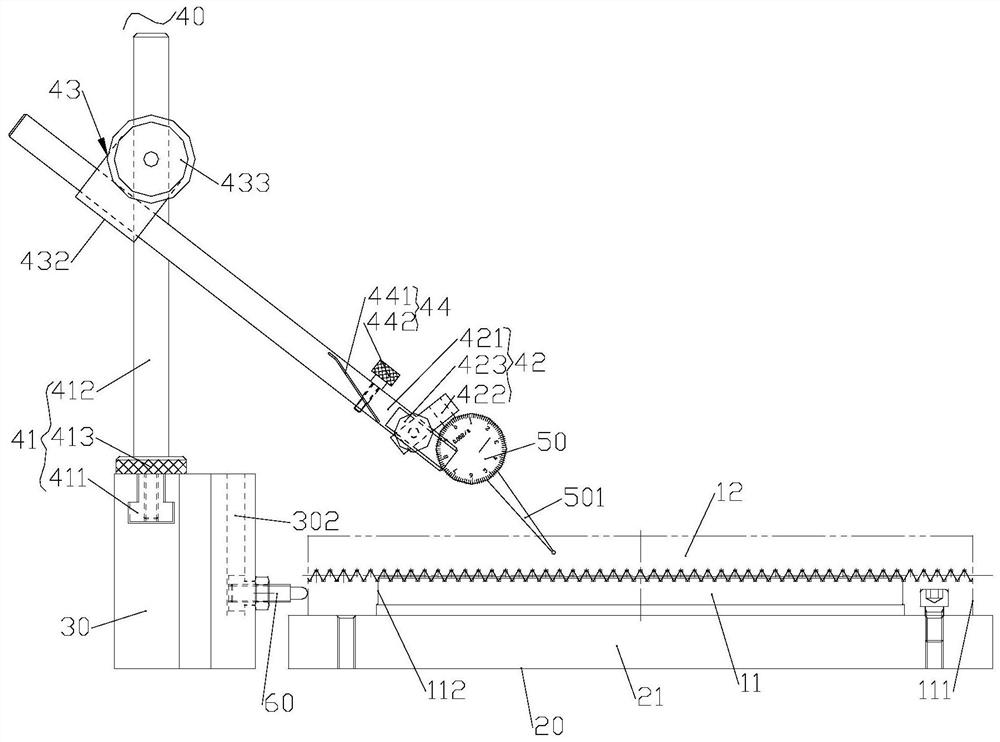

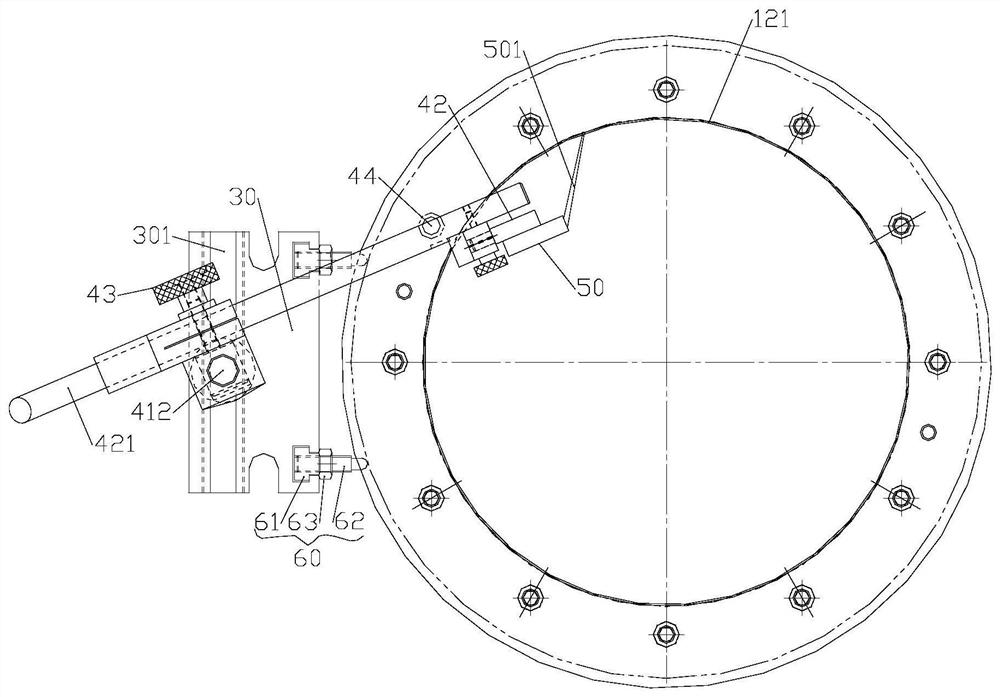

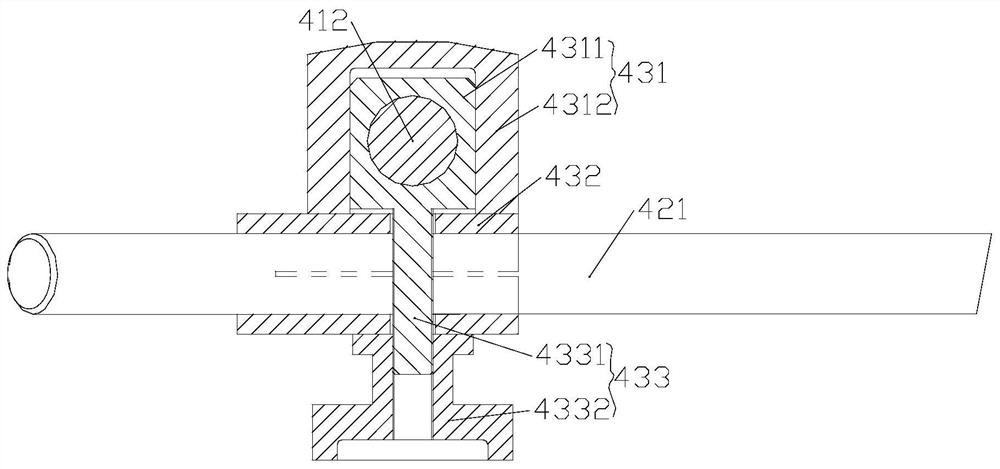

Hirth detection device

ActiveCN109654985BIncrease production capacitySpeed up the preparation processMechanical measuring arrangementsComputer hardwareMouse Tooth

The invention discloses a mouse tooth disc detection device, which comprises an installation table used for installing and positioning a mouse tooth disc pair, wherein an installation seat is supported on the installation table, and the installation seat is used for rotating around the mouse tooth disc pair in the end face parallelism error detection process. The installation seat is provided witha installation frame which can slide along the horizontal direction relative to the installation seat, the installation frame is provided with a measuring meter, and the installation frame is used for mounting a measuring meter and enabling the position of the meter head of the measuring meter to be adjustable relative to the upward end face of the mouse tooth disc. And the measuring meter is used for propping the upward end faces of the mouse tooth disc pair in the process of rotating the installation seat around the mouse tooth disc pair so as to detect the end face parallelism error of theupward end faces of the mouse tooth disc pair relative to the downward end faces of the mouse tooth disc pair. When the mouse tooth disc detection device is used for detection, the operation is simple, the requirement on skills of operators is low, the detection is convenient and rapid, the cost required by detection can be greatly reduced, the detection period can be greatly shortened, and the production and manufacturing processes of the mouse tooth disc can be accelerated.

Owner:CHINA HANGFA SOUTH IND CO LTD

A multifunctional drilling and milling mechanism

ActiveCN103949887BRealize heavy cutting drilling and millingImprove machining accuracyOther manufacturing equipments/toolsLarge fixed membersGear wheelMouse Tooth

The invention discloses a multifunctional drilling and milling mechanism. The multifunctional drilling and milling mechanism comprises a main shaft head and a main shaft box, wherein the main shaft head comprises four drilling power heads, a main shaft box shell, two milling power heads, a mouse-tooth disc and a cutter disc gear, wherein the four drilling power heads and the two milling power heads are uniformly distributed along the circumferential direction of the cylindrical profile of the main shaft box shell, and are arranged on the main shaft box shell by rolling bearings; the mouse-tooth disc is arranged on the end surface of one side of the main shaft box shell, and the cutter disc gear is arranged on the center of the main shaft box shell; the main shaft head is connected to one end of the main shaft box by virtue of the mouse-tooth disc; the main shaft box comprises a shaft VIII, a shaft II, an indexing main shaft, a main transmission shaft, a shaft X, a shaft III, a shaft IV, a shaft IX, a worm shaft VI, a shaft VII and a turbine shaft which adopt the main shaft box body as support, as well as a lead-screw support, a connecting rod mechanism and a main driving clutch device. The multifunctional drilling and milling mechanism disclosed by the invention is applied on a machine tool and realizes drilling and milling processing of workpieces under the condition of once clamping, so that the accuracy of shapes and positions of holes or key grooves is ensured and the environment-friendly and energy-saving effects are achieved.

Owner:安阳市海之达新型建材有限公司

Depth error detection device for the shape and depth of the tooth surface of the rat tooth plate

ActiveCN109654979BIncrease production capacitySpeed up the preparation processMechanical depth measurementsMouse ToothMechanical engineering

The invention discloses a device for detecting the shape and depth error of a tooth surface of a mouse tooth disc, which comprises a mounting table, wherein a mounting seat is supported on the mounting table and is used for rotating around the mouse tooth disc. The mounting seat is provided with a slidable contact component which is used for propping against the outer circle of the mounting table.The mounting seat is also provided with a slidable mounting frame, and the mounting frame is provided with a measuring meter. The measuring meter is used for pressing the meter on the inner circle ofthe mouse tooth disc so as to adjust the position of the mouse tooth disc relative to the mounting table, so that the mouse tooth disc is coaxial with the mounting table. The detection device also comprises a measuring rod, and the measuring rod is used for being installing and positioning the tooth-shaped surface to be detected of the mouse tooth disc. A measuring meter head is also used for pressing the meter on the outer circle of the measuring rod so as to find out the maximum value of the meter pressing amount of the generatrix of the outer conical circle of the measuring rod. When the detection device is adopted, the operation is simple, the detection period can be greatly shortened, and the production and manufacturing flow of the mouse tooth disc can be accelerated; in addition, the mouse tooth disc detection device is simple in structure, easy to prepare and high in detection precision.

Owner:CHINA HANGFA SOUTH IND CO LTD

A servo tool holder structure and its application method

ActiveCN104815994BEasy to installEasy to debugPrecision positioning equipmentMachine tool componentsNumerical controlMouse Tooth

The invention relates to the field of tool holders for numerically controlled machine tools, in particular to a servo tool holder structure and a method for using the same. The servo tool holder is provided with a casing, a rear cover assembly, a box assembly, a proximity switch assembly, and a water separator. The casing is installed at the tail of the rear cover assembly, and the reducer end of the rear cover assembly is connected to the rear end of the box assembly. The proximity switch assembly is installed in the box body of the box body assembly, and the water diversion plate is installed on the movable tooth plate of the box body assembly. The motor and reducer of the rear cover group are installed on the rear cover to provide the power source; the box assembly is positioned with a three-piece ratchet structure, and the proximity switch assembly uses a cam structure to detect the locking state of the knife holder. The present invention can solve the problems existing in the prior art, such as complex movement and cumbersome structure during the positioning and indexing of the tool holder, and the difficulty of increasing the manufacturing of the tool holder parts and the assembly of the complete machine, etc. Tool change function.

Owner:SHENYANG MASCH TOOL CO LTD

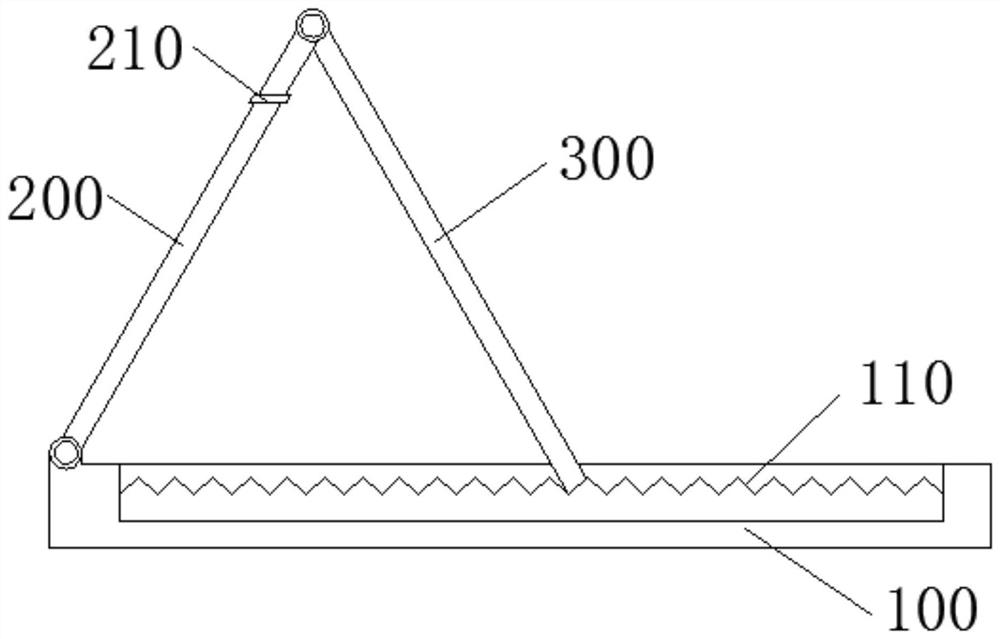

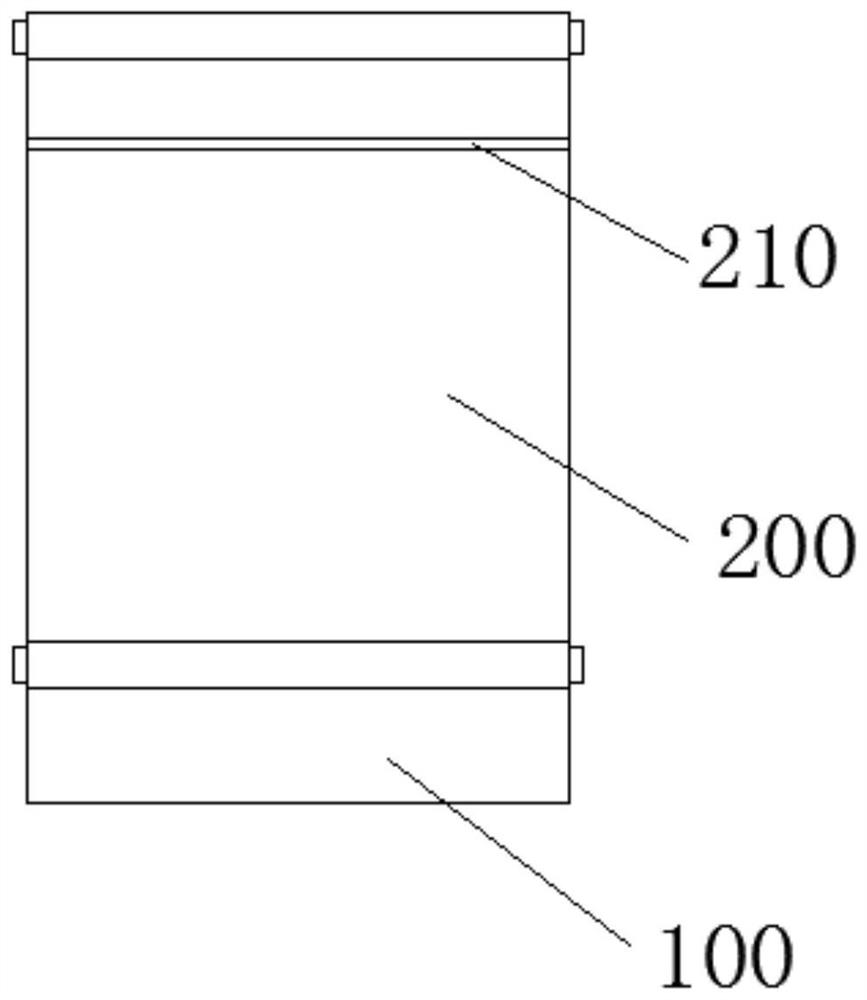

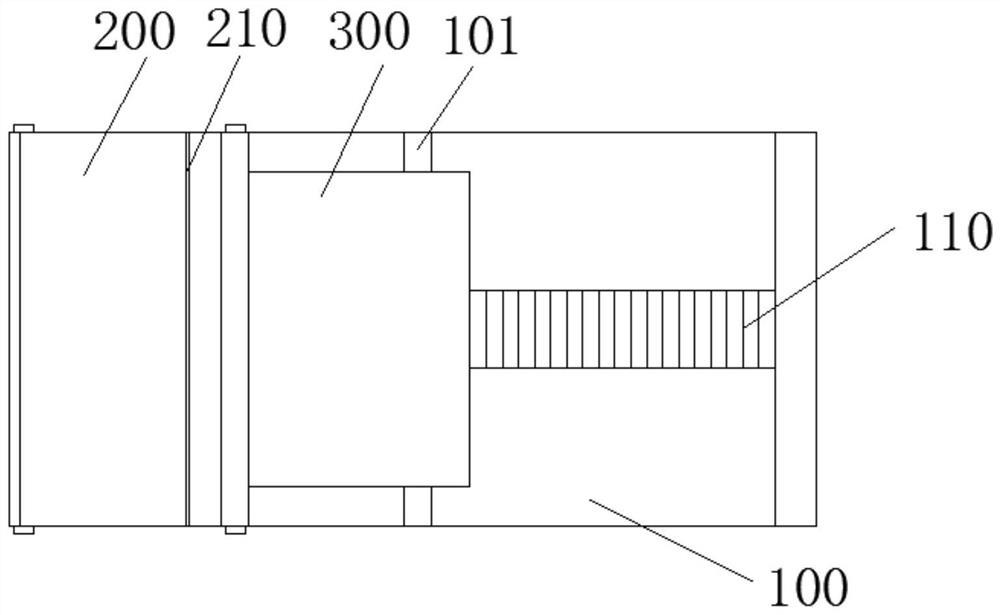

Rapid mouse trachea intubation device

The invention provides a rapid mouse trachea intubation device. The rapid mouse trachea intubation device comprises a fixing base, a working plate and a supporting plate; One end of the working plate is connected with the fixing base in a rotatable or bendable manner; the other end of the working plate is connected with the supporting plate in a rotatable or bendable mode; the other end of the supporting plate can move on the fixing base and can be fixed to the fixing base; and the working plate is provided with a mouse tooth suspension rope which is horizontally arranged. The device has the advantages that a mouse can be quickly fixed and taken down, the operation is convenient and quick, the structure is simple, and the configuration cost is low.

Owner:SHANGHAI CHANGZHENG HOSPITAL

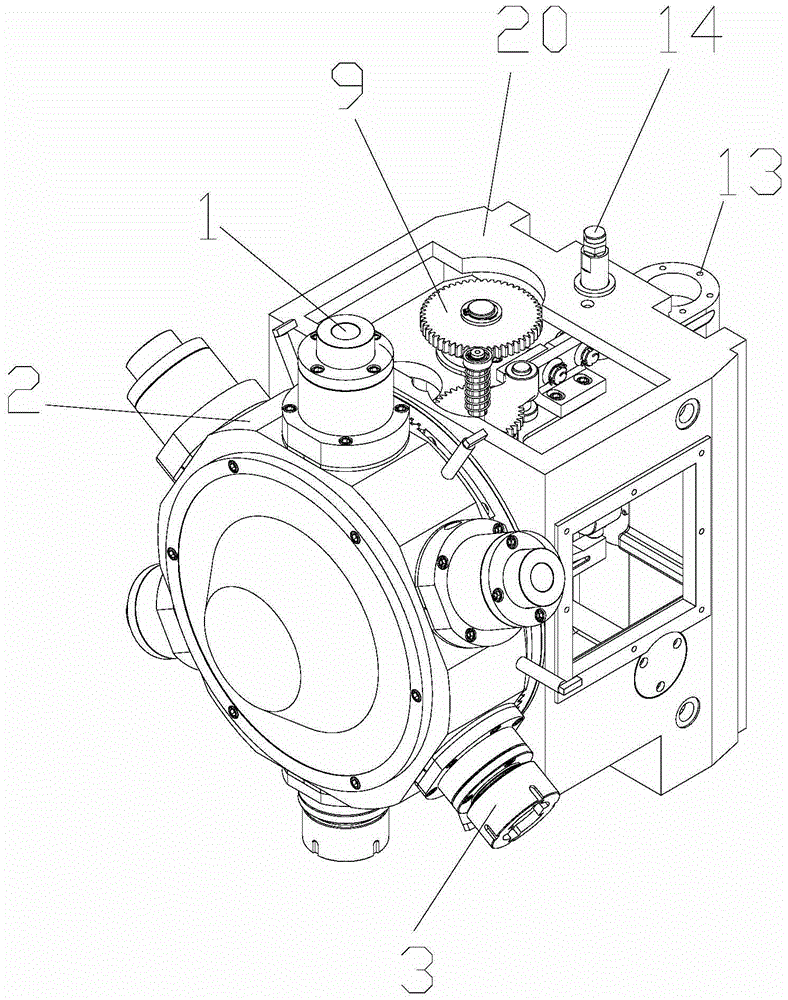

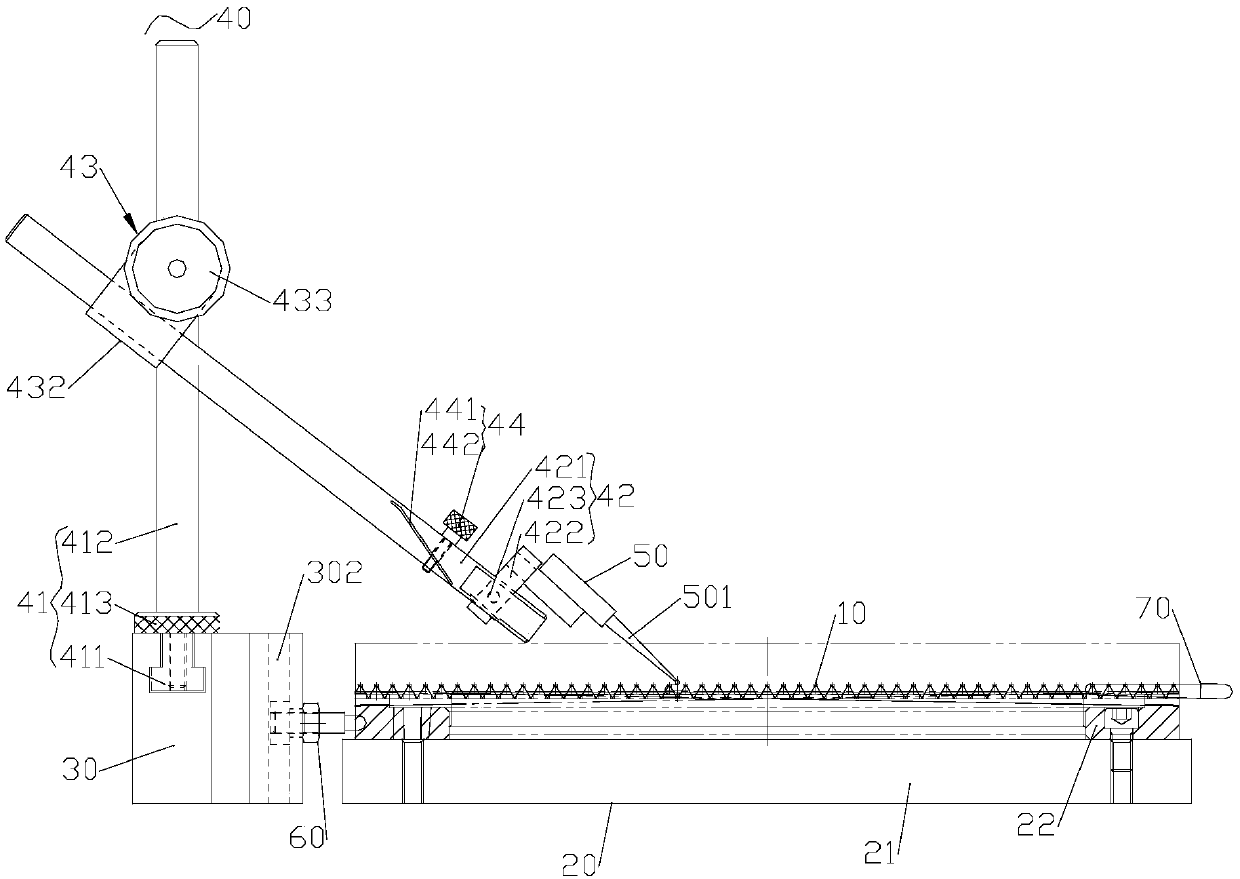

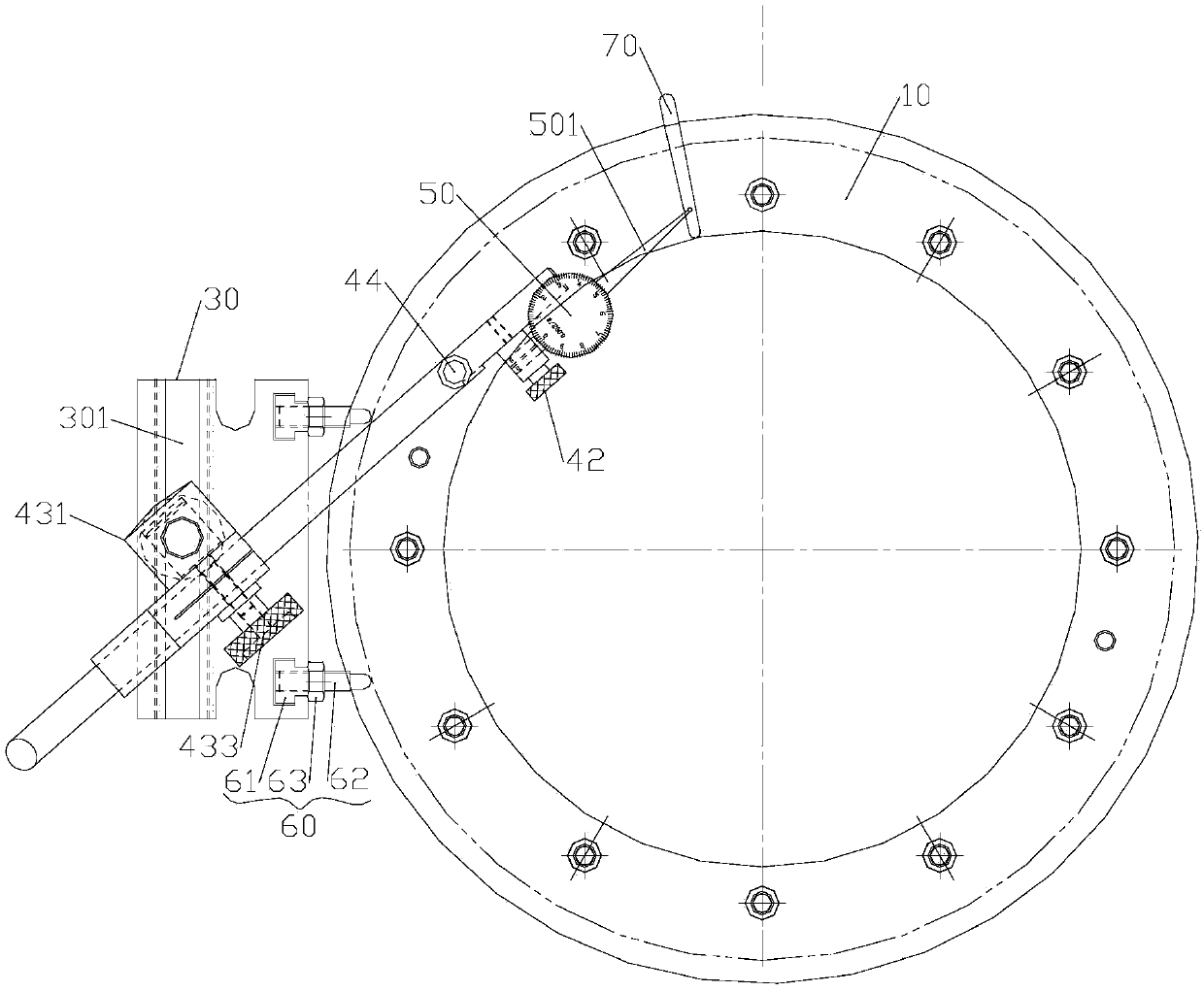

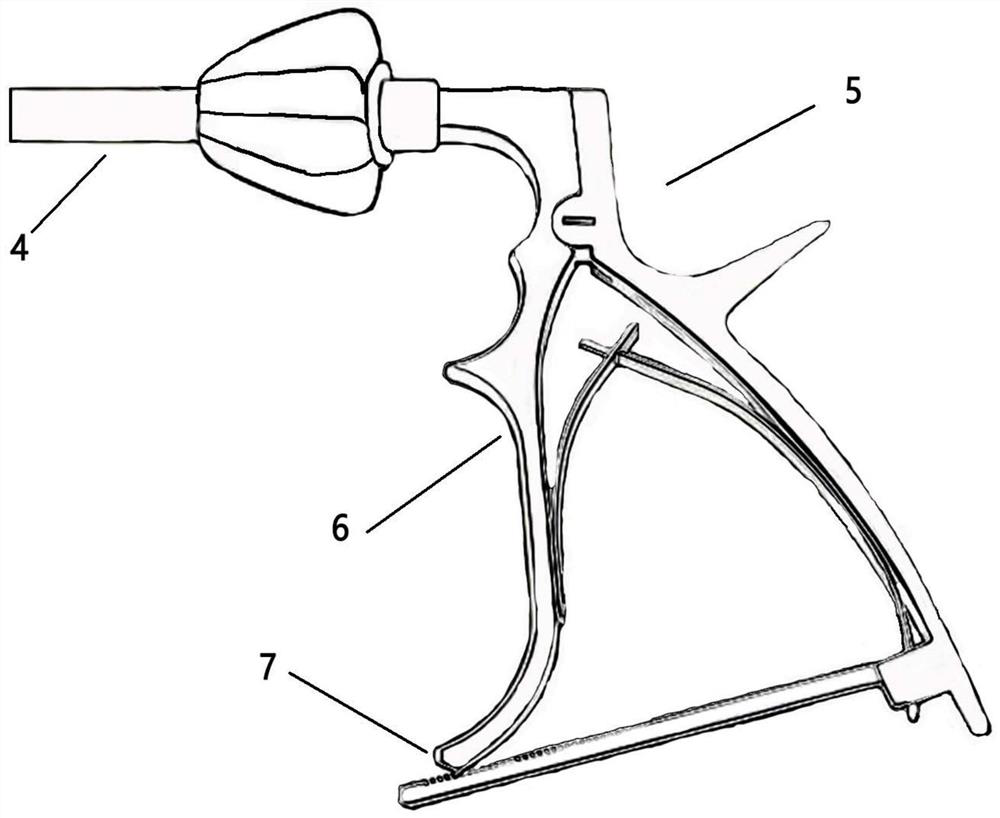

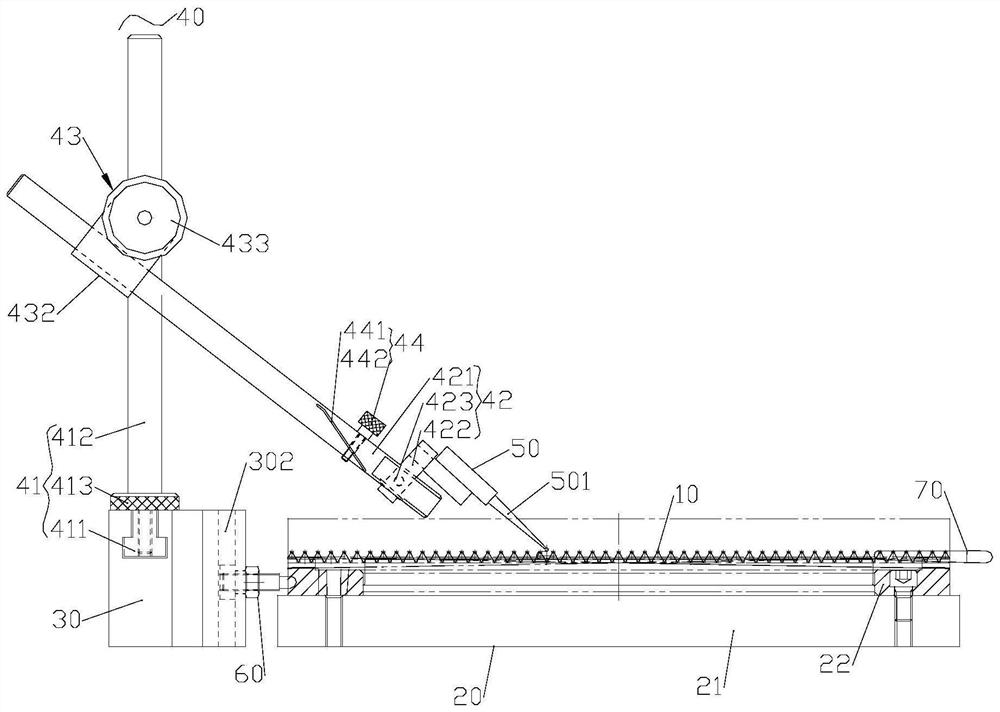

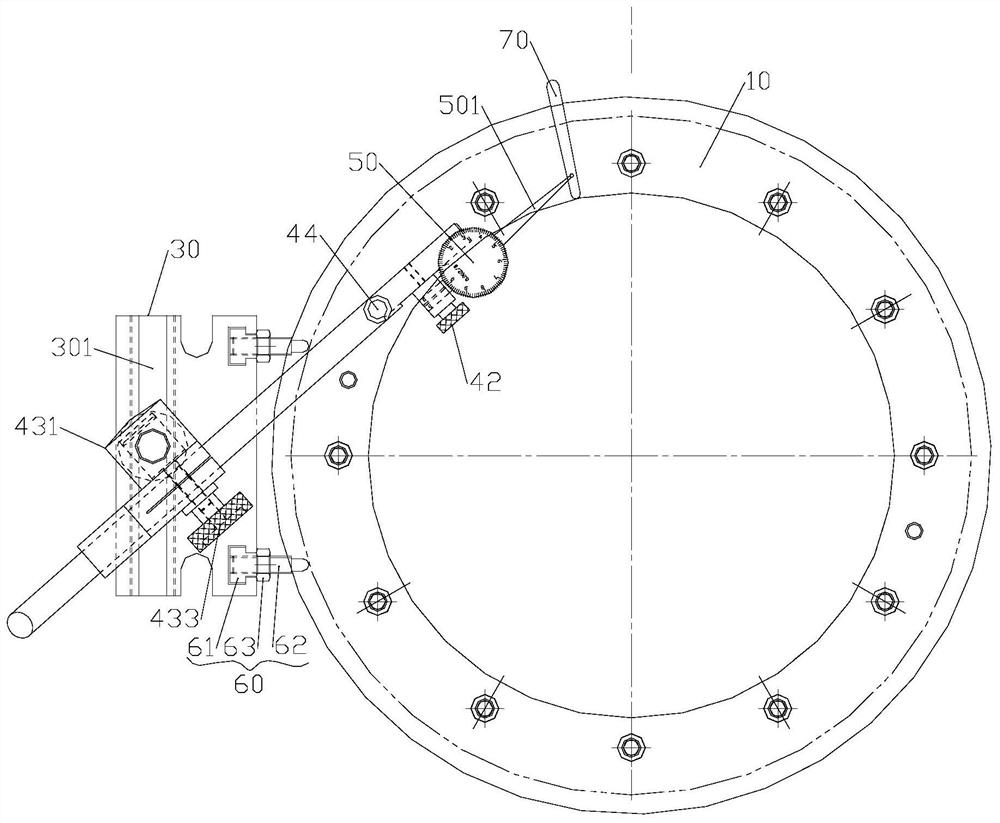

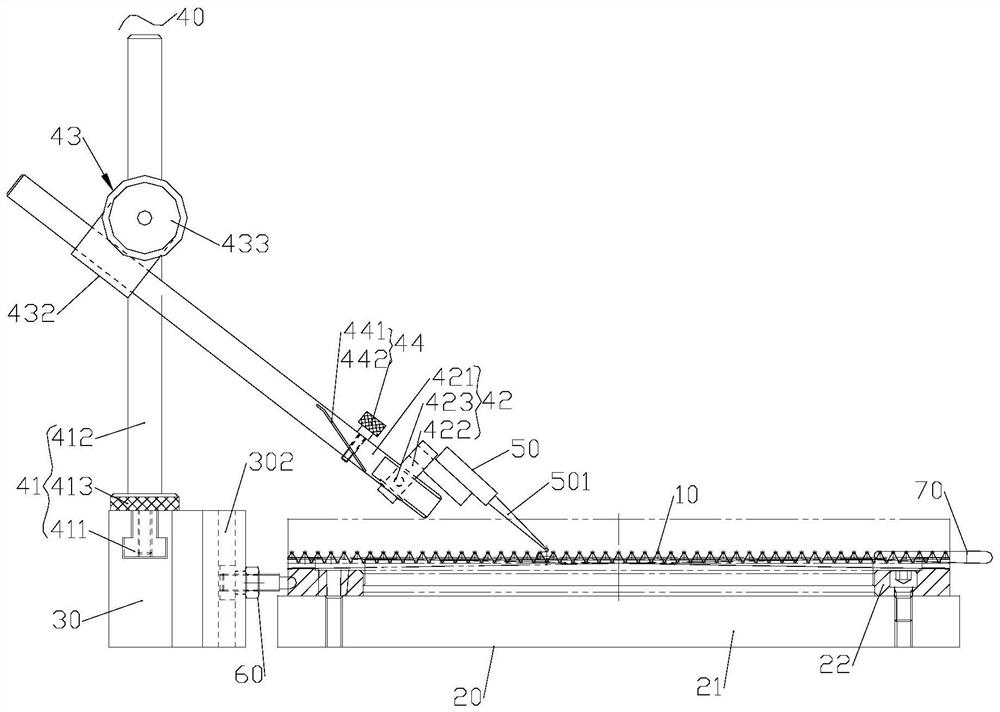

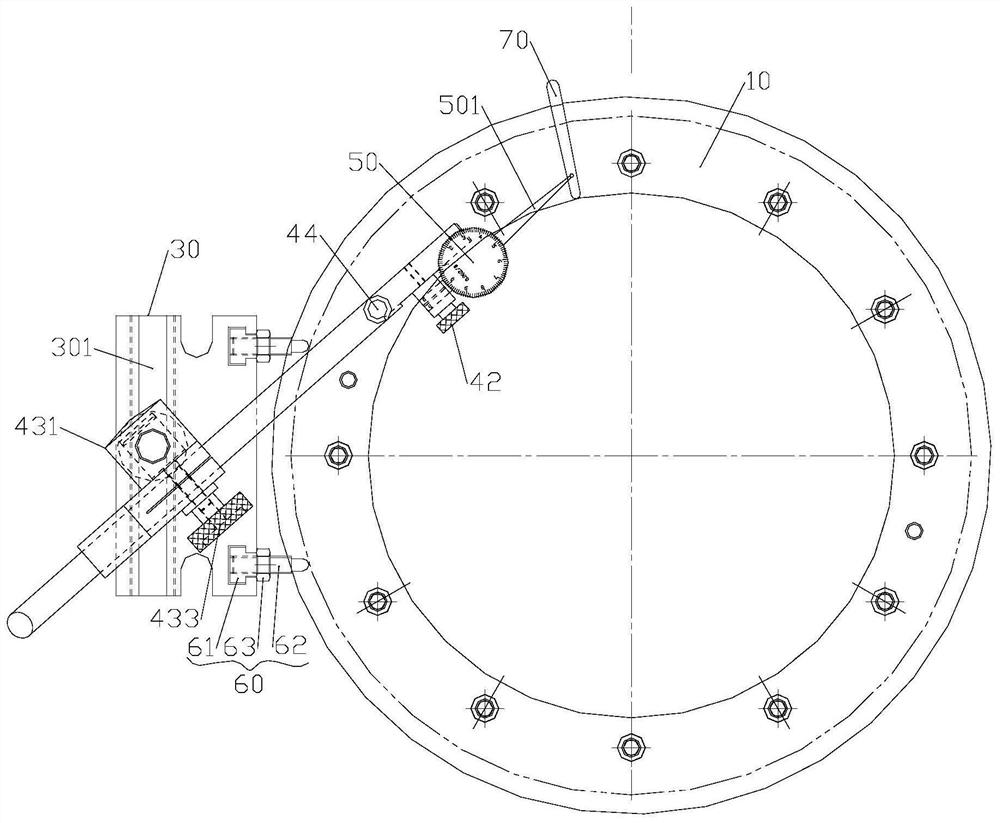

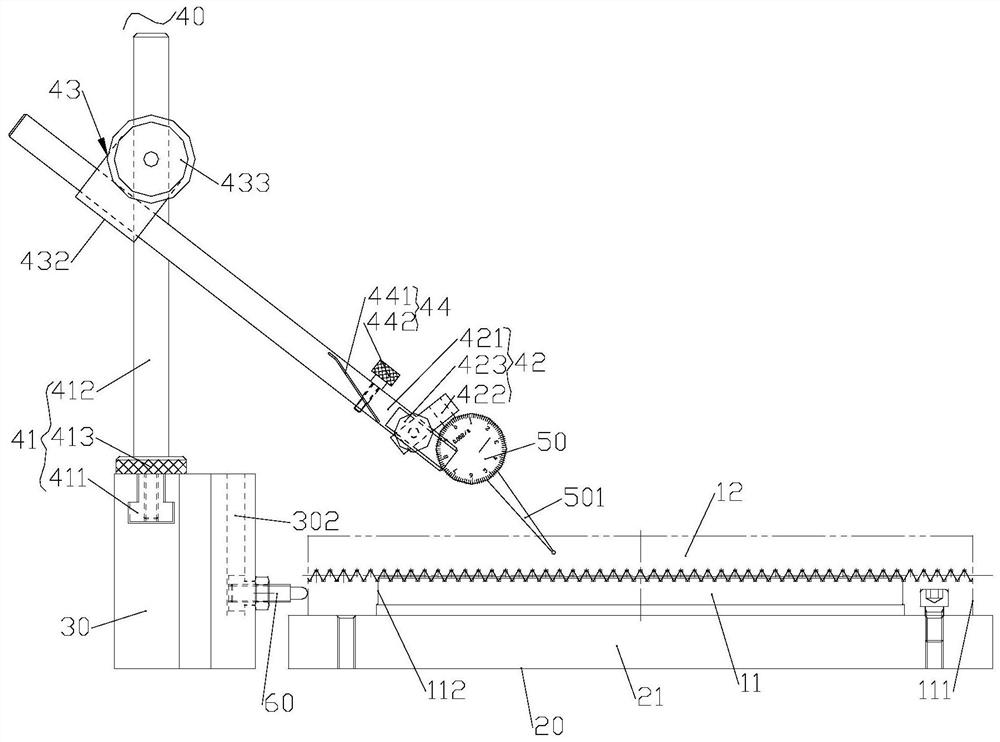

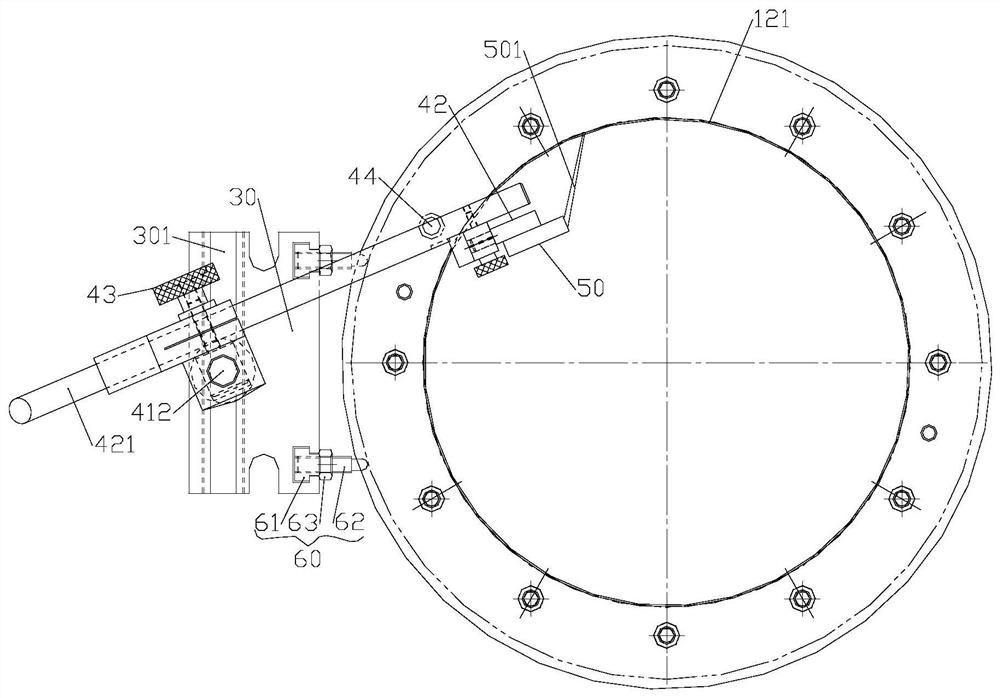

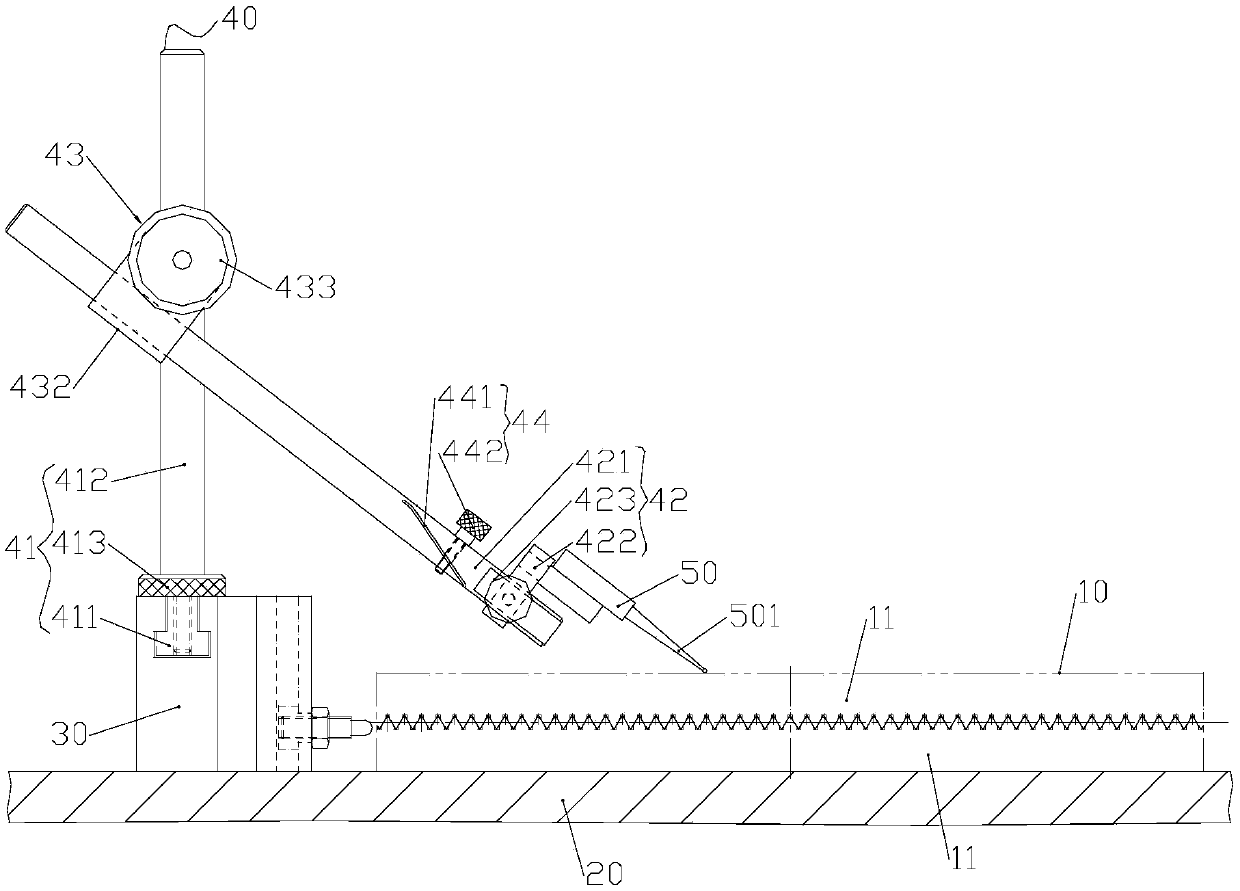

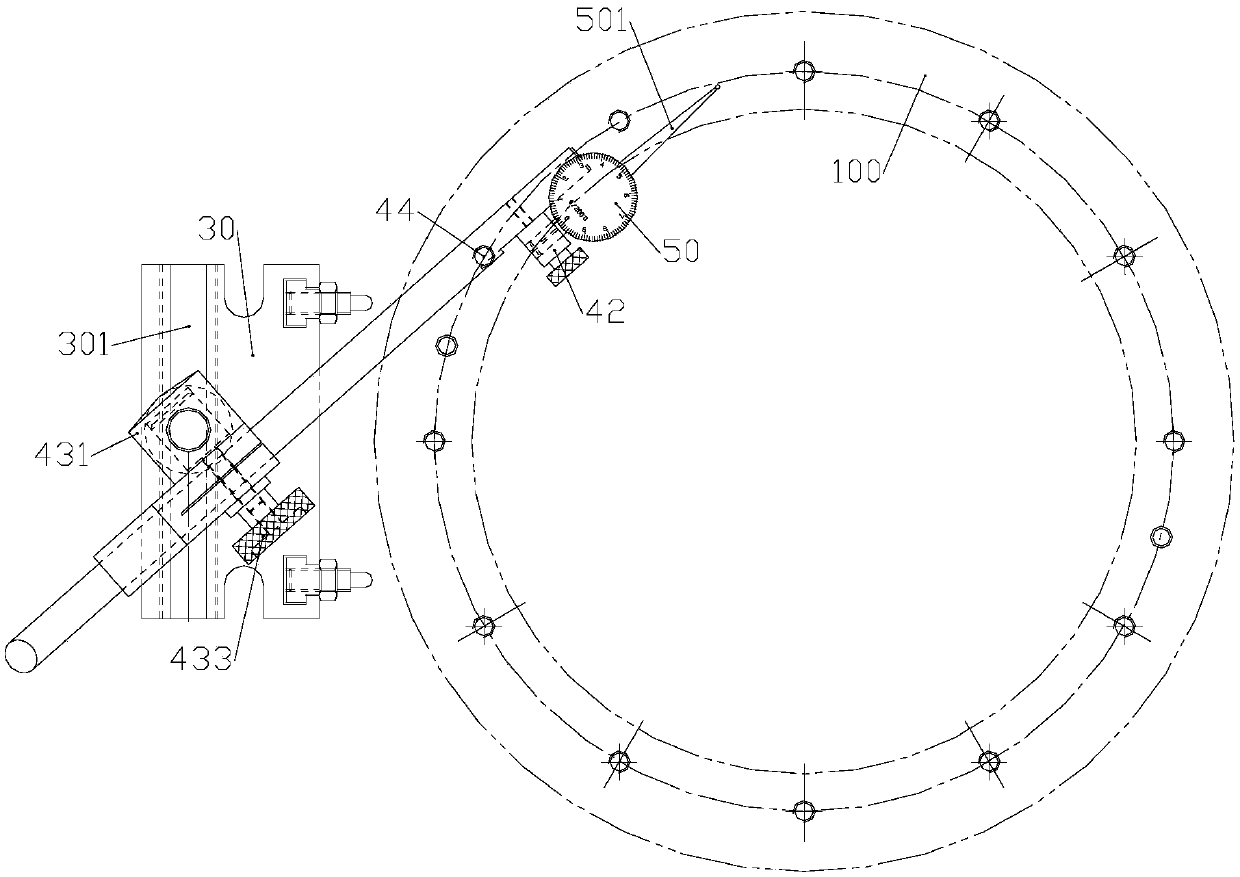

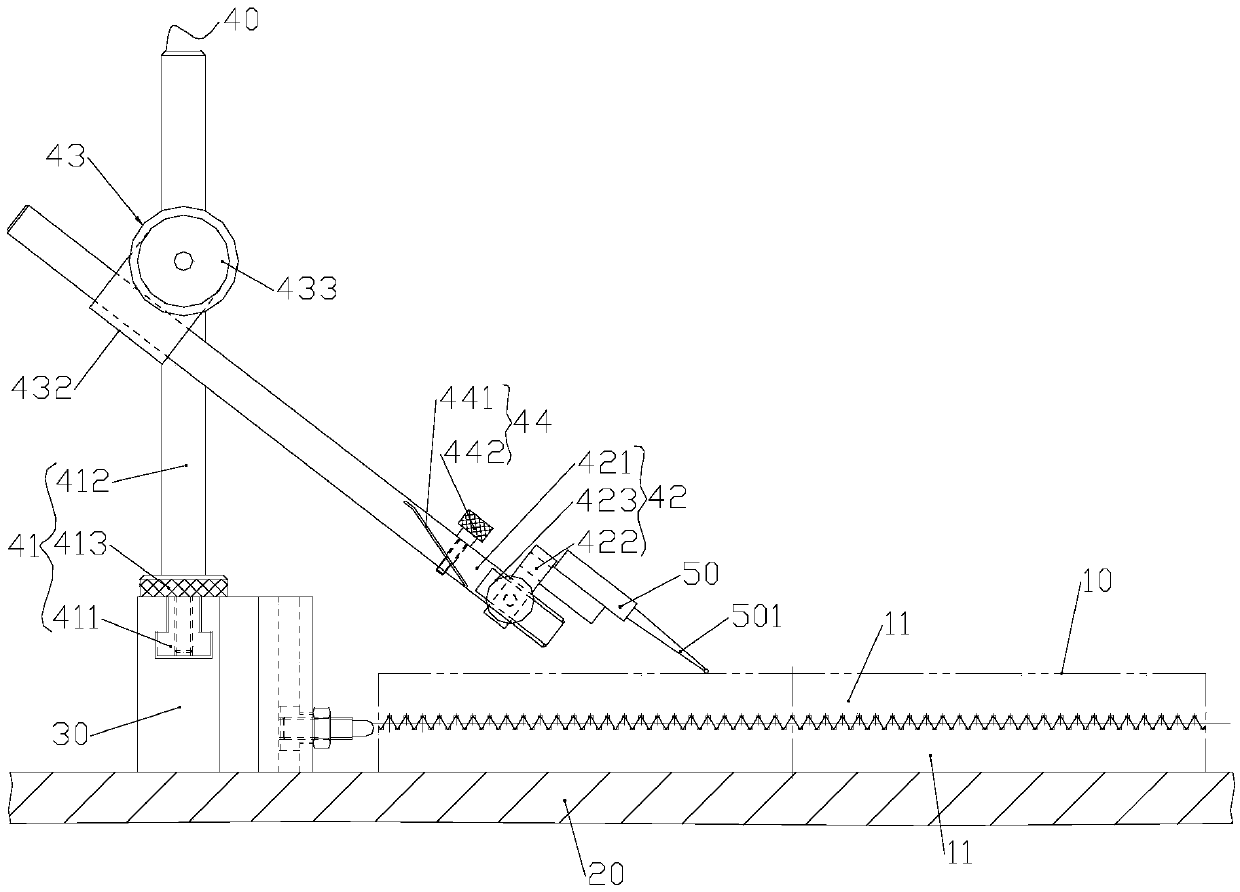

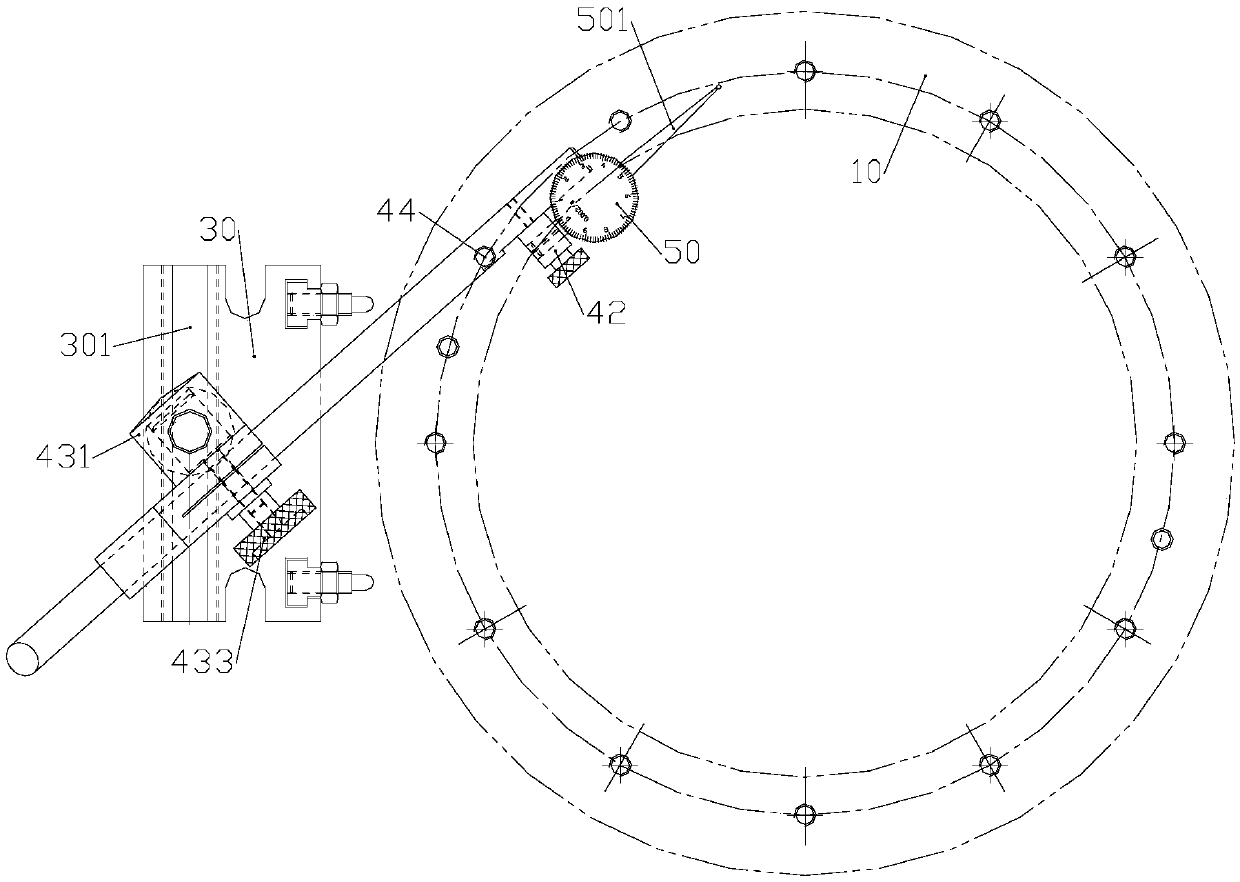

Manual accurate-indexing right-angle milling head

ActiveCN102848251BSimple structureCompact and reasonablePrecision positioning equipmentDriving apparatusMouse ToothEngineering

Owner:JIANGSU SHINRI HEAVY IND SCI & TECH

Method for detection of tooth surface shape depth error of rat tooth plate

ActiveCN109654978BLower skill requirementsEasy to operateMechanical depth measurementsMouse ToothMechanical engineering

The invention discloses a method for detecting the shape and depth error of a tooth surface of a mouse tooth disc, which comprises the following steps of: the mouse tooth disc is installed and positioned. A measuring rod in the detection device is arranged and positioned on a tooth-shaped surface to be detected of the mouse tooth disc. A measuring gauge pressure gauge in the detection device is arranged on an outer circle of the measuring rod and moves along the outer conical circle generatrix of the measuring rod so as to display the maximum pressure gauge value of the outer conical circle generatrix. And the steps are sequentially repeated to obtain the maximum pressure gauge values of a plurality of outer conical circular generatrixes corresponding to a plurality of tooth-shaped surfaces to be measured, and the tooth surface shape and depth error of the mouse tooth disc is obtained according to the maximum pressure gauge values of the plurality of outer conical circular generatrixes. When the detection method is adopted, the operation steps are simple, and the detection period can be greatly shortened.

Owner:CHINA HANGFA SOUTH IND CO LTD

Multi-station tooth making clamp and clamping method for cutter used in sugar industry

ActiveCN113021038AAvoid inaccurate indexing accuracyAvoid vibration and even rolloverPositioning apparatusMetal-working holdersMouse ToothMechanical engineering

The invention provides a multi-station tooth making clamp and clamping method for a cutter used in the sugar industry. The multi-station tooth making clamp comprises a mouse tooth type index plate, a transition plate, a workpiece positioning plate, a workpiece base plate, a self-locking clamping mechanism, a pressing plate reset mechanism and a workpiece length direction positioning clamping loosening mechanism. The mouse tooth type index plate can guarantee the accuracy during any integer degree indexing. The transition plate can convert an oil way of a rotary table plane to the outer circle of the transition plate. The total reinforcement ratio of the self-locking clamping mechanism is 7: 1, and the self-locking clamping mechanism is formed by combining a self-locking reinforcement mechanism and a lever reinforcement mechanism. The pressing plate reset mechanism is formed by three-station pressing plates sharing one extension spring reset mechanism. According to the multi-station tooth making scheme for the cutter used in the sugar industry, the scheme that three stations are rotated to replace three stations in a parallel array is adopted, the occupied space of equipment is greatly reduced, and the equipment purchasing cost is reduced.

Owner:宜昌长机科技有限责任公司

Device for detecting shape and depth error of tooth surface of mouse tooth disc

ActiveCN109654979AIncrease production capacitySpeed up the preparation processMechanical depth measurementsMouse ToothEngineering

The invention discloses a device for detecting the shape and depth error of a tooth surface of a mouse tooth disc, which comprises a mounting table, wherein a mounting seat is supported on the mounting table and is used for rotating around the mouse tooth disc. The mounting seat is provided with a slidable contact component which is used for propping against the outer circle of the mounting table.The mounting seat is also provided with a slidable mounting frame, and the mounting frame is provided with a measuring meter. The measuring meter is used for pressing the meter on the inner circle ofthe mouse tooth disc so as to adjust the position of the mouse tooth disc relative to the mounting table, so that the mouse tooth disc is coaxial with the mounting table. The detection device also comprises a measuring rod, and the measuring rod is used for being installing and positioning the tooth-shaped surface to be detected of the mouse tooth disc. A measuring meter head is also used for pressing the meter on the outer circle of the measuring rod so as to find out the maximum value of the meter pressing amount of the generatrix of the outer conical circle of the measuring rod. When the detection device is adopted, the operation is simple, the detection period can be greatly shortened, and the production and manufacturing flow of the mouse tooth disc can be accelerated; in addition, the mouse tooth disc detection device is simple in structure, easy to prepare and high in detection precision.

Owner:CHINA HANGFA SOUTH IND CO LTD

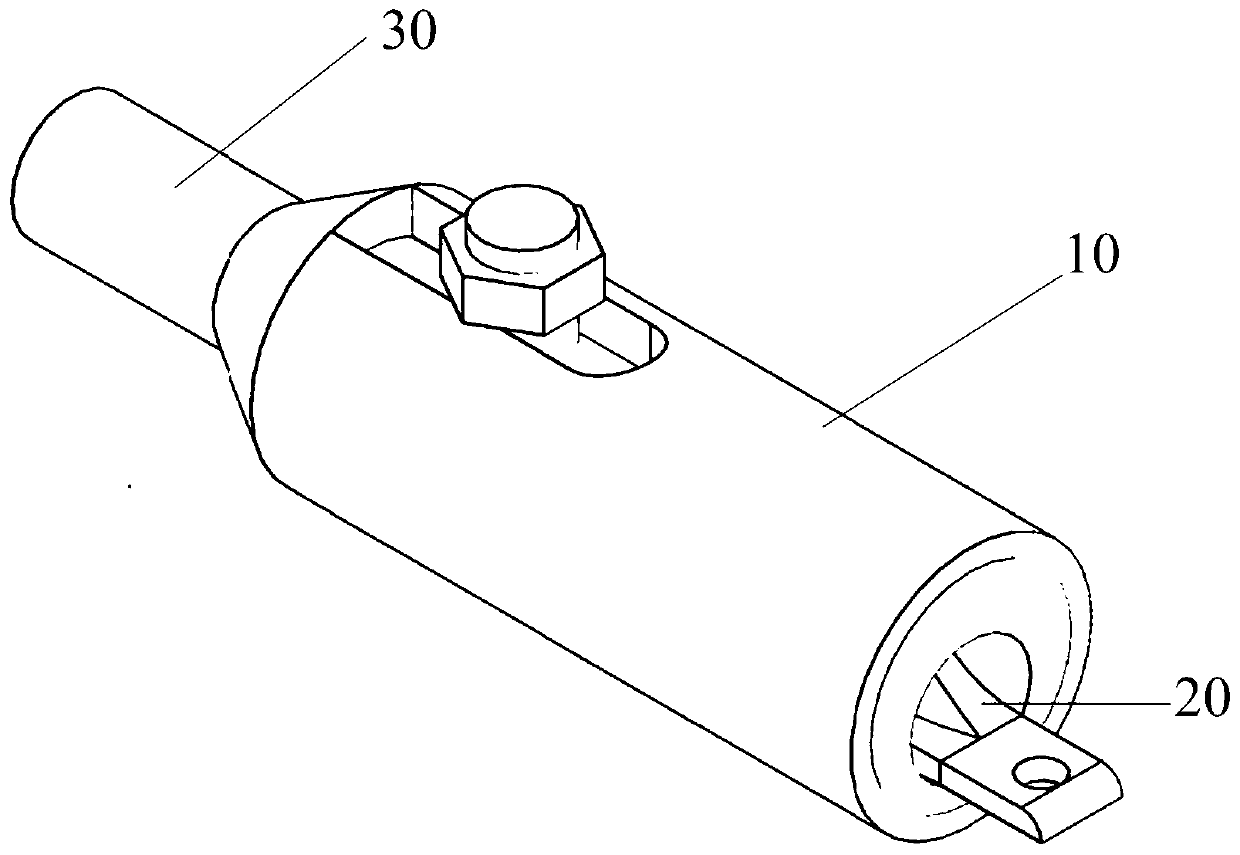

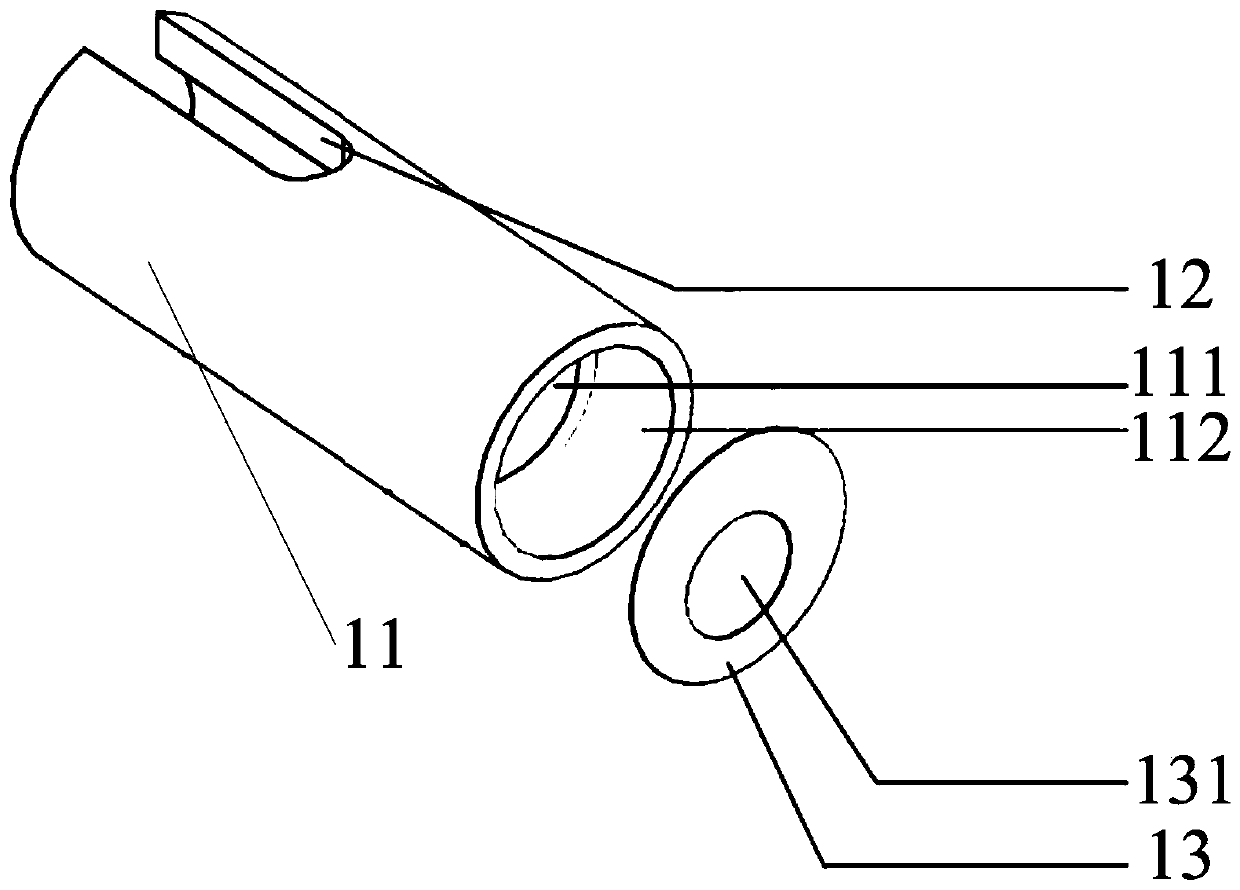

Manual accurate-indexing right-angle milling head

ActiveCN102848251ASimple structureCompact and reasonablePrecision positioning equipmentDriving apparatusGear wheelMouse Tooth

The invention relates to the technical field of right-angle heads of machine tools, and in particular relates to a manual accurate-indexing right-angle milling head. The manual accurate-indexing right-angle milling head comprises a ram, a pad, a mouse tooth disc, a spindle sleeve, a right-angle head box body, a machine tool spindle, a key block, a gear knife handle, a spiral bevel gear I, a spiral bevel gear II, a shaft, a clamping jaw and a pop rivet, wherein the ram is fixedly connected with the pad; the upper end of the mouse tooth disc is fixedly connected with the spindle sleeve, and the lower end of the mouse tooth disc is fixedly connected with the right-angle head box body; the machine tool spindle is connected with the key block; the gear knife handle is connected with the spiral bevel gear I; the spiral bevel gear I is connected with the spiral bevel gear II which is connected with the shaft; and the clamping jaw is arranged at the center of the machine tool spindle and is connected with the pop rivet. According to the manual accurate-indexing right-angle milling head, the positioning precision and the repeated positioning precision after a manual right-angle head is rotated are improved, the machining precision of the manual right-angle head is improved, the problem that the right-angle head is not concentric with the machine tool during assembly is solved, and meanwhile, the problem that a bearing of the right-angle head is easily rusted due to water is solved, therefore, the right-angle milling head is easy to use and popularize.

Owner:JIANGSU SHINRI HEAVY IND SCI & TECH

Motion vector de-interleaving method

InactiveCN1316824CConservative judgmentEliminate (Mice Teeth) PhenomenonStandards conversionComputer graphics (images)Motion vector

The method includes following steps: decoding a image content into multiple macro data pieces; from the multiple macro data pieces, calculating a motion vector, which is as a judgment value; from the said judgment value, generating multiple deinterleaved labels; implementing time stretching operation for generated deinterleaved labels. The time stretching operation includes following actions further: setting up multiple buffers of deinterleaved labels; determining whether current deinterleaved label is a field combination format (Weave); determining whether other buffers of deinterleaved labels are single field interpolation format (BOB); and setting up the deinterleaved labels as derived single field interpolation format (BOB 2); carrying out destructive operation to destroy multiple isolated deinterleaved labels, and making them possess correlativity in spatial motion. The invention prevents phenomena of mouse teeth in more degree.

Owner:ALICORP

Hirth disc pair coaxiality and indexing uniform error detection device

ActiveCN109654983BSimple structureEasy to manufactureAngles/taper measurementsMouse ToothMechanical engineering

Owner:CHINA HANGFA SOUTH IND CO LTD

Method for detecting parallelism error of end faces mouse tooth disc pair

InactiveCN109654986AIncrease production capacityLower skill requirementsMechanical measuring arrangementsMouse ToothComputer science

The invention discloses a method for detecting parallelism error of end faces of a mouse tooth disc pair, which comprises the following steps of: a mouse tooth disc pair is installed and positioned sothat end faces to be detected on the mouse tooth disc pair are upwards, and end faces opposite to the end faces to be detected are downwards to serve as a reference end faces. And a detection deviceis used for propping against the end faces to be detected of the mouse tooth disc pair and sliding relative to the end faces to be detected so as to display the change of the pressure meter value of the end faces to be detected. And the end face parallelism error of the end faces to be detected relative to the reference end faces is obtained according to the maximum value of a gauge amount and theminimum value of the gauge amount. When the detection method is adopted to detect the end face parallelism error of the upper end faces to be detected relative to the reference end faces of the mousetooth disc pair, the operation steps are simple, the execution is easy, and the skill requirement on operators is low; the error detection is convenient and fast, the detection period can be greatlyshortened, the production and manufacturing flow of the mouse tooth disc is accelerated, and the detection precision is high.

Owner:CHINA HANGFA SOUTH IND CO LTD

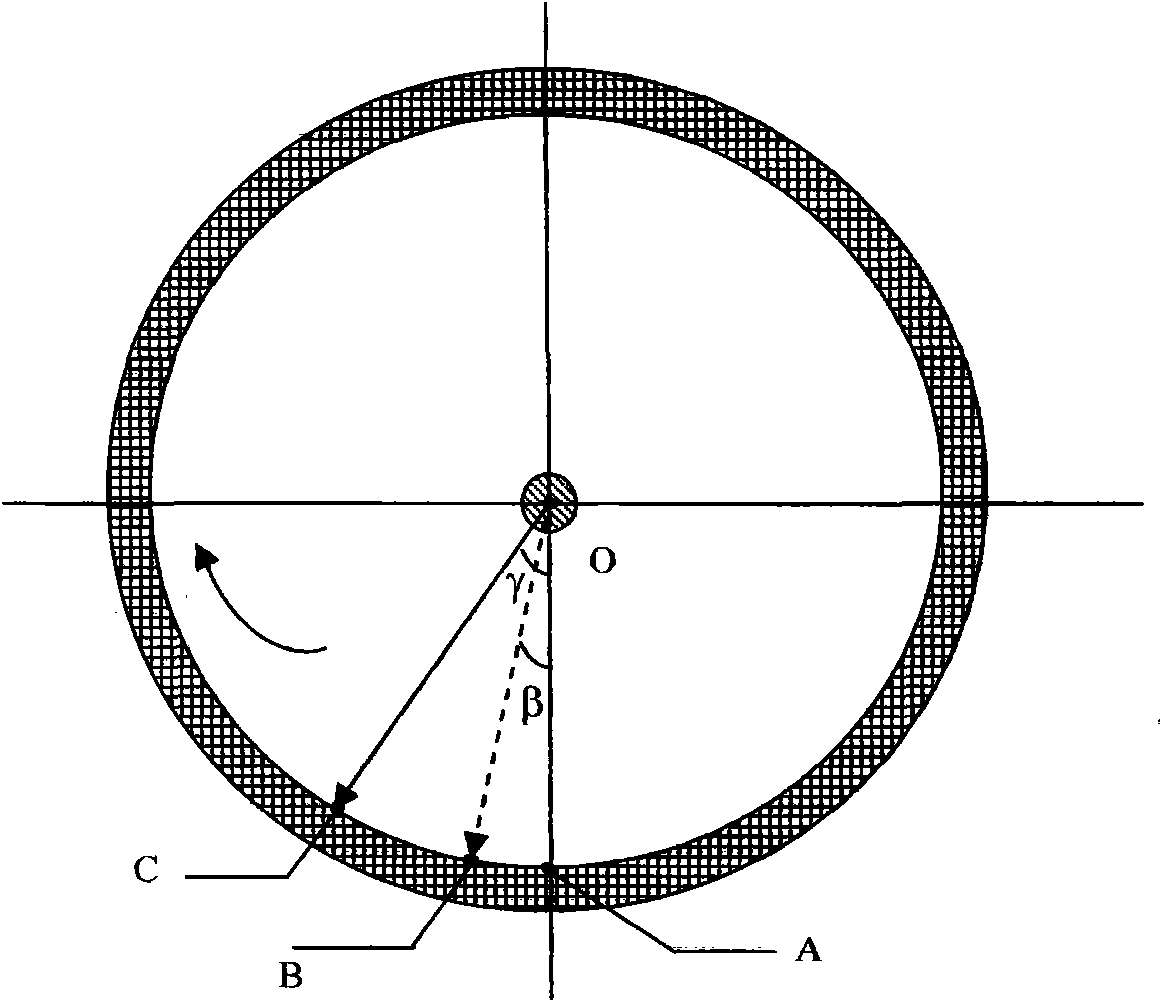

Method for detecting the coaxiality error of the hirth plate to the central axis

ActiveCN109654984BLower skill requirementsEasy to operateAngles/taper measurementsMouse ToothEngineering

The invention discloses a method for detecting the coaxiality error of central axes of mouse tooth disk pair, which comprises the following steps of: a mouse tooth disk pair is installed and a reference mouse tooth disc is fixed. A detection device is respectively propped against the reference outer circle and reference inner circle of the reference mouse tooth disc and synchronously slides alongthe reference outer circle and the reference inner circle so as to obtain a plurality of first meter values corresponding to a plurality of position points on the reference inner circle; and then a detection device is adopted to respectively prop against the reference outer circle and detection inner circle for measuring the mouse tooth disc and synchronously slide along the reference outer circleand the detection inner circle so as to obtain a plurality of second meter values which respectively correspond to a plurality of position points on the detection inner circle corresponding to the reference inner circle one by one. According to the plurality of first meter values and the plurality of second meter values, the coaxiality error of central axes of mouse tooth disc pair is obtained, when the detection method is adopted, the operation steps are simple, the error detection is convenient and fast, the detection period can be greatly shortened, and the production and manufacturing processes of the mouse tooth disc are accelerated.

Owner:CHINA HANGFA SOUTH IND CO LTD

Whole blisk high-efficiency compound milling disc milling device Hirth disc locking mechanism

InactiveCN103143762BLarge locking torqueEasy to controlMilling equipment detailsMetal working apparatusLocking mechanismMouse Tooth

The invention discloses a mouse tooth disk locking mechanism for an efficient and compound milling disk mill device of a blisk. The mouse tooth disk locking mechanism is used for solving the technical problem that an existing hydraulic locking mechanism for the efficient and compound milling disk mill device of the blisk is poor in locking force. The technical scheme is that the mouse tooth disk locking mechanism comprises a disk mill box body (1), an inner box body (5), a worm (6), a worm gear (7), an outer box body (8), a serve motor (11), a left side fluted disk (2), a push ring (3) and a right side fluted disk (4). The left side fluted disk (2) and the right side fluted disk (4) are meshed, and two end faces of the push ring (3) are respectively matched with the left side fluted disk (2) and the right side fluted disk (4). The mouse tooth locking mechanism can generate locking force through mesh between tooth faces between mouse disk teeth so as to be large in locking torque and meet high-rigidity and large-torque requirements in a disk milling process. Furthermore, the minimum scale division of three piece type end face fluted disks of the mouse tooth disk is 1 degree so as to achieve accurate control of a swing angle of the disk mill device.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Mechanism for tooth difference rigidity dividing adjustment for spinning machine

ActiveCN101576127BEliminate biasArtificial thread manufacturing machinesInterengaging clutchesMouse ToothEngineering

The invention provides a mechanism for tooth difference rigidity dividing adjustment for thread spinners, which comprises an upper-layer part, a middle-layer part and a lower-layer part, wherein the layers are linked by mouse tooth type clutches; suppose that the number of the teeth between the upper-layer part and the middle-layer part is Z, the tooth difference between the upper-layer part and the lower-layer part can be 1, 2, 3 or N(N is an integer more than or equal to 1). During the adjustment of a gear transmission device, if the upper-layer part and the middle-layer part are needed to be rotated one tooth difference clockwise or counter-clockwise, the lower-layer part and the middle-layer part are rotated one or more tooth differences in the same direction. The structure can be usedin design of coaxial mechanisms capable of transmitting a plurality of planes at the same time to ensure that the mechanisms keep precise synchronization or distribute at a certain fixed angle to eliminate machining or installation errors.

Owner:QINGDAO TEXTILE MACHINERY

Mouse tooth disc detection device

ActiveCN109654985AIncrease production capacitySpeed up the preparation processMechanical measuring arrangementsMouse ToothEngineering

The invention discloses a mouse tooth disc detection device, which comprises an installation table used for installing and positioning a mouse tooth disc pair, wherein an installation seat is supported on the installation table, and the installation seat is used for rotating around the mouse tooth disc pair in the end face parallelism error detection process. The installation seat is provided witha installation frame which can slide along the horizontal direction relative to the installation seat, the installation frame is provided with a measuring meter, and the installation frame is used for mounting a measuring meter and enabling the position of the meter head of the measuring meter to be adjustable relative to the upward end face of the mouse tooth disc. And the measuring meter is used for propping the upward end faces of the mouse tooth disc pair in the process of rotating the installation seat around the mouse tooth disc pair so as to detect the end face parallelism error of theupward end faces of the mouse tooth disc pair relative to the downward end faces of the mouse tooth disc pair. When the mouse tooth disc detection device is used for detection, the operation is simple, the requirement on skills of operators is low, the detection is convenient and rapid, the cost required by detection can be greatly reduced, the detection period can be greatly shortened, and the production and manufacturing processes of the mouse tooth disc can be accelerated.

Owner:CHINA HANGFA SOUTH IND CO LTD

Multi-tooth positioning hydraulic rotary workbench

PendingCN111823054AHigh indexing accuracyNumber of high divisionsPrecision positioning equipmentHydraulic cylinderMouse Tooth

The invention discloses a multi-tooth positioning hydraulic rotary workbench. The multi-tooth positioning hydraulic rotary workbench comprises a workbench, a base, a clamping hydraulic cylinder, an indexing hydraulic cylinder and a mouse tooth plate, wherein the positioning mode of the multi-tooth positioning hydraulic rotary workbench is a mouse tooth plate positioning, the disengagement and meshing of the precision upper and lower gear plates are used for interval indexing, and a hydraulical drive rack shaft drives an empty sleeve and a rotating position on a rotary shaft to rotate; when theworkbench is raised, a rack stroke is controlled, and the rotating position with different workstations is realized; during working, the upper and lower gear plates are in a clamping state; and the multi-tooth positioning hydraulic rotary workbench improves the production efficiency, has a long service life, and higher processing accuracy.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com