Bolt positioning type blade rotating structure and blade type pneumatic rotating index plate

A rotating structure and positioning technology, which is used in precision positioning equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of inability to merge forward rotation and reverse rotation, high production costs, and low positioning accuracy. The effect of light weight, low cost and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

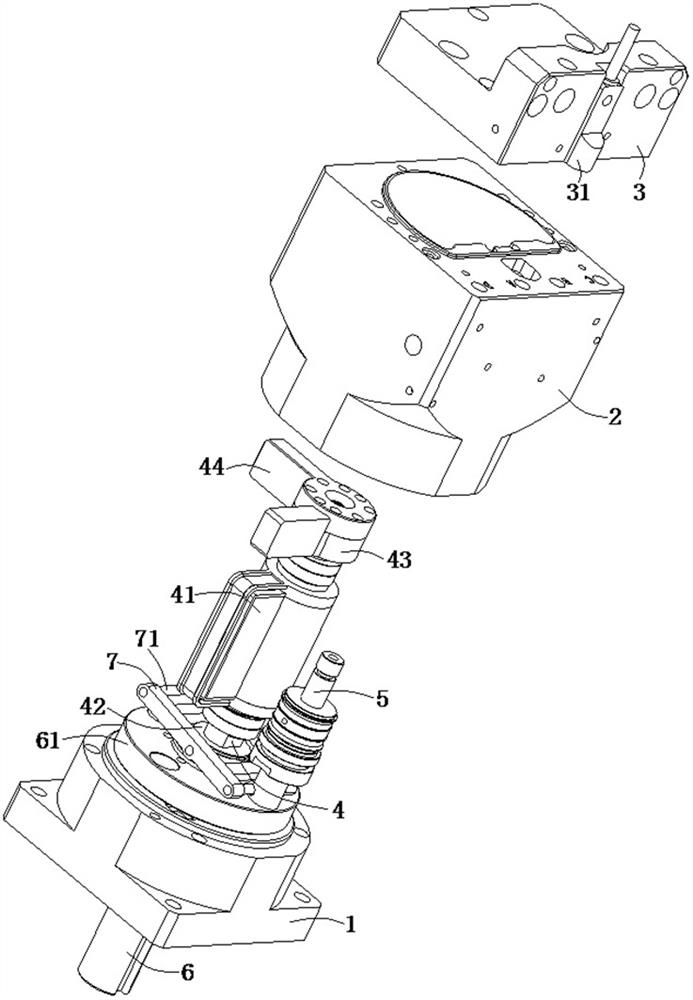

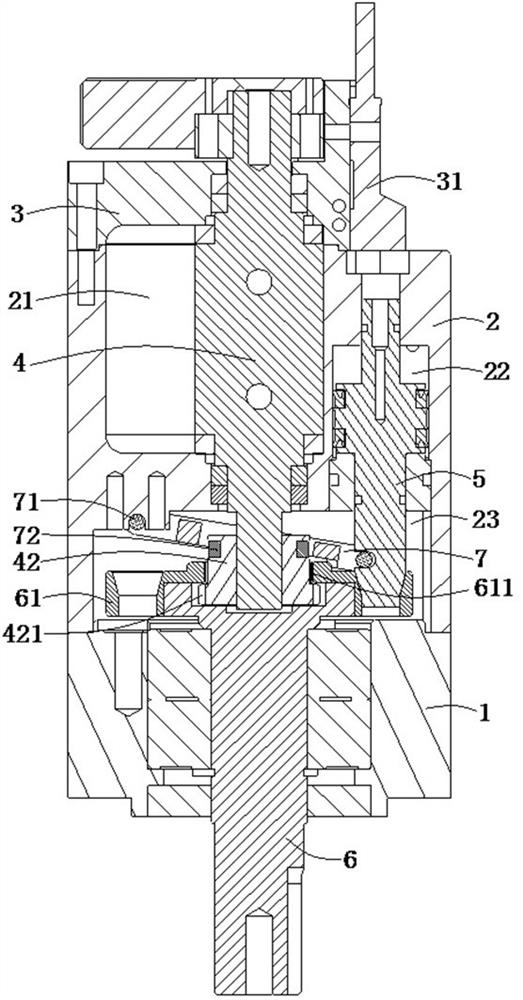

[0030] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

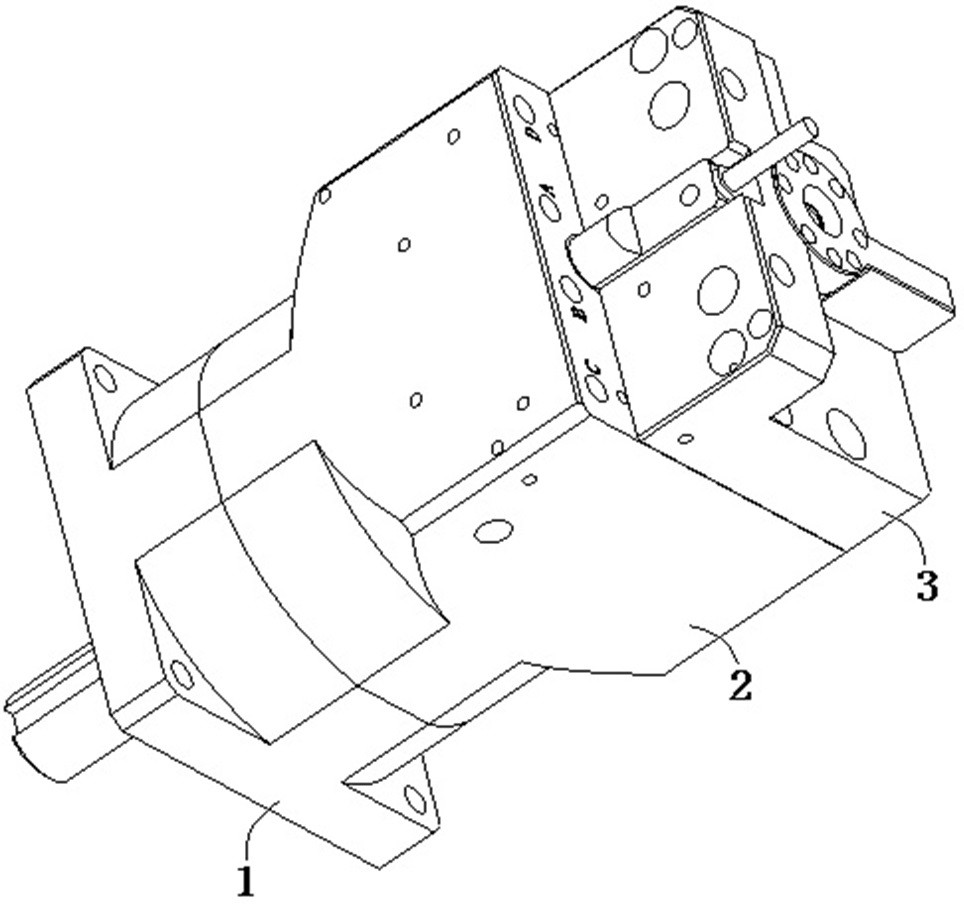

[0031] refer to Figure 1 to Figure 7 , a pin positioning type blade rotating structure, including a housing assembly, the input end of the housing assembly is provided with a blade aerodynamic chamber 21 and a bolt aerodynamic chamber 22, a blade shaft 4 is rotatably connected in the blade aerodynamic chamber 21, the blade The blade 41 of the shaft 4 is accommodated in the blade aerodynamic chamber 21, the pin aerodynamic chamber 22 is slidingly connected with the pin 5, the output end of the housing assembly is provided with an output piece and a linkage chamber 23, and the connection end of the output piece is located in the linkage chamber 23 , the end of the pin 5 extends into the linkage cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com