Patents

Literature

39results about How to "Large locking torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

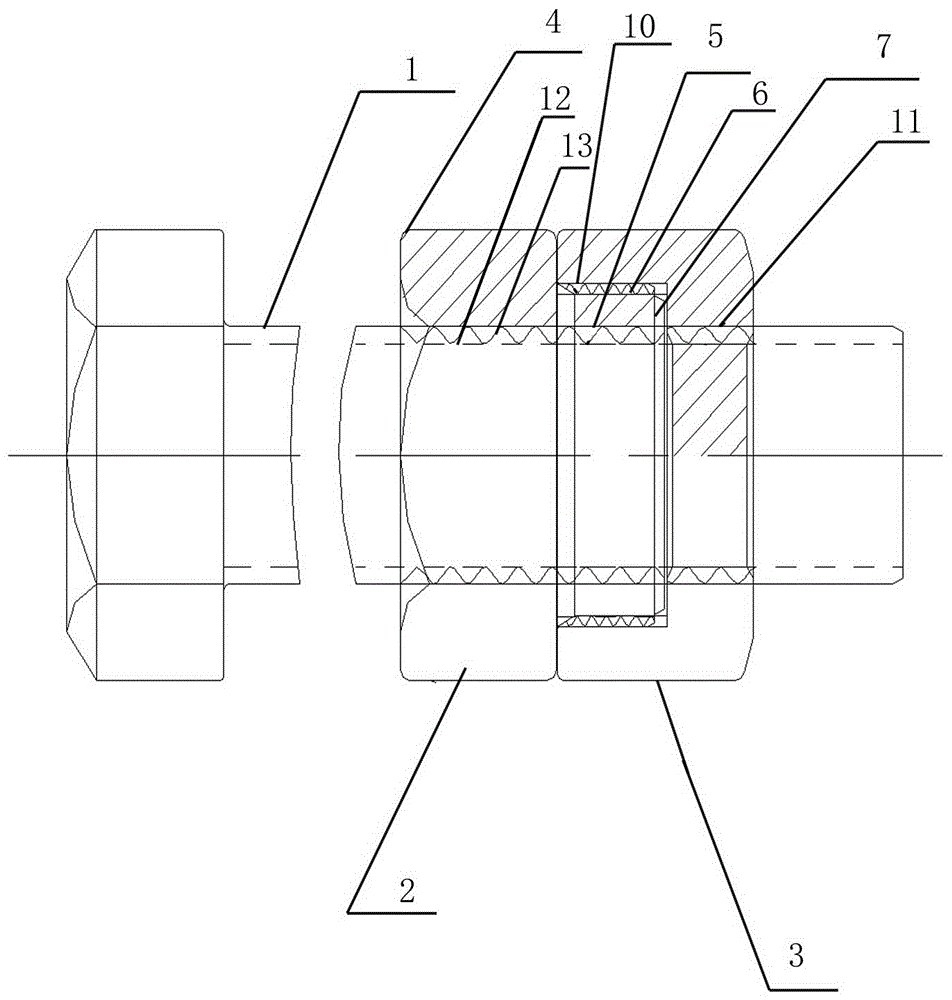

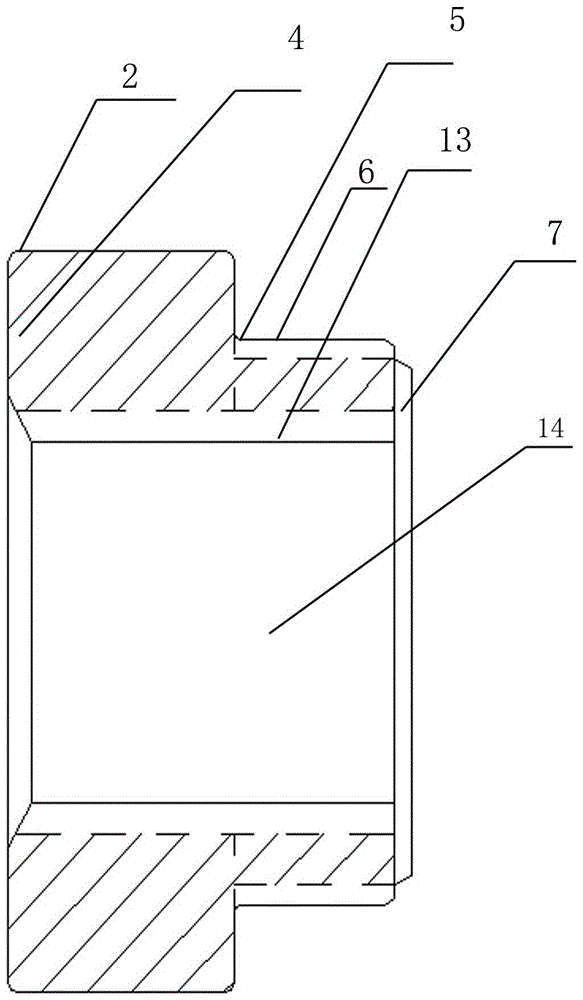

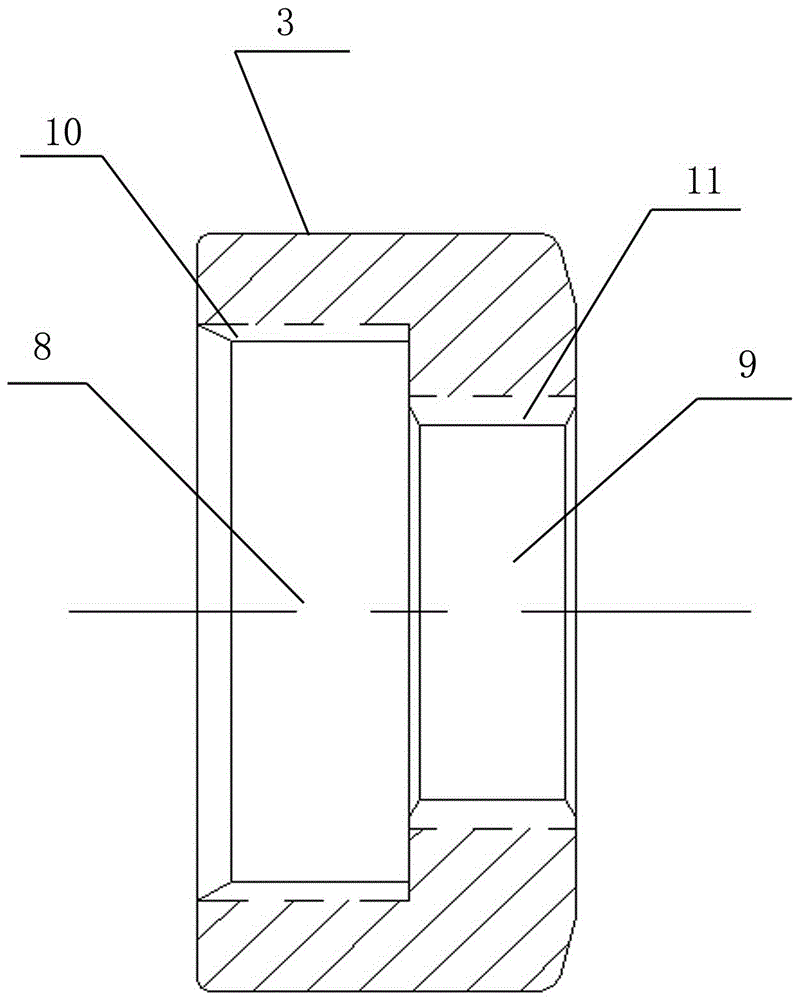

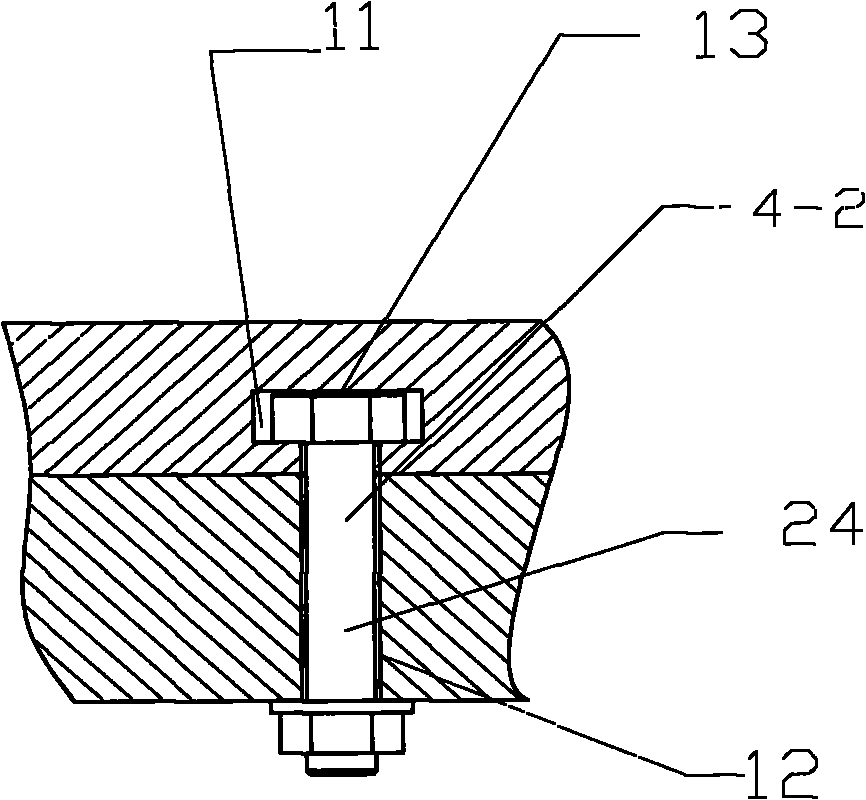

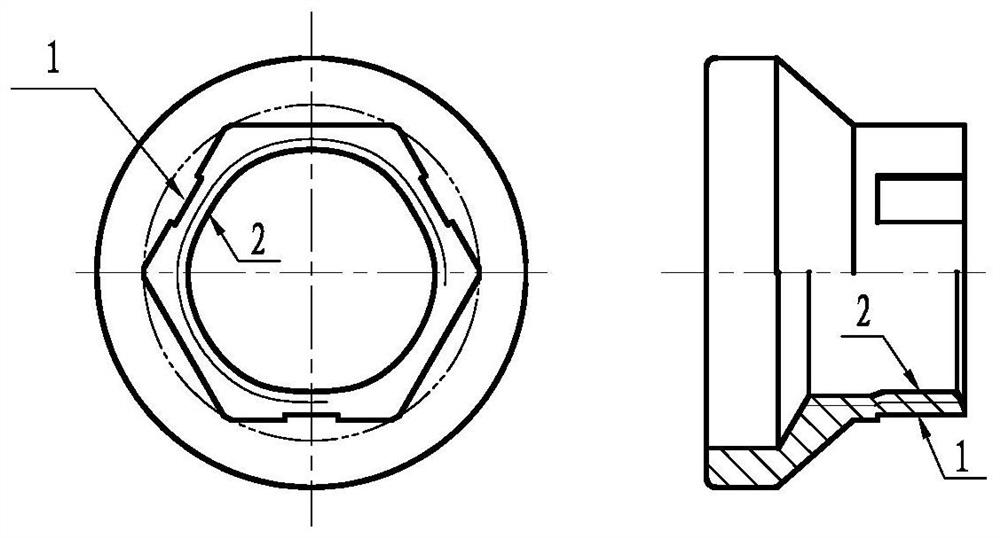

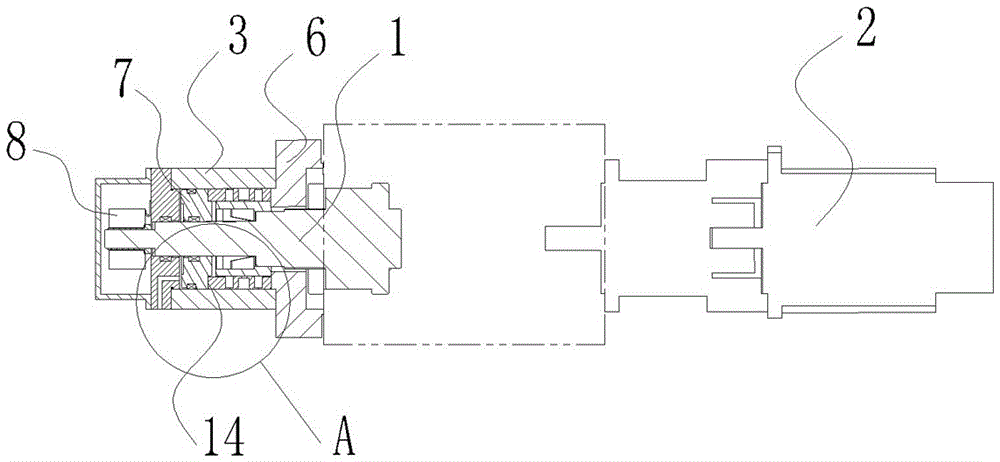

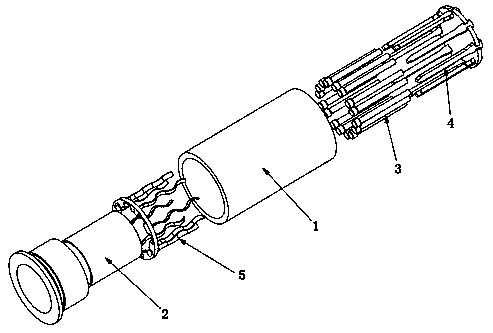

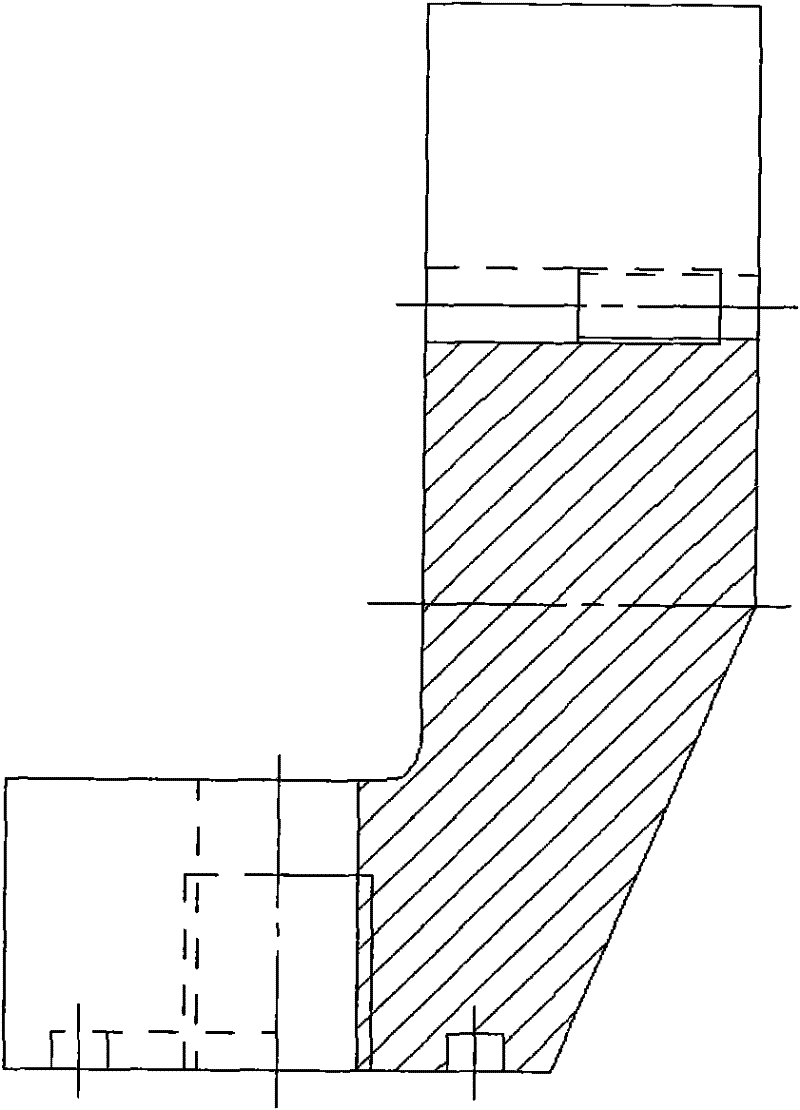

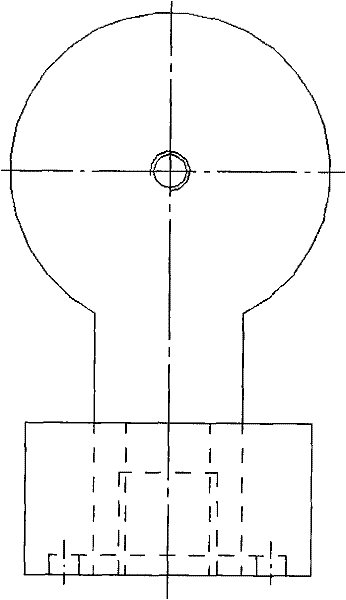

Structure of locknut and locking adjusting method for locknut

InactiveCN105937538ALarge locking torqueImprove impact resistanceNutsBoltsWorking environmentEngineering

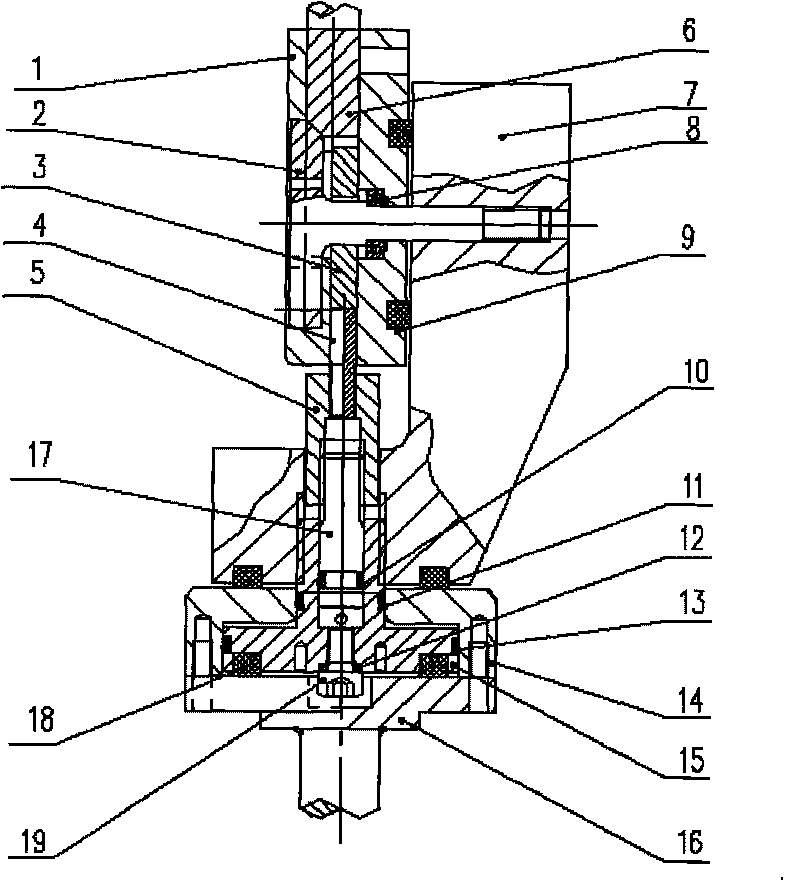

The invention discloses a structure of a locknut. A main nut (2) comprises a nut head (4), a middle screw joint section (5) and a tail adjusting section (7) from front to back. An external thread I (6) is arranged on the surface of the middle screw joint section (5). The perimeter of the nut head (4) is larger than that of the middle screw joint section (5). The diameter of the middle screw joint section (5) is larger than that of the tail adjusting section (7). The diameter of a front-section internal screw hole (8) of an auxiliary nut (3) is larger than that of a back-section internal screw hole (9) of the auxiliary nut (3). A front internal thread II (10) is arranged on the inner wall of the front-section internal screw hole (8). A back internal thread III (11) is arranged on the inner wall of the back-section internal screw hole (9). The invention further discloses a locking adjusting method between the main nut and the auxiliary nut of the locknut. By the adoption of the structure of the locknut and the locking adjusting method, a fastened workpiece is protected, it is guaranteed that looseness of all the locking links in various bad working environments such as frequent vibration and load fluctuation is avoided, and the real constant looseness-prevention effect is achieved.

Owner:李武彬

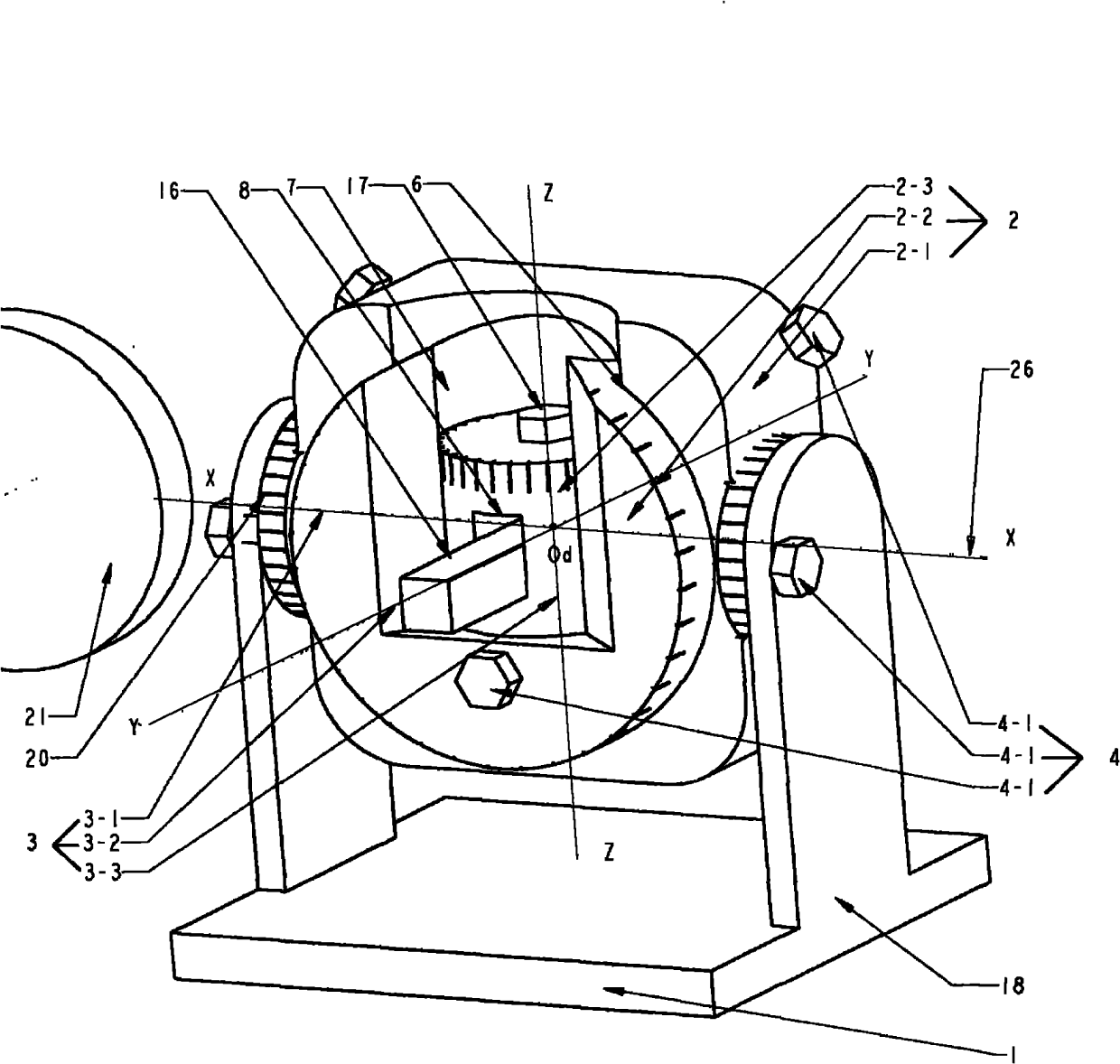

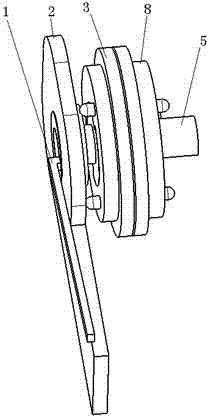

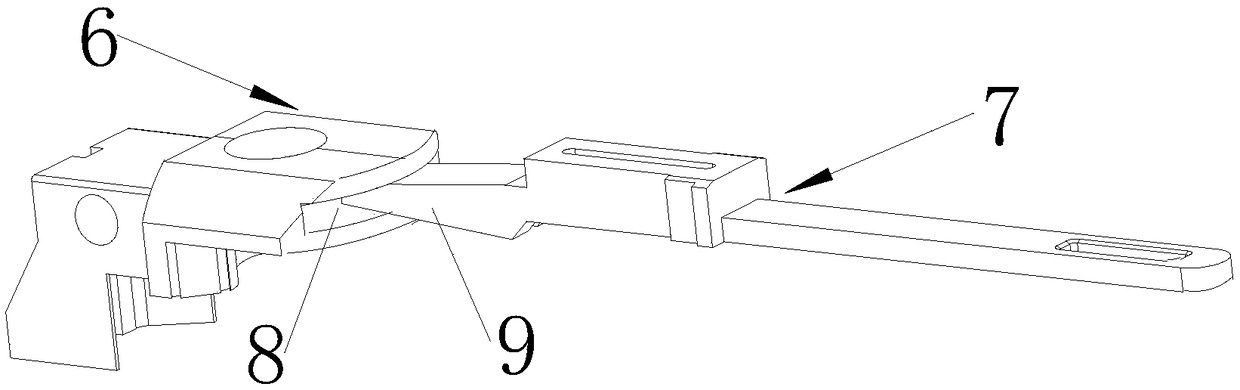

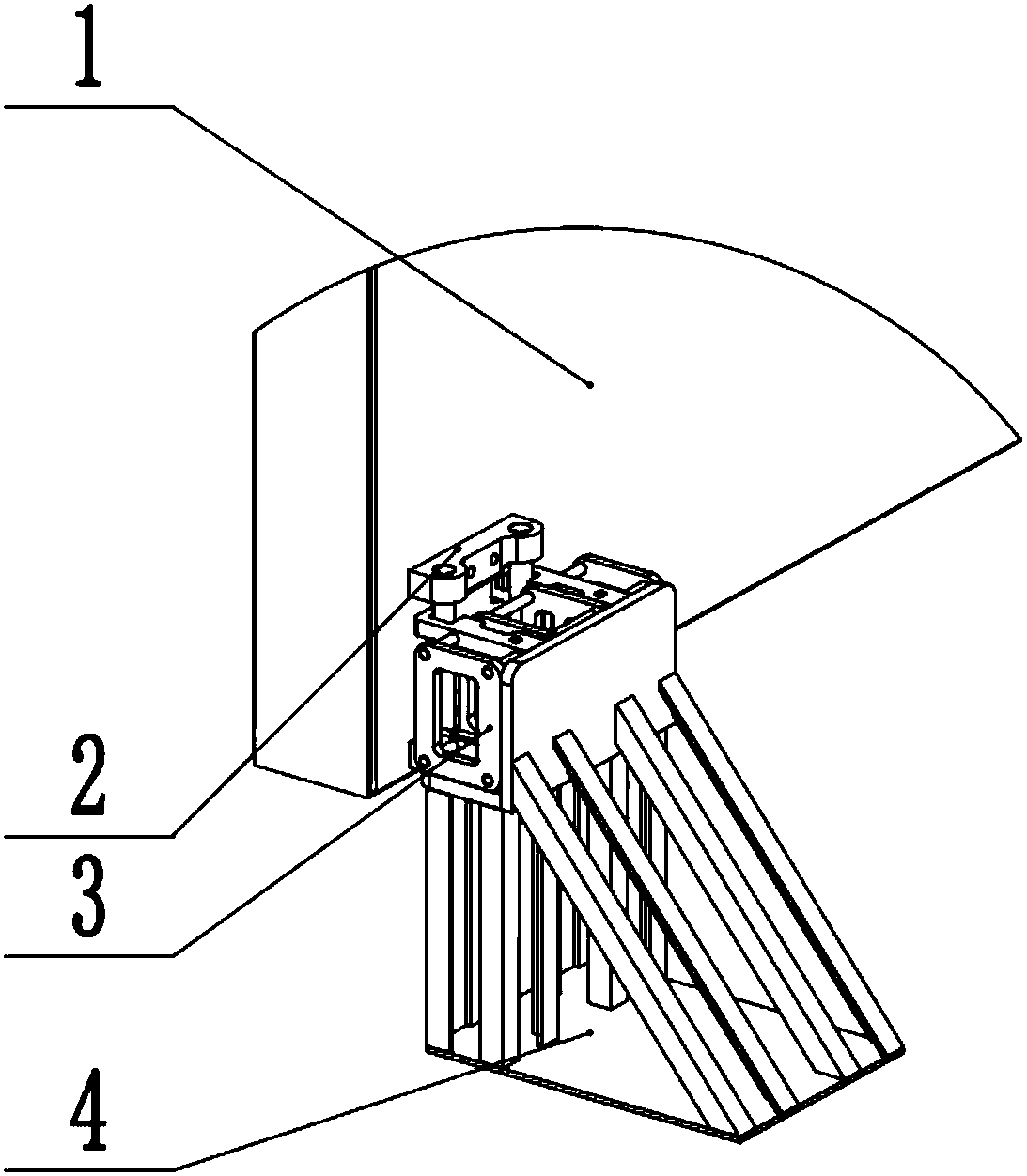

Rotary cutter sharpening seat for cutter

ActiveCN102476328AImprove structural rigidityLarge locking torquePlaning/slotting toolsTurning toolsMiniaturizationEngineering

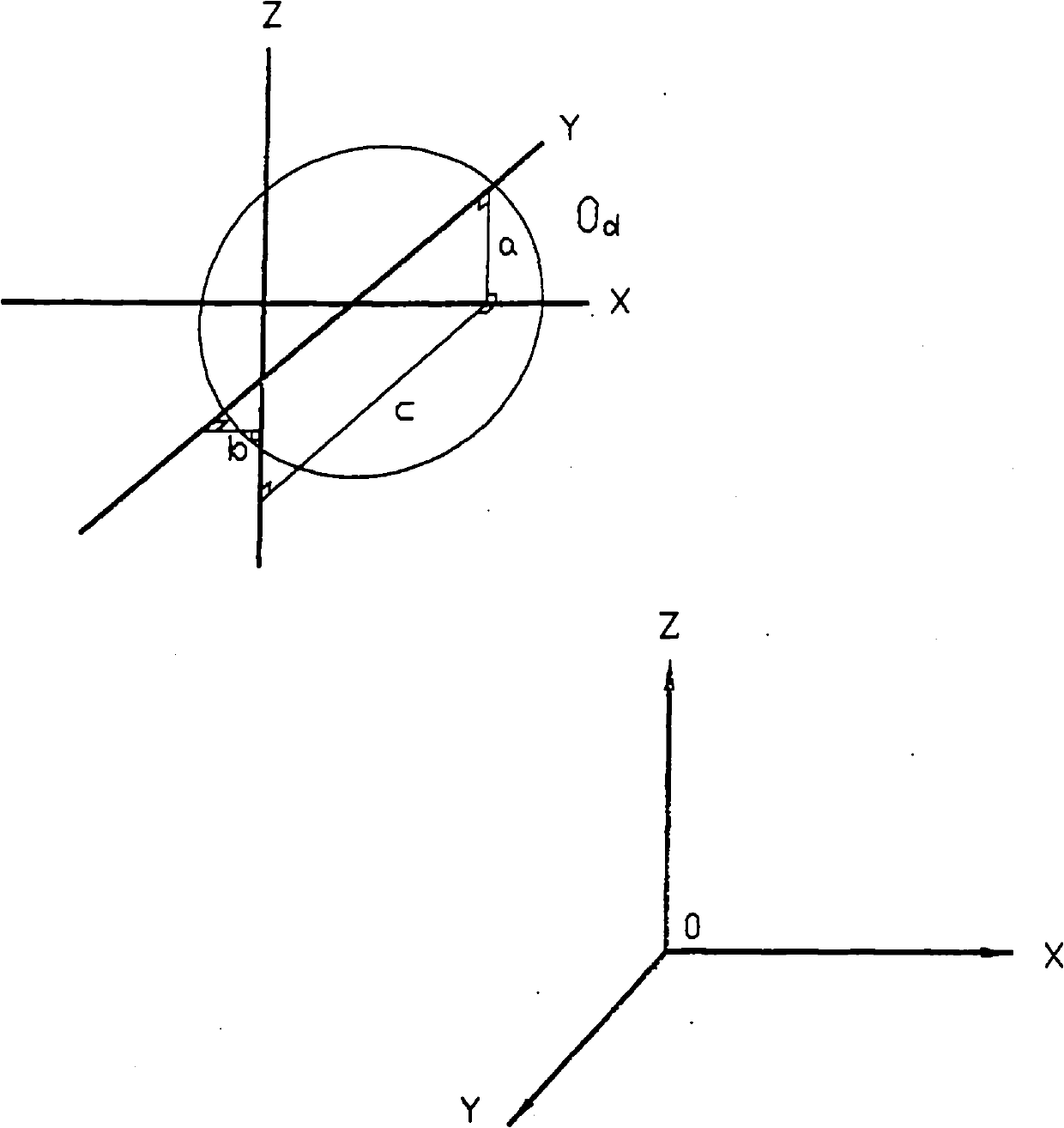

The invention discloses a rotary cutter sharpening seat for a cutter, comprising a base, rotating pieces, a rotary shaft and a locking piece, wherein the rotary shaft is divided into X, Y and Z rotary shafts; the Z rotating piece is provided with a lathe tool mounting hole, the center line of which is vertical to the Z rotary shaft of the Z rotating piece; the Y rotating piece is provided with a YZ middle-position hole, the center line of which is vertical to the Y rotary shaft of the Y rotating piece; the Z rotating piece is sleeved in the YZ middle-position hole, the center line of which is collinear with the axis of the Z rotary shaft; the X rotating piece is provided with an XY middle-position hole the center line of which is vertical to the X rotary shaft of the X rotating piece; the Y rotating piece is sleeved in the XY middle-position hole the center line of which is collinear with the axis of the Y rotary shaft; the center line of the YZ middle-position hole of the Y rotating piece is crossed on the X rotating piece; the base is also provided with an X rotating support; and the X rotating piece is sleeved on the X rotating support, the rotating shaft of which is collinear with the X rotary shaft of the X rotating piece. When the rotary cutter sharpening seat is used, after a tool grinding machine provided with the cutter sharpening seat is clamped and lathed, continuous multi-face grinding can be performed at any blade surface angles to finish integral lathing and blade sharpening once, the operation of clamping for multiple times is avoided, and angle space conversion is not needed; the big lathing offset when the angle is regulated is eliminated; the rigidity of the cutter sharpening seat is improved; machining errors due to the cutter relieving phenomenon are reduced; and the locking reliability is further improved to increase the convenience in use and realize the miniaturization of a matched tool grinding machine and higher blade grinding precision.

Owner:JIAXING EXPERT MACHINE TECHN

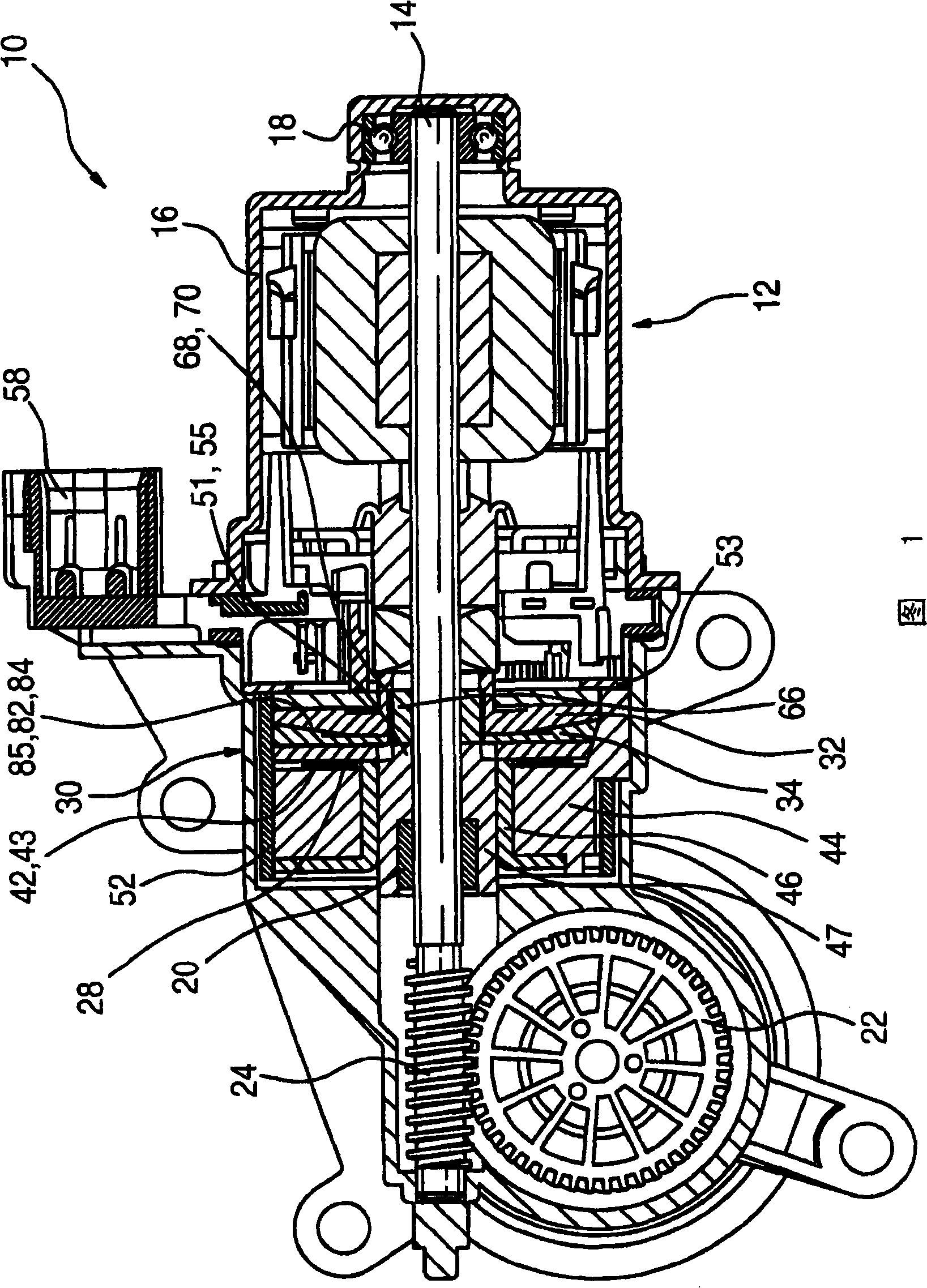

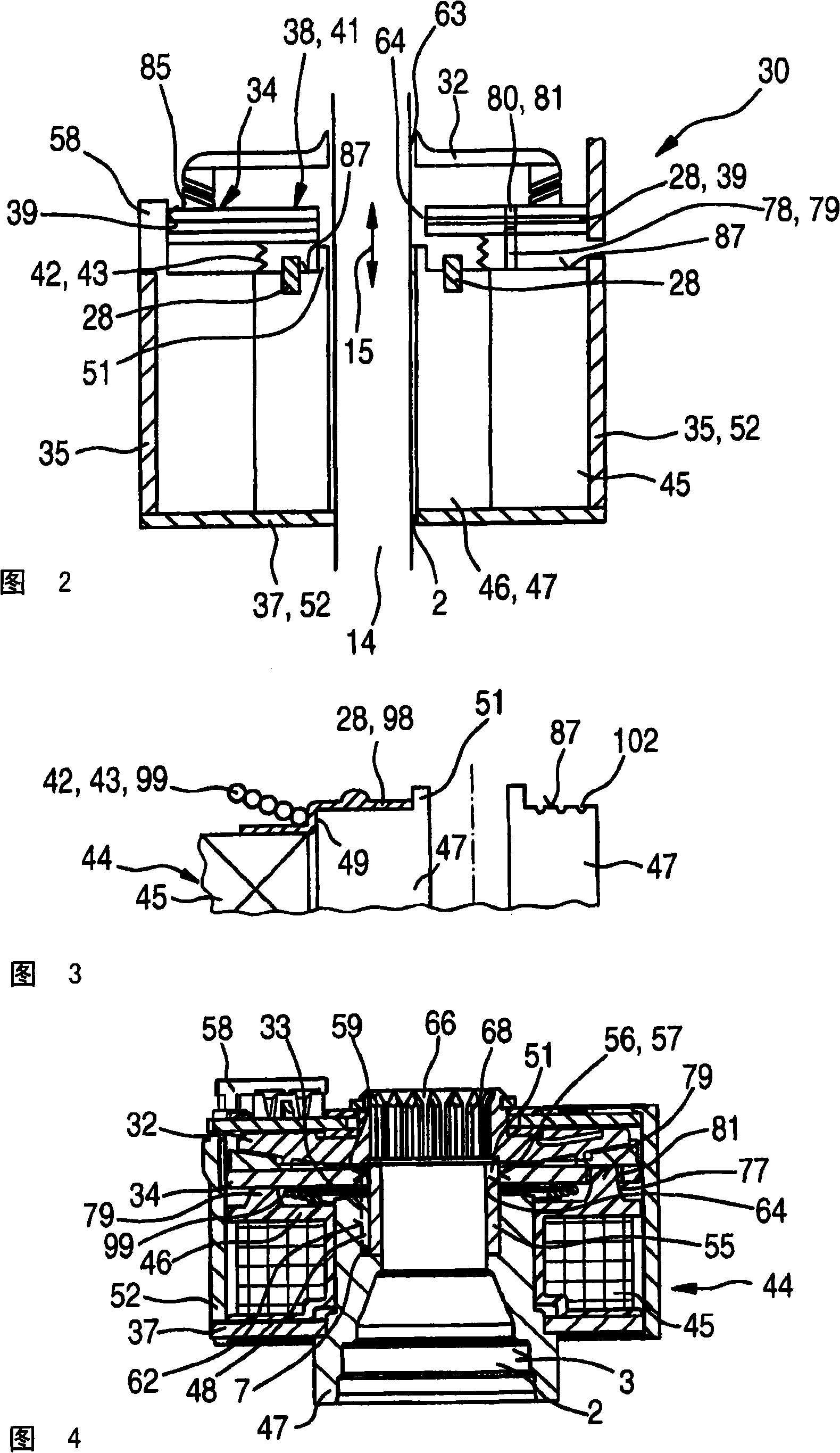

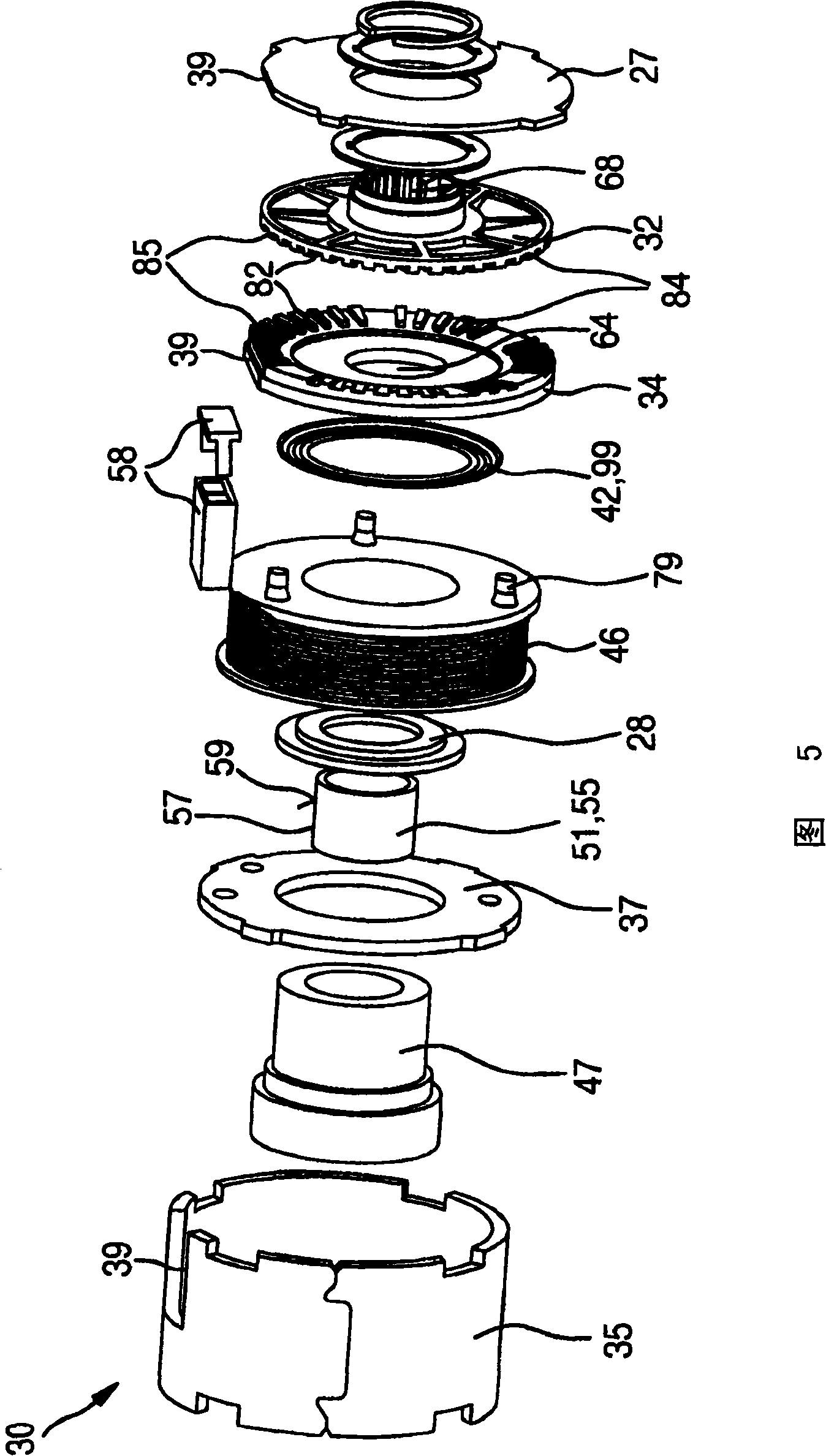

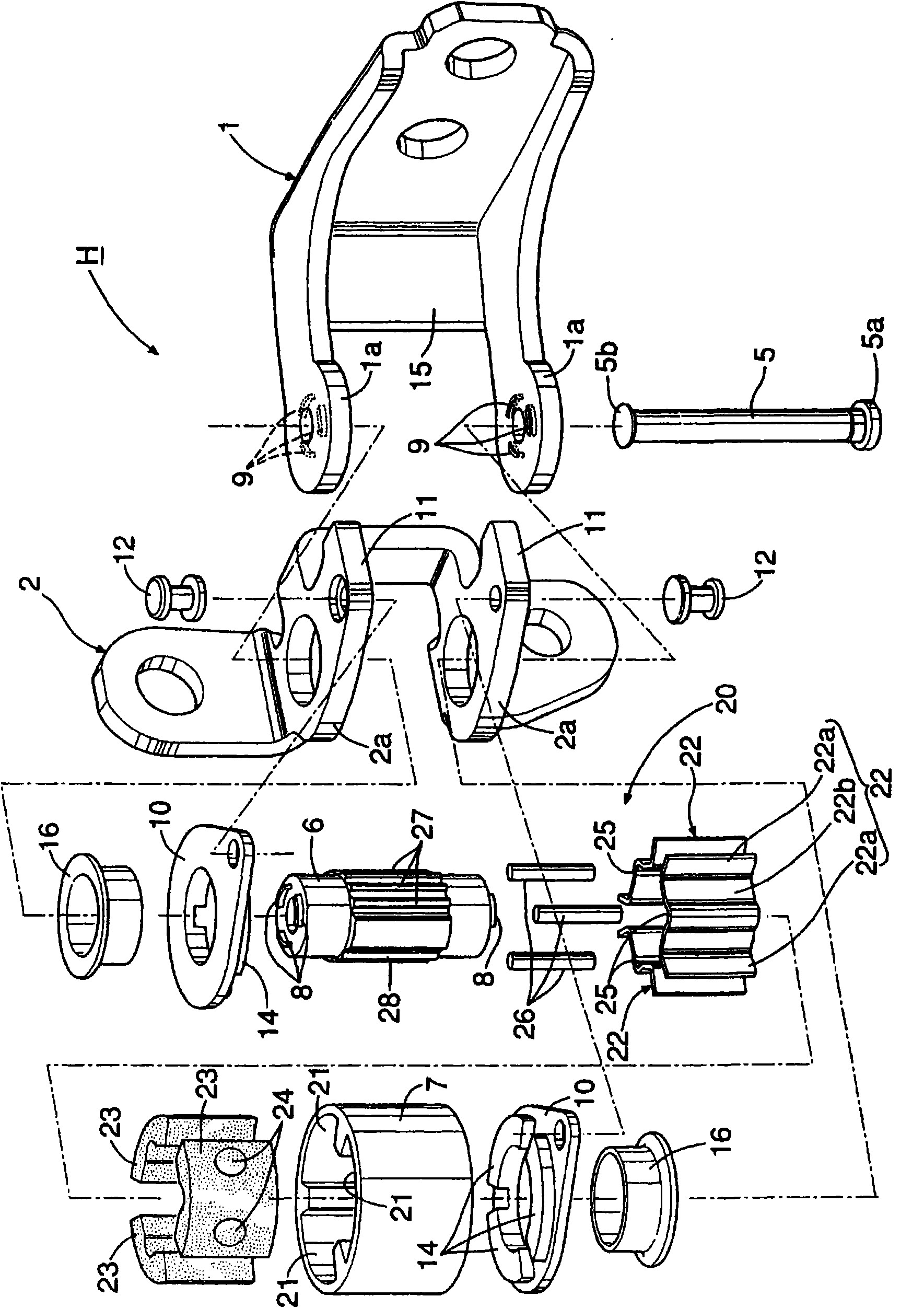

Blocking apparatus, gearbox drive unit containing a blocking apparatus such as this, as well as a method for production of a gearbox drive unit such as this

InactiveCN101317317ALower assembly costsExtended service lifeElectric machinesBrake actuating mechanismsEngineeringCentring

Blocking apparatus, as well as a gearbox drive unit containing such a blocking apparatus, as well as a method for production of a gearbox drive unit such as this for blocking any rotary movement of a shaft (14) with respect to a housing (16) of a gearbox drive unit (10), having a first blocking element (32) and having a second blocking element (34) which can be moved axially with respect to the first blocking element (32) by means of an electromagnet (44) and at least one return element (42), in order to produce a connection between the first blocking element (32) and the second blocking element (34) such that they cannot rotate with respect to one another, with the electromagnet (44) having an inner pole (47) which is surrounded by an electrical coil (45), and with the inner pole (47) having an axial projection (51) which engages in a corresponding opening (64); in the second blocking element (34), for axial guidance and centring.

Owner:ROBERT BOSCH GMBH

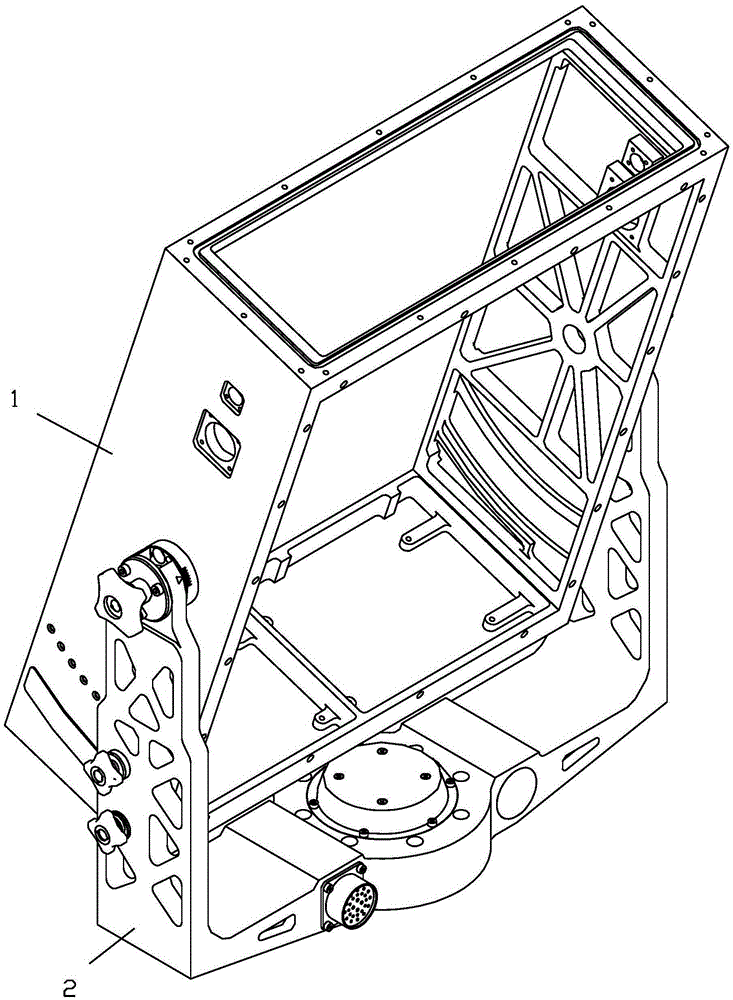

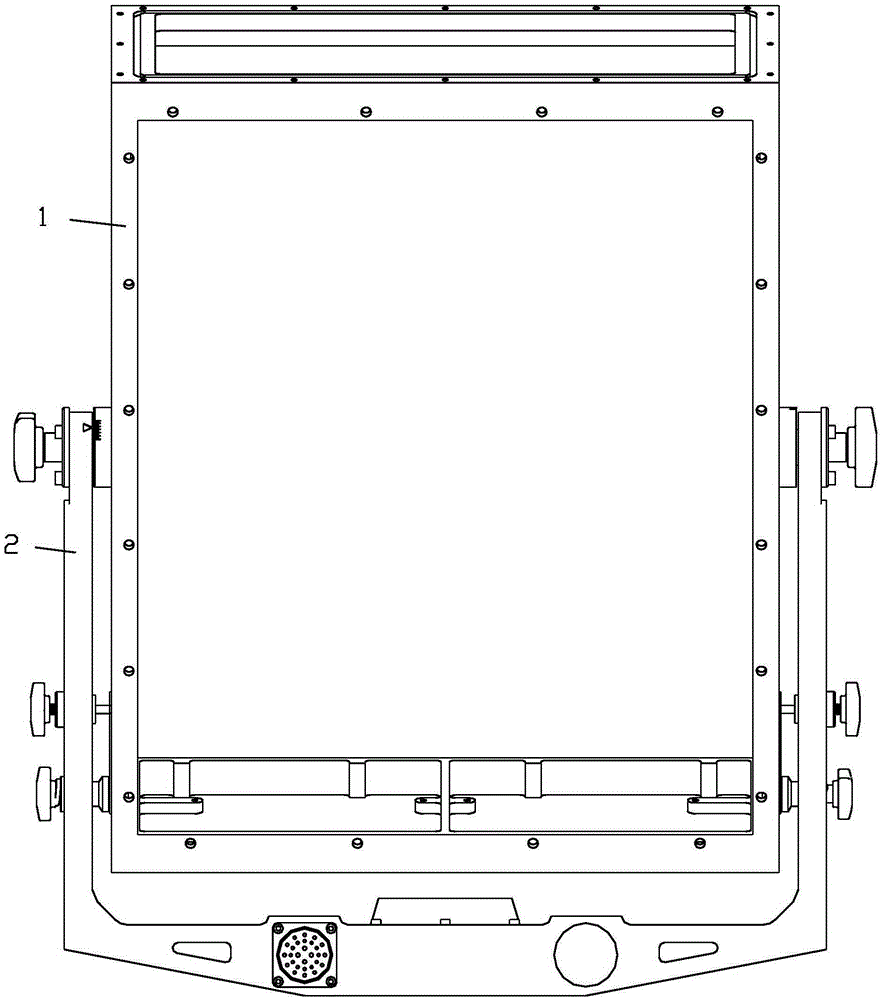

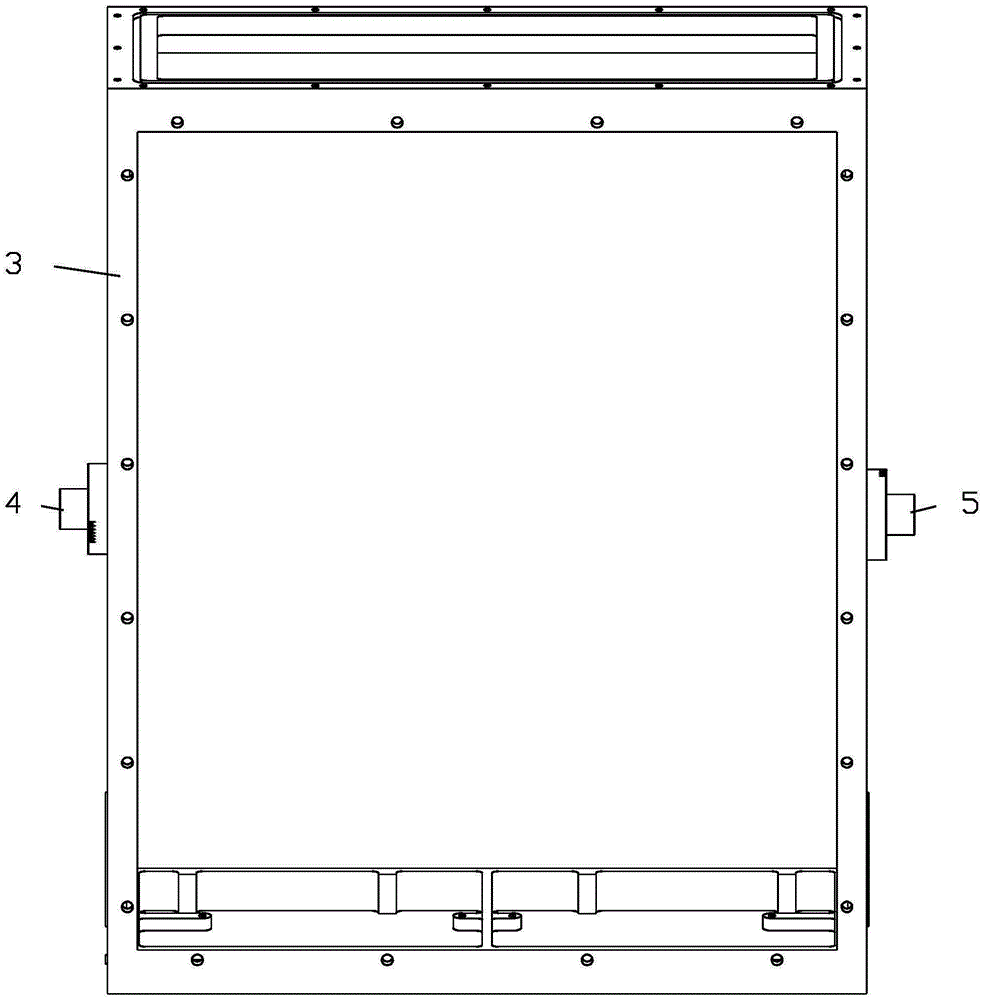

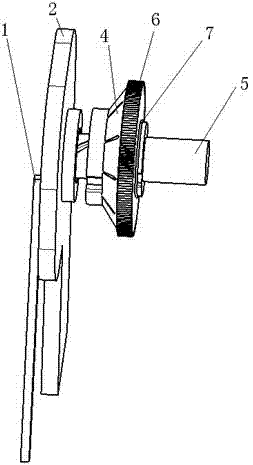

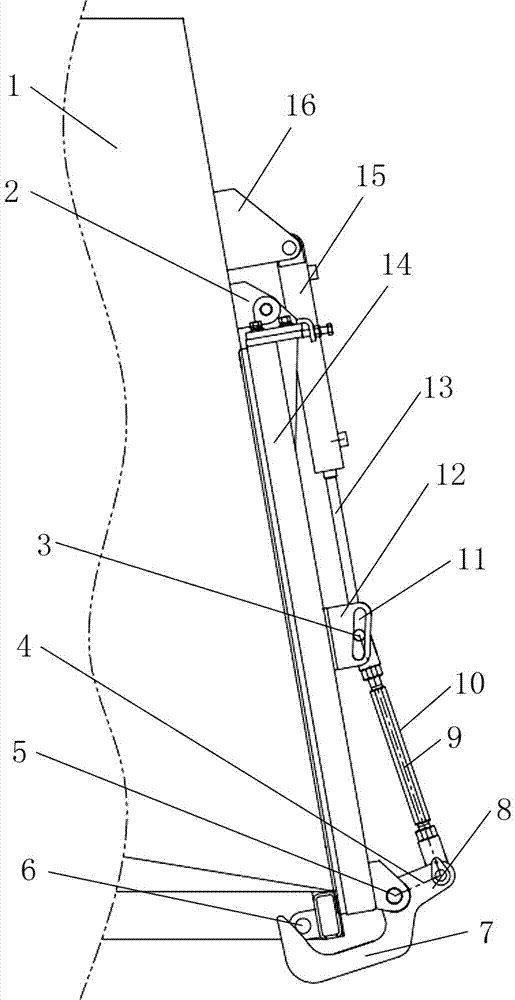

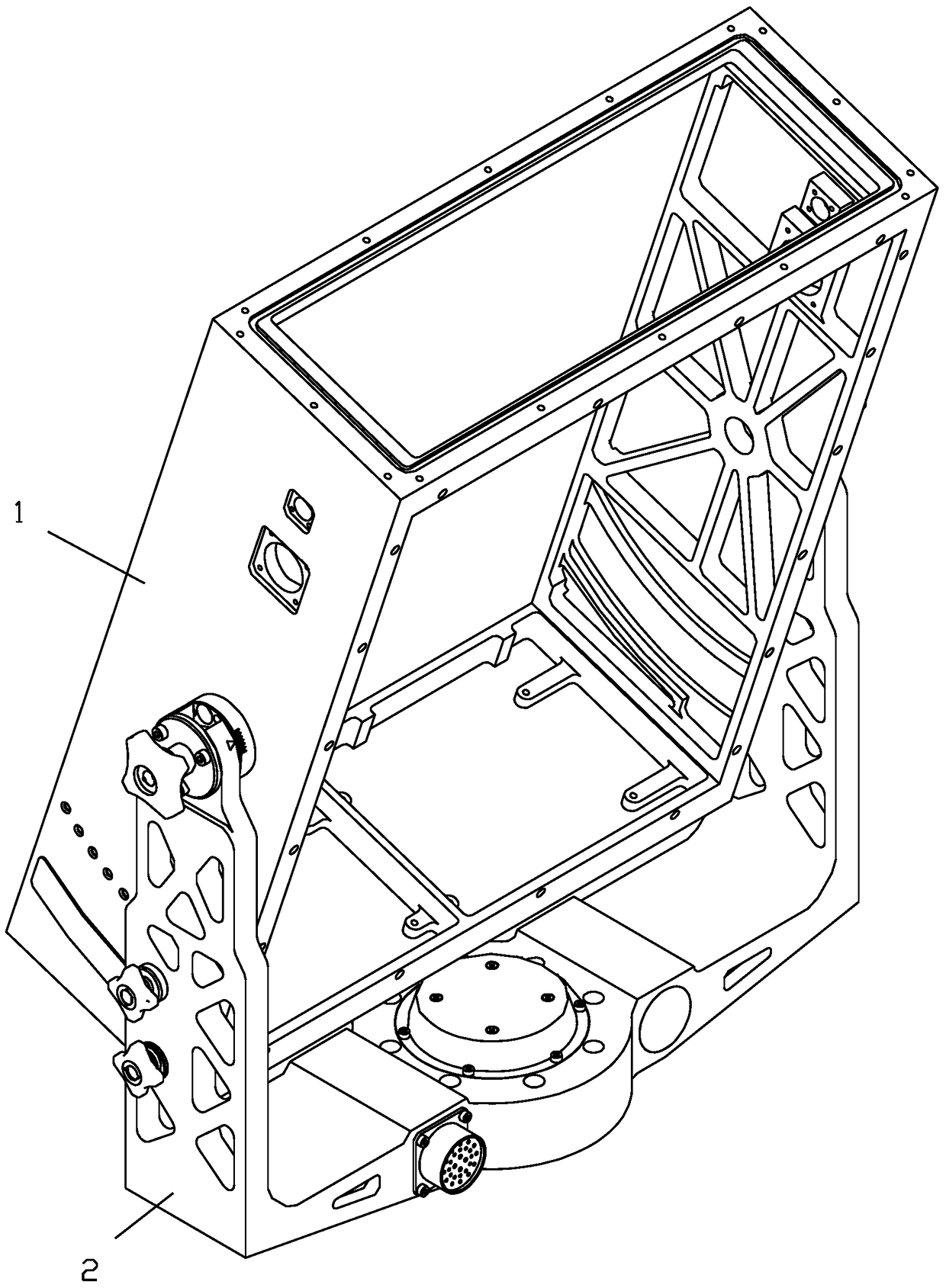

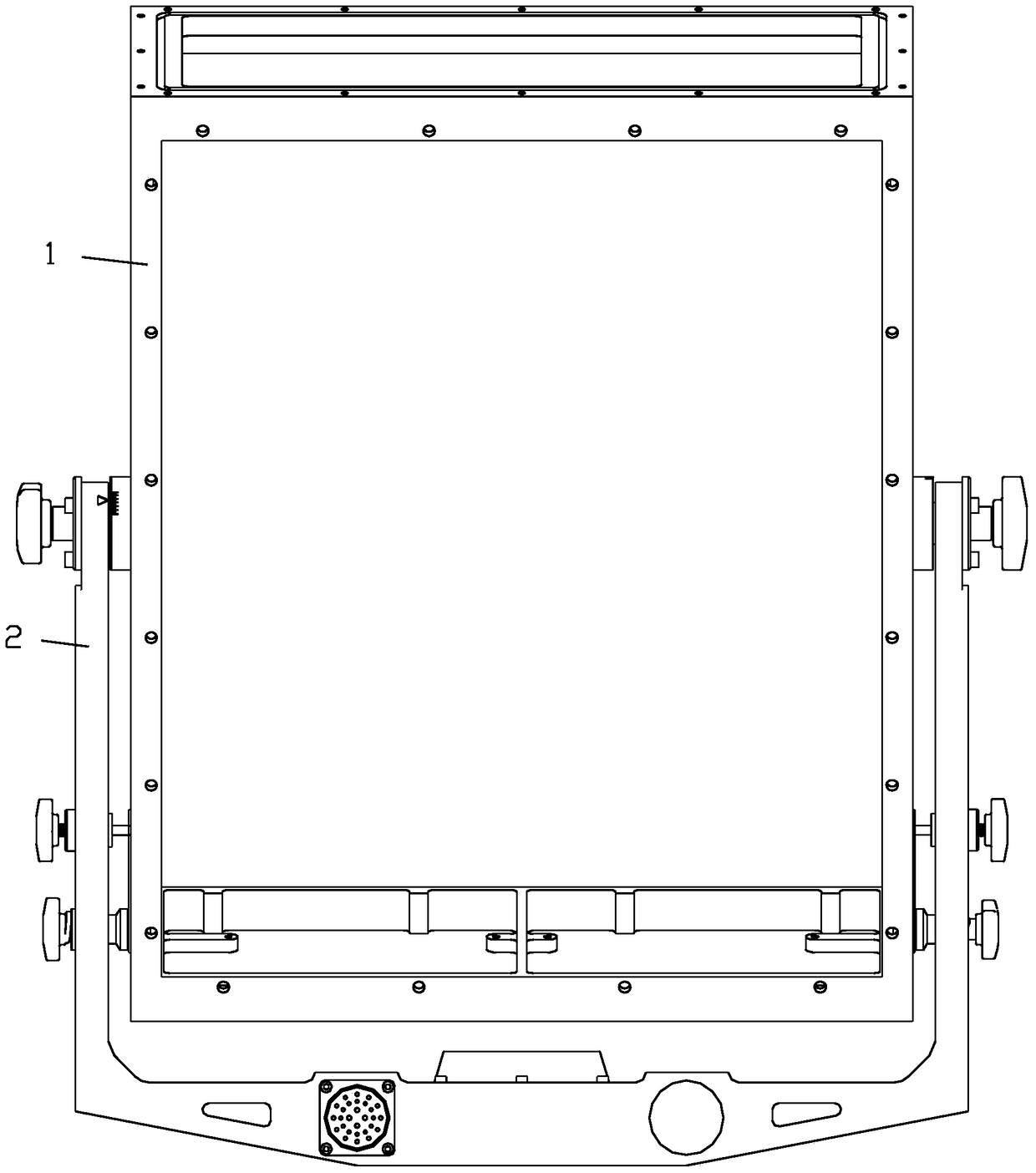

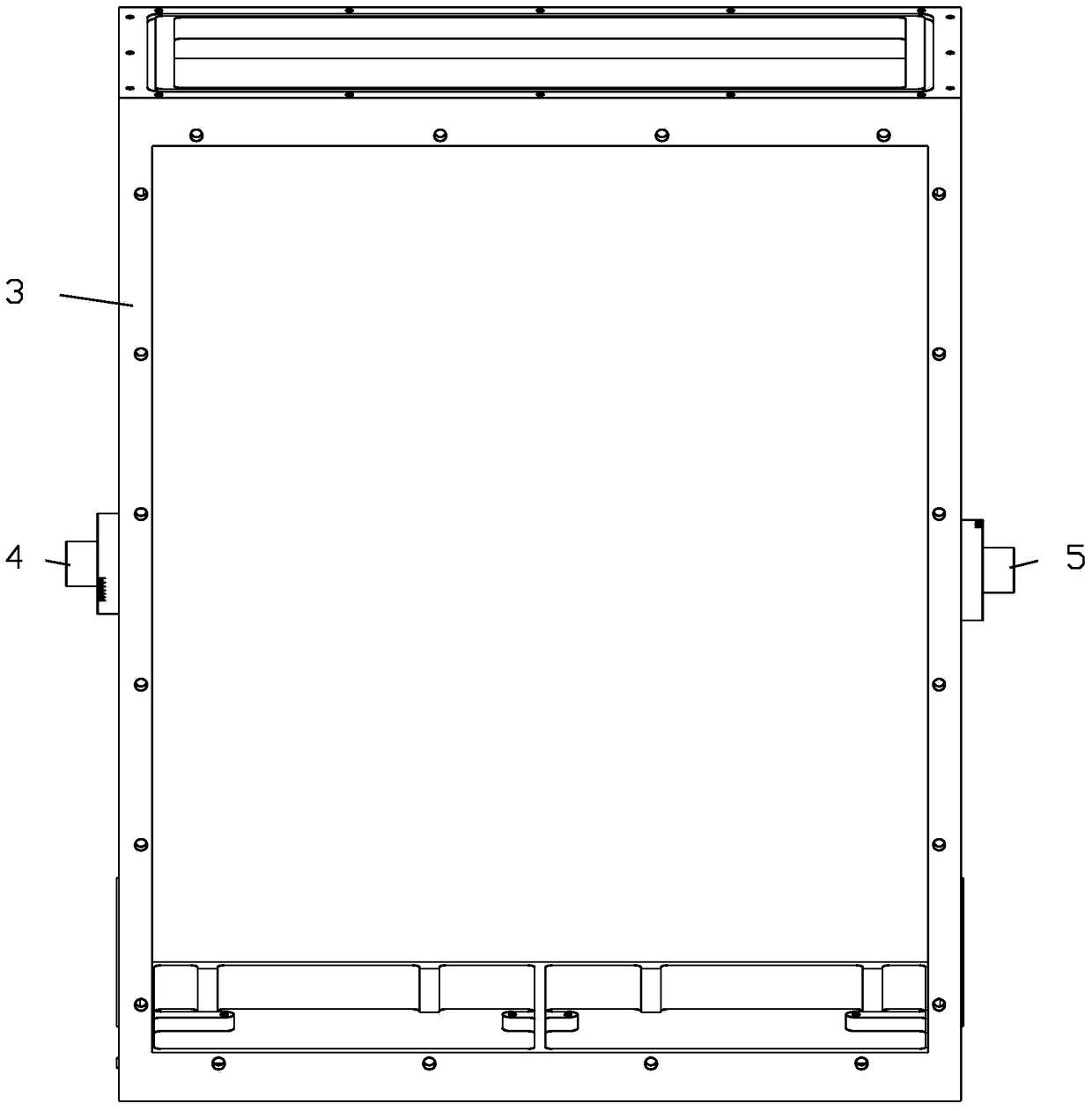

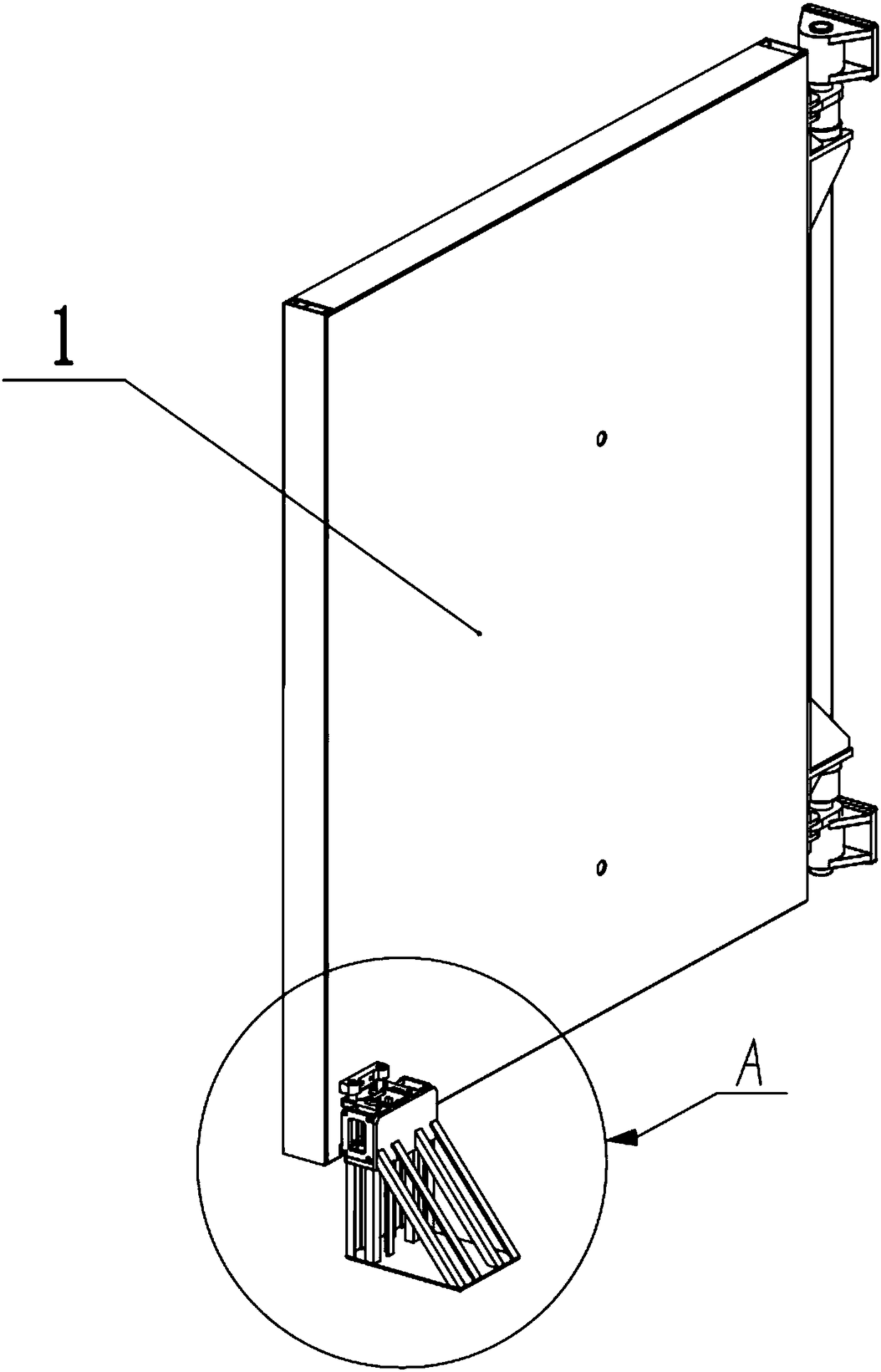

Radar antenna manual pitching mechanism

InactiveCN105428778AEasy to assemble and disassembleLight structureAntenna supports/mountingsRadarEngineering

The invention relates to a radar antenna manual pitching mechanism. The radar antenna manual pitching mechanism comprises a flat plate radar case assembly and a pitching bracket assembly; the flat plate radar case assembly comprises a box body, a left pitching shaft and a right pitching shaft; the left pitching shaft and the right pitching shaft have the same structure, and are fixed on the middle parts of the left wall and the right wall of the box body respectively; a left locking threaded hole and a left jacking projection block are arranged on the left side wall and the right side wall of the box body respectively; the pitching bracket assembly comprises a left supporting arm and a right supporting arm; a U-shaped groove that is in clearance fit with the left pitching shaft is formed in the uppermost end of the left supporting arm; a left pitching shaft locking screw is fixed on the left supporting arm on the outer side of the U-shaped groove; the left pitching shaft locking screw and the left pitching shaft are detachably hinged and matched; a left middle locking screw and a left compressing head that are matched with the left locking threaded hole and the left jacking projection block are in screw thread fit with the left supporting arm; and the right supporting arm and the left supporting arm have the same structure. The radar antenna manual pitching mechanism is light and handy in structure, high in locking torque, convenient to adjust and high in load capacity, and the radar antenna is convenient to disassemble and assemble.

Owner:HEBEI HANGUANG HEAVY IND

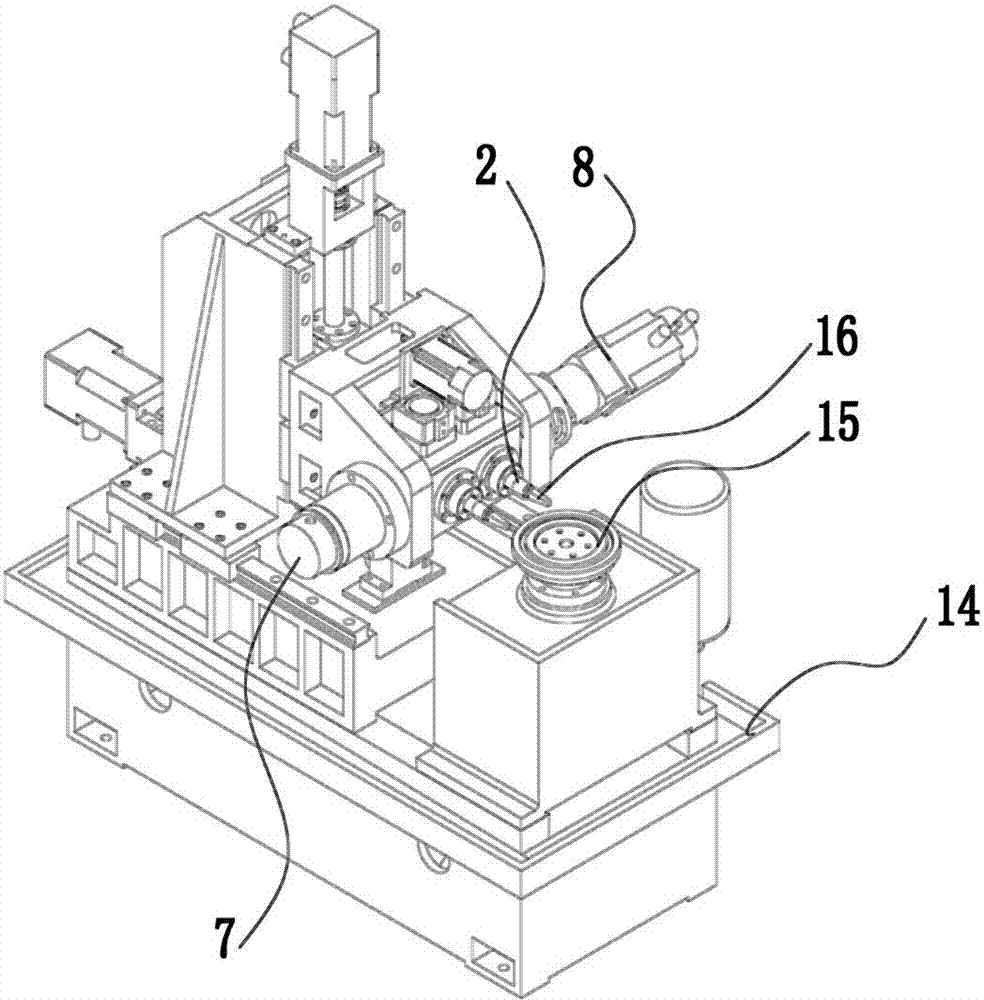

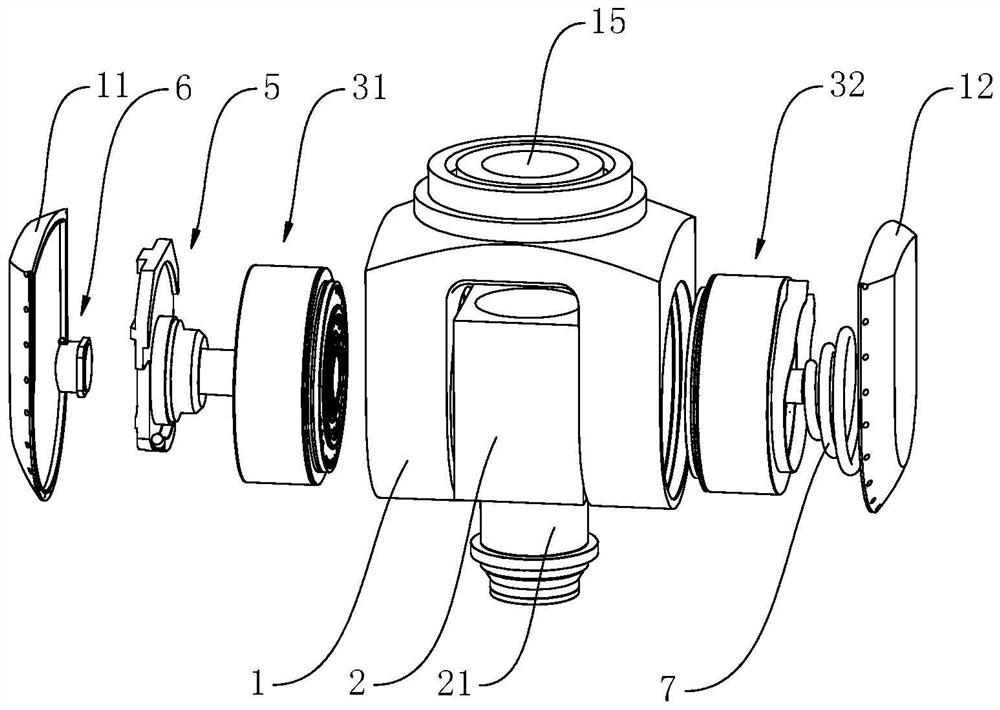

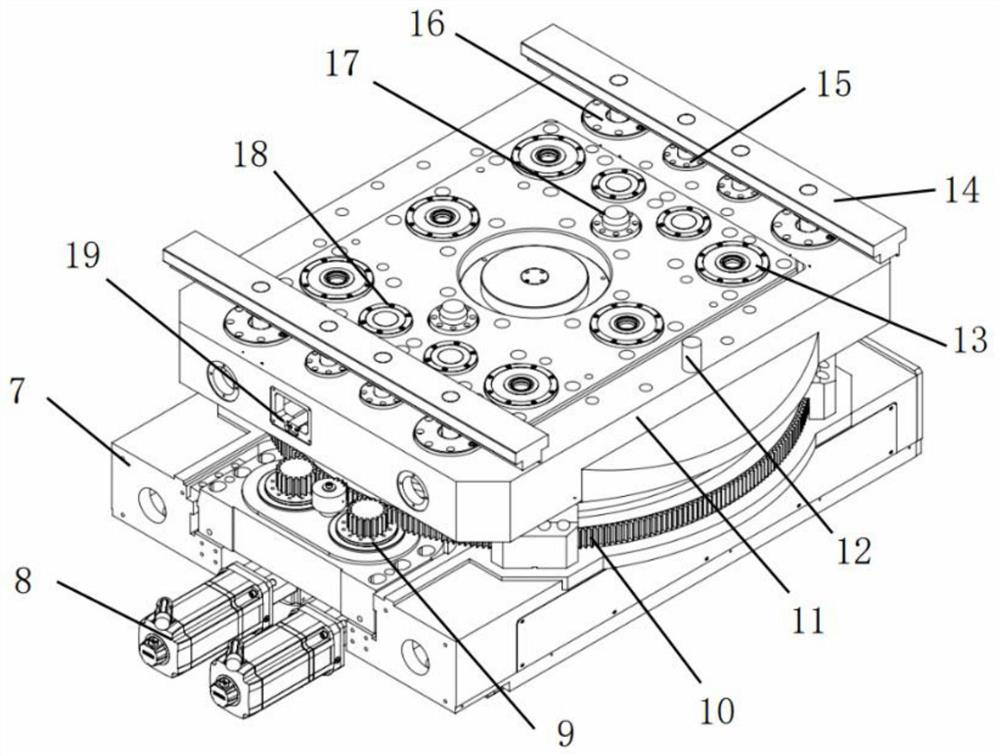

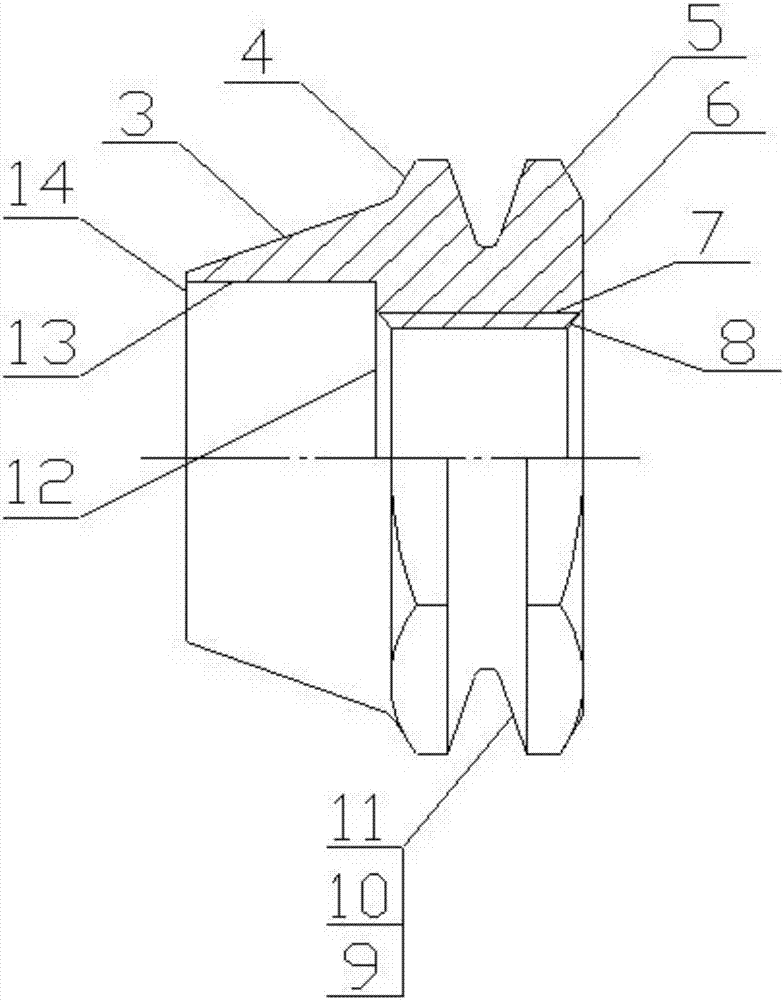

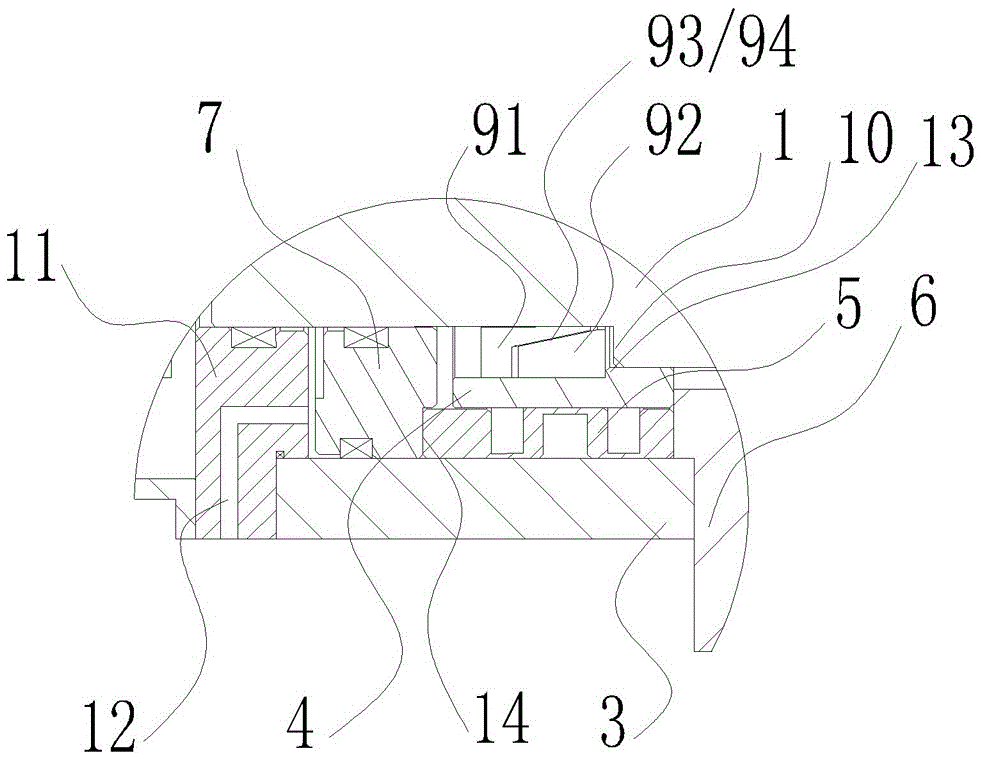

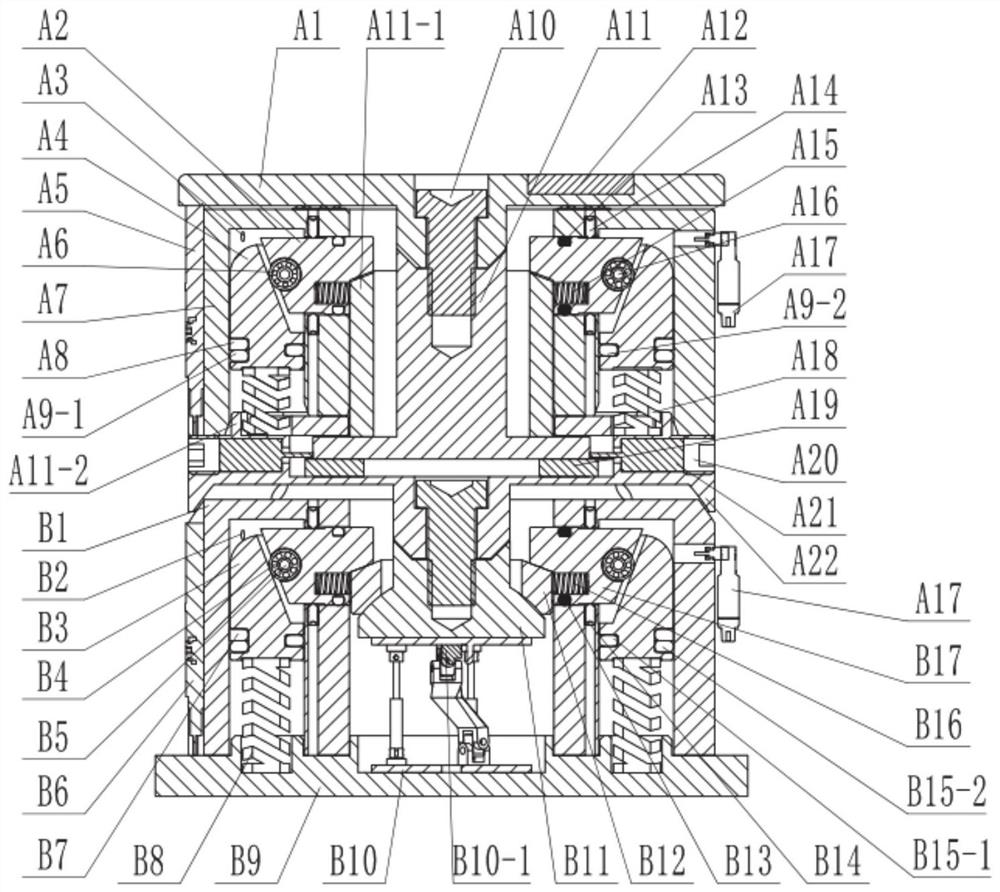

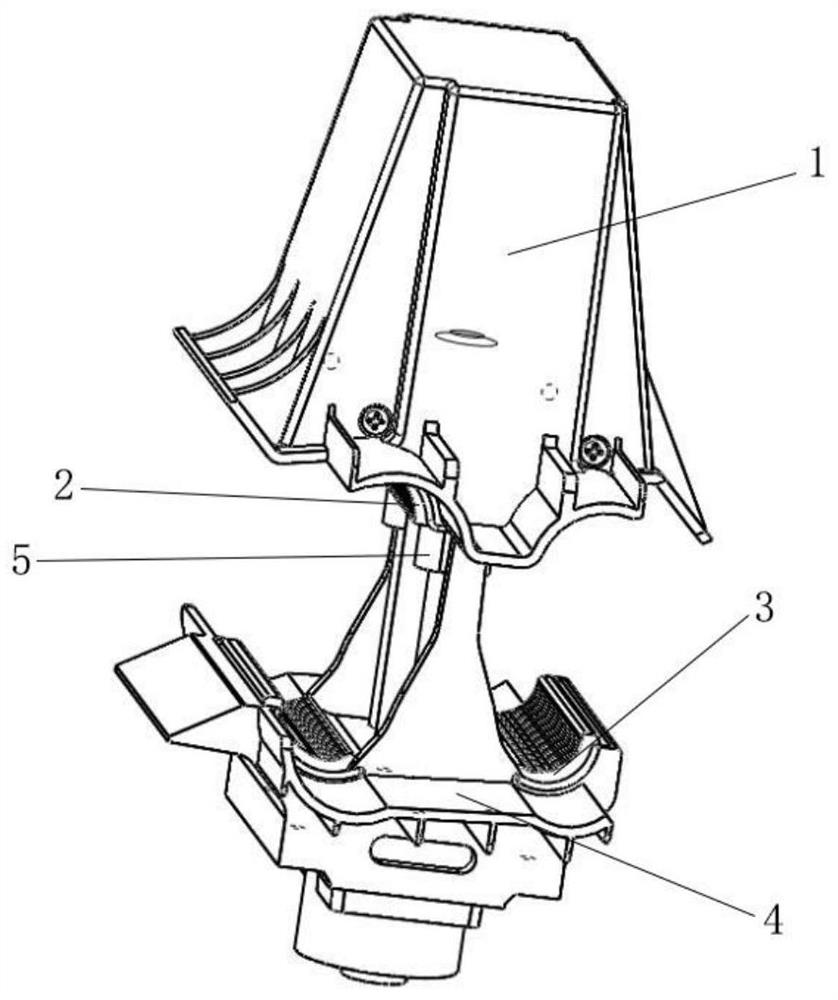

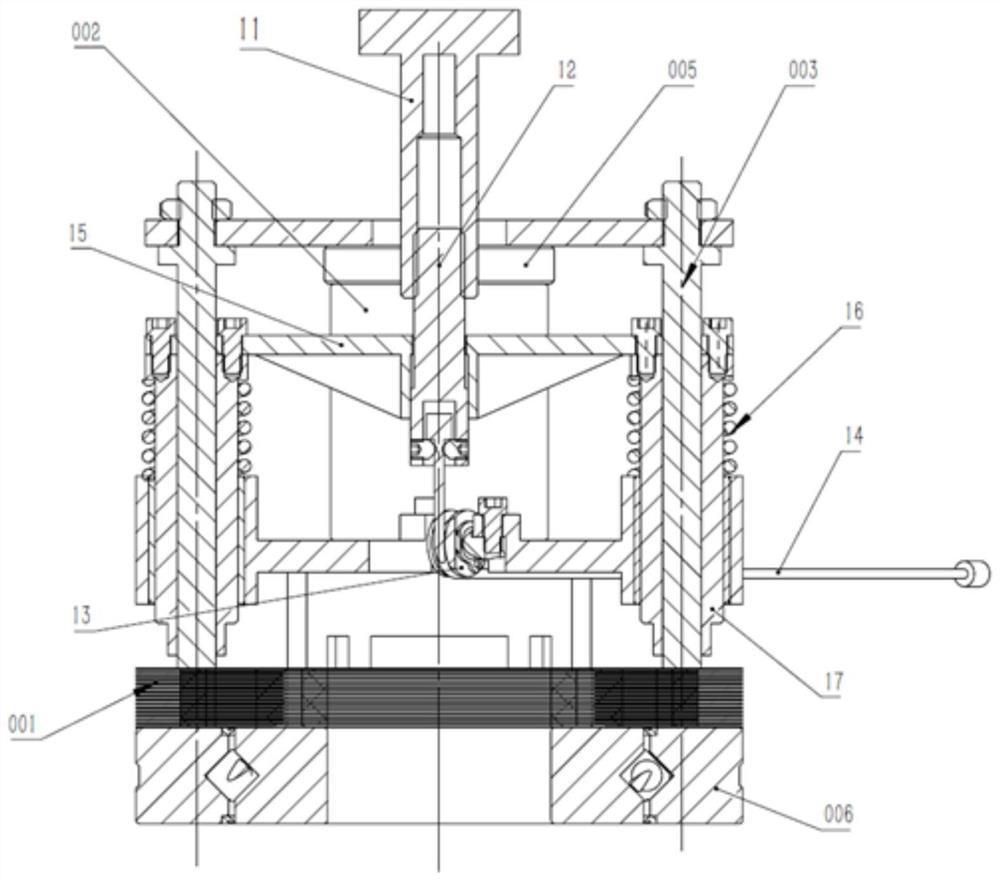

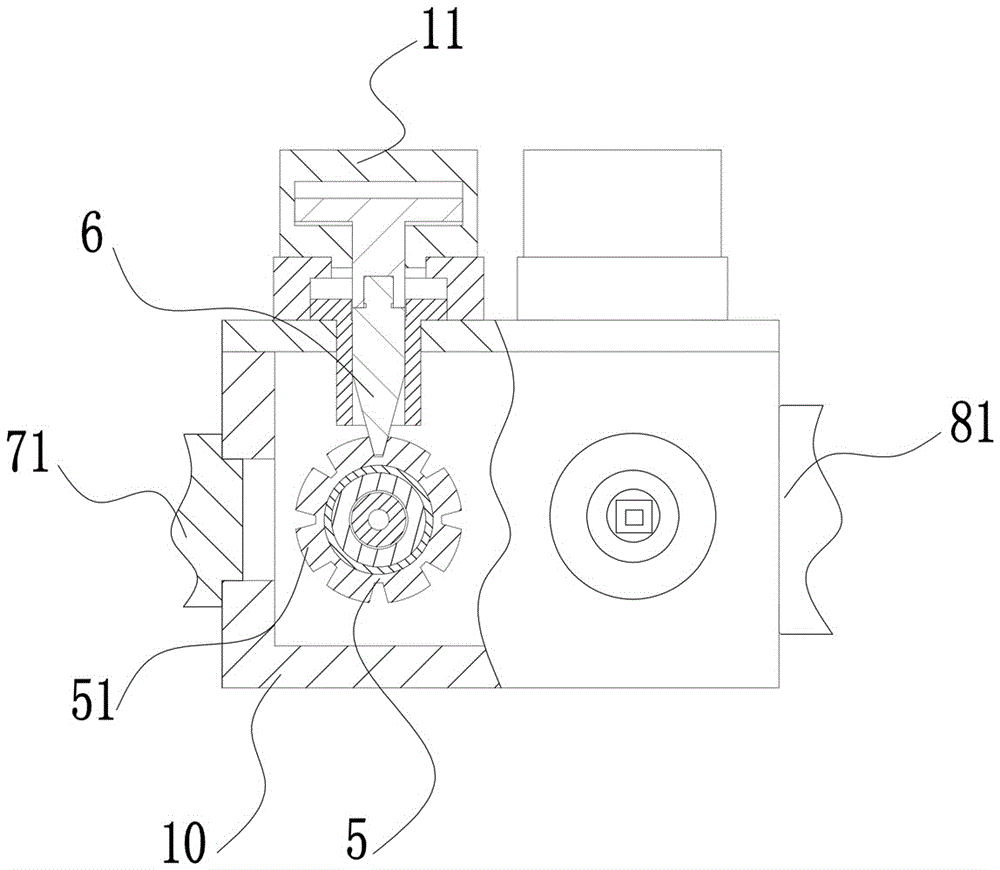

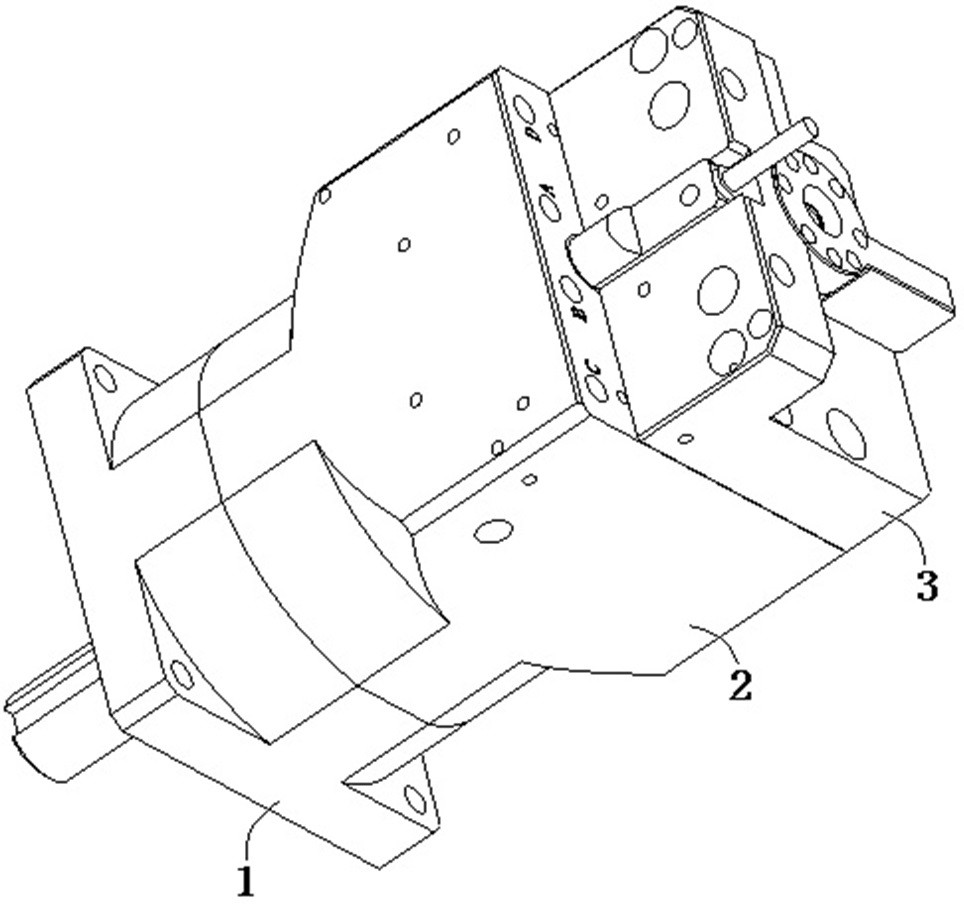

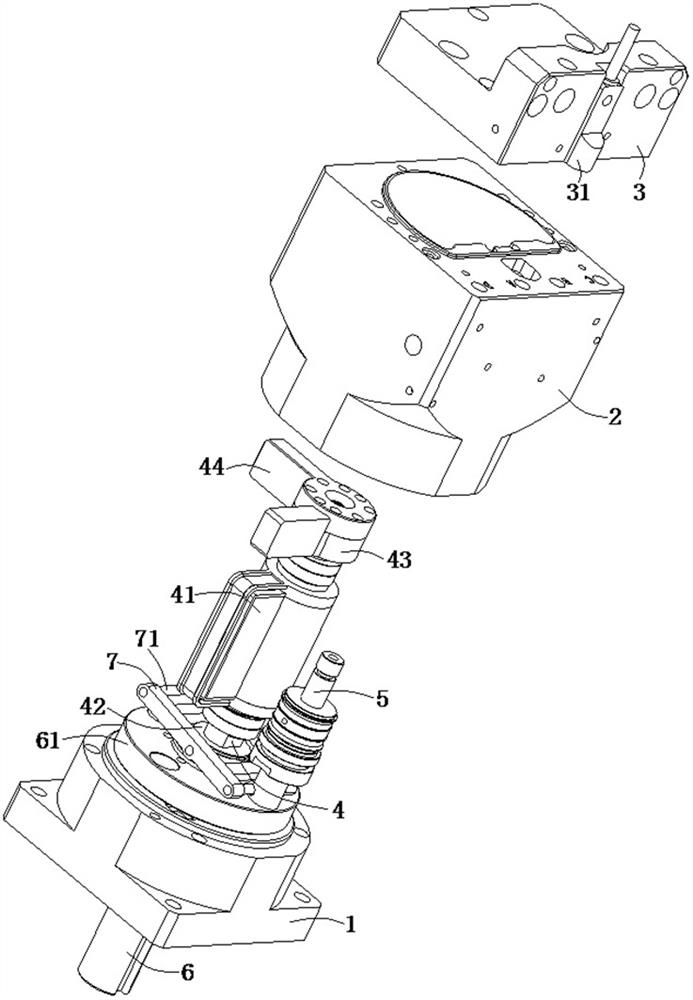

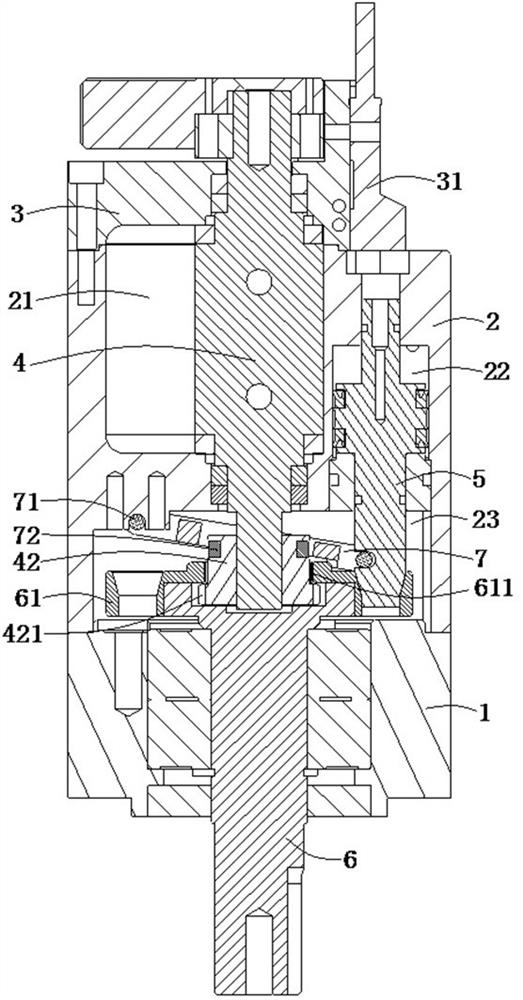

Polyhedron precision machining device with feedback detection function

ActiveCN103802000ALarge locking torqueHigh positioning accuracyEdge grinding machinesGrinding feed controlEngineeringMachining

The invention discloses a polyhedron precision machining device and provides the polyhedron precision machining device with a feedback detection function. The polyhedron precision machining device with the feedback and detection function is large in locking torque, high in locating accuracy, low in manufacturing cost and capable of accurately locking face turning positions of a polyhedral blank to be machined and solves the technical problems that in the prior art, the grinding accuracy, the machining accuracy and the locating accuracy of a polyhedral workpiece are low, the manufacturing cost of an existing polyhedron precision machining device is high. The polyhedron precision machining device comprises a machining platform, a grinding disk and a grinding head device, wherein the grinding disk and the grinding head device are arranged on the machining platform. A face turning mechanism, an angle turning mechanism and a turning angle locking mechanism are arranged on the grinding head device. The face turning mechanism comprises a box body and a plurality of tubular indexing shafts, wherein the indexing shafts are connected to the interior of the box body in a rotating mode. The front ends of the indexing shafts penetrate through the box body and extend to the positions above the grinding disk. Workpiece fixing rods provided with the polyhedral blanks are fixed to the front ends of the indexing shafts through clamping mechanisms. Indexing plates with indexing teeth are arranged on the corresponding indexing shafts in the box body in a sleeved mode. Taper pins which can be inserted between the adjacent indexing teeth in a matched mode are arranged on the positions, above the indexing plates, of the box body.

Owner:陈小青

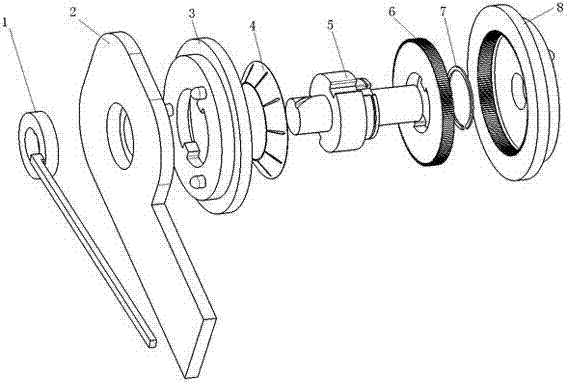

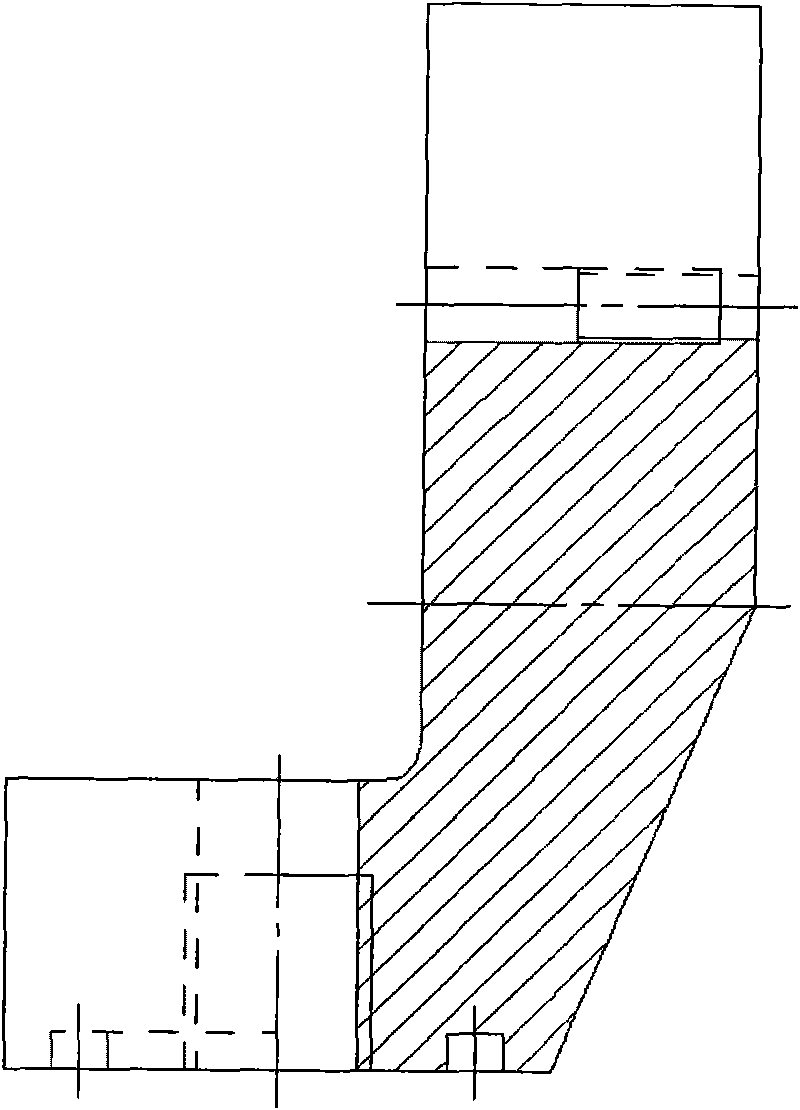

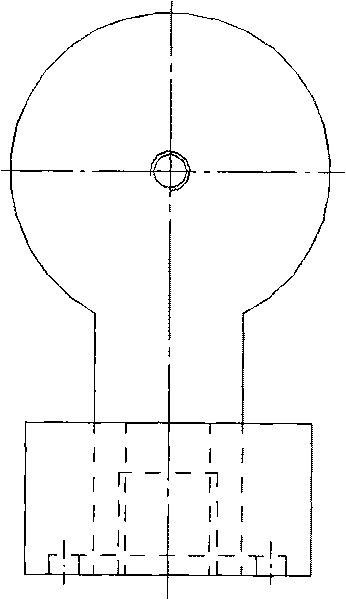

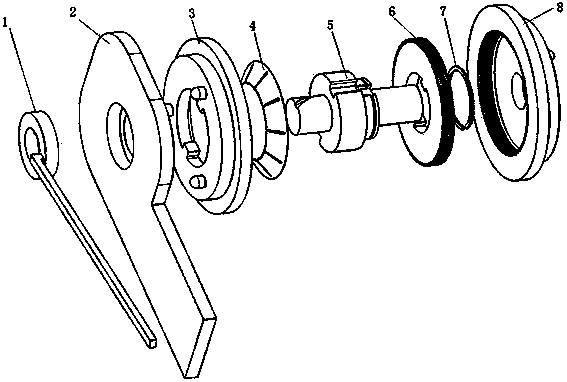

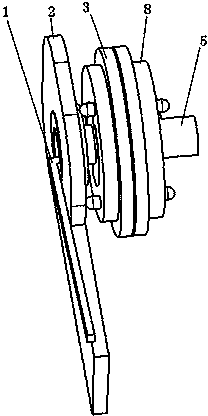

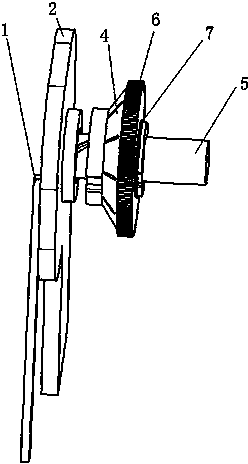

Angle adjuster

The invention relates to an angle adjuster. A diaphragm spring is arranged between the front end surface of a locking tooth plate and the inner end surface of a fixed seat, a rotation shaft extruding out of the fixed seat is provided with an unlocking handle, the inner bore of the unlocking handle is provided with a boss, the boss is stuck in the left rotation slot on the rotation shaft, and the locking tooth plate is engaged with inner teeth of an annular gear during locking; the locking tooth plate is in fit connection with the rotation shaft through the boss and grooves, the fixed seat is in fit connection with the rotation shaft through the boss and the grooves, the excircle of the rotation shaft is provided with the grooves, and inner pores of the locking tooth plate and the fixed seat are respectively provided with a boss; the rotation shaft is axially fixed on the locking tooth plate through sticking a clasp in the clasp slot of the rotation shaft; and the unlocking handle is axially positioned through sleeving the flange of the unlocking handle in the inner pore of an entity skeleton. The angle adjuster which allows all the teeth to be engaged with each other during locking is a stepless adjustable angle adjuster which can be locked at an arbitrary angle and has the advantages of large locking moment, simple structure and reliable working. The angle adjuster which can be applied to seat chairs and also can be used to adjust angles of other entities has a wide application range.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

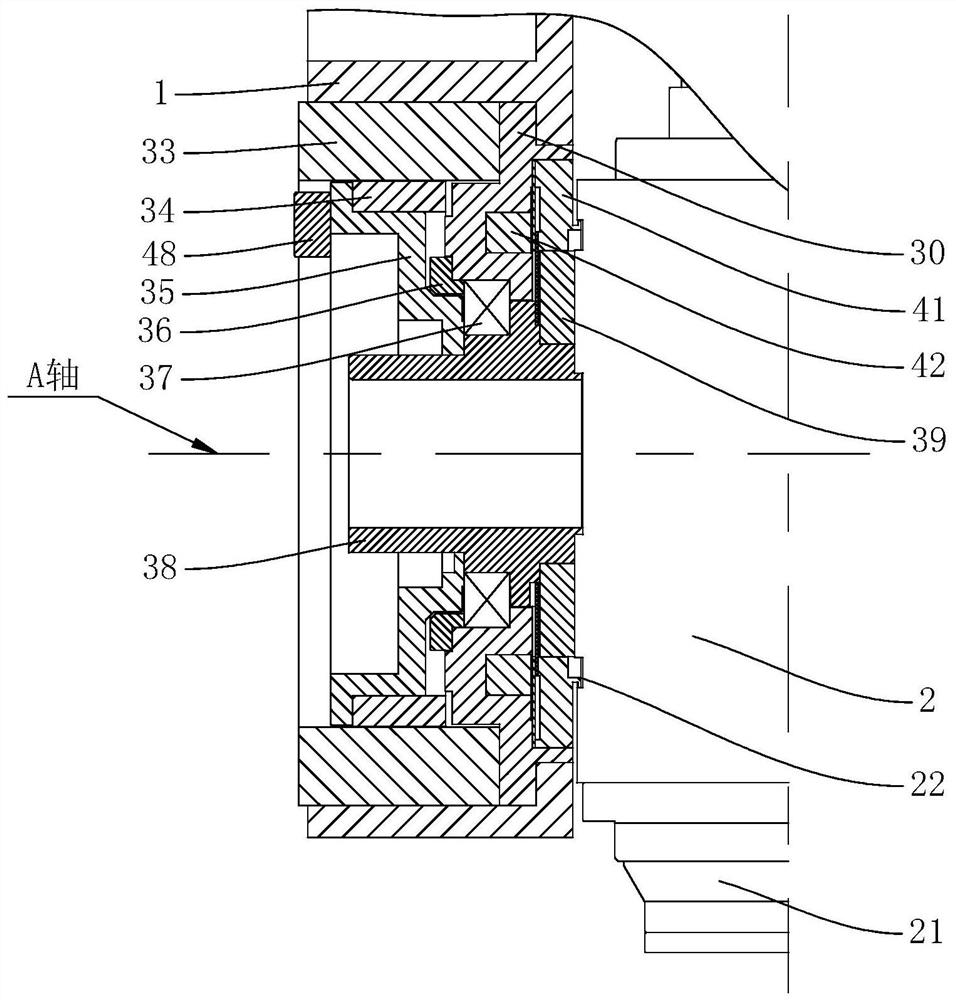

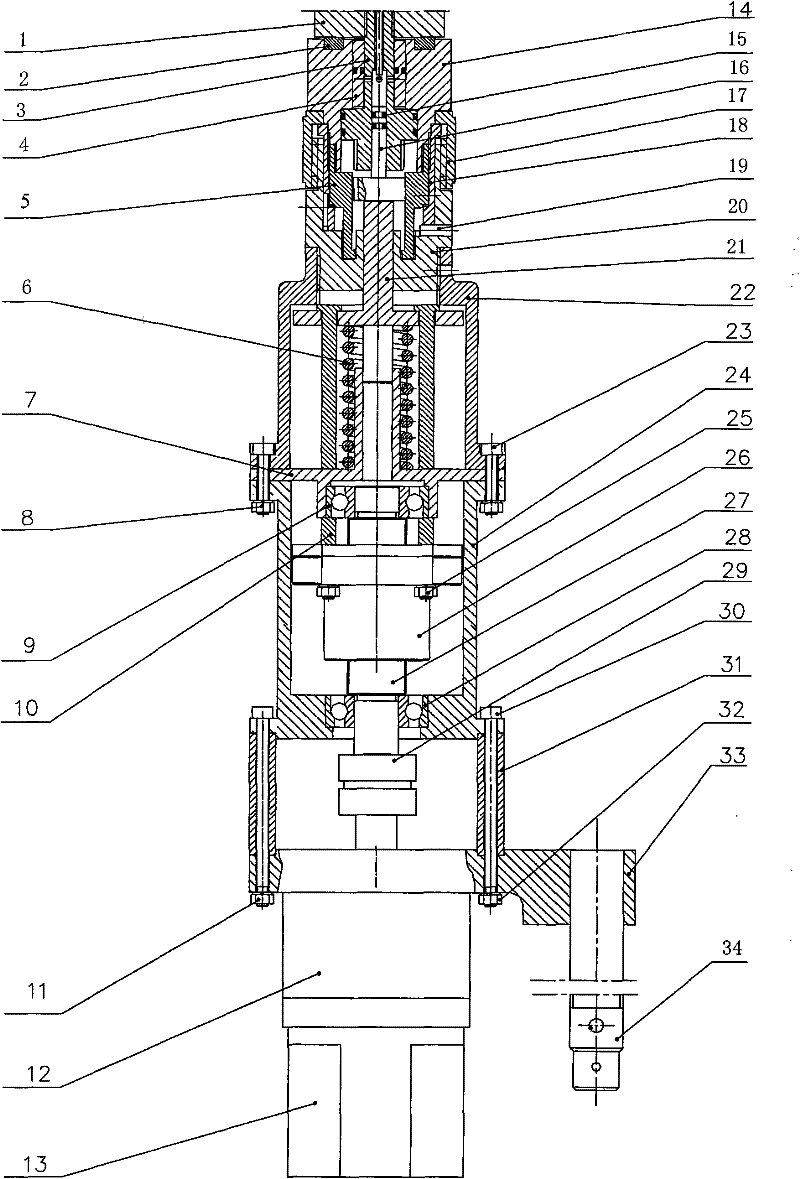

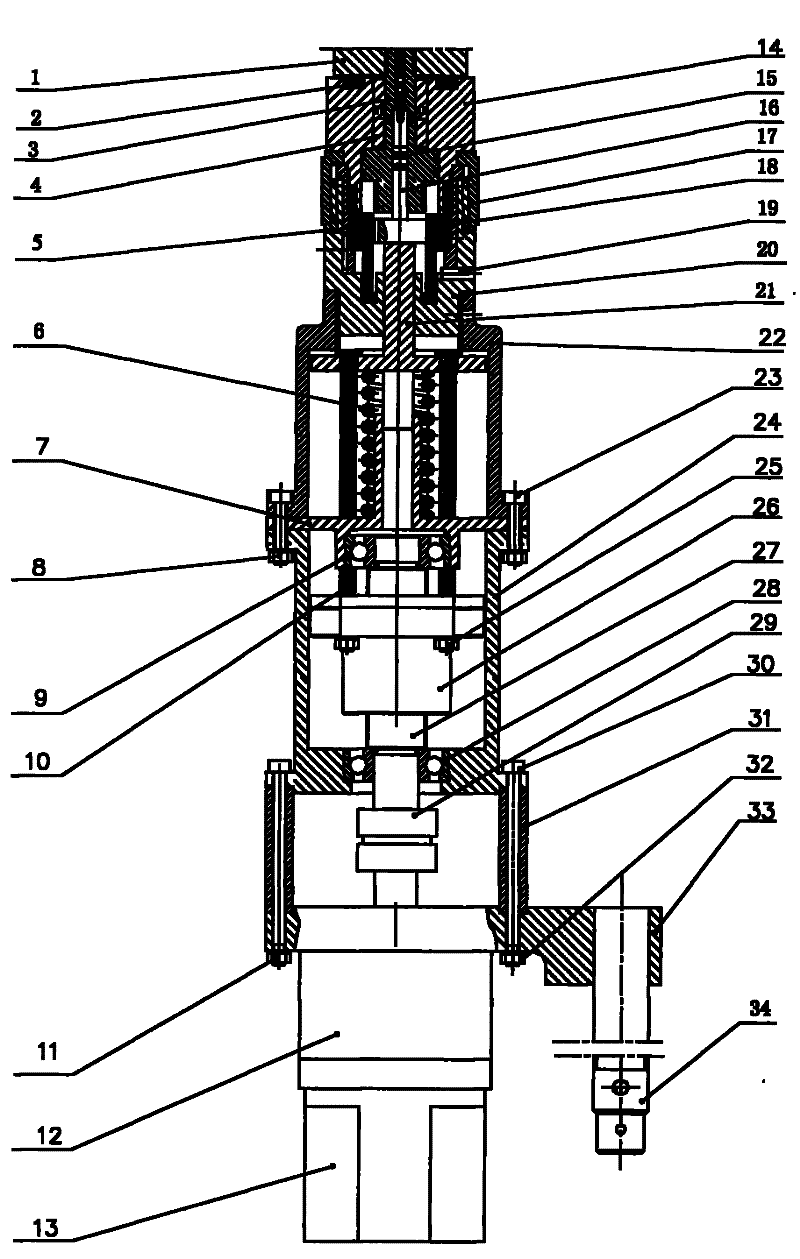

Double-drive single-swing head for vertical machining center

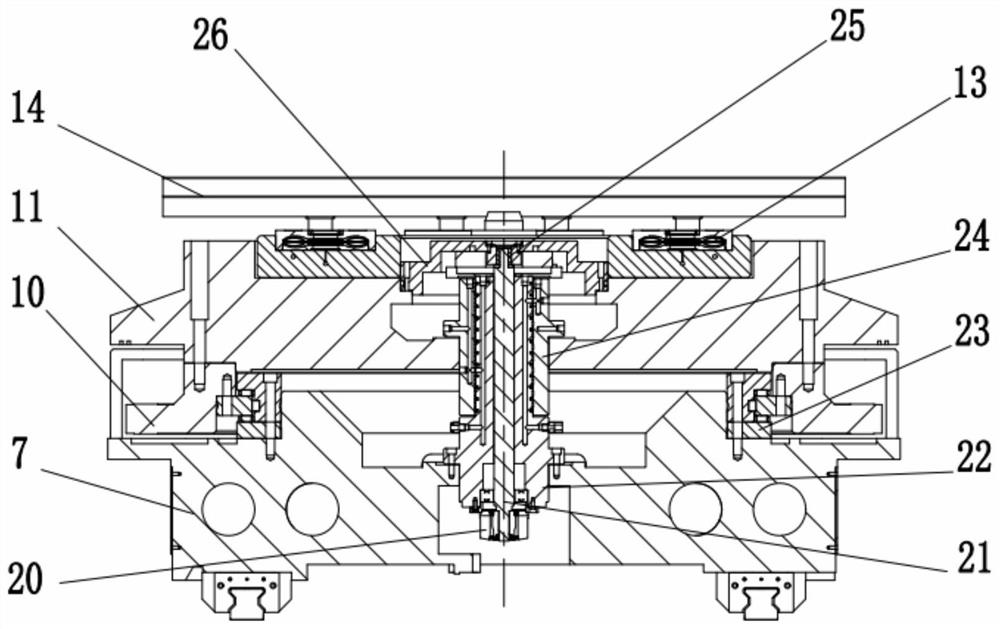

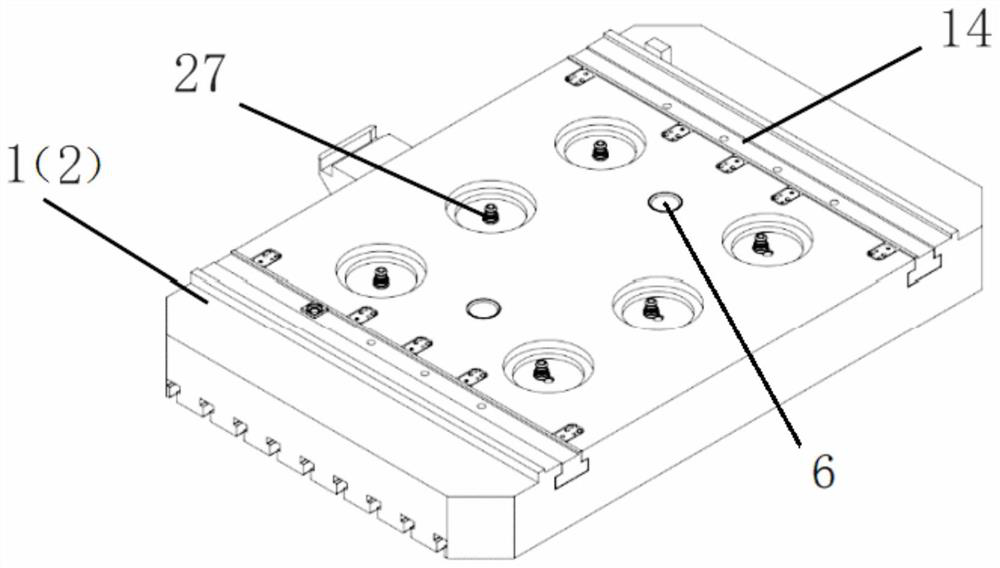

PendingCN112171351AGuaranteed stiffnessIncrease rotational torqueDriving apparatusLine tubingControl engineering

The invention discloses a double-drive single-swing head for a vertical machining center. The double-drive single-swing head for the vertical machining center comprises a swing head box body, a main shaft box, a main shaft, an A-axis left driving assembly, an A-axis right driving assembly, an A-axis oil distributor assembly, an A-axis encoder assembly and a main shaft pipeline outlet unit. The A-axis left driving assembly comprises a left torque motor assembly and a left hydraulic clamping mechanism. The A-axis right driving assembly comprises a right torque motor assembly and a right hydraulic clamping mechanism. A main shaft pipeline spirally surrounds the main shaft pipeline outlet unit, and a left protective cover and a right protective cover are fixed to the left side and the right side of the swing head box body respectively. According to the double-drive single-swing head, the main shaft box is driven by the double-torque motors which are symmetrically designed, larger rotatingtorque can be provided, high dynamic characteristics and stability required by machining are guaranteed, and the problem that a rotating shaft is distorted and deformed in a traditional single-side driving mode is solved. Meanwhile, the double hydraulic clamping mechanisms are adopted, larger locking torque can be provided, the braking effect can be ensured, and the rigidity of the single swing head in the machining process is ensured.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

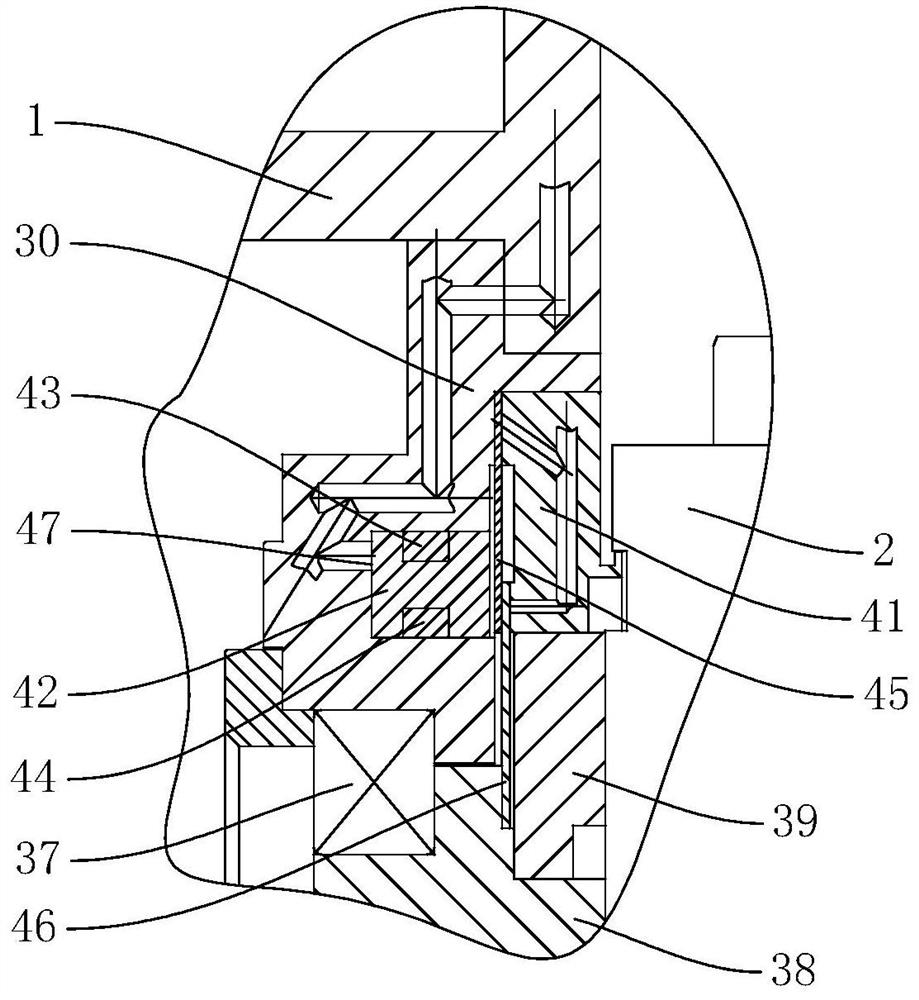

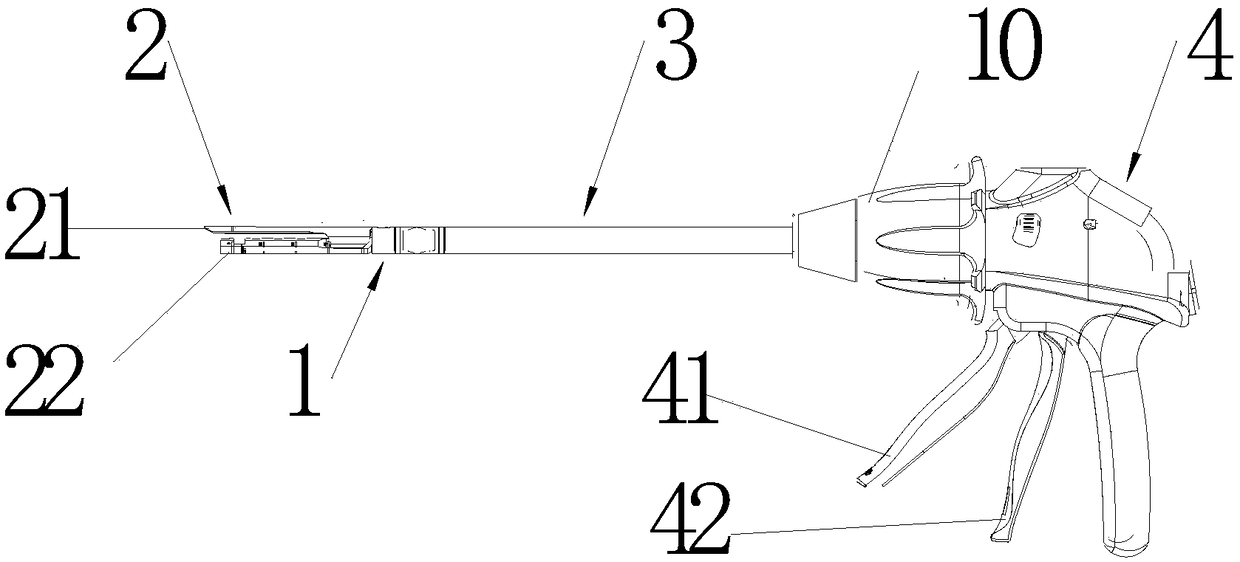

Improved locking mechanism on surgical instrument

PendingCN108992115ALarge locking torqueTechnical problems that are not susceptible to damage by the teeth on the jointSurgical staplesSurgical instrumentKnuckle

The invention provides an improved locking mechanism on a surgical instrument, and specifically relates to an improved locking mechanism on a knuckle joint on an anastomat. A knuckle structure betweenan anastomat end execution device and a slender shaft is improved. A locking plate with an arc groove and a locking rod with a slope are cooperated, through upper and lower inner surfaces of the arcgroove and the upper and lower inner surfaces of the locking rod, the locking mechanism clamps or contacts in a frictional manner, so that the locking mechanism has large locking moment, and a technical problem that a soft tissue in a conventional locking mechanism is easily damaged by teeth on a knuckle would not occur.

Owner:SUZHOU FRANKENMAN MEDICAL EQUIP

Biplanar frictional two-freedom-degree joints based on hydraulic pressure

The invention relates to biplanar frictional two-freedom-degree joints based on hydraulic pressure. The outer edge of the upper side of the lower plane of a T-shaped shaft of an upper joint is provided with wedge-shaped faces, a bar part is sleeved with a force transmission slide block of the upper joint, the diameter of a round hole of the force transmission slide block of the upper joint is larger, the bar part is installed in a casing of the upper joint by a bearing, extends out to be connected with one end of a platform body of the joints, and the end part of a push bar is matched with the two wedge-shaped faces of the T-shaped shaft of the upper joint; a T-shaped shaft of a lower joint is connected below the other end of the platform body of the joints, the lower end is sealed in a sealing cover of the lower joint, and the sealing cover of the lower joint is fixedly connected with a supporting shaft of the joints; and an ejector bar is installed in a hollow structure of the T-shaped shaft of the lower joint, a sealing bolt is installed at the hollow bottom, a distance exists between the lower end of the ejector bar and the lower end of an ejector bar of the sealing bolt, and the upper end contacts with the force transmission slide block of the upper joint. The invention has small volume, compact structure, light weight, large locking moment, simple structure and small joint clearance after being locked and can be suitable for locking the joints of various miniature type mechanical arms with lighter end static bearing.

Owner:昆山市工业技术研究院有限责任公司

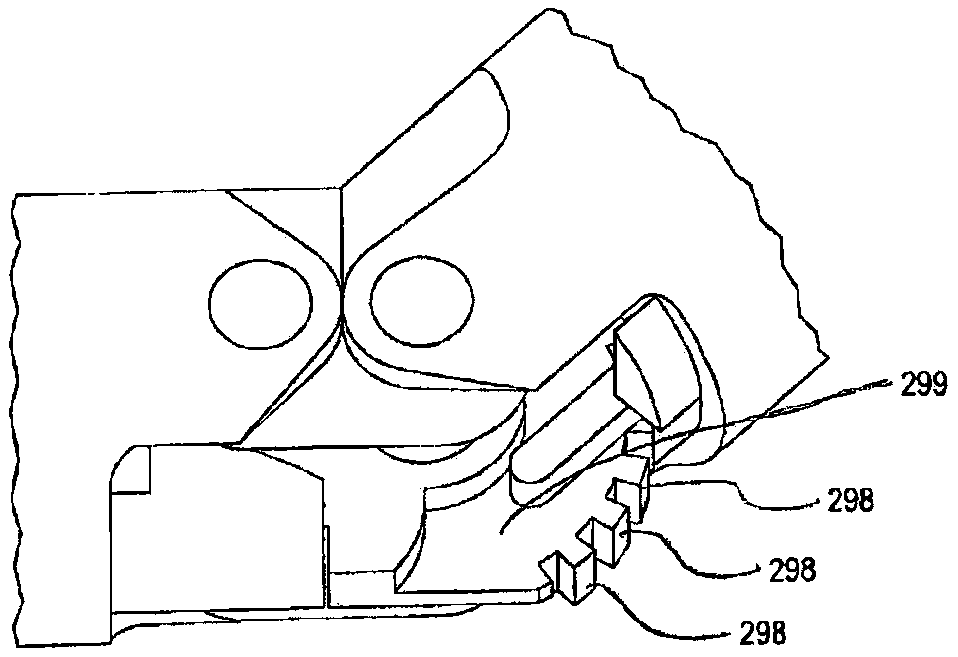

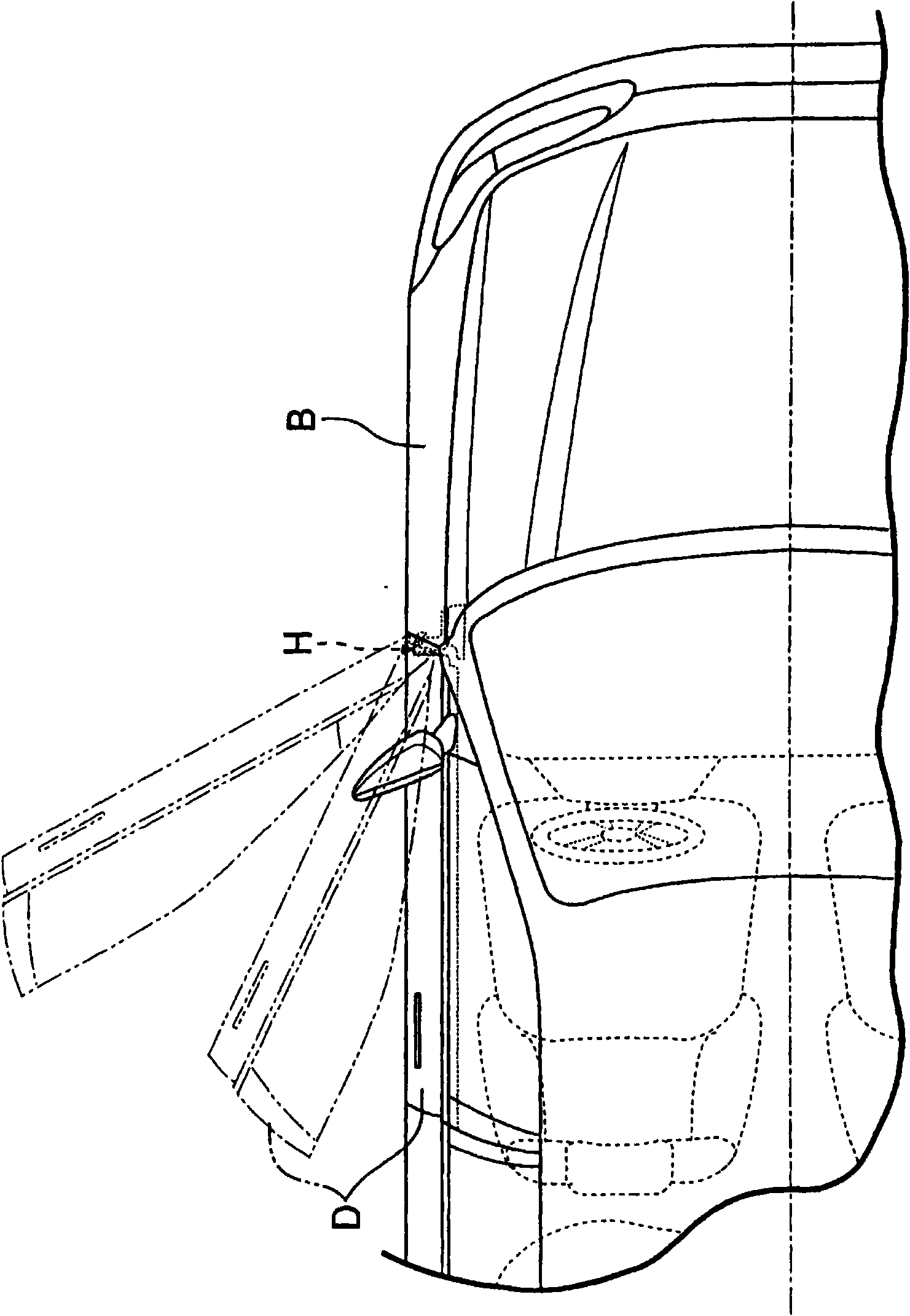

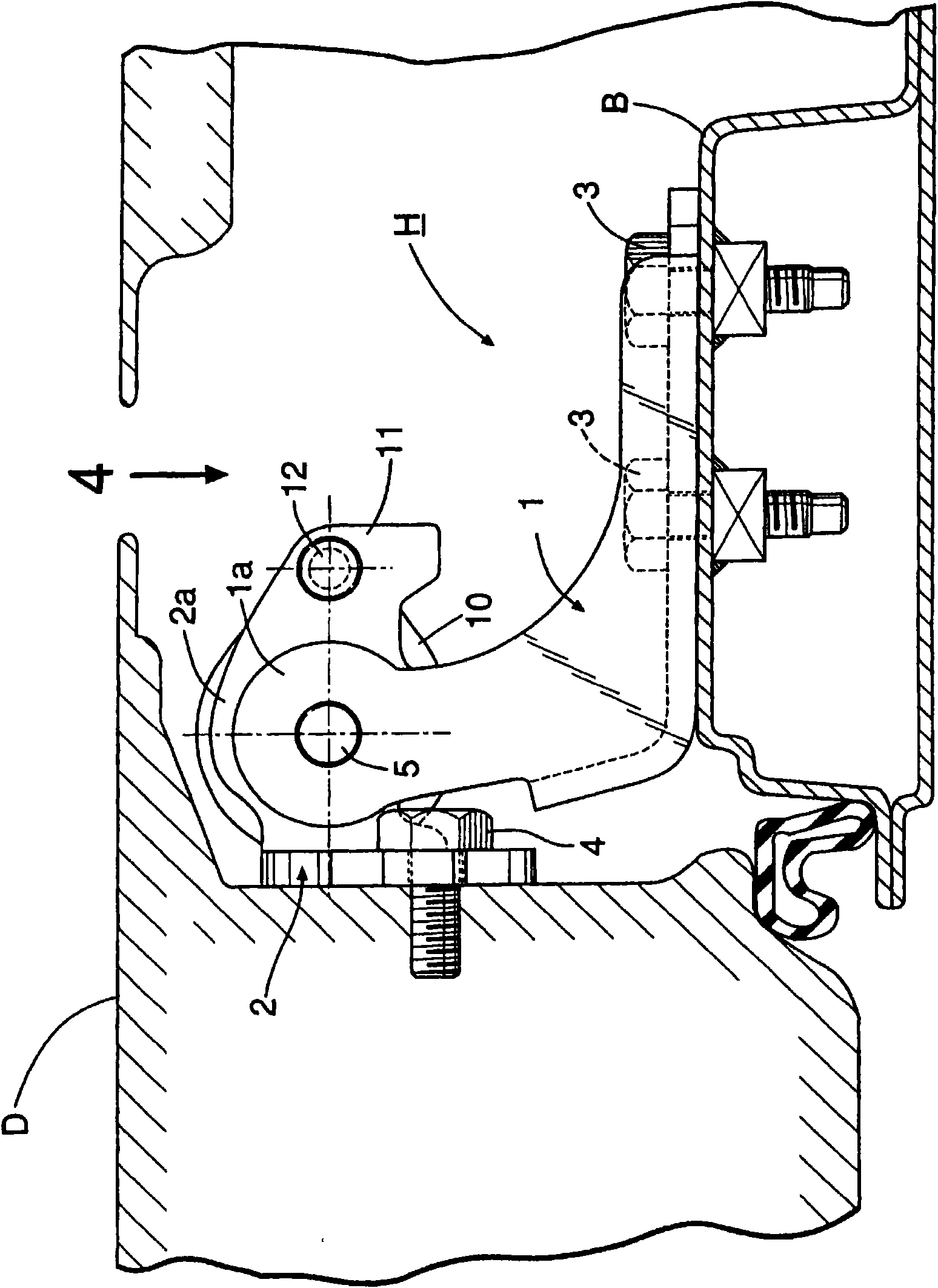

Vehicular door-hinge device with checker

Provided is a vehicular door-hinge device with a checker, which comprises an inner cylinder (6) to be jointed to a female bracket (1), an outer cylinder (7) to be jointed to a female bracket (2), and a check force generating mechanism (20) interposed between the two cylinders (6 and 7). The mechanism (20) is constituted of a plurality of holding members (22) attached to the outer cylinder (7) and arrayed in the circumferential direction of the same, and a plurality of elastic members (23) for biasing those holding members (22) individually toward the inner cylinder (6). Each of the holding members (22) is equipped with a detent projection (26) for abutting against the outer circumference of the inner cylinder (6). The inner cylinder (6) is equipped, in its outer circumference, with a plurality of detent grooves (27), into and out of which the engagements of the detent projections (26) are made according to the relative rotations of the inner cylinder (6) and the outer cylinder (7). The pressure receiving areas of the holding members (22) for receiving the pressures from the elastic members (23) are set larger than the abutting areas of the detent projections (26) and the detent grooves (27). As a result, the vehicular door-hinge device does not lose the checking function, even if the check force generating mechanism is partially troubled, but is high in durability.

Owner:RIKEN KAKI KOGYO CO LTD

Rear door locking device of multifunctional washing and sweeping truck

PendingCN107284930AGuaranteed to lockPrevent openingVehicle locksRoad cleaningRotational axisEngineering

The invention discloses a rear door locking device of a multifunctional washing and sweeping truck. The rear door locking device comprises a box body, a rear door, an oil cylinder, a push-pull rod hinge base, a push-pull rod, a locking base, a locking hook rotating shaft and a locking hook; the push-pull rod hinge base is fixed in the middle of the rear door; a kidney-shaped guide groove is formed in the push-pull rod hinge base; a hinge shaft is connected to the inner side of the kidney-shaped guide groove in a sliding mode, is hinged to a piston rod of the oil cylinder and is hinged to the upper end of the push-pull rod; the locking hook comprises a thrust arm and a hook body; a shaft hole matched with the locking hook rotating shaft is formed in the intersection of one end of the hook body and one end of the thrust arm; the lower end of the push-pull rod is hinged to the other end of the thrust arm; the locking base is arranged at the rear lower part of the box body; and when the piston rod of the oil cylinder extends out to reach the extreme value, the other end of the hook body of the locking hook is hooked on the locking base, and an included angle between the center line of the push-pull rod and the center line of the thrust arm of the locking hook is a right angle. The rear door locking device has the advantages that the rear door can be guaranteed to be locked under the impact of sewage in the box body, and therefore opening of the rear door can be avoided.

Owner:JINGSU YUEDA SPECIAL VEHICLE CO LTD

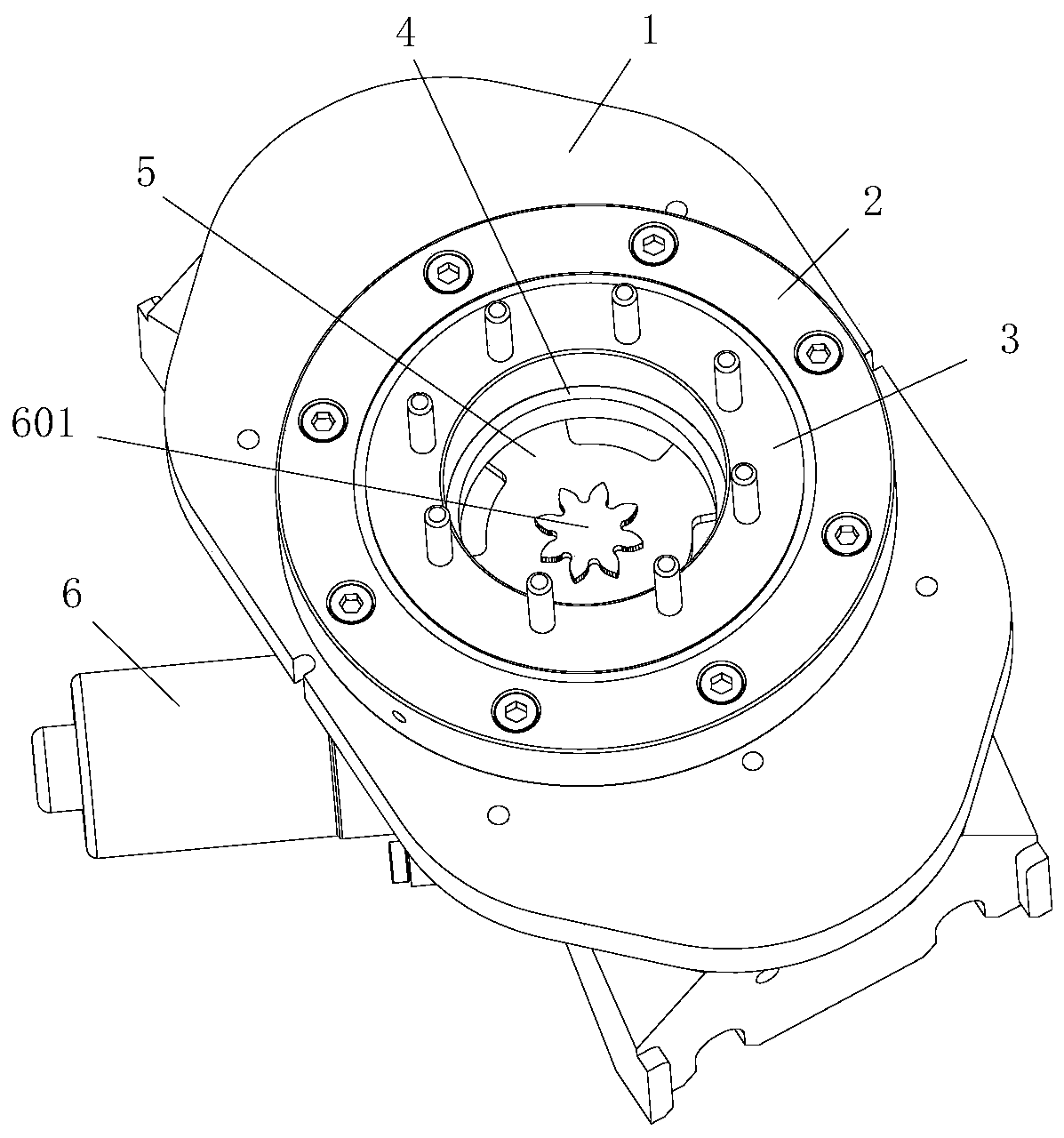

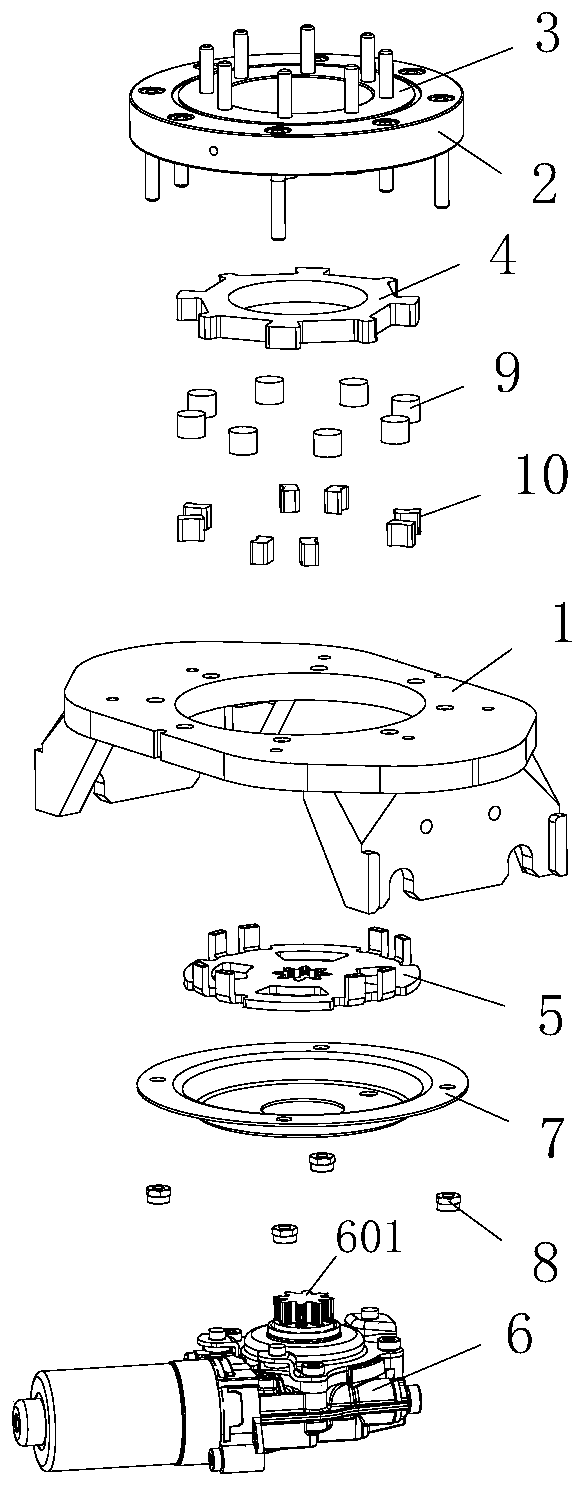

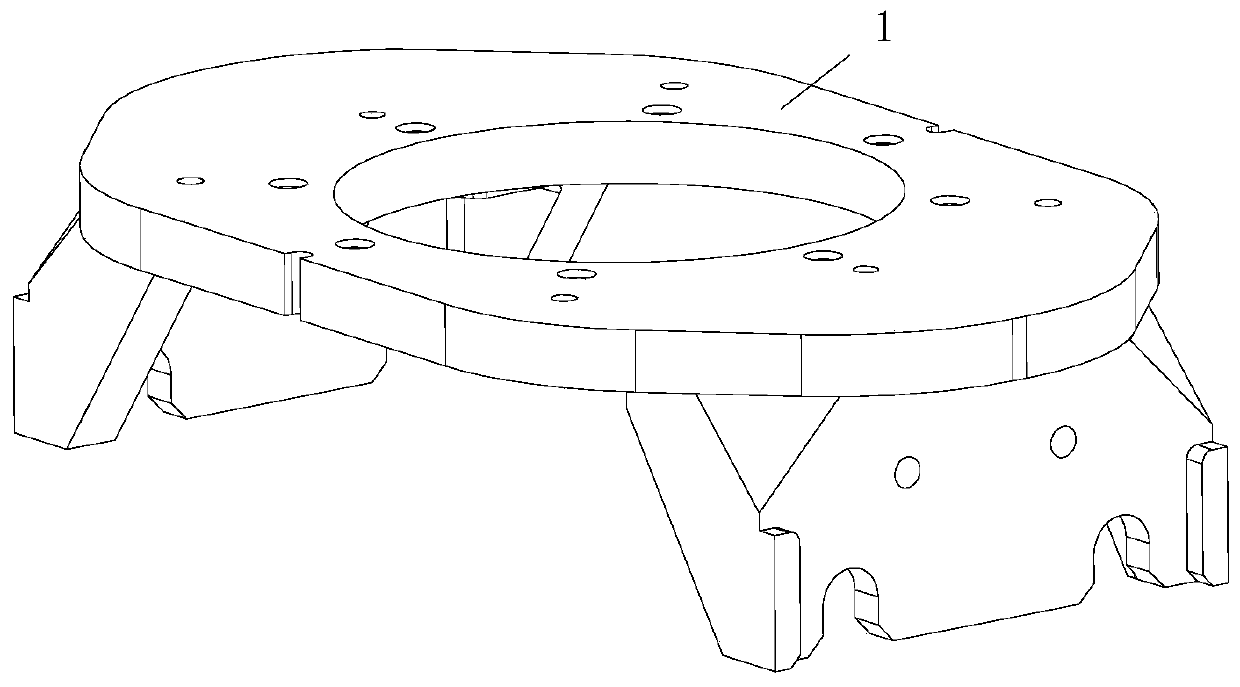

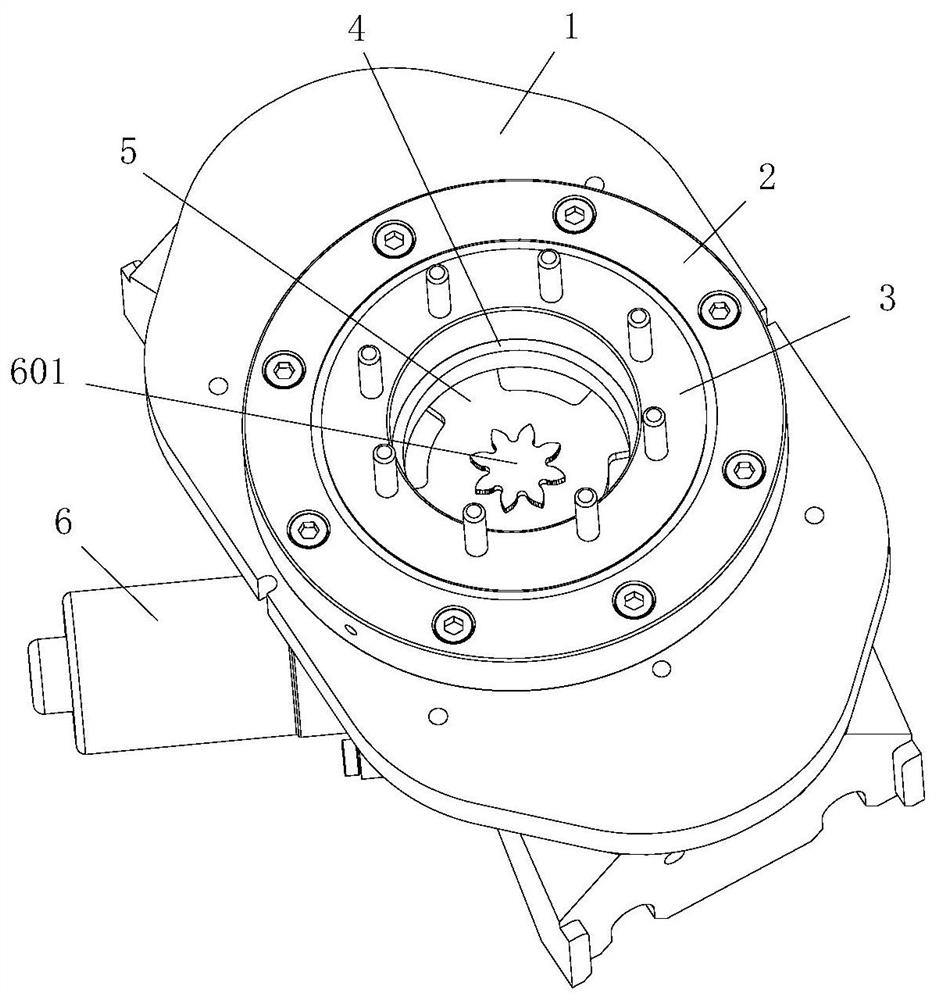

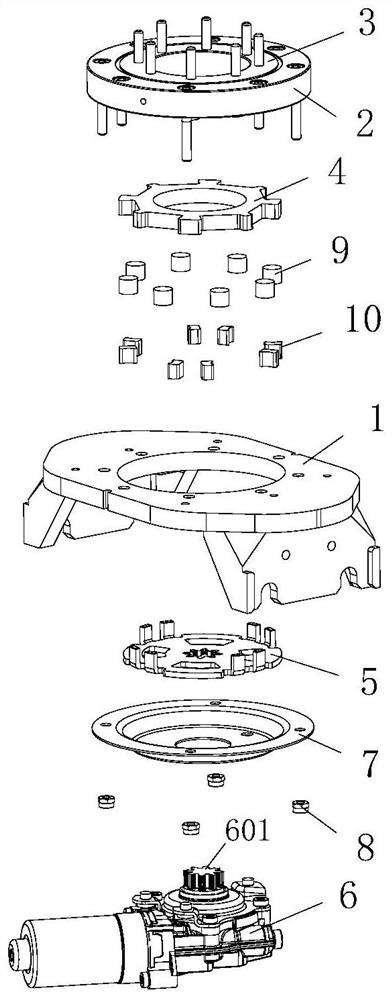

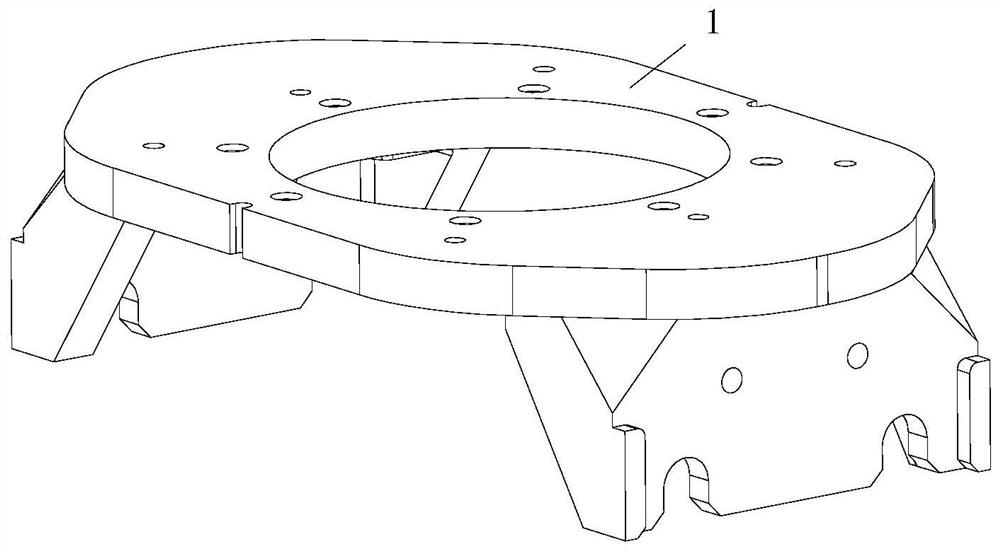

Rotary table based on zero point positioning and application thereof

PendingCN114770147AQuick exchangeReduce labor intensityLarge fixed membersControl engineeringControl theory

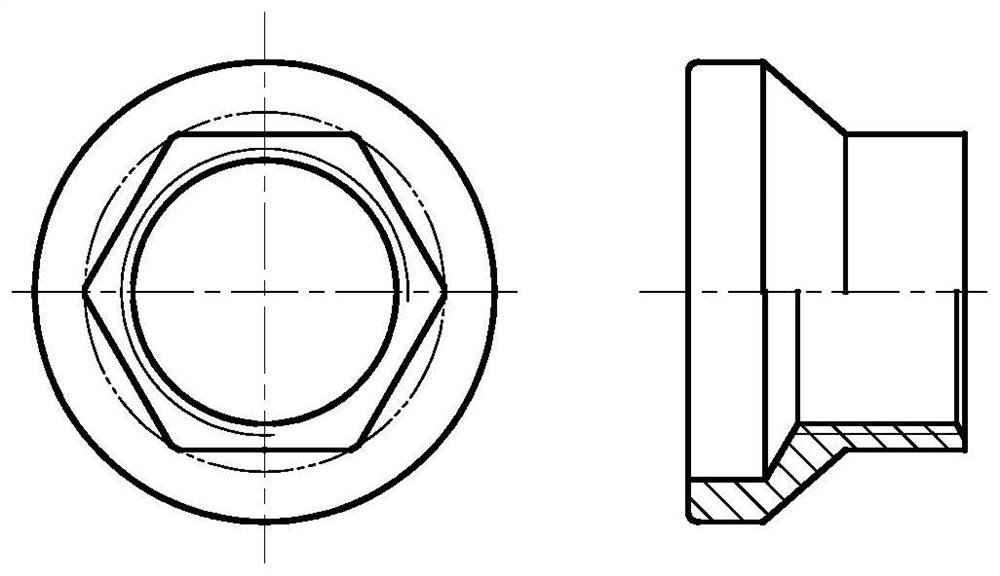

The invention belongs to the field of machine tool machining and production, and particularly relates to a rotating table based on zero point positioning and application of the rotating table. According to the technical scheme, the rotary table comprises a sliding base, a rotary base, a working table plate, T-shaped guide rails, a rotary table bearing, a rotation control mechanism, a lifting control mechanism and a locking mechanism, the rotary base is rotationally connected with the sliding base through the rotary table bearing, the two T-shaped guide rails are symmetrically installed on the upper end face of the rotary base, and two T-shaped guide grooves are formed in the lower end face of the working table plate; the working table plate is mounted on the T-shaped guide rails through the T-shaped guide grooves; a plurality of zero-point positioning female discs are arranged on the upper end face of the rotary seat, a plurality of zero-point positioning male heads are arranged on the lower end face of the working table plate, and the zero-point positioning male heads correspond to the zero-point positioning female discs one by one in position; the rotation control mechanism, the lifting control mechanism and the locking mechanism are used for controlling rotation, lifting and locking of the workbench plate. The device is reliable and stable in positioning, large in locking torque, high in repeated positioning precision and capable of achieving rapid exchange of parts.

Owner:通用技术集团沈阳机床有限责任公司

Electromagnetic brake control device and method

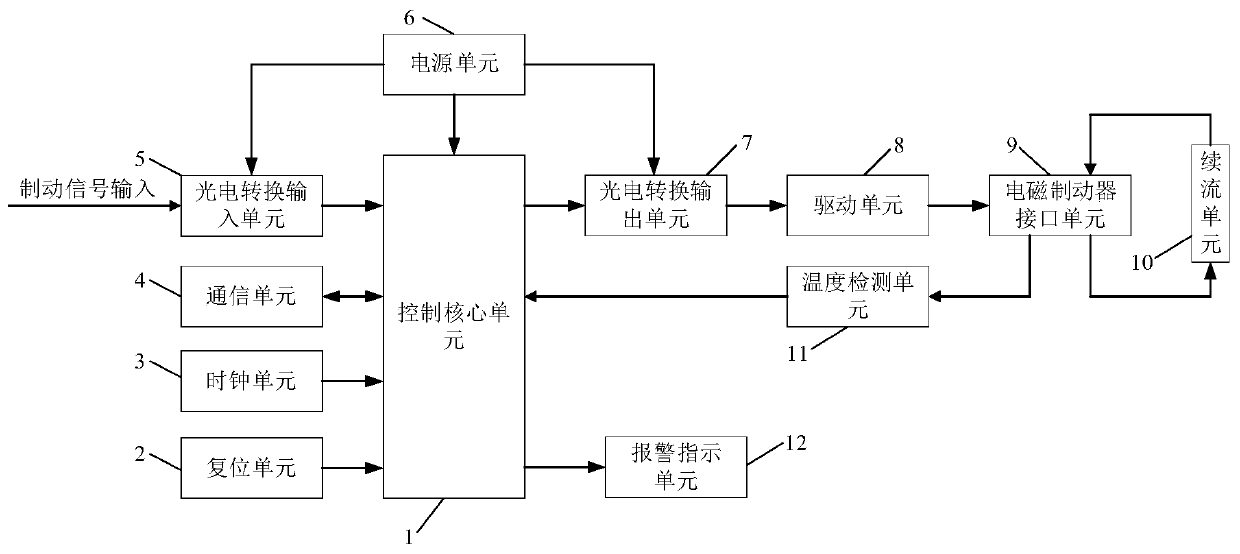

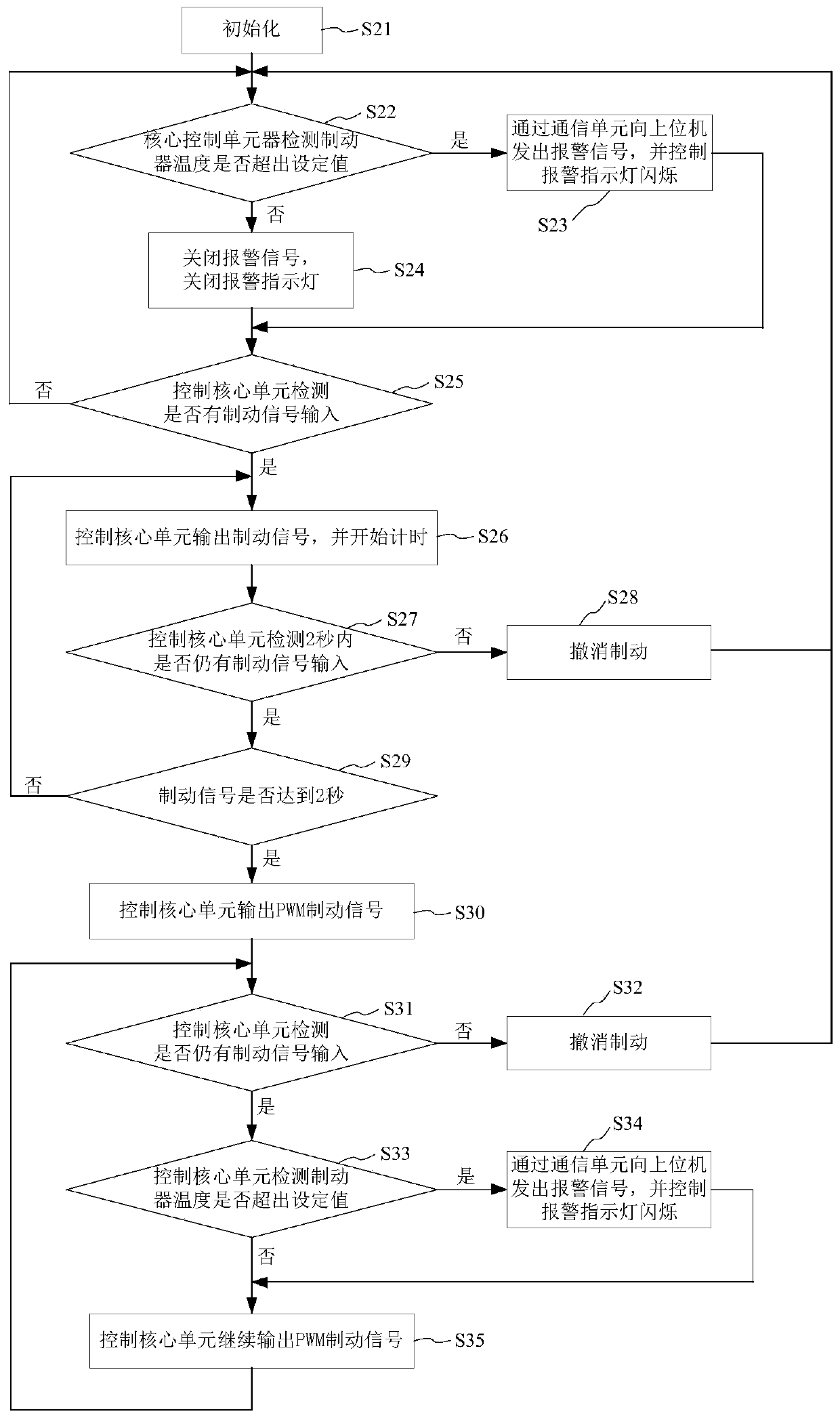

InactiveCN109782656ALarge locking torqueSlow down heat agingProgramme controlComputer controlControl mannerControl engineering

The invention discloses an electromagnetic brake control device and method. The device comprises a control core unit, a clock unit, a photoelectric conversion input unit, a photoelectric conversion output unit and an electromagnetic brake control interface unit, The control core unit is used for receiving a brake input signal and a clock signal and sending a brake output signal; the photoelectricconversion input unit is used for sending the brake input signal to the control core unit; the photoelectric conversion output unit is used for sending the brake output signal to the electromagnetic brake control interface unit; the electromagnetic brake control interface unit is used for driving an electromagnetic brake to attract. The system adopts a control mode of high-pressure suction and low-pressure holding, the high-pressure suction ensures that the electromagnetic brake has larger locking torque at the suction moment, the low-pressure holding can effectively reduce the heating aging of the electromagnetic brake caused by long-time high-pressure suction, and the service life of the electromagnetic brake is greatly prolonged.

Owner:AEROSPACE INFORMATION

Lockable rotary driving mechanism, electric rotary seat and automobile

ActiveCN110901479ALarge locking torqueOvercoming insufficient locking torqueMovable seatsRotational axisMotronic

The invention provides a lockable rotary driving mechanism, an electric rotary seat and an automobile. The rotary driving mechanism comprises a fixed support, a rotary bearing disc which is fixedly connected with the fixed support and provided with an inner ring, a locking disc which is fixedly connected with the inner ring and provided with a plurality of protruding blocks, wedge-shaped spaces defined by the locking disc and the fixed support jointly are formed between the adjacent protruding blocks, and rigid gap sealing bodies and elastic reset pieces are arranged in the wedge-shaped spaces. The rotary driving mechanism further comprises a rotary driving module fixedly connected with the fixing support and a shifting fork connected to the power output end of the rotary driving module. The rotary driving mechanism has a locking function, can provide large locking torque, and can overcome the defect of insufficient locking torque in the prior art.

Owner:诺创汽车科技(上海)有限公司

High-locking anti-crack mandrel and closing-in method thereof

PendingCN113586590ALarge locking torqueEasy to disassembleNutsBoltsIndustrial engineeringScrew thread

Owner:AEROSPACE PRECISION PROD INC LTD

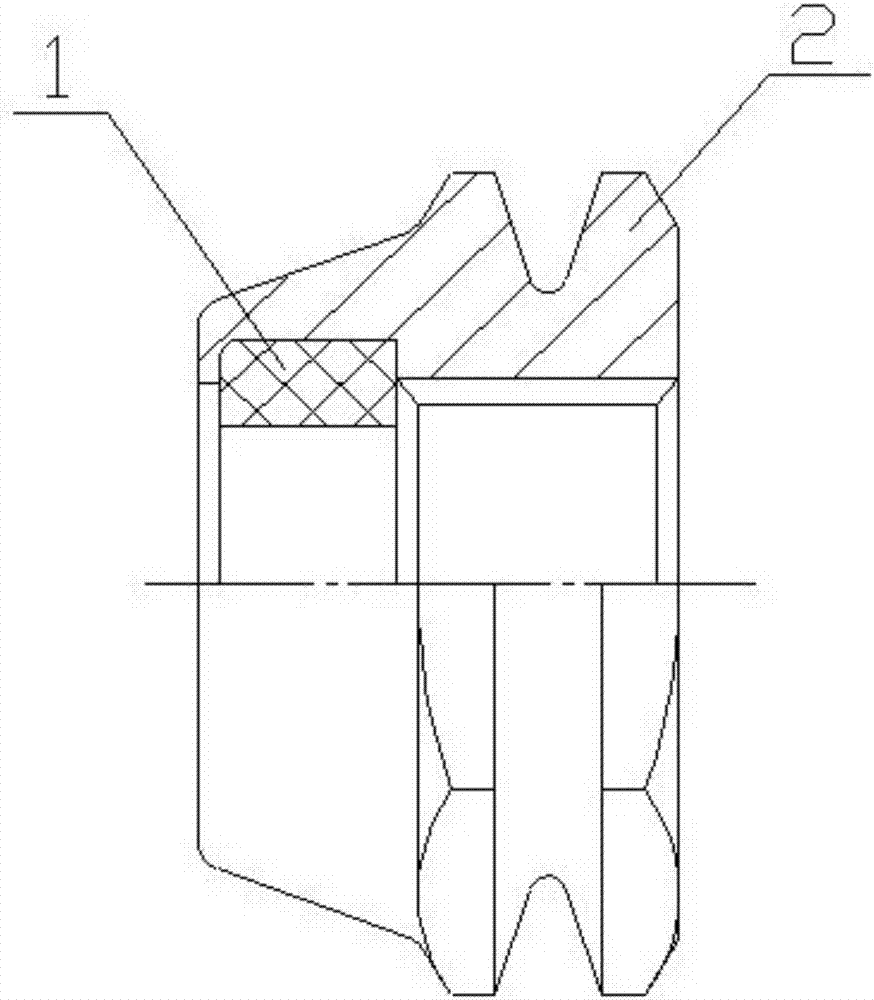

Self-lubricating cold welding preventing light self-locking nut and manufacturing and use methods thereof

PendingCN107035755AIncrease profitReduce thicknessWashersNutsMechanical engineeringIndustrial engineering

The invention discloses a self-lubricating cold welding preventing light self-locking nut and manufacturing and use methods thereof. The self-locking nut comprises a self-locking nut body (2) and a sealing locking ring (1) used for being mounted in the self-locking nut body (2) and generating locking torque through plastic deformation. The structural design weight of the self-locking nut is minimized, the locking torque can be controlled, meanwhile, an ideal sealing effect is obtained, and cold welding bonding between the nut and a bolt after assembly is effectively prevented. High safety reliability is achieved, mechanical performance is stable, and maintenance is convenient.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

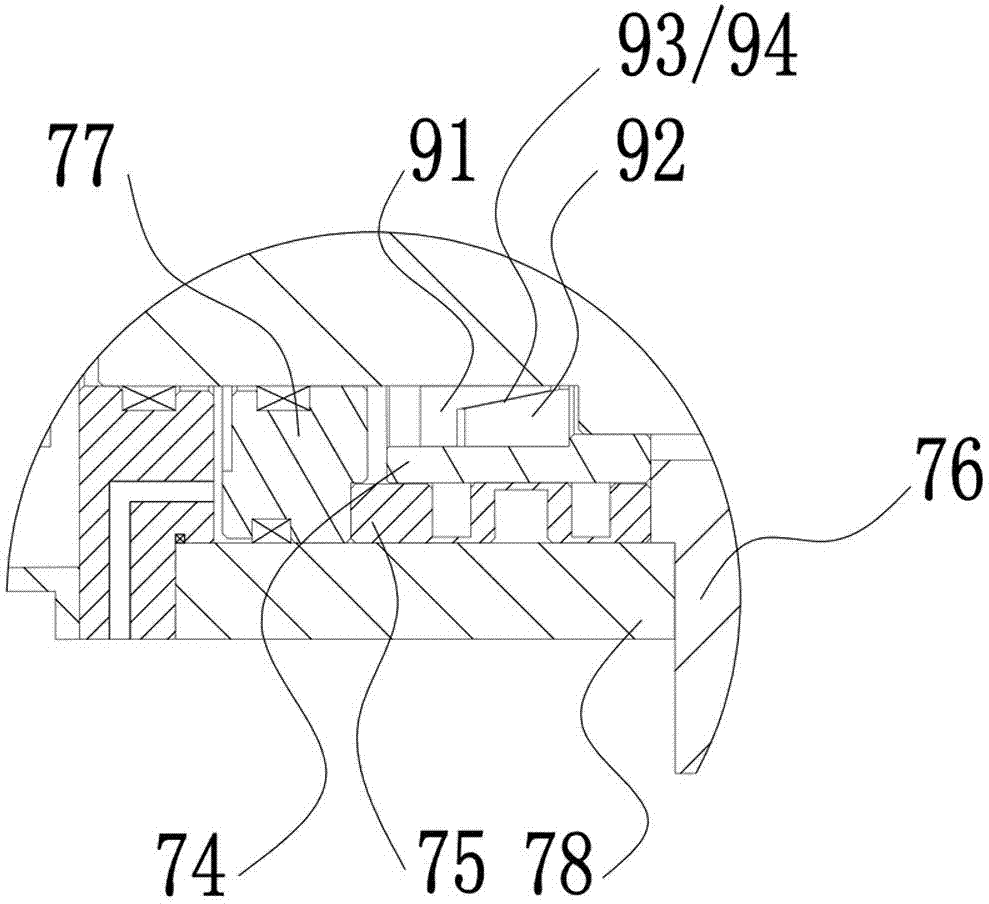

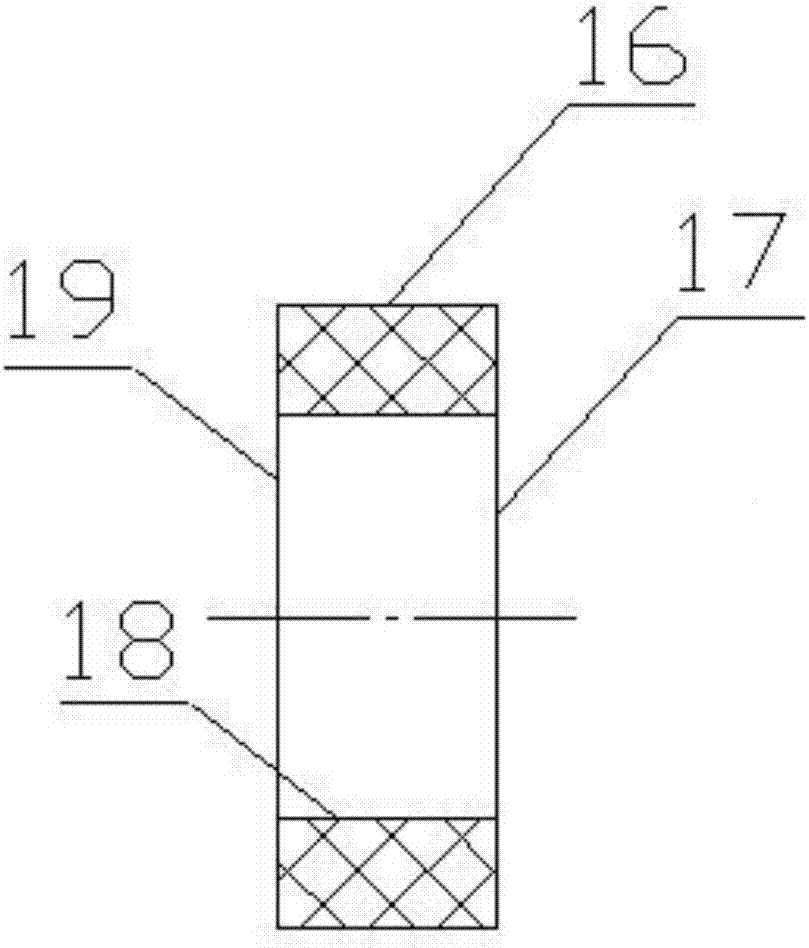

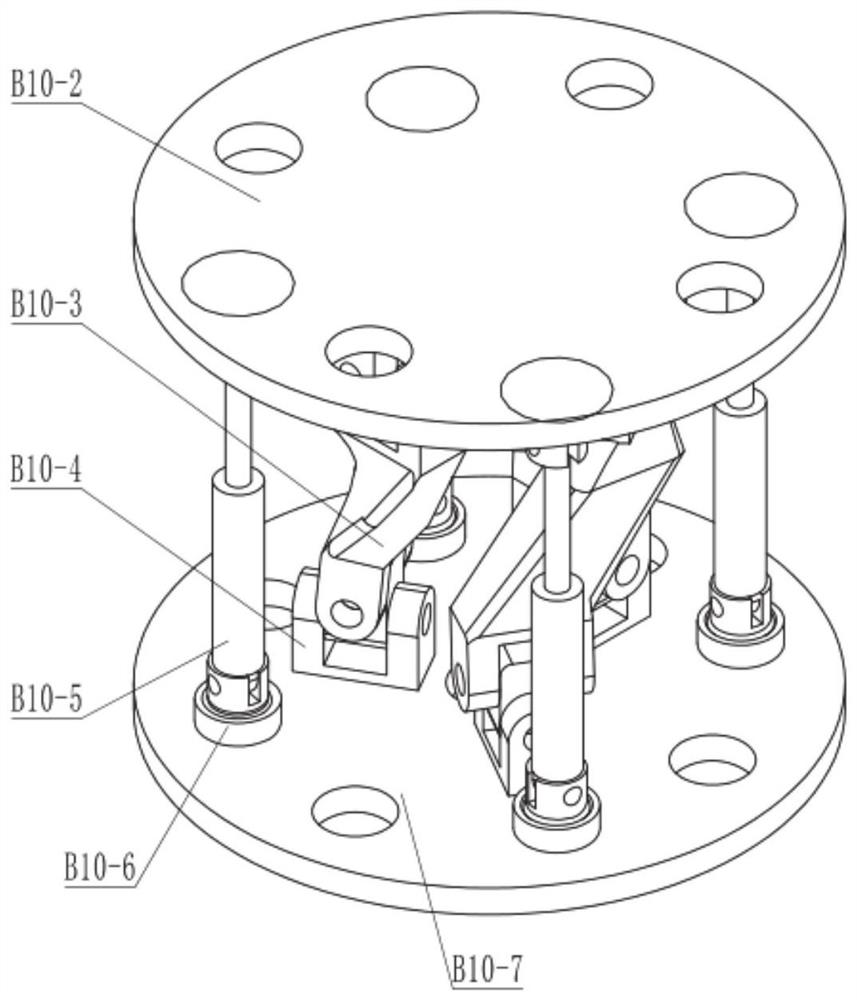

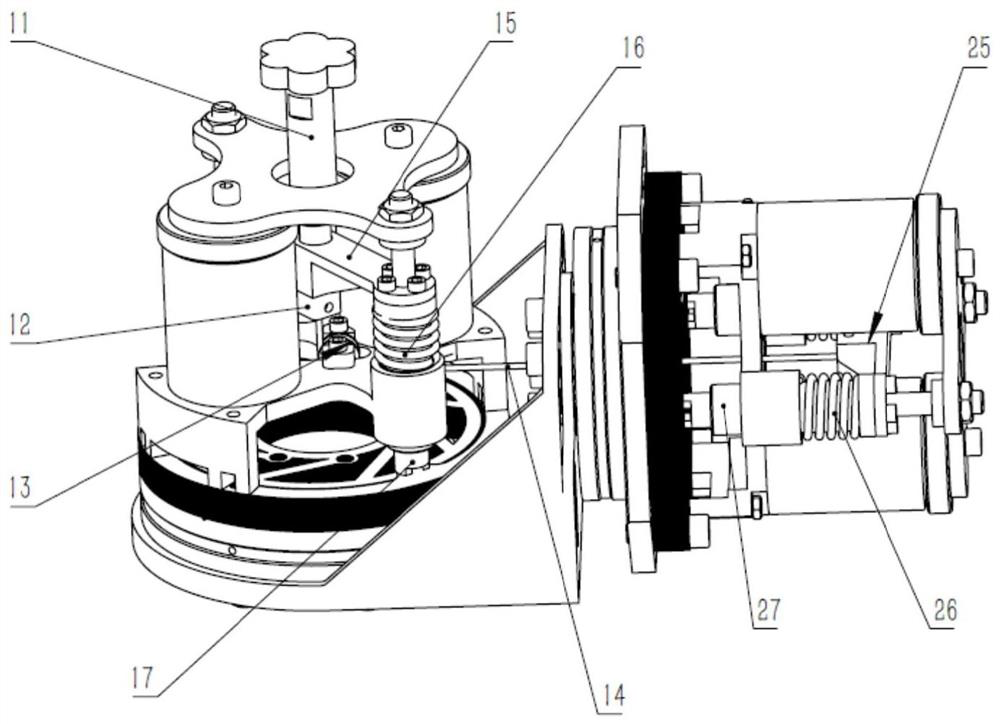

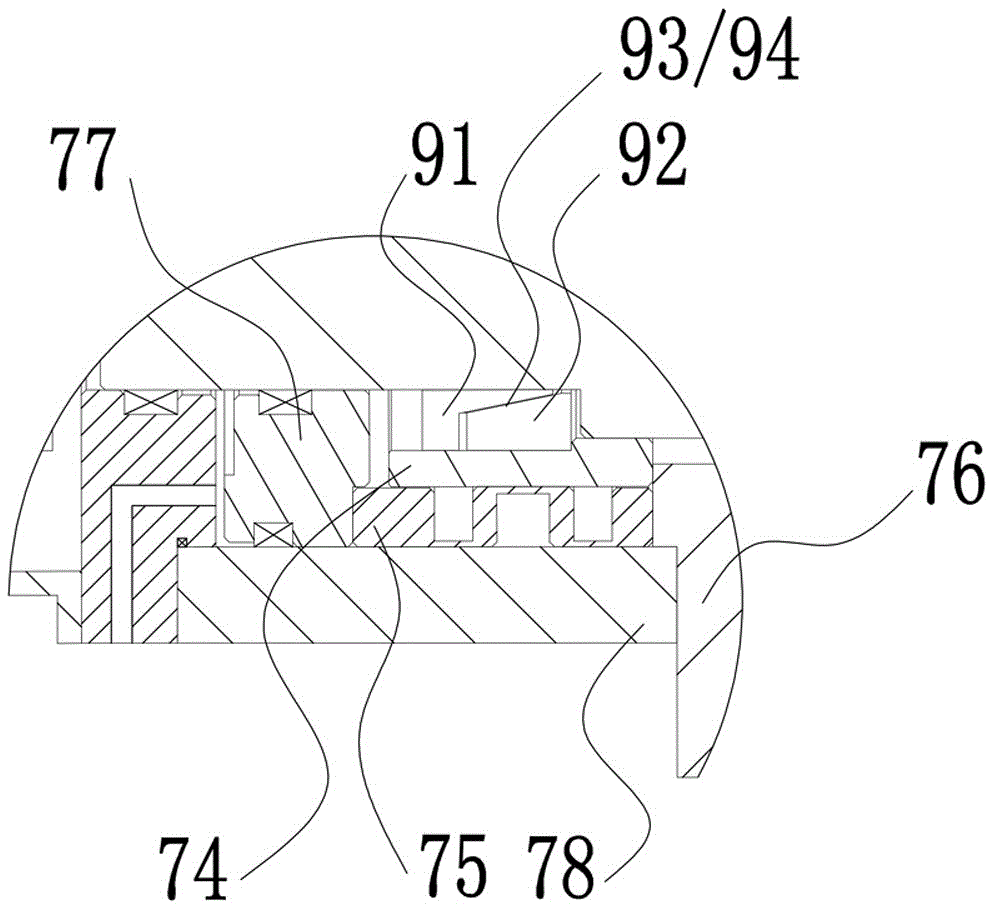

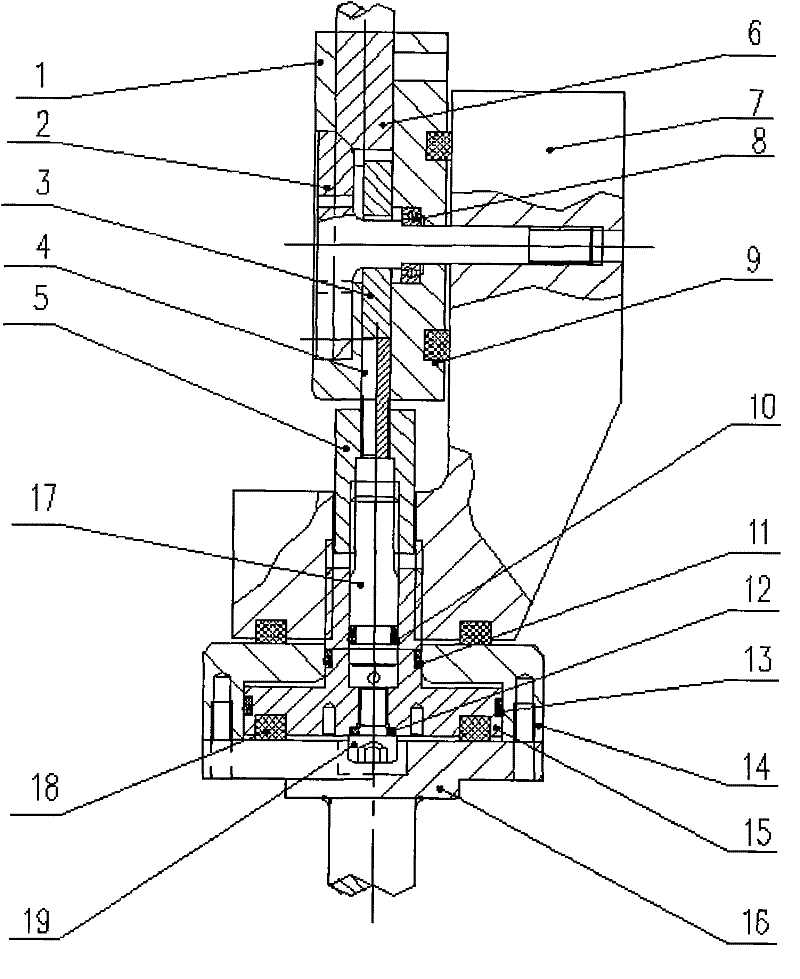

Rotary shaft feedback detection hydraulic locking system

ActiveCN103801983BAvoid wear and tearThe fixing method is simple and reliableAutomatic control devicesGrinding drivesControl systemCylinder block

The invention discloses a rotating shaft feedback detection hydraulic locking system, provides a locking system with large locking torque, high positioning accuracy, and can accurately identify and feedback the position of the box body, and solves the problem of box body positioning accuracy in the prior art Low, the position of the cabinet cannot be adjusted and corrected and other technical problems. It includes a mandrel and a servo motor connected to one end of the mandrel. The middle part of the mandrel rotates and connects to the box. The other end of the mandrel opposite to the servo motor is sleeved with a cylinder connected to the box. The corresponding core in the cylinder A wear-resistant sleeve is fixed on the shaft, and the wear-resistant sleeve is covered with a corrugated sleeve. The inner end of the corrugated sleeve is connected to the box body, and the outer end extends to the outside of the wear-resistant sleeve, and is slidably connected to the mandrel corresponding to the outer end of the corrugated sleeve. There is a piston, the piston is driven by the power unit and pushes the corrugated sleeve inwards to compress it so that the cylinder body is tightened and fixed on the wear-resistant sleeve, and an encoder that can automatically identify the position of the box relative to the mandrel is installed on the mandrel. The controller is connected to the servo motor through the control system.

Owner:陈小青 +1

A terminal conformal module

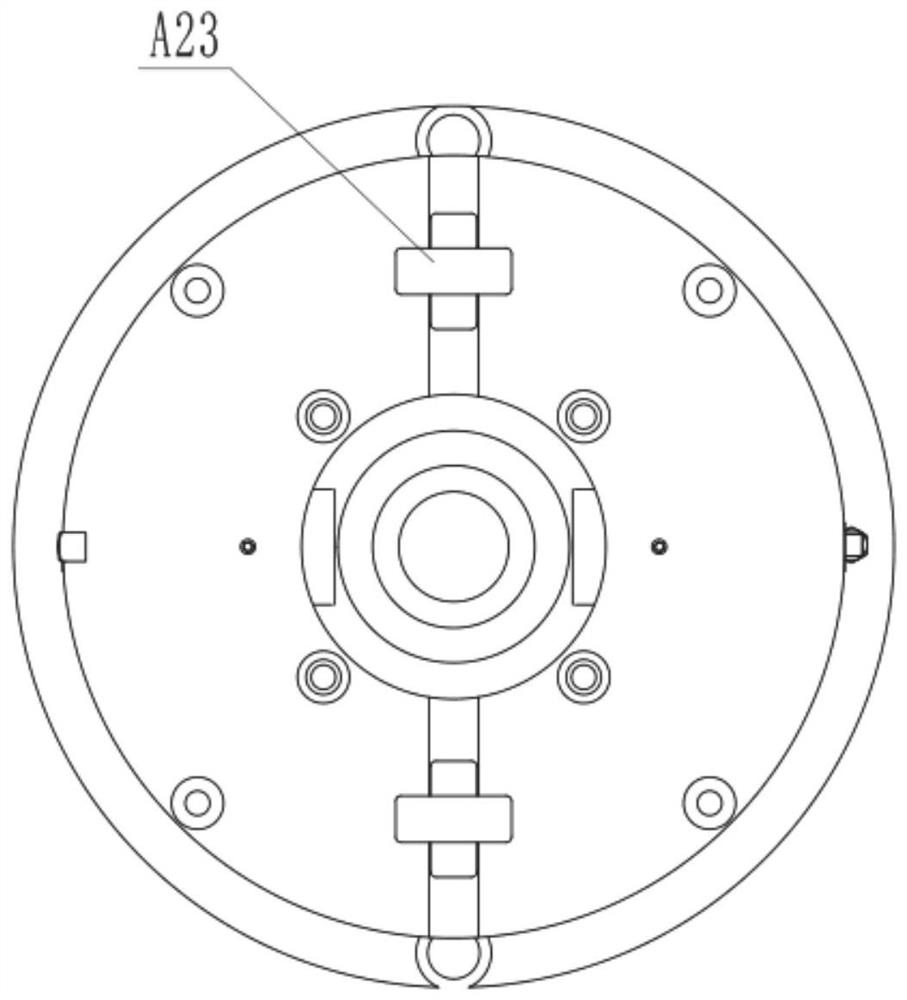

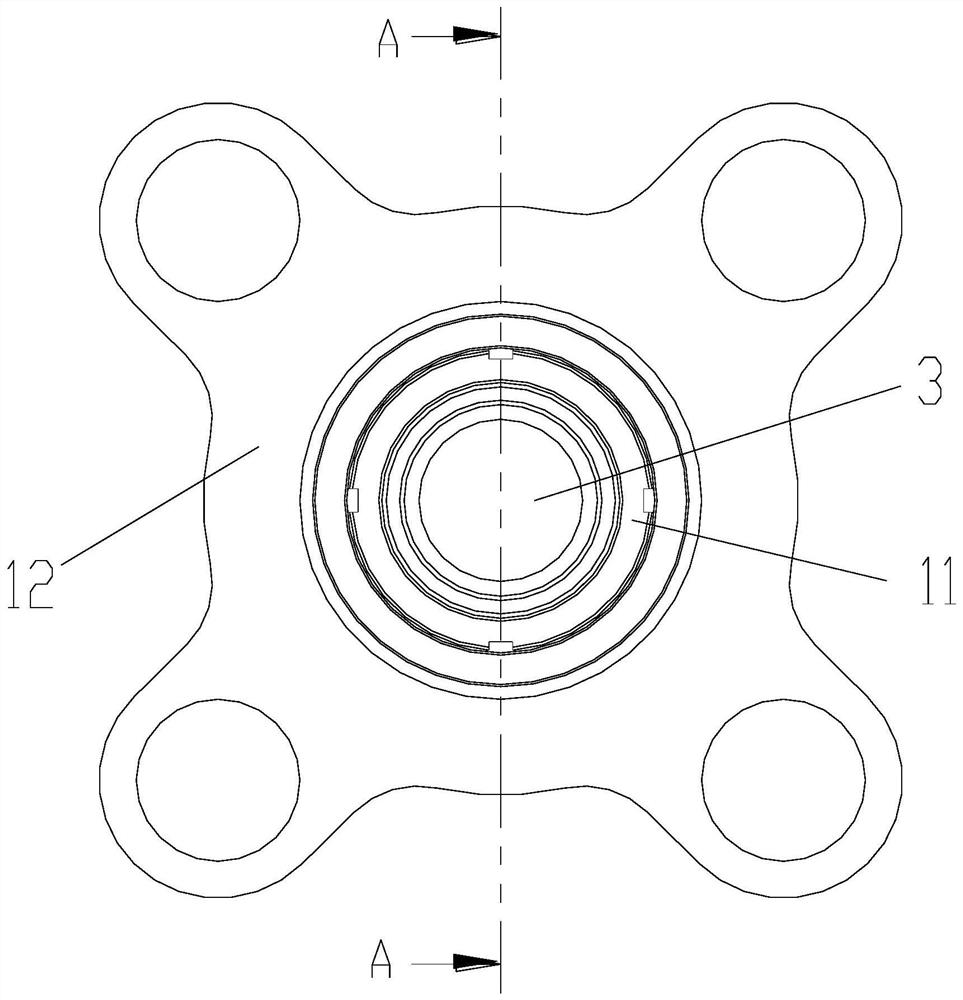

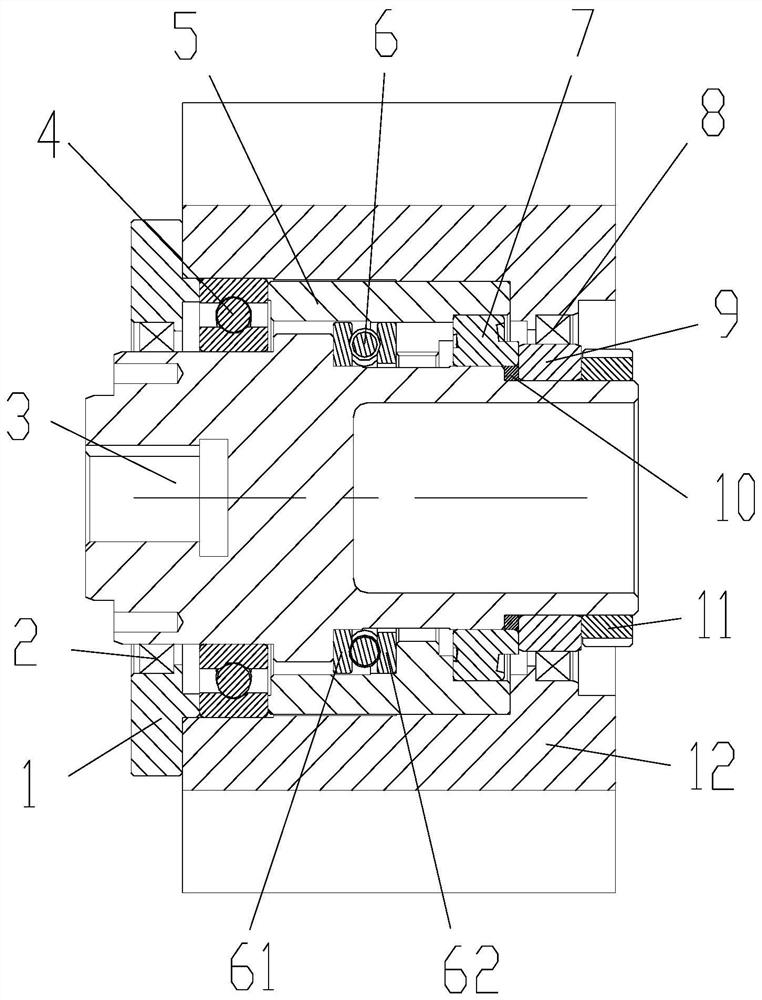

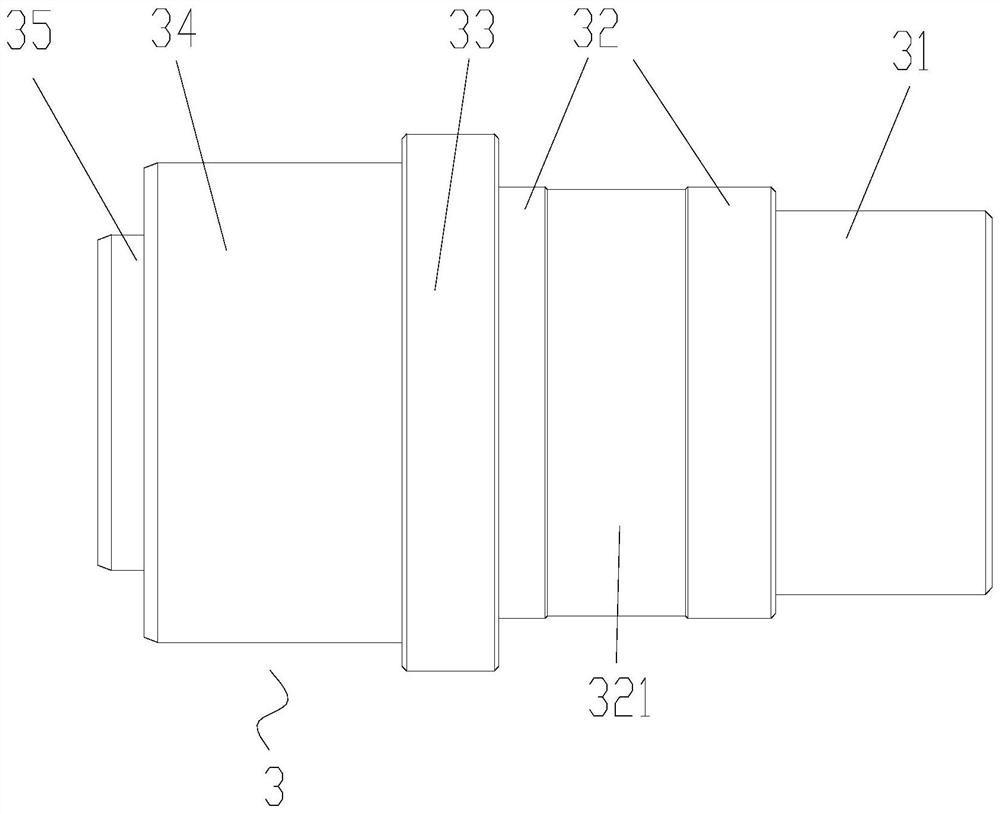

ActiveCN112247972BGuaranteed accuracy requirementsMeet the precision requirementsProgramme-controlled manipulatorControl theoryPendulum

The invention discloses a terminal conforming module, which solves the problem of poor conforming ability of the existing robot terminal system in the prior art, and has the advantages of compact installation, conforming movement in X and Y directions, and full freedom of swing compliance. The effect, the specific scheme is as follows: a terminal follow-up module, including a pendulum body, an XY compliance mechanism, a swing compliance mechanism, and an automatic centering mechanism, the pendulum body is coaxial with at least one set of XY compliance mechanisms and at least one set of swing compliance mechanisms Setting, the pendulum body is set between the XY compliance mechanism and the swing compliance mechanism, and supports the XY compliance mechanism and the swing compliance mechanism, the XY compliance mechanism can realize the compliance movement in the X direction and the Y direction, and the swing compliance mechanism can drive the pendulum body around The center of the swing ball realizes the swing, and the bottom end of the pendulum body is provided with a circular arc surface, which is used as an auxiliary track for swing compliance. The center of the auxiliary track coincides with the swing center of the swing compliance mechanism. the lower end of.

Owner:SHANDONG UNIV

Pre-molding seat structure and injection molding machine with same

InactiveCN112356387AFix work quality issuesGuaranteed locking and anti-loosening functionLocknutStructural engineering

The invention provides a pre-molding seat structure and an injection molding machine with the pre-molding seat structure. The pre-molding seat structure comprises a pre-molding seat which is used forbeing arranged on a transmission shaft in a sleeving manner, a first bearing arranged on the transmission shaft in a sleeving manner and located between the pre-molding seat and the transmission shaft, a locking piece arranged on one side of the first bearing and adjustably arranged in the axial position of the transmission shaft so as to axially lock the first bearing, and an isolation pad arranged on the inner side of the inner ring of the first bearing, wherein the isolation pad is fixedly arranged relative to the transmission shaft, so that after the locking piece pushes the inner ring ofthe first bearing by a preset distance in the axial direction of the transmission shaft, part of pressure of the locking piece is borne through the isolation pad. According to the technical scheme, the problem that in the prior art, the locking torque of a locking nut in a pre-molding seat structure is not easy to control, and consequently the working quality of a bearing is affected is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Lockable rotary drive mechanism and electric rotary seat and automobile

The present invention provides a lockable rotary drive mechanism, an electric rotary seat and an automobile. The rotary drive mechanism of the present invention includes a fixed bracket, a rotary bearing plate fixedly connected with the fixed bracket and having an inner ring, and a The locking disc with several protrusions is fixedly connected, and a wedge-shaped space is formed between the adjacent protrusions, which is jointly surrounded by the locking disc and the fixing bracket, and the wedge-shaped space is provided with a rigid sealing body and an elastic reset piece and the rotary drive mechanism also includes a rotary drive module fixedly connected to the fixed bracket, and a shift fork connected to the power output end of the rotary drive module. The rotary driving mechanism of the present invention has a locking function and can provide relatively large locking torque, thereby overcoming the shortcoming of insufficient locking torque in the prior art.

Owner:诺创汽车科技(上海)有限公司

A live lap compatible wire clip

ActiveCN112310675BSimple structureEasy to disassembleElectric connection structural associationsPhotovoltaic energy generationEngineeringScrew thread

The invention discloses a live lap compatible wire clamp, comprising a wire clamp fixed plate (3) and a wire clamp moving plate (2), the wire clamp fixed plate (3) and the wire clamp moving plate (2) are both It includes the middle part and the clamping parts on both sides, and the clamping parts on both sides are provided with grooves whose radius is tapered from the outside to the inside; the middle part of the wire clamping plate (3) is provided with a front end A locking screw (7) that is docked with the working tool to transmit torque is provided at the middle part of the wire clamping plate (2) corresponding to the locking screw (7) for the locking screw ( 7) A redundant through hole that moves parallel to the clamping direction, a compatible nut (6) is slidably installed in the redundant through hole, and the end of the locking screw (7) passes through the compatible nut (6) Thread fit connection. The wire clip of the invention has the advantages of simple structure, convenient disassembly and strong compatibility, and greatly reduces the cost of using wire diameters of various specifications.

Owner:YIJIAHE TECH CO LTD

A brake safety locking mechanism

ActiveCN113124074BLarge locking torqueSimple structureBrake actuating mechanismsActuatorsBrakeControl engineering

The invention relates to a safety locking mechanism for a brake, comprising: an additional locking component, located above multiple layers of the brake device and movably arranged on a push rod of the brake device; a starting component, and an additional locking component connected to drive the additional locking component to move axially along the ejector rod; when the activation component drives the additional locking component to move toward the direction close to the multi-layer, the additional locking component compresses the multi-layer; when the activation component drives When the additional locking component moves away from the multi-sheet layer, the additional locking component releases the multi-sheet layer. The present invention is simple in structure, easy to realize, and the risk of purely mechanical structure failure is small, and only the safety locking mechanism can be used as a manual locking mechanism without using an electromagnet, so that the stop brake device can be used even when the electromagnet It can still be used in the event of a failure, and can avoid the risk of overall structural failure caused by a single failure of the brake device on important occasions.

Owner:BEIJING SURGERII TECH CO LTD

Angle adjuster

The invention relates to an angle adjuster. A diaphragm spring is arranged between the front end surface of a locking tooth plate and the inner end surface of a fixed seat, a rotation shaft extruding out of the fixed seat is provided with an unlocking handle, the inner bore of the unlocking handle is provided with a boss, the boss is stuck in the left rotation slot on the rotation shaft, and the locking tooth plate is engaged with inner teeth of an annular gear during locking; the locking tooth plate is in fit connection with the rotation shaft through the boss and grooves, the fixed seat is in fit connection with the rotation shaft through the boss and the grooves, the excircle of the rotation shaft is provided with the grooves, and inner pores of the locking tooth plate and the fixed seat are respectively provided with a boss; the rotation shaft is axially fixed on the locking tooth plate through sticking a clasp in the clasp slot of the rotation shaft; and the unlocking handle is axially positioned through sleeving the flange of the unlocking handle in the inner pore of an entity skeleton. The angle adjuster which allows all the teeth to be engaged with each other during locking is a stepless adjustable angle adjuster which can be locked at an arbitrary angle and has the advantages of large locking moment, simple structure and reliable working. The angle adjuster which can be applied to seat chairs and also can be used to adjust angles of other entities has a wide application range.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A Radar Antenna Manual Pitching Mechanism

InactiveCN105428778BEasy to assemble and disassembleLight structureAntenna supports/mountingsRadarEngineering

The invention relates to a radar antenna manual pitching mechanism. The radar antenna manual pitching mechanism comprises a flat plate radar case assembly and a pitching bracket assembly; the flat plate radar case assembly comprises a box body, a left pitching shaft and a right pitching shaft; the left pitching shaft and the right pitching shaft have the same structure, and are fixed on the middle parts of the left wall and the right wall of the box body respectively; a left locking threaded hole and a left jacking projection block are arranged on the left side wall and the right side wall of the box body respectively; the pitching bracket assembly comprises a left supporting arm and a right supporting arm; a U-shaped groove that is in clearance fit with the left pitching shaft is formed in the uppermost end of the left supporting arm; a left pitching shaft locking screw is fixed on the left supporting arm on the outer side of the U-shaped groove; the left pitching shaft locking screw and the left pitching shaft are detachably hinged and matched; a left middle locking screw and a left compressing head that are matched with the left locking threaded hole and the left jacking projection block are in screw thread fit with the left supporting arm; and the right supporting arm and the left supporting arm have the same structure. The radar antenna manual pitching mechanism is light and handy in structure, high in locking torque, convenient to adjust and high in load capacity, and the radar antenna is convenient to disassemble and assemble.

Owner:HEBEI HANGUANG HEAVY IND

Guiding and locking device for vertical rotating type anti-flooding protective door

ActiveCN108386089AReduce shockSave layout spaceWing accessoriesWing fastenersHydraulic cylinderEngineering

The invention discloses a guiding and locking device for a vertical rotating type anti-flooding protective door. The device specifically comprises a guiding and locking stand column unit, a hydraulicdrive locking unit and a hydraulic drive locking unit mounting support, wherein the guiding and locking stand column unit is installed at the bottom of the cantilever end of a door body, the hydraulicdrive locking unit is arranged on the hydraulic drive locking unit mounting support, and the hydraulic drive locking unit mounting support is fixed on the ground according to the limit position afterthe door body is opened. When the door body is opened to the limit position, a hydraulic cylinder in the hydraulic drive locking unit drives two sets of spring bolt units to hold tightly a locking stand column on the guiding and locking stand column unit so as to complete locking of the door body, and therefore, the door body is fixed; and the device has the advantages of being simple in structure, small in occupied space, high in locking speed, large in locking torque and stable and reliable in operation.

Owner:GUANGZHOU METRO DESIGN & RES INST +1

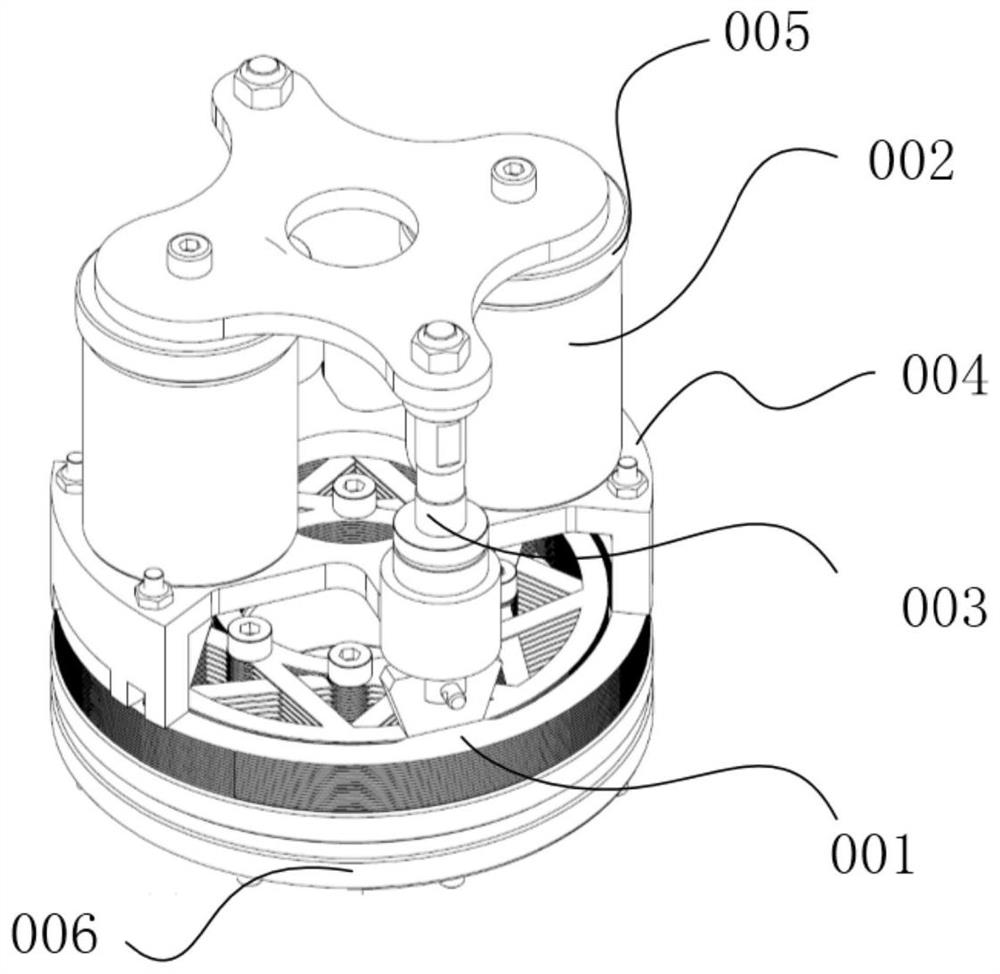

Surgical mechanical arm joint hydraulic locking power generator

InactiveCN101700656BReduce volumeCompact structureDiagnosticsSurgical robotsChest surgeryNeurosurgery

The invention discloses a surgical mechanical arm joint hydraulic locking power generator. The power generator comprises a supporting mechanism, a transmission mechanism, a thrust mechanism in electric control and a force-generating mechanism, wherein the thrust mechanism contains a lead screw housing; the lead screw housing is fixedly linked with a connection cover of the transmission mechanism,the center axle of the thrust mechanism is vertical to the axle of the transmission mechanism; the force-generating mechanism and the transmission mechanism both have symmetric structures, share the same axle and are fixedly locked through loop nuts arranged on the periphery of the force-generating mechanism, and the supporting mechanism is fixedly linked with the thrust mechanism. The invention provides a hydraulic power source of joint locking to ensure that the mechanical arm can be used as the puncture positioning device and supporting device for the surgery; and the power generator of the invention has the advantages of small volume, compact structure, light weight, large locking torque, convenient operation and maintenance, long service life and the like, and is applicable to joint positioning of the mechanical arm used in the minimally invasive sugery of neurosurgery, chest surgery, orthopeadic surgery, stomatology and the like.

Owner:昆山市工业技术研究院有限责任公司

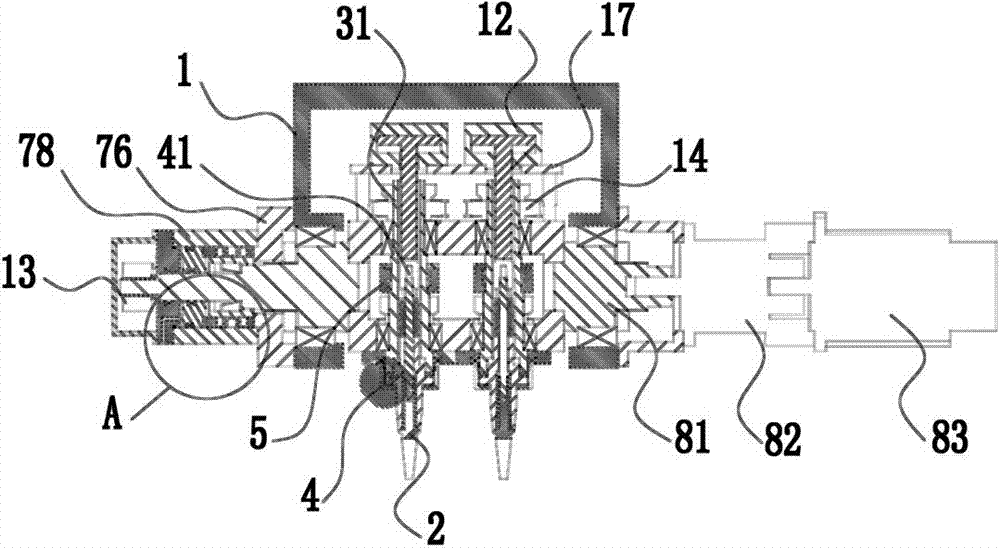

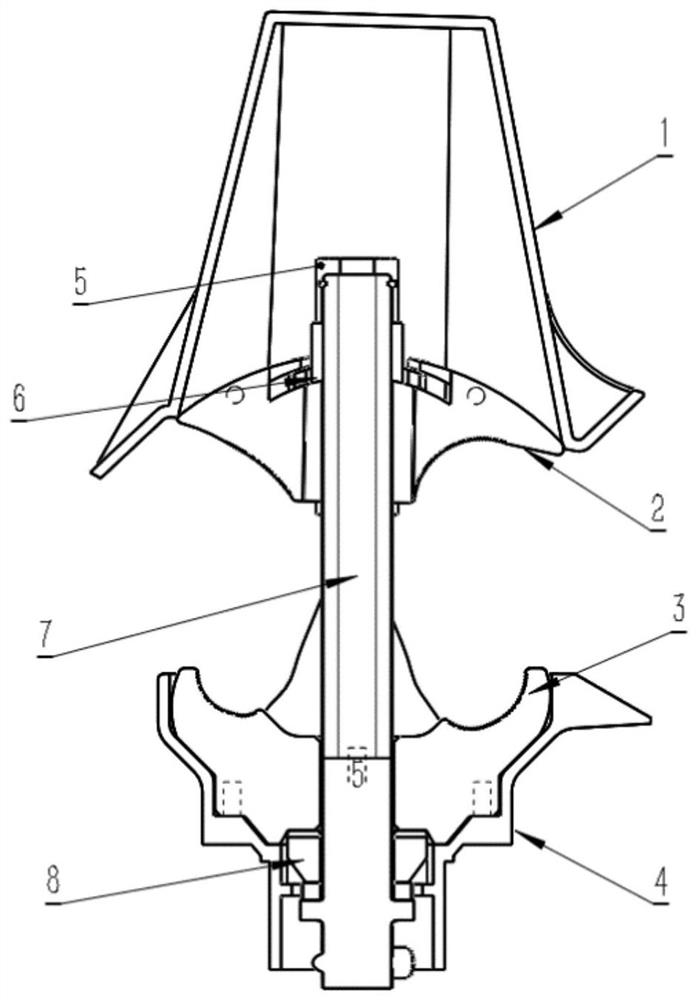

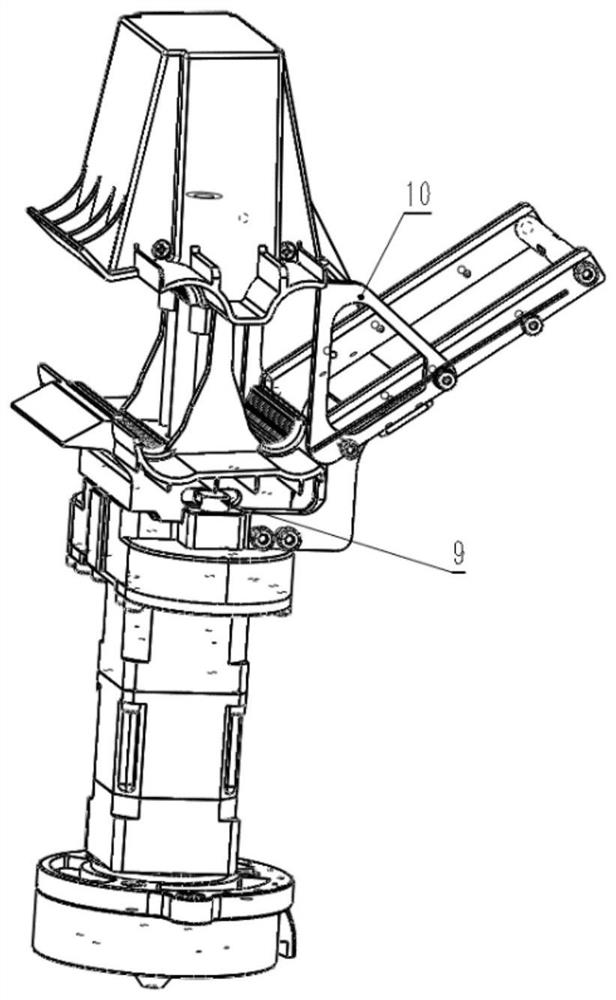

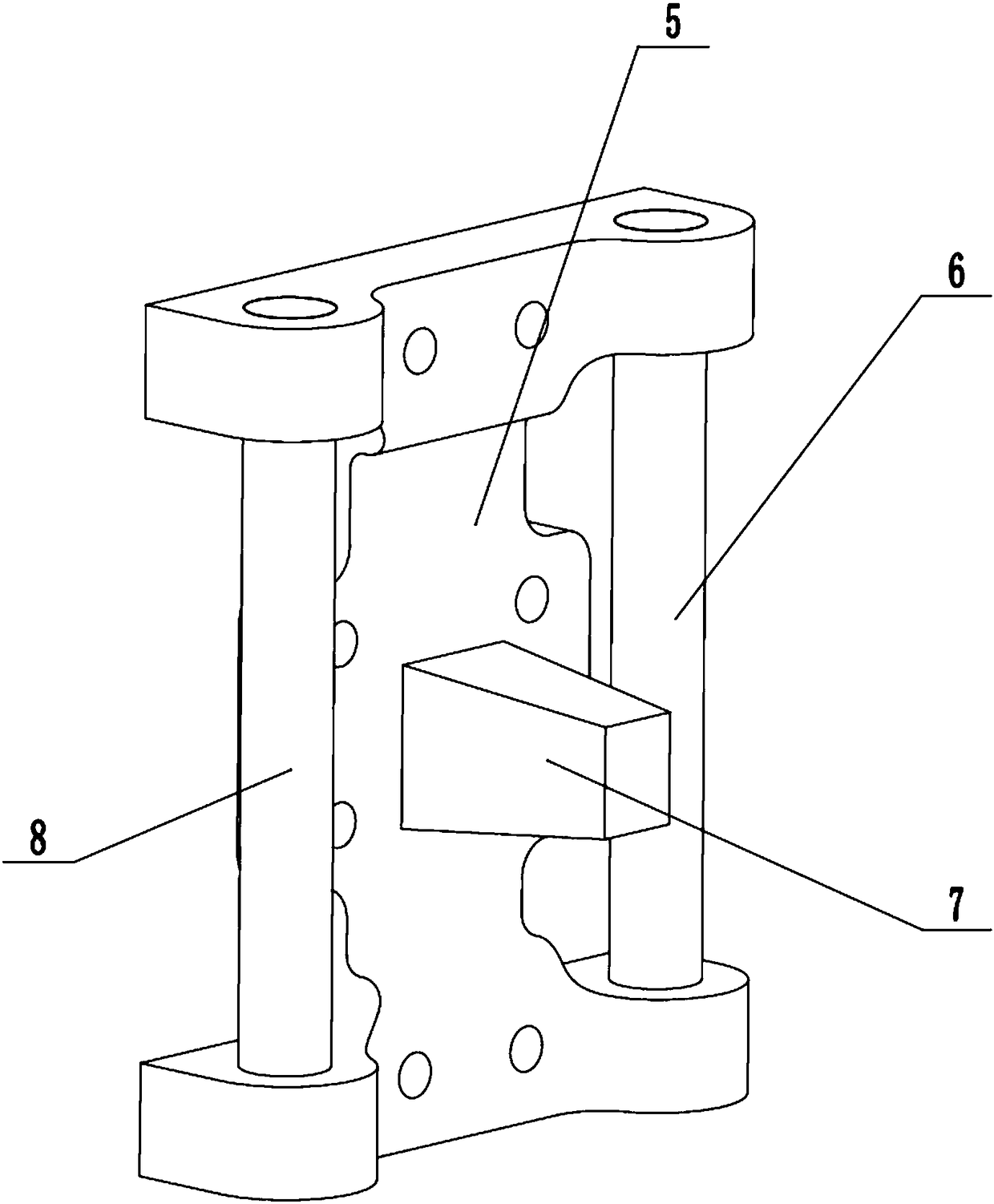

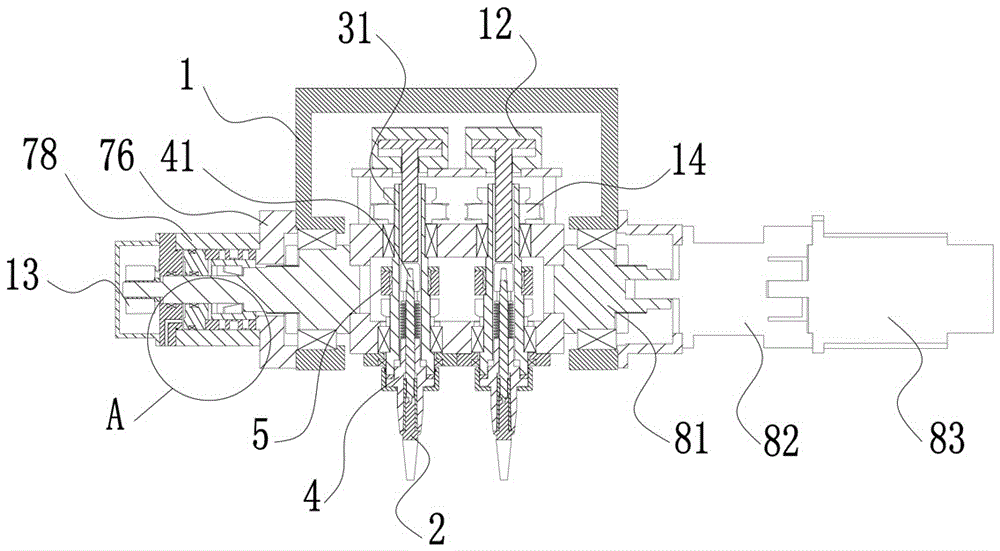

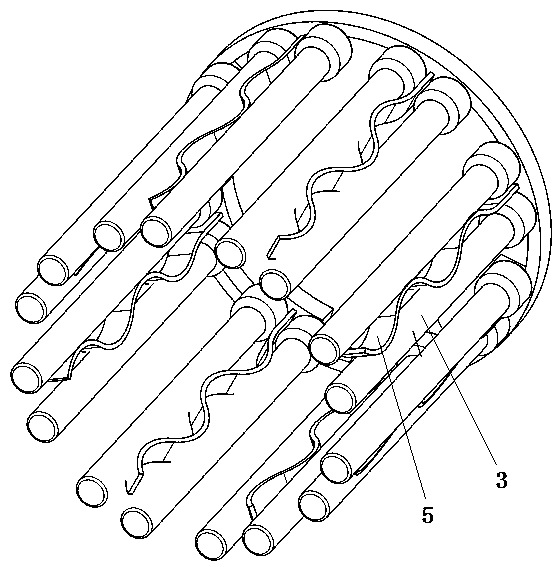

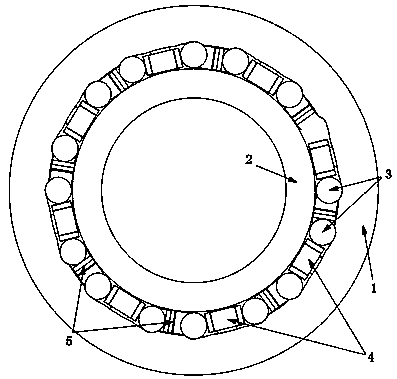

An indexing grinding head device with feedback detection and hydraulic locking positioning mechanism

ActiveCN103802020BLarge locking torqueHigh positioning accuracyGrinding feed controlGrinding work supportsMechanical engineeringPhysics

The invention discloses a grinding head device, which provides a feedback detection and hydraulic lock with large locking torque, high positioning accuracy, low manufacturing cost, and can accurately lock the polyhedral workpiece to be processed on the position of the rotating surface. The indexing grinding head device with a tight positioning mechanism solves the technical problems in the prior art such as low positioning accuracy of polyhedral workpieces, high manufacturing cost, and inability to meet the processing requirements of high-precision polyhedrons. It includes a box, in which there is a turning mechanism, and on both sides of the box are respectively equipped with a corner driving mechanism and a corner locking mechanism that can change the pitch angle of the turning mechanism. The tubular indexing shaft, the indexing shaft extends through the front wall of the box to the outside of the box, the workpiece fixing rod is clamped and fixed on the corresponding indexing shaft outside the box by the clamping mechanism, and the corresponding indexing shaft in the box An indexing plate with indexing teeth is sheathed and fixed on the shaft, and the corresponding box above the indexing plate is provided with a taper pin that can be mated and plugged between the corresponding two indexing teeth on the indexing plate.

Owner:陈小青

Shaft sleeve mechanism capable of being locked at any angle and position in two directions

PendingCN109083943AReliable two-way high torque lockingLarge locking torqueFreewheel clutchesElectricityEngineering

The invention relates to the field of rolling mechanisms, in particular to a shaft sleeve mechanism capable of being locked at any angle and position in two directions. A rolling mechanism comprises amechanism housing, a shaft, roller pins, unlocking pin discs, elastic piece discs, wedge-shaped groove large head ends and wedge-shaped grooves; the wedge-shaped grooves are distributed in the innerwall of the mechanism housing, a wedge-shaped groove large head end is arranged on one side of each wedge-shaped groove, one end of each roller pin is arranged in the corresponding wedge-shaped grooveand disposed in the mechanism housing, the elastic piece discs and the unlocking pin discs are movably connected in two openings of the mechanism housing respectively, and every two roller pins constitute a roller pin group; elastic pieces are distributed on the elastic piece discs, each elastic piece is arranged between the two corresponding roller pins constituting a roller pin group, and unlocking pins for penetrating through the portion between every two adjacent roller pin groups are distributed on the unlocking pin discs. The locking torque is large, the size is small, the middle part can also be designed to be hollow, working media such as gas, liquid and electricity can be passed, signal cables can be connected, and the rolling mechanism can be conveniently integrated into a wholemachine for use.

Owner:是云树

Biplanar frictional two-freedom-degree joints based on hydraulic pressure

The invention relates to biplanar frictional two-freedom-degree joints based on hydraulic pressure. The outer edge of the upper side of the lower plane of a T-shaped shaft of an upper joint is provided with wedge-shaped faces, a bar part is sleeved with a force transmission slide block of the upper joint, the diameter of a round hole of the force transmission slide block of the upper joint is larger, the bar part is installed in a casing of the upper joint by a bearing, extends out to be connected with one end of a platform body of the joints, and the end part of a push bar is matched with the two wedge-shaped faces of the T-shaped shaft of the upper joint; a T-shaped shaft of a lower joint is connected below the other end of the platform body of the joints, the lower end is sealed in a sealing cover of the lower joint, and the sealing cover of the lower joint is fixedly connected with a supporting shaft of the joints; and an ejector bar is installed in a hollow structure of the T-shaped shaft of the lower joint, a sealing bolt is installed at the hollow bottom, a distance exists between the lower end of the ejector bar and the lower end of an ejector bar of the sealing bolt, and the upper end contacts with the force transmission slide block of the upper joint. The invention has small volume, compact structure, light weight, large locking moment, simple structure and small joint clearance after being locked and can be suitable for locking the joints of various miniature type mechanical arms with lighter end static bearing.

Owner:昆山市工业技术研究院有限责任公司

Bolt positioning type blade rotating structure and blade type pneumatic rotating index plate

The invention belongs to the technical field of control components, and particularly discloses a bolt positioning type blade rotating structure and a blade type pneumatic rotating index plate. The bolt positioning type blade rotating structure comprises a shell assembly; a blade pneumatic cavity and a bolt pneumatic cavity are arranged at an input end of the shell assembly; a blade shaft is rotatably connected into the blade pneumatic cavity; blades of the blade shaft are contained in the blade pneumatic cavity; a plug pin is slidably connected into the plug pin pneumatic cavity; an output end of the shell assembly is provided with an output piece and a linkage cavity; a connecting end of the output piece is located in the linkage cavity; a tail end of the plug pin extends into the linkage cavity and is intermittently inserted into or withdrawn from an indexing positioning hole of the output piece; and a tail end of the blade shaft extends into the linkage cavity and is rotatably connected with the output piece along with retreating of the plug pin. The blade rotating structure integrates the rotating action of the blades and the sliding positioning action of the plug pin, and has the advantages of being small in size, light in weight, large in driving and locking torque force, high in positioning precision and capable of smoothly switching forward rotation and reverse rotation.

Owner:东莞市迈阔自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com