Rotary shaft feedback detection hydraulic locking system

A feedback detection and locking system technology, applied in the direction of positioning devices, large fixed members, measuring/indicating equipment, etc., can solve the problem that the position of the cabinet cannot be adjusted and corrected in time, the position of the cabinet cannot be effectively identified and fed back, and cannot meet the requirements High-precision polyhedron processing requirements and other issues, to achieve the effect of simple and reliable fixing method, simple structure, and large locking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

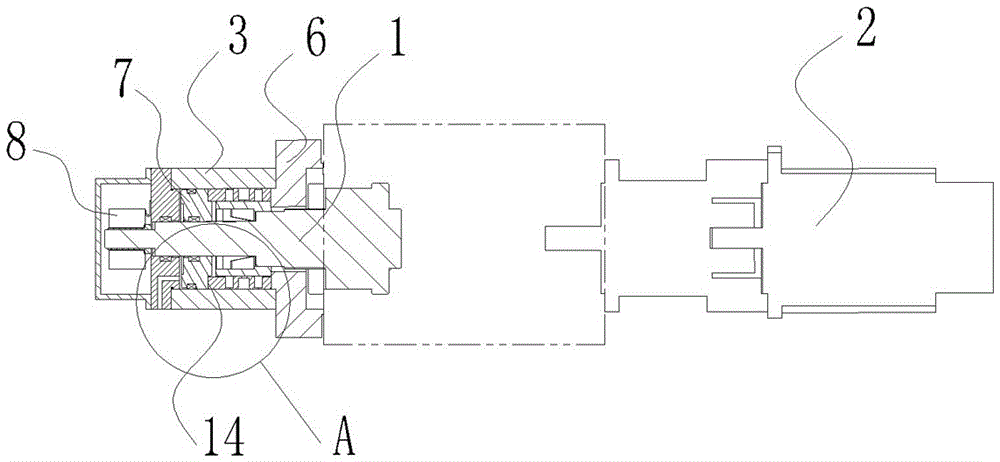

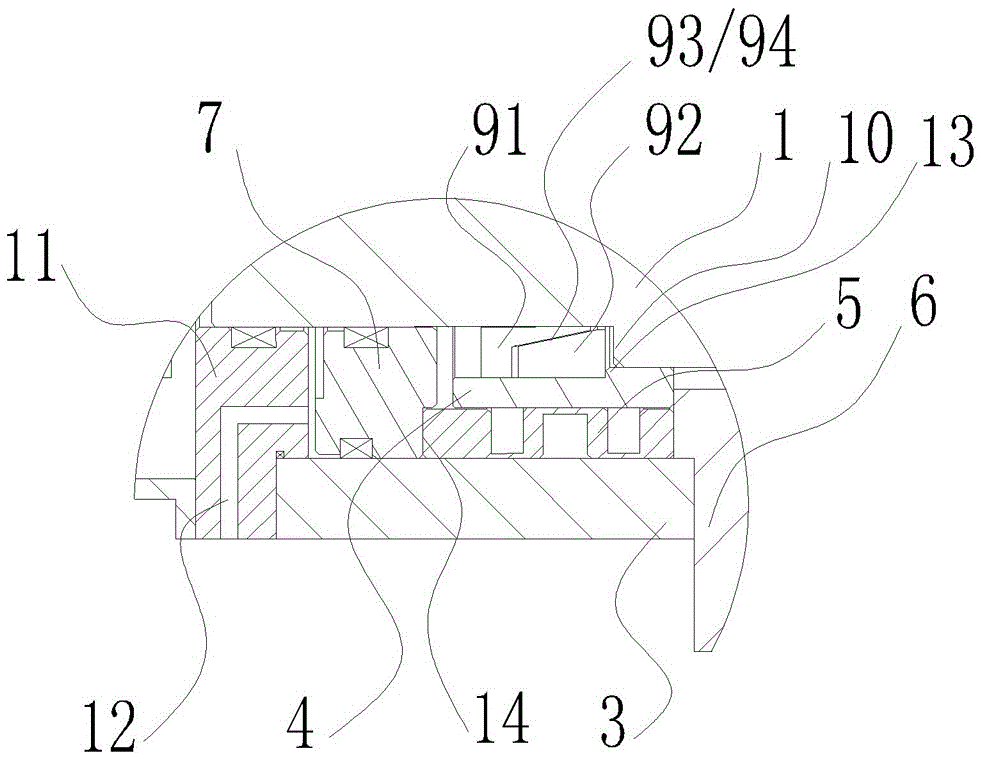

[0018] Such as figure 1 and figure 2 As shown, a rotary shaft feedback detection hydraulic locking system of the present invention includes a mandrel 1 and a servo motor 2 coaxially connected to the right end of the mandrel 1 through a coupling sleeve. The box body 6 of the blank, the left end of the mandrel 1 is coaxially sleeved with a cylinder body 3, the inner end of the cylinder body 3 is fixed on the box body 6, and the corresponding mandrel 1 in the cylinder body 3 is tightened by conical expansion A ring-shaped wear-resistant sleeve 4 is fixed in the mechanism suit, and the conical expansion mechanism includes an inner split ring 91 and an outer split ring 92 that are matched with each other. It is embedded in the middle hole of the wear-resistant sleeve 4. One end of the inner split ring 91 opposite to the outer split ring 92 has an outer tapered surface 93, and one end of the outer split ring 92 opposite to the outer split ring 93 has an inner ring. The tapered s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com