Lockable rotary driving mechanism, electric rotary seat and automobile

A rotary drive mechanism and locking technology, applied in the direction of movable seats, vehicle seats, vehicle parts, etc., can solve the problems affecting seat comfort, hidden dangers, insufficient locking torque of electric rotating seats, etc. Effects of insufficient locking torque and large locking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment relates to a lockable rotary drive mechanism, which can be used on a car seat to realize the electric rotary adjustment of the seat, and at the same time, the locking torque after the seat adjustment can be improved through the rotary drive mechanism , to ensure the stability of the seat.

[0045] It should be noted that this embodiment specifically uses a car seat as an example to describe the structure and use of the rotary drive mechanism. It can be used in seats on other occasions to also realize the rotatable adjustment of the seat and provide better locking torque.

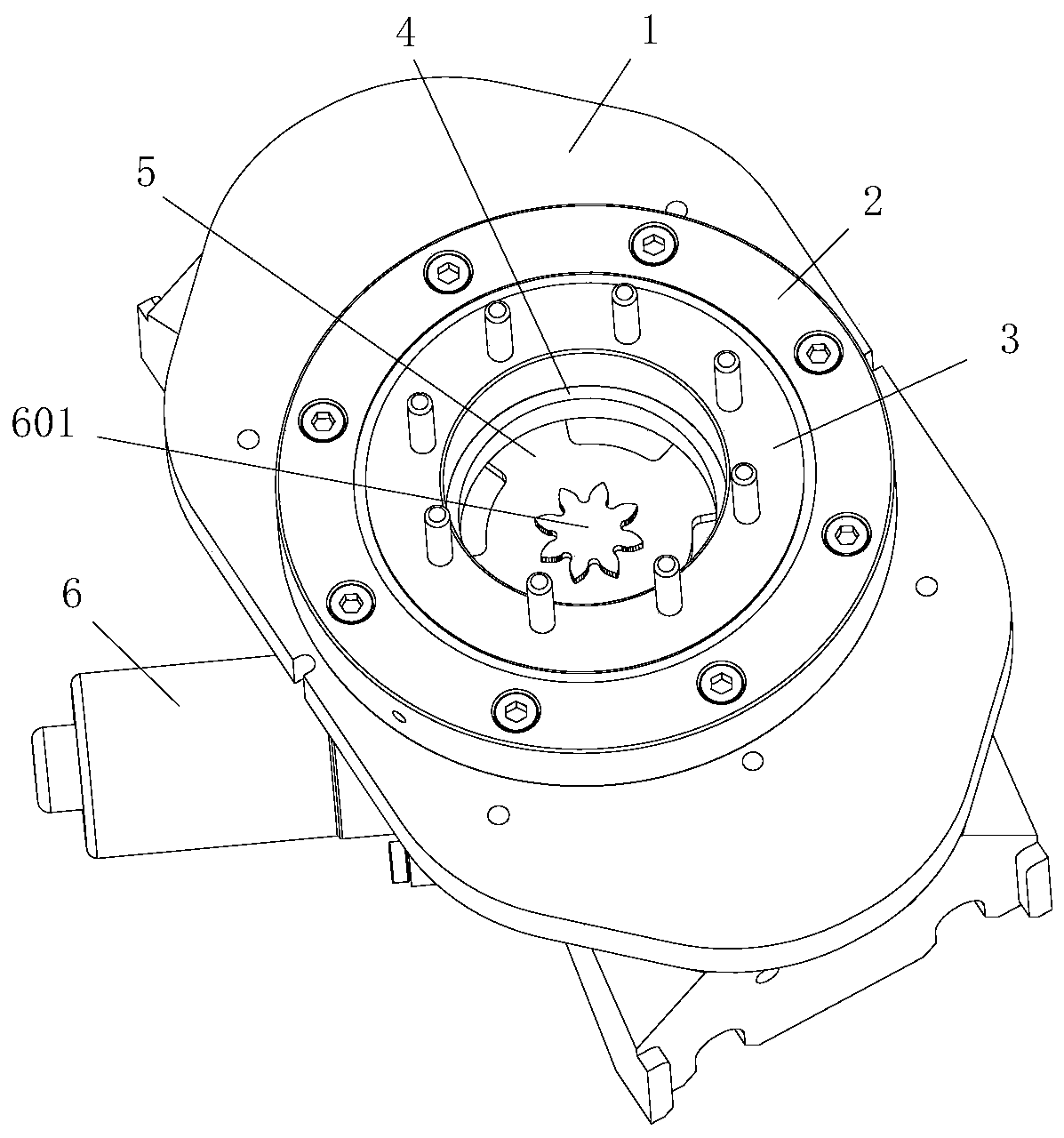

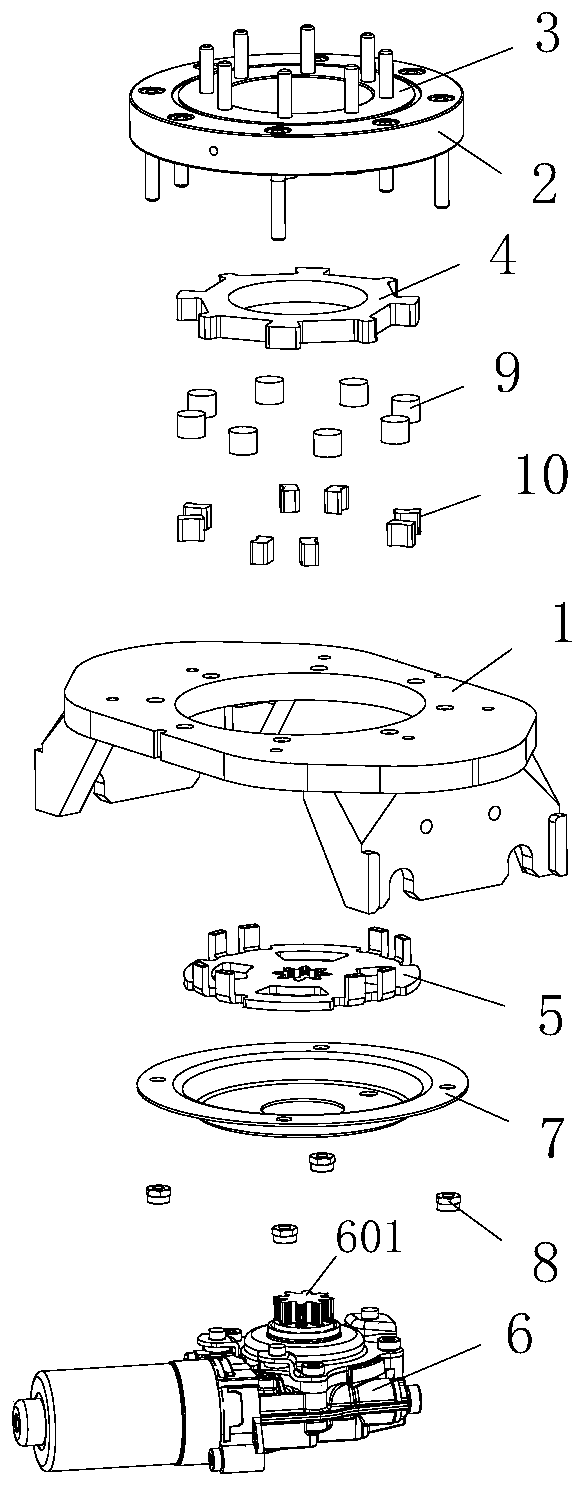

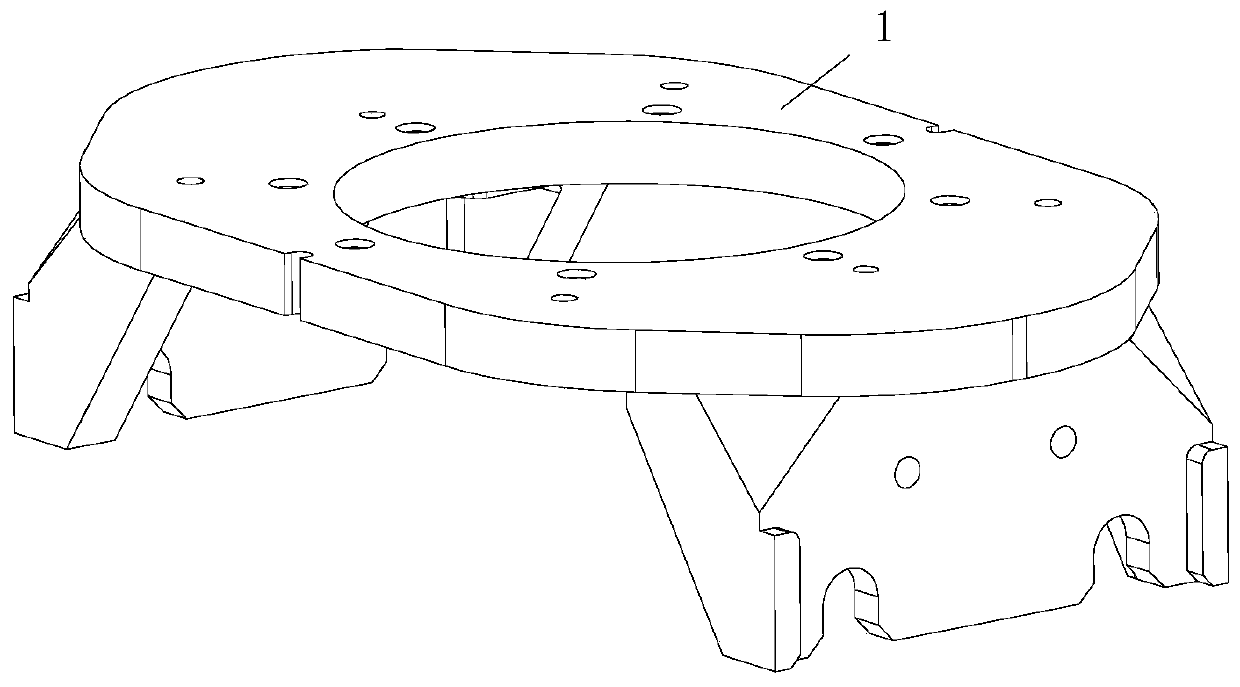

[0046] In overall design, the figure 1 and combine figure 2 As shown in , the lockable rotary drive mechanism of this embodiment includes a fixed bracket 1, a rotary bearing plate, a locking plate 4, a rotary drive module, a shift fork 5, a rigid sealing body 9 and an elastic reset member 10 .

[0047] Wherein, the fixed bracket 1 of this embodiment constitutes the load-bearing ba...

Embodiment 2

[0066] This embodiment relates to an electric swivel seat, which includes a seat body with a seat frame, and a lockable rotary drive mechanism as in Embodiment 1, and the above-mentioned seat frame and the rotary drive mechanism Circle 3 is fixedly connected.

[0067] Simultaneously, this embodiment also relates to a kind of automobile, promptly is equipped with above electric rotating seat on this automobile.

[0068] The automobile and the electric rotating seat of this embodiment, by applying the rotating drive mechanism in Embodiment 1, not only can realize the electric rotating adjustment of the seat, but also can provide a larger locking torque, which can overcome the locking torque in the prior art. It has the disadvantage of small stop torque, but has good practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com