An indexing grinding head device with feedback detection and hydraulic locking positioning mechanism

A locking positioning and feedback detection technology, which is applied to the parts of grinding machine tools, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problem of inability to meet the requirements of high-precision polyhedron processing, low positioning accuracy of polyhedron workpieces, and locking Large torque and other problems, to achieve the effect of large locking torque, low manufacturing cost and high positioning accuracy

Active Publication Date: 2016-06-22

陈小青

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention mainly provides an indexing mechanism with feedback detection and hydraulic locking and positioning mechanism, which has large locking torque, high positioning accuracy and low manufacturing cost, and can accurately lock the polyhedral workpiece to be processed on the position of the rotating surface. The grinding head device solves the technical problems of low positioning accuracy of polyhedral workpieces, high manufacturing costs, and inability to meet the processing requirements of high-precision polyhedrons in the prior art.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0028] The specific embodiments described herein are merely illustrative of the concepts of the present invention. Those skilled in the art to which the present invention belongs can make various modifications or supplements to the described specific embodiments or adopt similar methods to replace them, but they will not deviate from the spirit of the present invention or go beyond the definition of the appended claims range.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

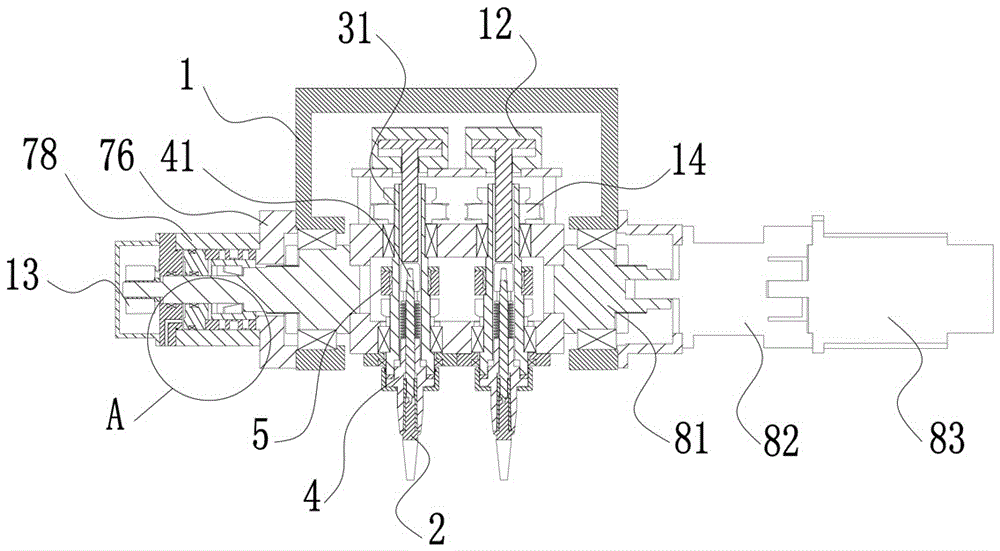

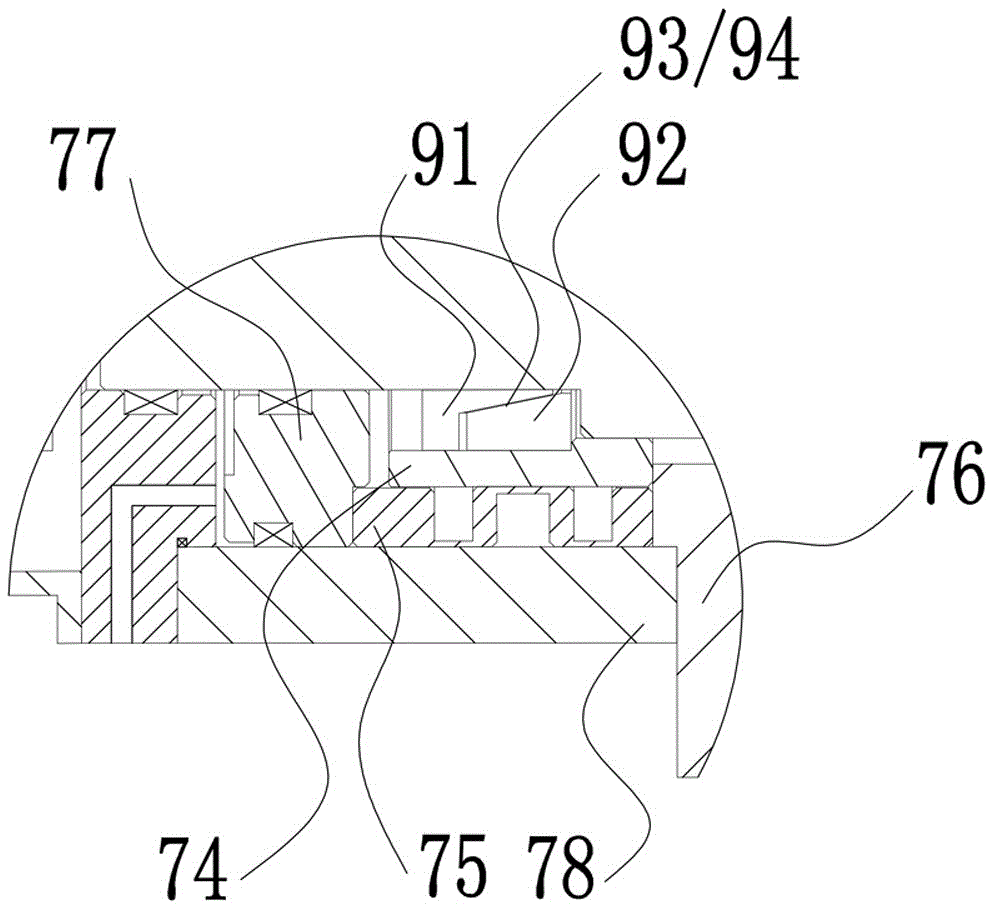

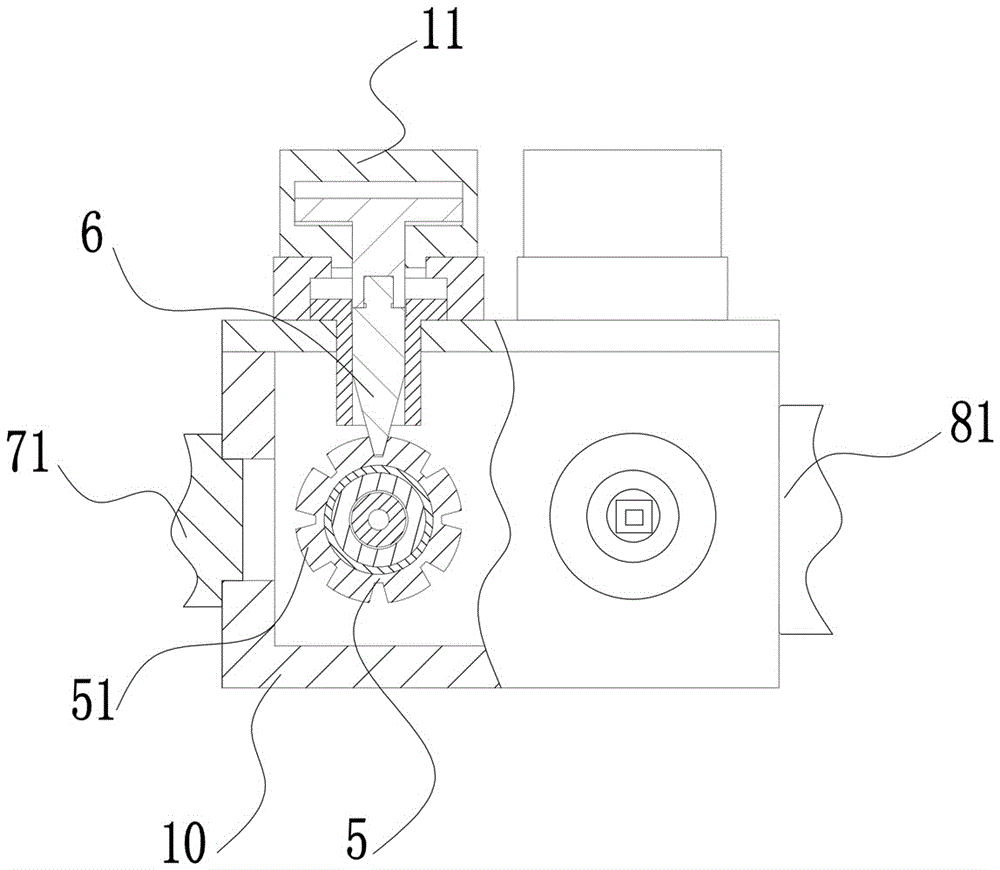

The invention discloses a grinding head device, which provides a feedback detection and hydraulic lock with large locking torque, high positioning accuracy, low manufacturing cost, and can accurately lock the polyhedral workpiece to be processed on the position of the rotating surface. The indexing grinding head device with a tight positioning mechanism solves the technical problems in the prior art such as low positioning accuracy of polyhedral workpieces, high manufacturing cost, and inability to meet the processing requirements of high-precision polyhedrons. It includes a box, in which there is a turning mechanism, and on both sides of the box are respectively equipped with a corner driving mechanism and a corner locking mechanism that can change the pitch angle of the turning mechanism. The tubular indexing shaft, the indexing shaft extends through the front wall of the box to the outside of the box, the workpiece fixing rod is clamped and fixed on the corresponding indexing shaft outside the box by the clamping mechanism, and the corresponding indexing shaft in the box An indexing plate with indexing teeth is sheathed and fixed on the shaft, and the corresponding box above the indexing plate is provided with a taper pin that can be mated and plugged between the corresponding two indexing teeth on the indexing plate.

Description

technical field [0001] The invention relates to a polyhedron surface grinding processing device, in particular to a feedback detection and hydraulic locking positioning mechanism with low manufacturing cost and large locking torque, which can accurately lock the polyhedron workpiece to be processed on the position of the turning surface The indexing grinding head device. Background technique [0002] The early polyhedron grinding process is generally manual operation, not only the labor intensity is high, the production efficiency is low, but also the quality of the product cannot be guaranteed, and the reject rate is high. Hold the clamping mechanism of the polyhedron, and make the surface of the polyhedron rub against the surface of the rotating grinding wheel below to realize the grinding surface processing. After the polyhedron completes a processing surface, it is necessary to rotate the polyhedron to convert the processing surface. In order to improve production effici...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B41/04B24B49/08

CPCB24B41/06B24B49/00

Inventor 郭晋秦黄永生郑永黄金星

Owner 陈小青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com