Double-drive single-swing head for vertical machining center

A technology of vertical machining center and single swing head, which is applied in the direction of metal processing equipment, metal processing machinery parts, driving devices, etc. The effect of moving and avoiding the problem of twisting and deformation of the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

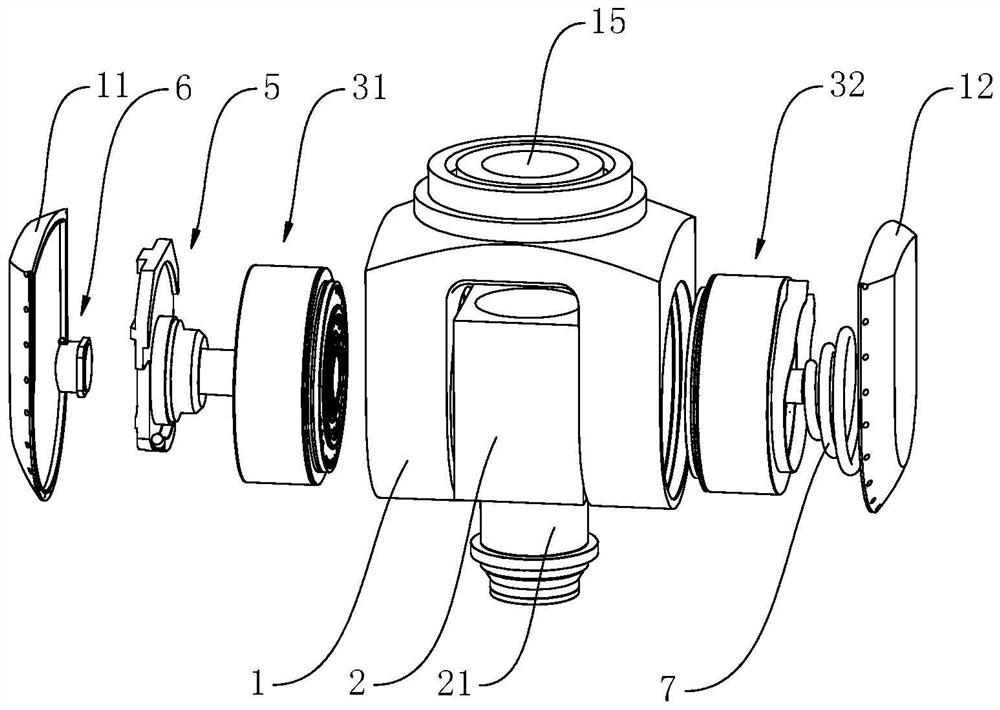

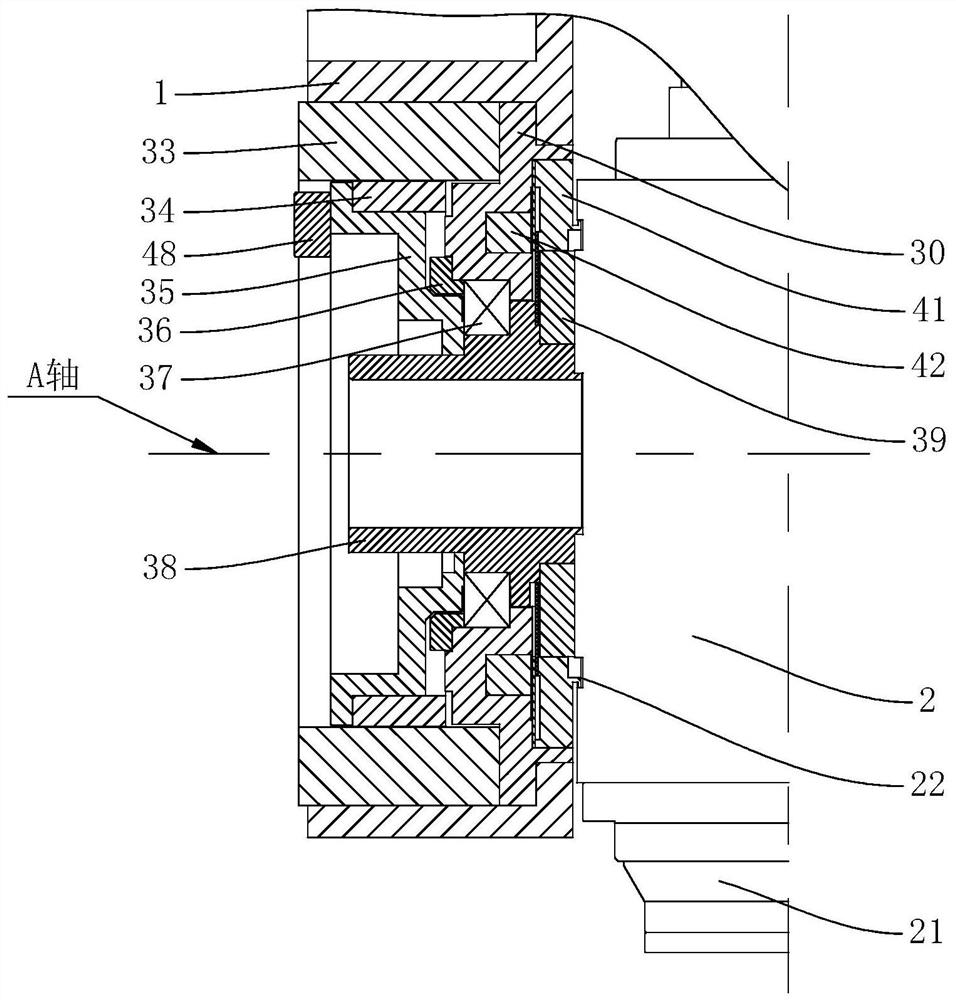

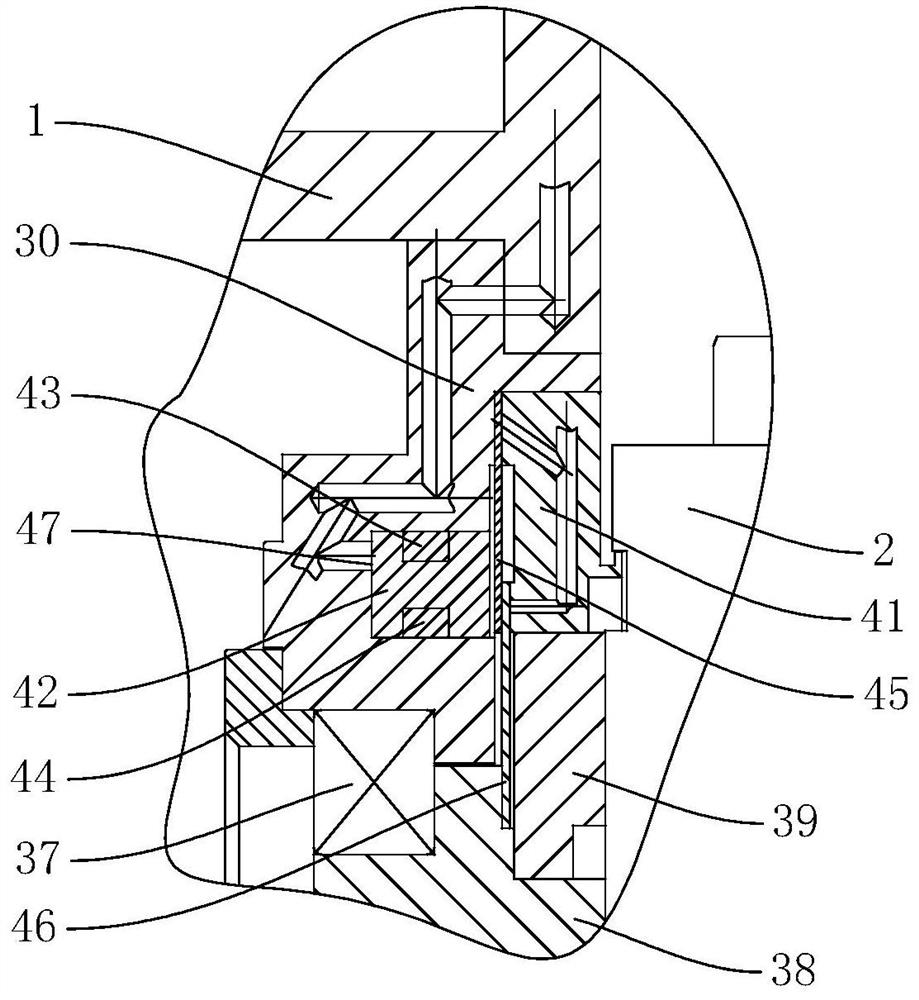

[0022] The double-drive single-swing head for the vertical machining center in Embodiment 1, as shown in the figure, includes the swing head box 1, the spindle box 2, the main shaft 21, and the A-axis left drive assembly 31 installed in the swing head box 1, A-axis right drive assembly 32, A-axis oil separator assembly 5, A-axis encoder assembly 6, A-axis hard limit junction and main shaft pipeline outlet unit. Installed upright on the headstock 2, the lower end of the main shaft 21 protrudes from the main headstock 2, the A-axis left drive assembly 31 and the A-axis right drive assembly 32 are symmetrically arranged on both sides of the headstock 2, and the A-axis left drive assembly 31 includes a left The torque motor assembly and the left hydraulic clamping mechanism, the A-axis right drive assembly 32 includes the right torque motor assembly and the right hydraulic clamping mechanism, the left torque motor assembly and the right torque motor assembly are used to provide dri...

Embodiment 2

[0028] The vertical machining center of embodiment 2 uses a double drive and single swing head. The difference from embodiment 1 is that in embodiment 2, a leak structure is provided between the bearing seat 30 and the swing head box 1, and the oil drain structure includes a connected The first oil passage 81 and the second oil passage 82, the first oil passage 81 is opened on the side wall of the bearing seat 30, the second oil passage 82 is opened on the side wall of the swing head box 1, the first oil passage 81 and the The gap between the bearing seat 30 and the outer brake pad 45 communicates, and the second oil passage 82 communicates with the outside world.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com