Patents

Literature

61results about How to "The fixing method is simple and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

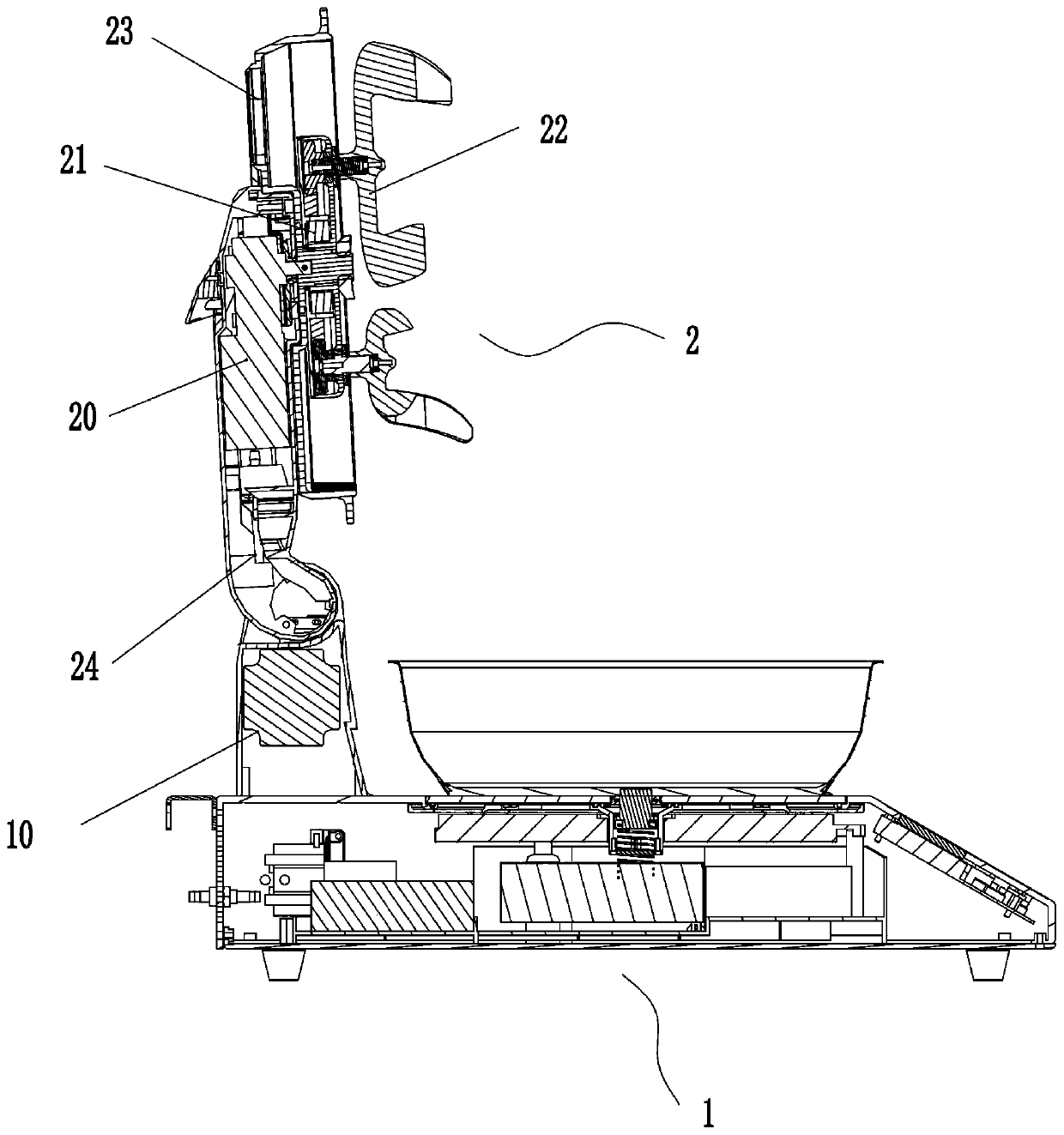

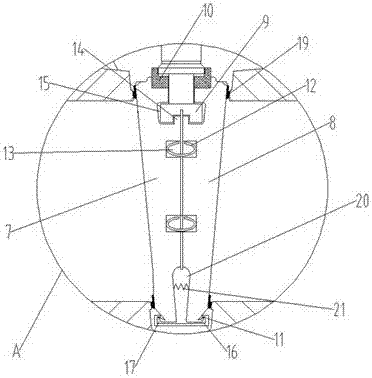

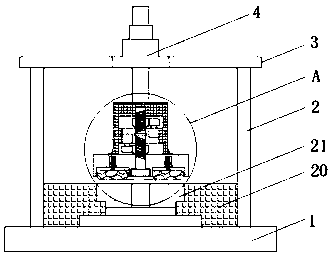

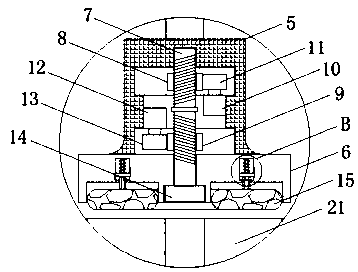

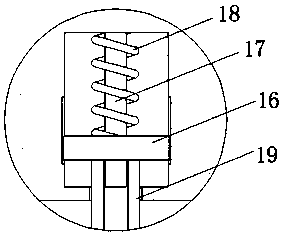

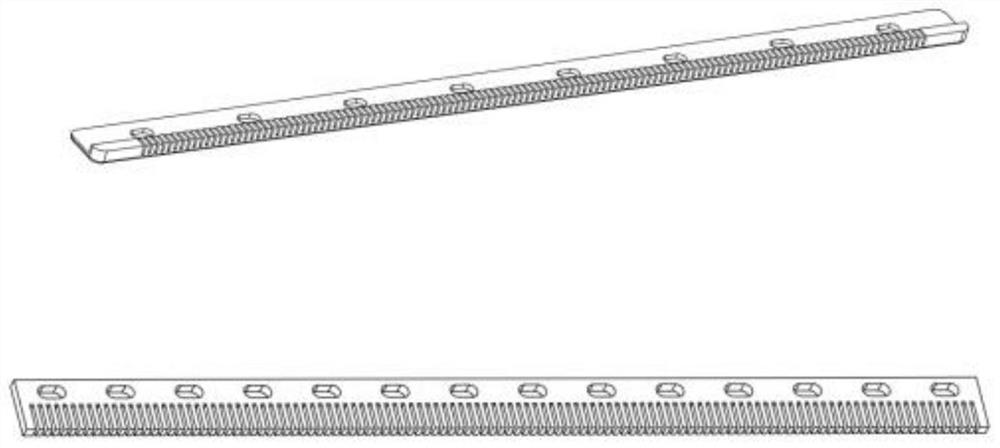

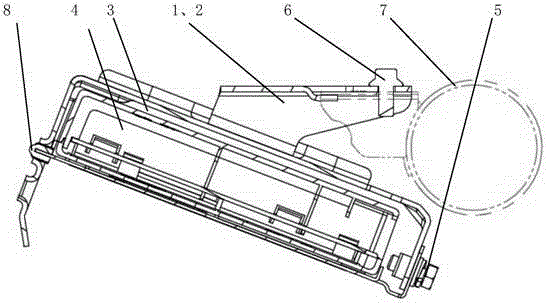

Shoe cleaning machine

ActiveCN104921686AThe fixing method is simple and reliableEasy to cleanFootwear cleanersDrive motorEngineering

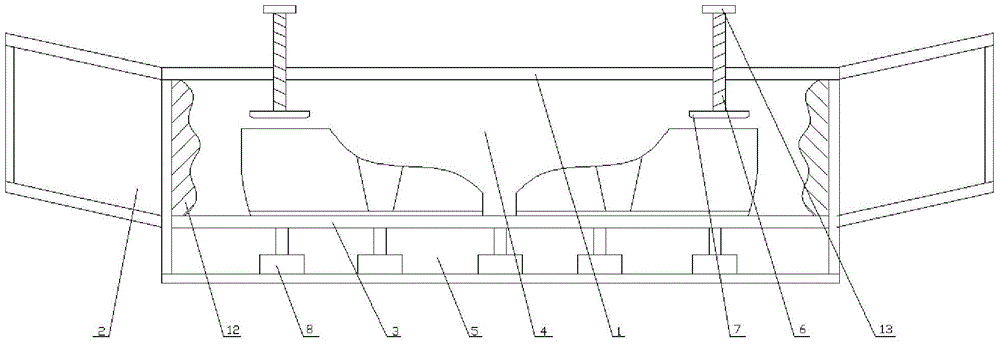

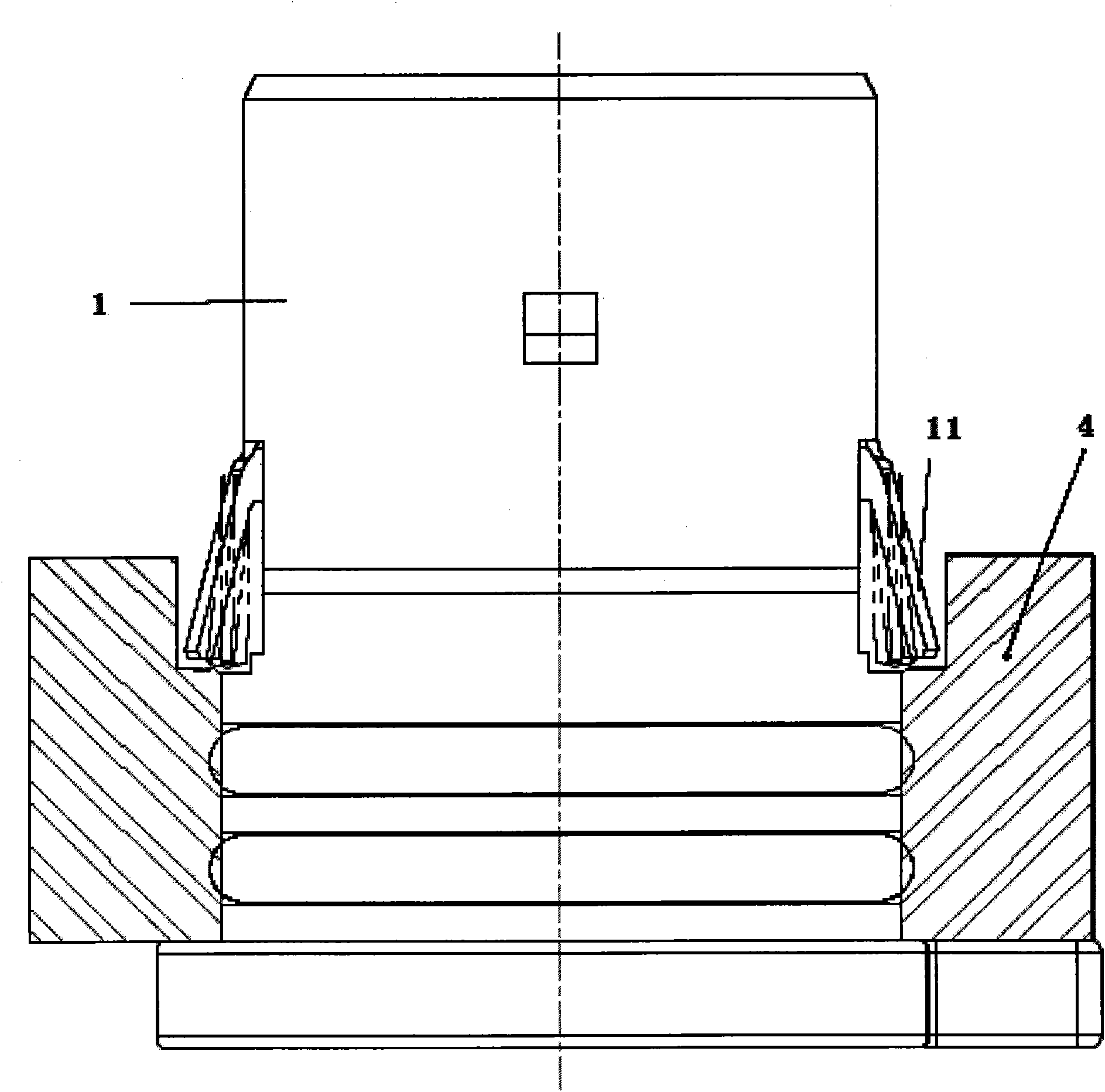

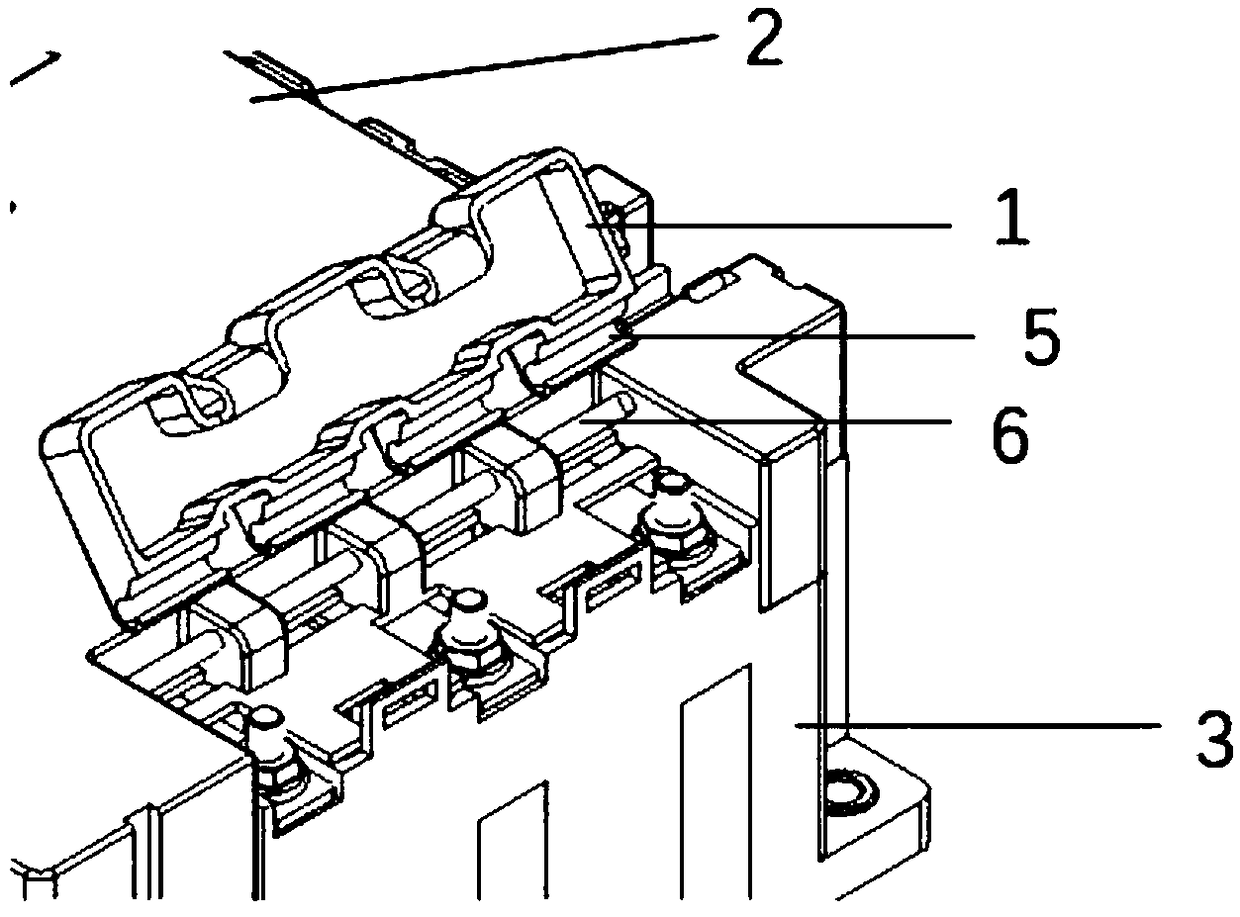

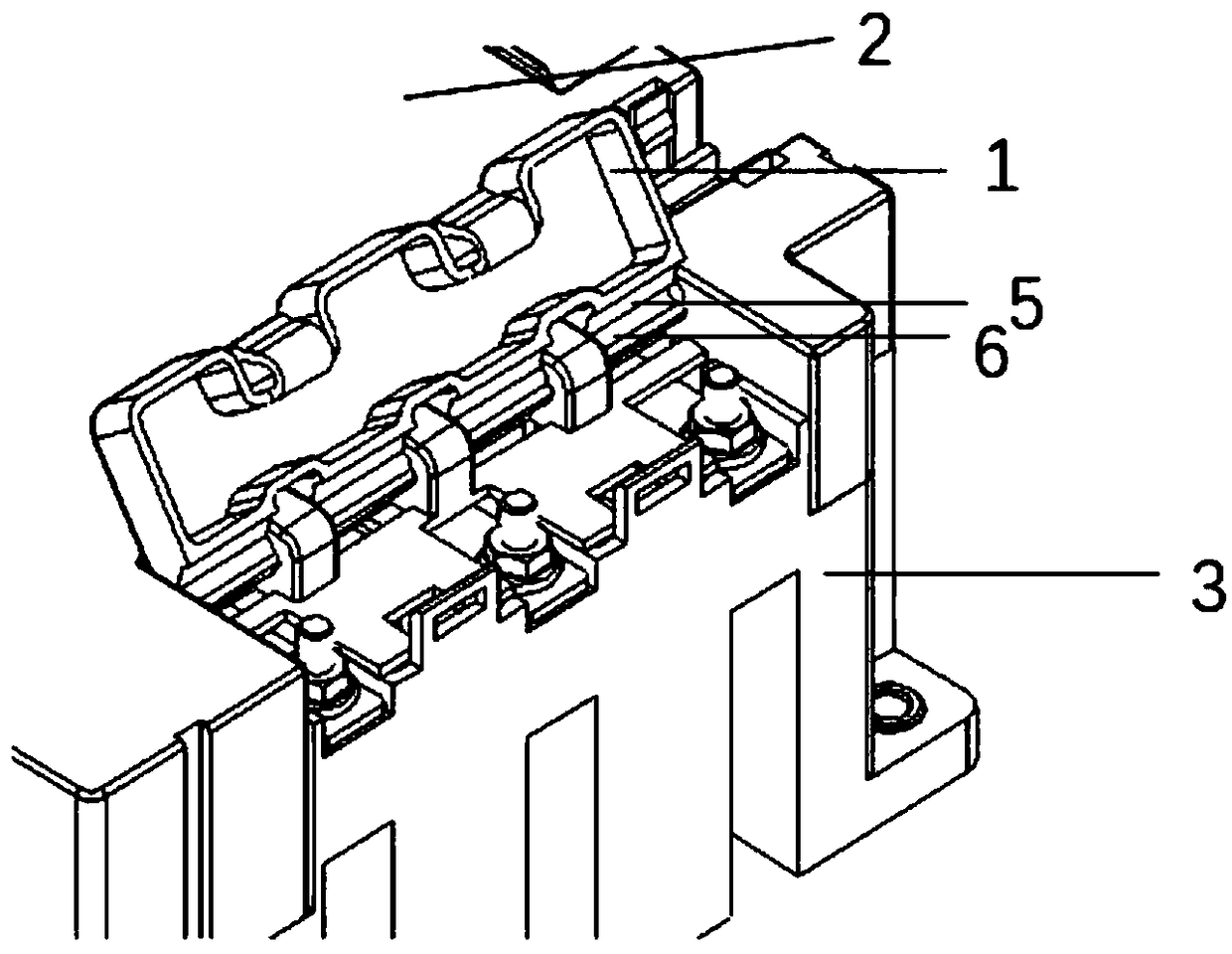

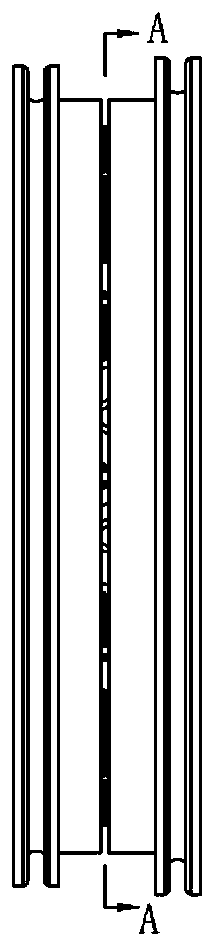

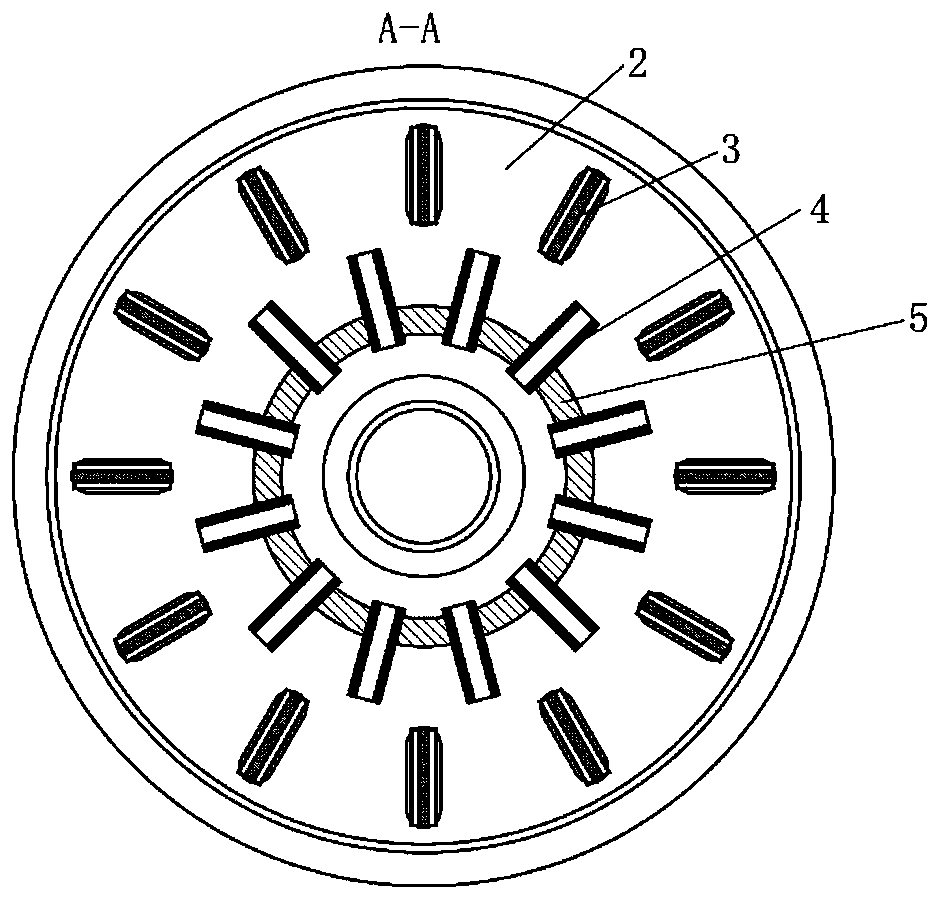

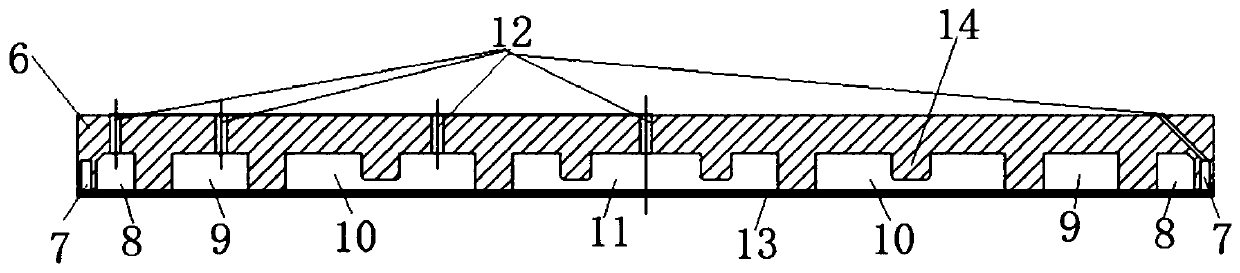

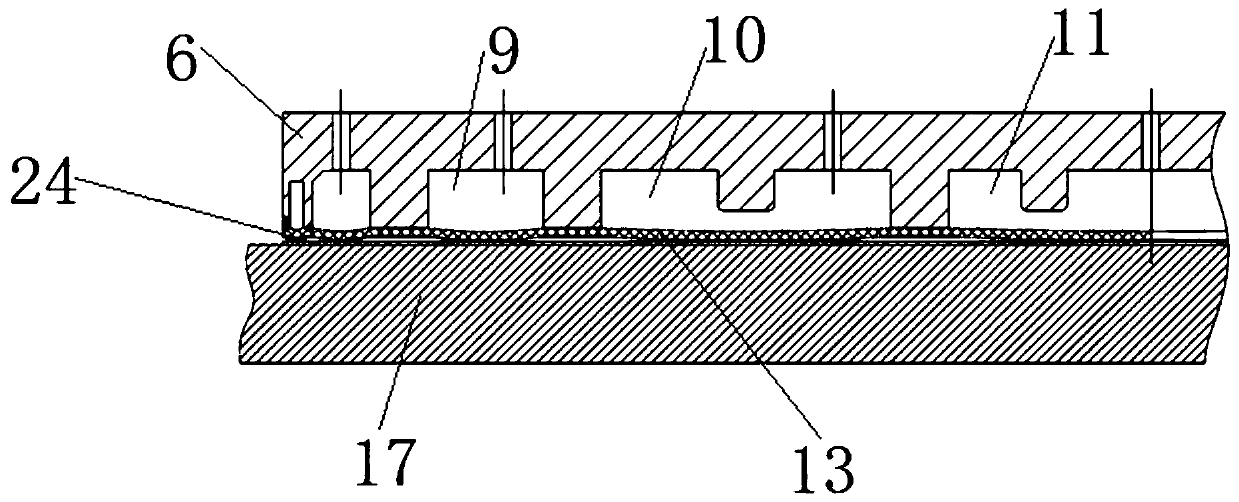

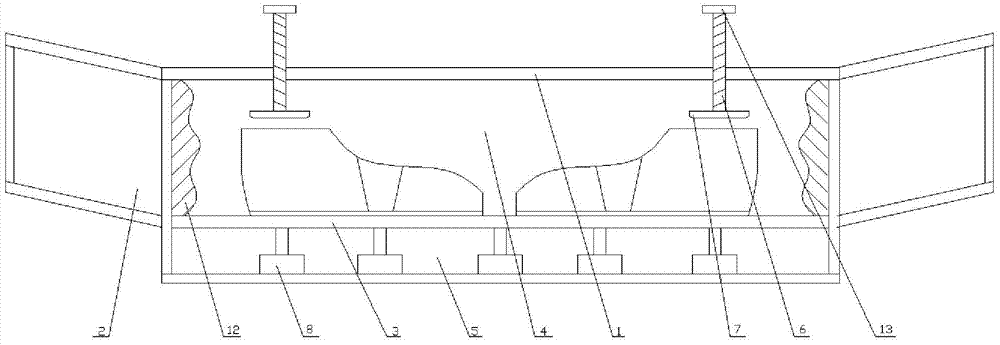

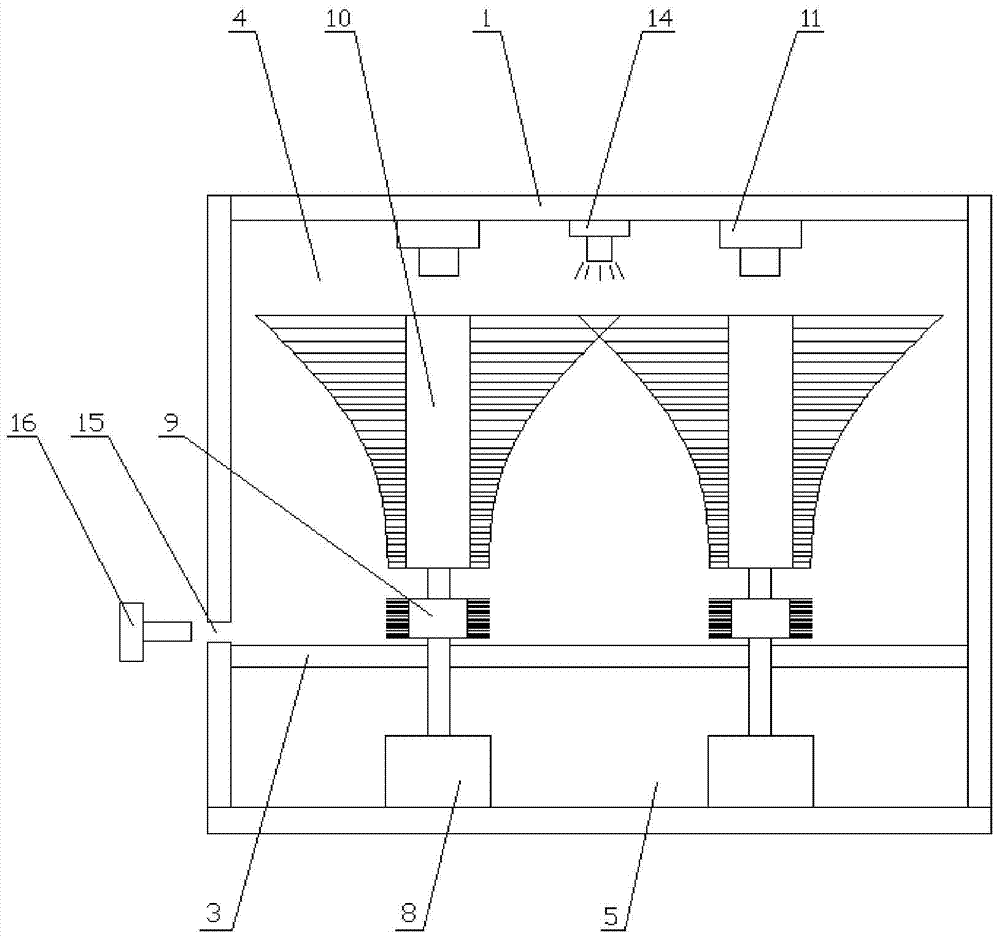

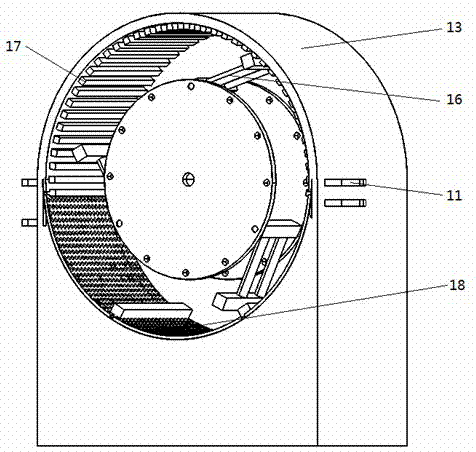

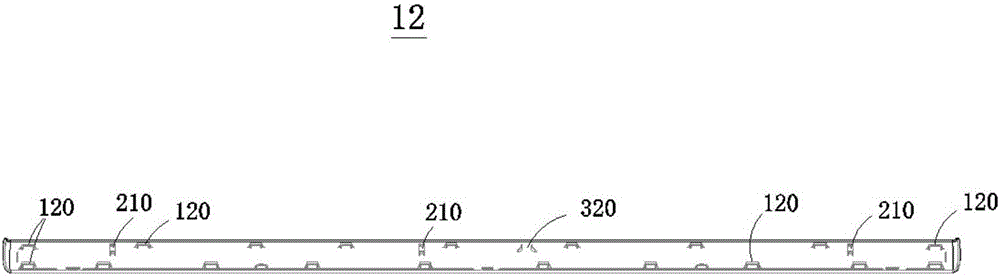

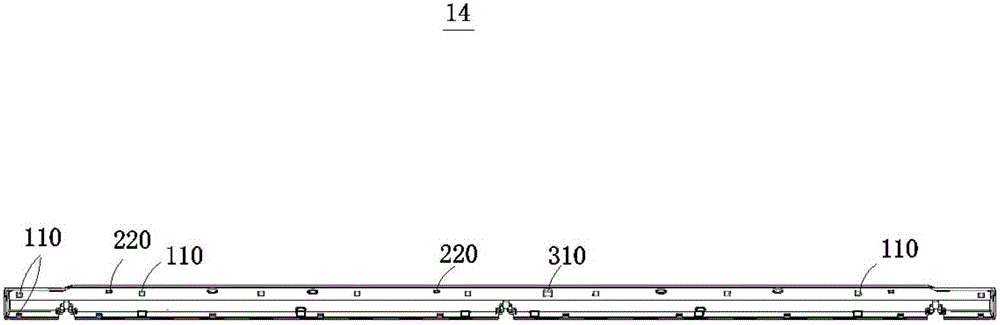

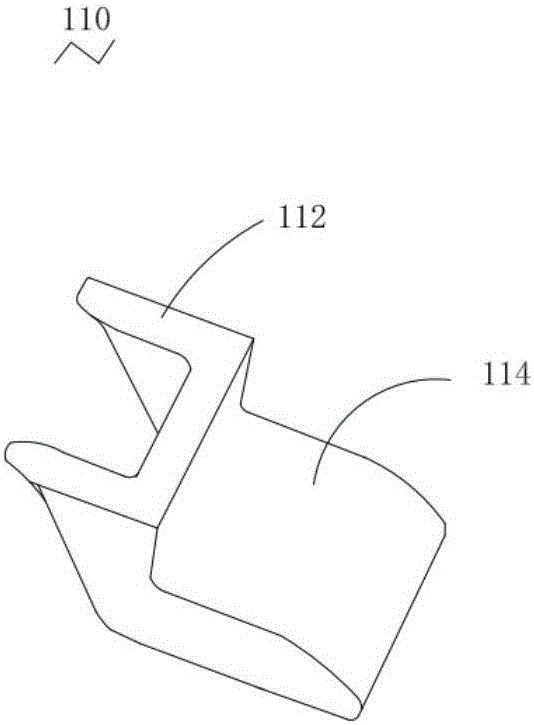

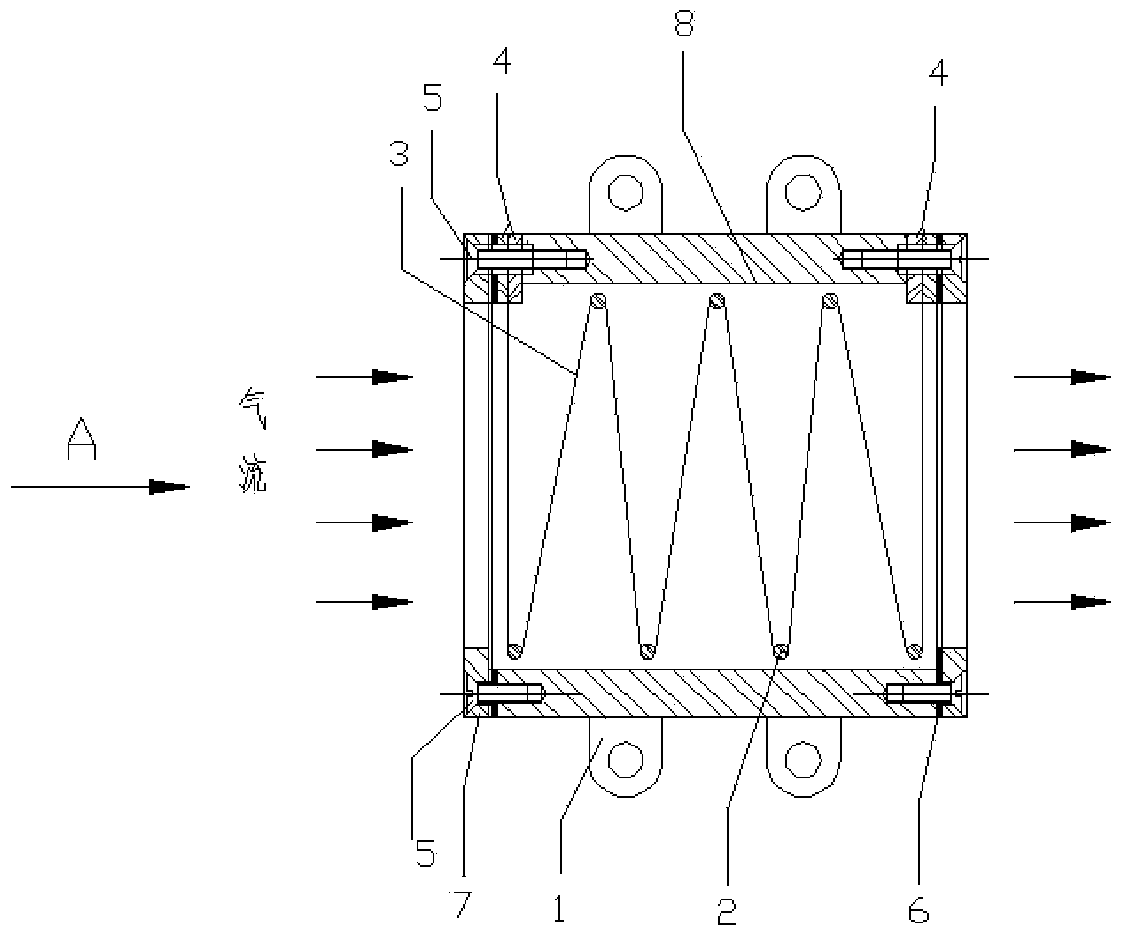

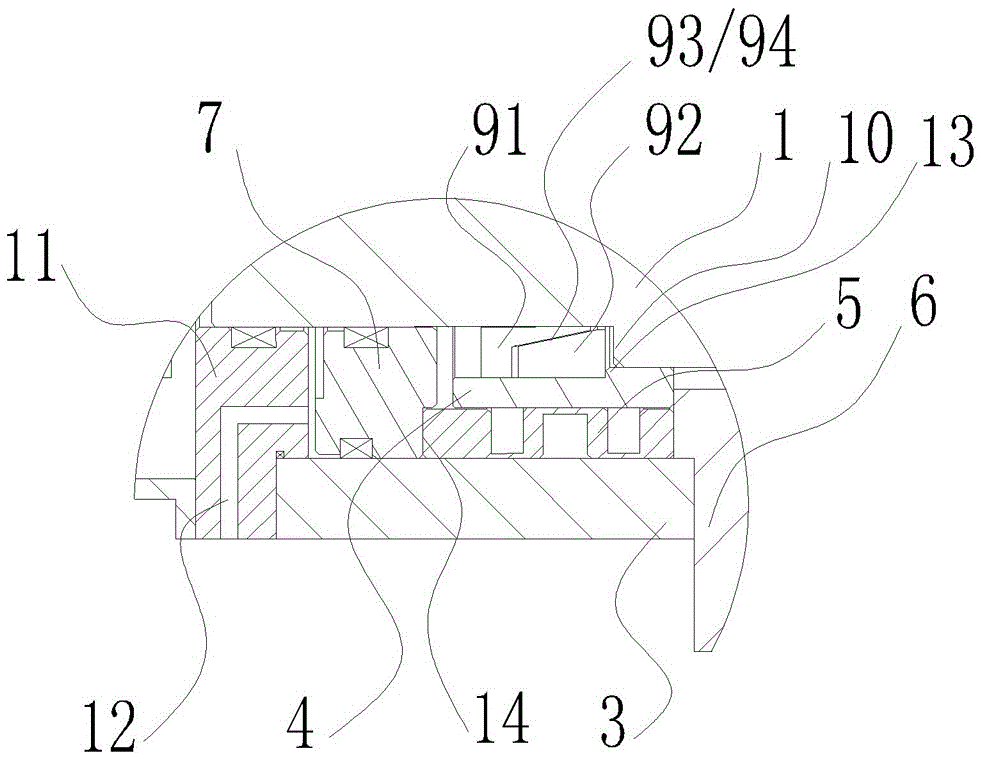

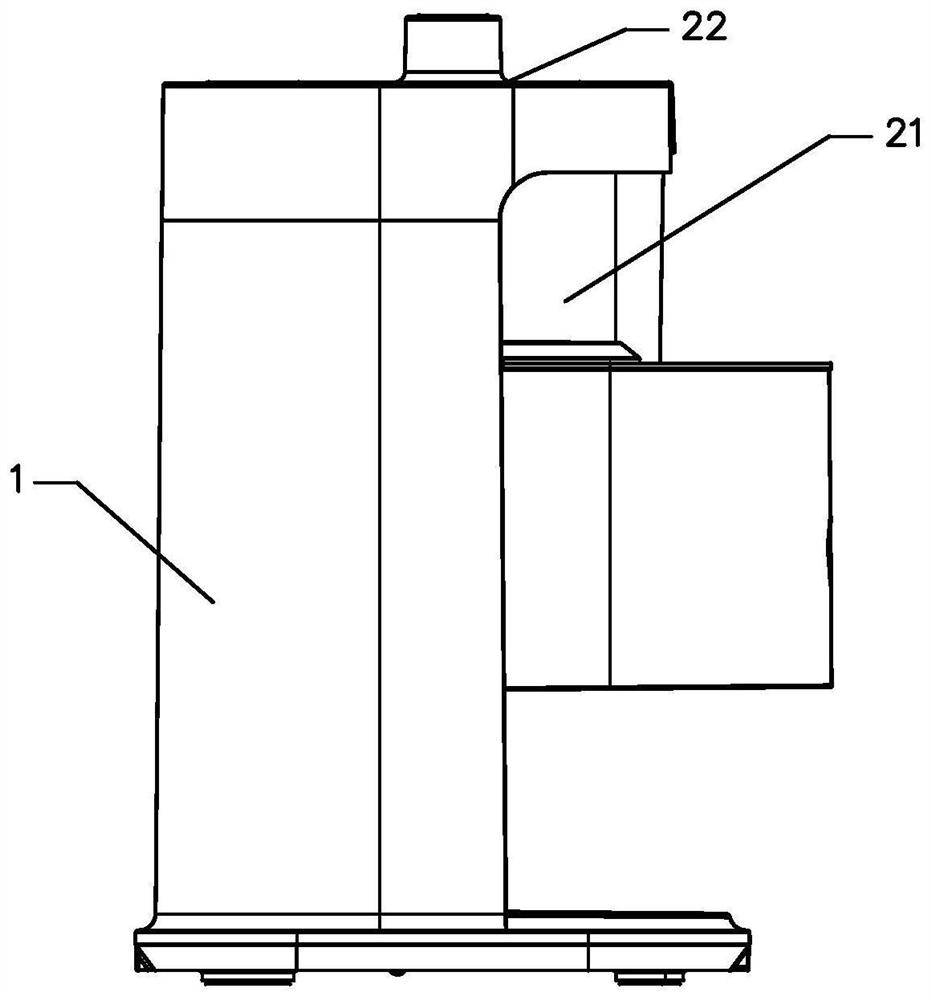

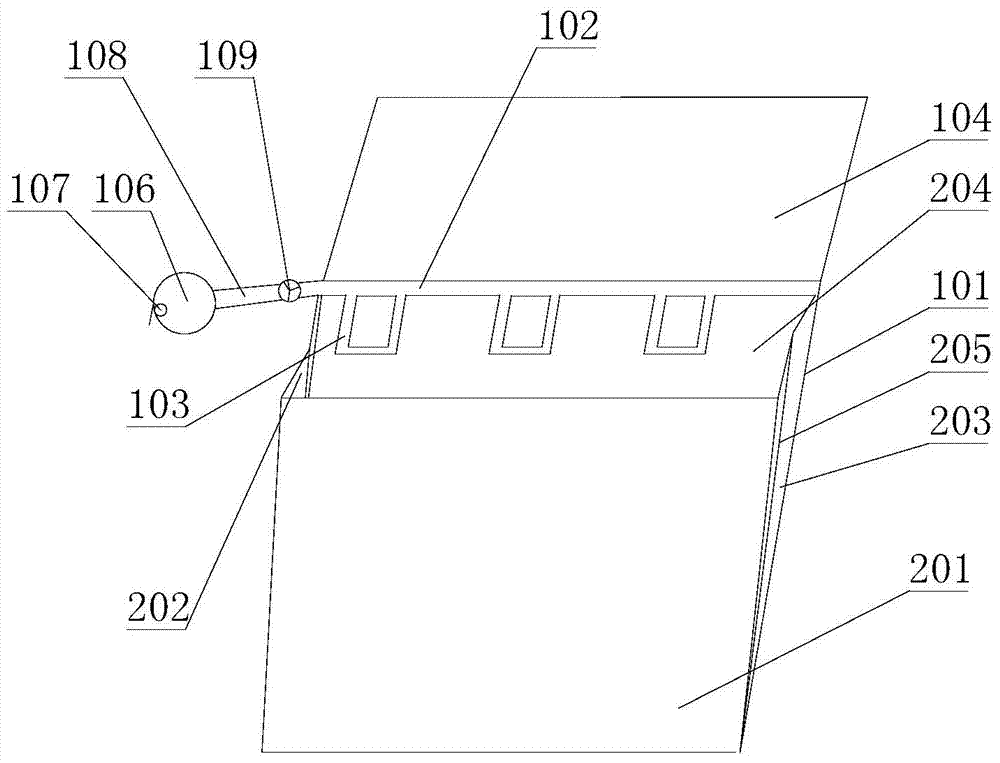

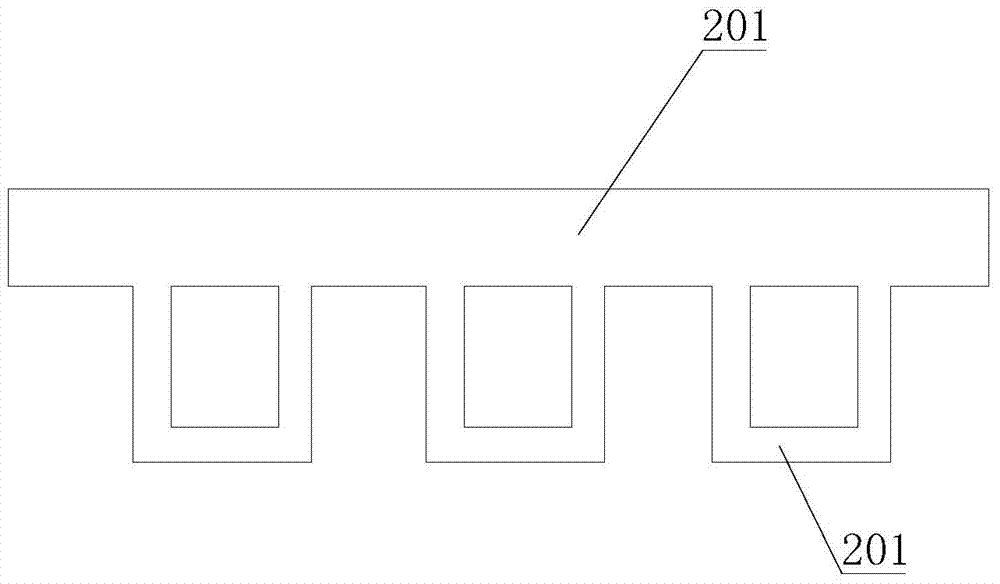

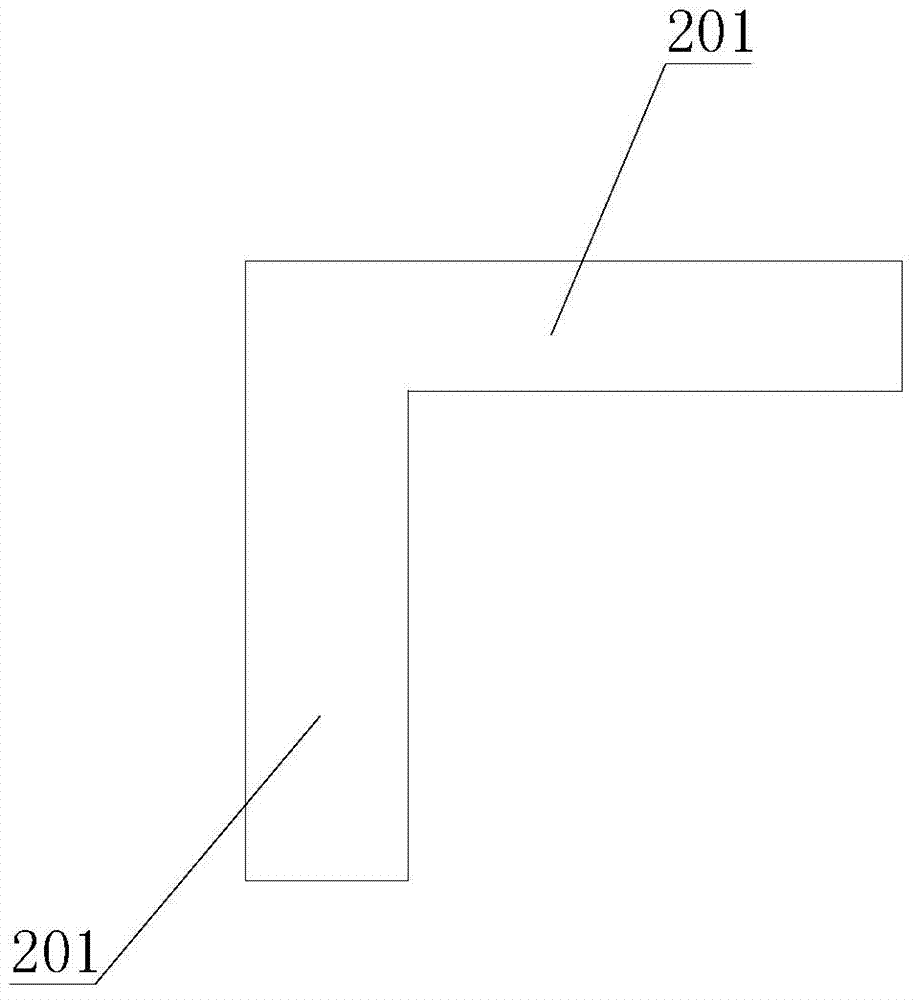

The invention discloses a shoe cleaning machine which comprises a main box. Cleaning inlets are formed in the left end and the right end of the main box, door plates are hinged at the left end and the right end of the main box, a partition plate is arranged in the main box, the main box is divided into an upper shoe cleaning area and a lower drive mounting area, two symmetrical shoe fixing rods are arranged on the upper bottom plate of the shoe cleaning area, and a pressing plate is arranged at the lower ends of the shoe fixing rods. A hairbrush arranged on a driving motor comprises a common rubber roller hairbrush and arc-shaped hairbrushes, the common rubber roller hairbrush is arranged at a shoe sole and can strongly clean the edge of the shoe sole, and the shapes of the arc-shaped hairbrushes correspond to that of an upper of a shoe. When the shoe cleaning machine is used for cleaning the shoe, the upper can be properly extruded by the two corresponding arc-shaped hairbrushes, the common rubber roller hairbrush is matched with the arc-shaped hairbrushes, so that all positions of the shoe can be cleaned, any blind angles are omitted, and the shoe cleaning machine is fine in cleaning effect.

Owner:望江县雷创科技有限公司

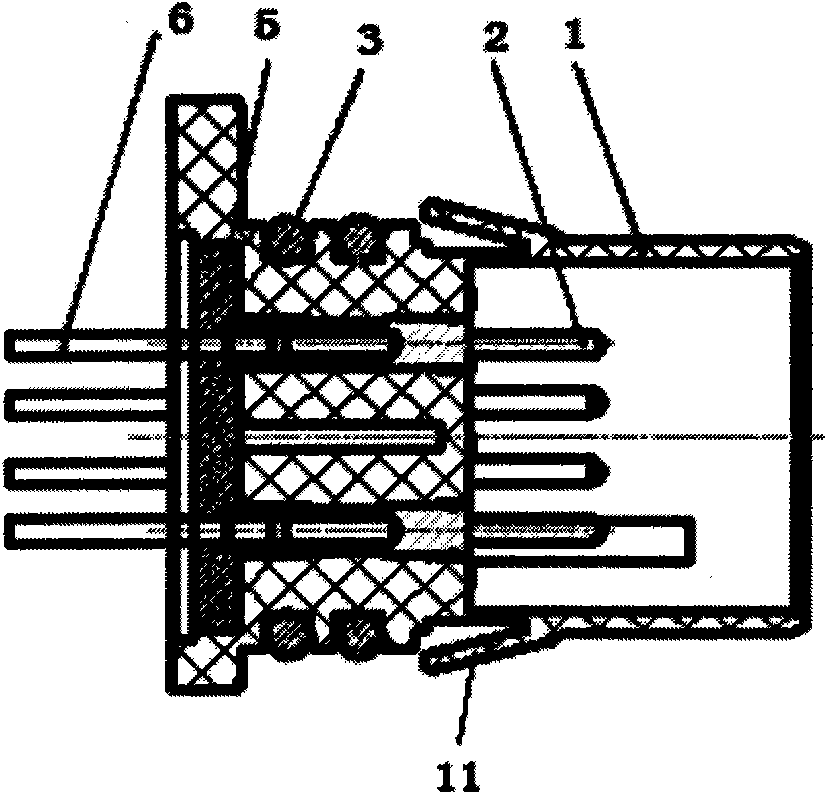

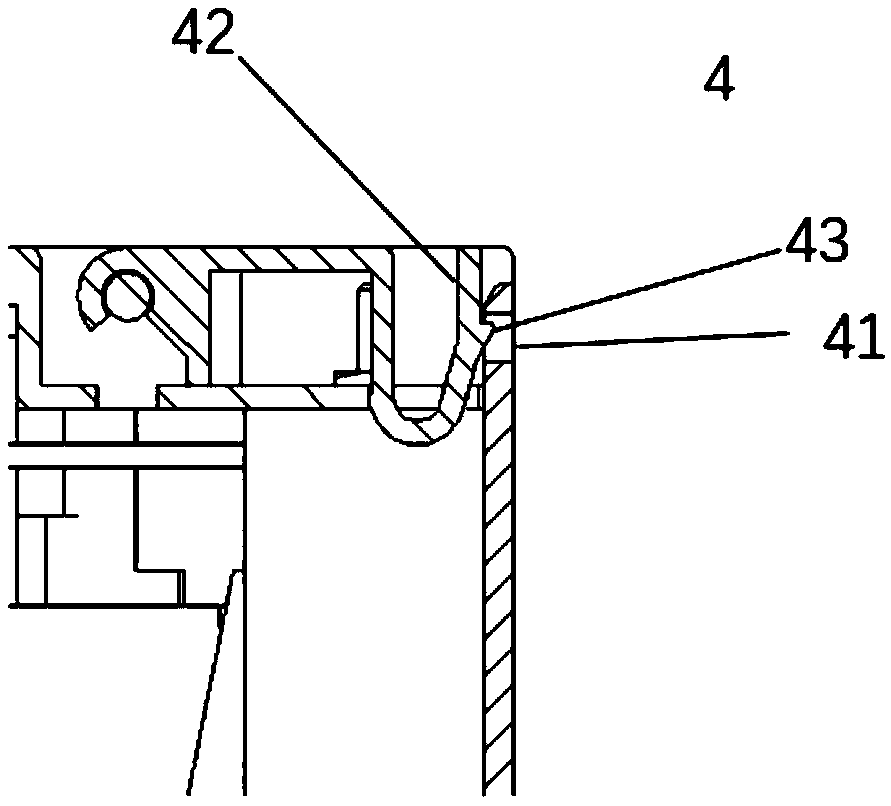

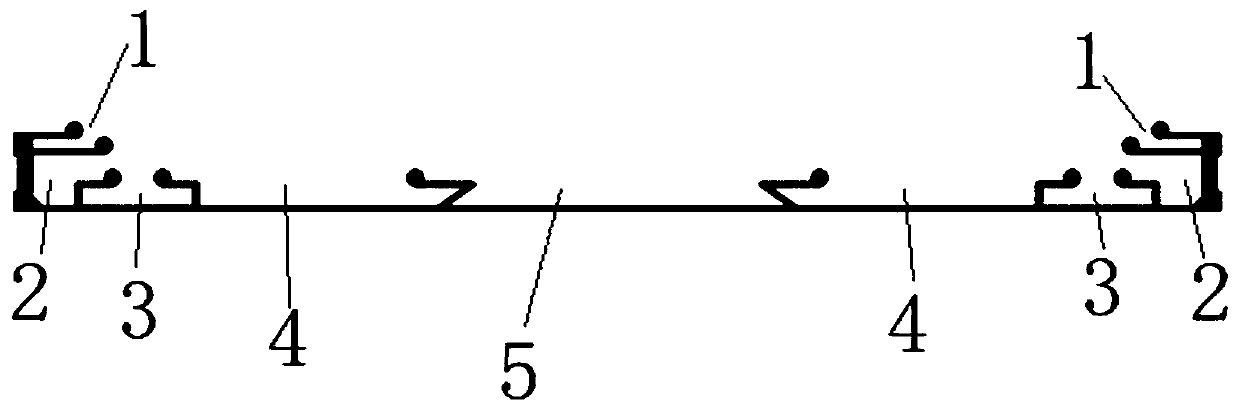

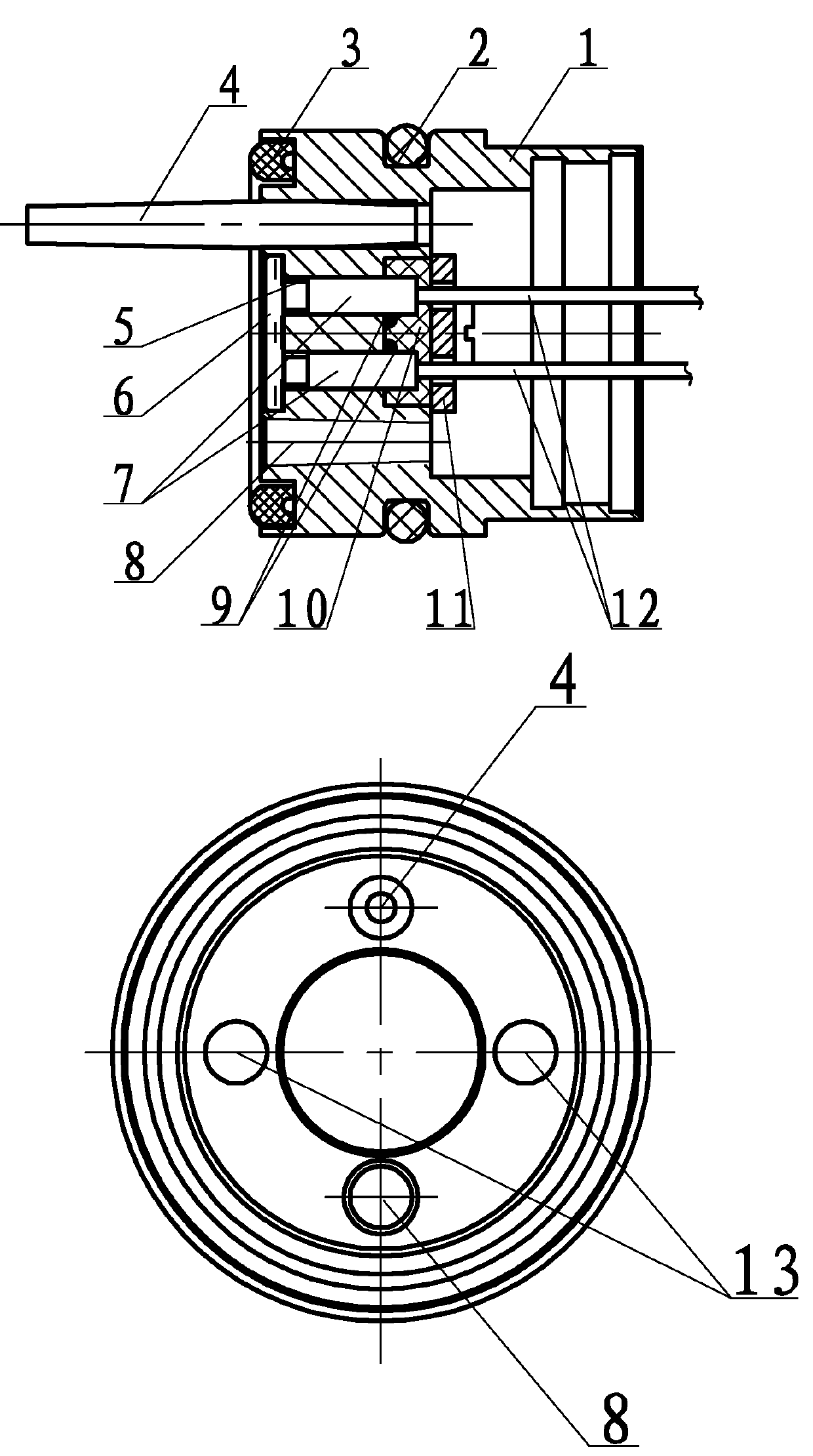

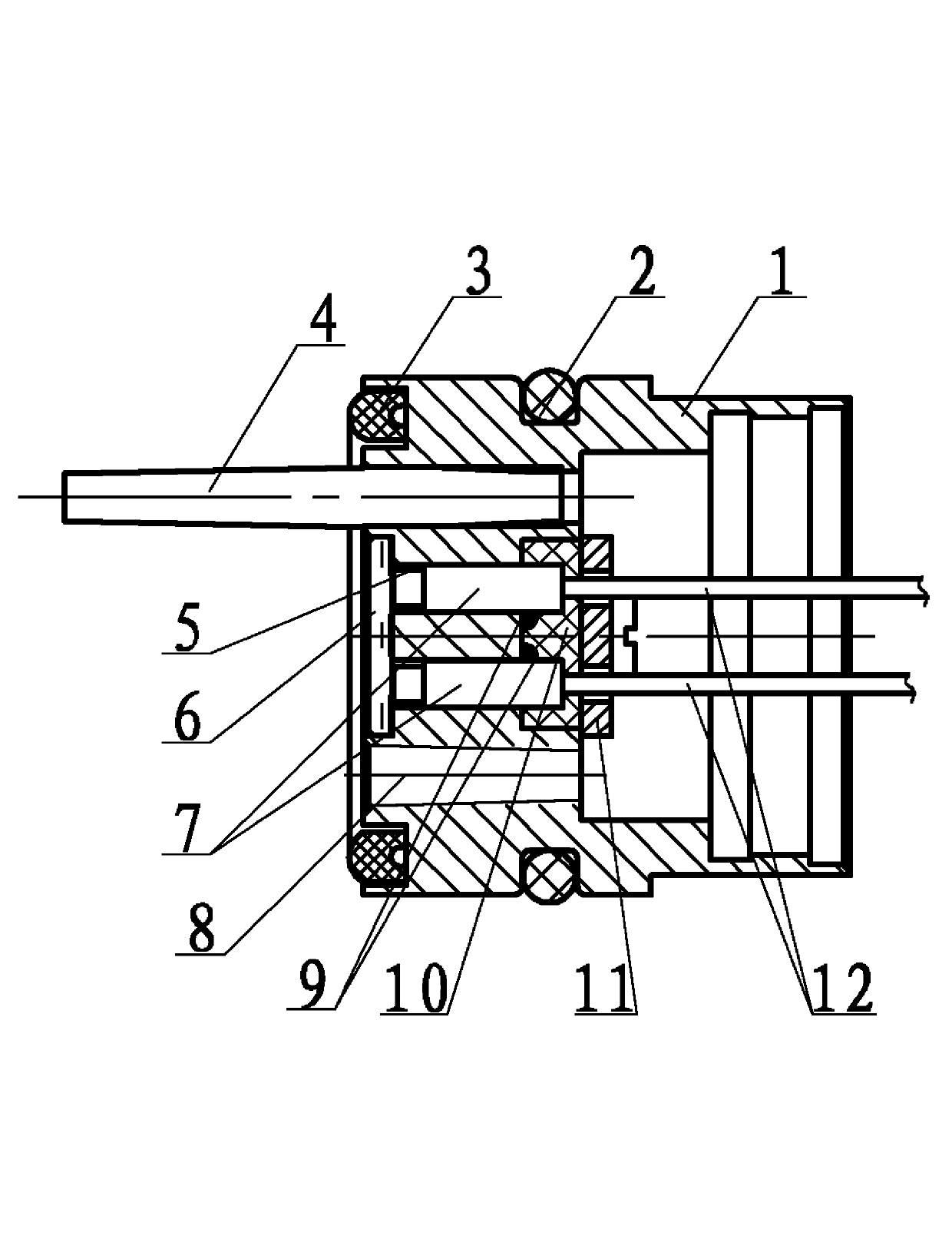

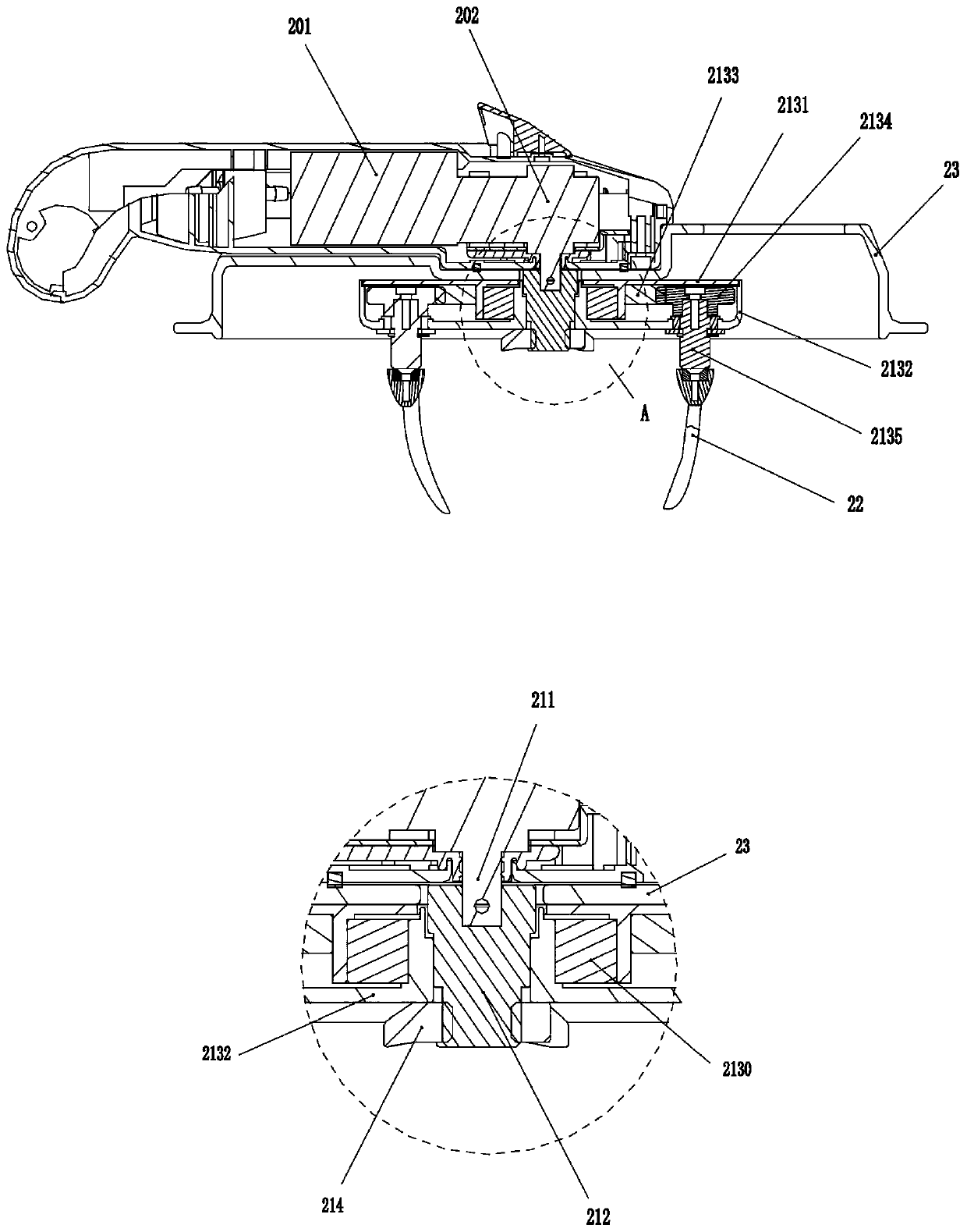

Harness connector with barb for automatic transmission

InactiveCN101867130ASmall form factorMating diameter reductionCouplings bases/casesCoupling parts mountingAutomatic transmissionEngineering

The invention relates to the technical field of the connector, in particular to a harness connector with barbs for an automatic transmission, which comprises a plastic connector shell. The front end of the plastic connector shell is a cylindrical body, the edge of the rear end of the plastic connector shell is provided with a propping part, and connecting holes penetrating from the cylindrical body to the rear end of the plastic connector shell are arranged in the cylindrical body of the plastic connector shell; and terminals penetrate through the front ends of the connecting holes, wires penetrate through the rear ends of the connecting holes, and the front ends of the wires are connected with the rear ends of the terminals. The harness connector is characterized in that inclined flexible barbs are symmetrically arranged outside the cylindrical body of the plastic connector shell. The invention mainly solves the technical problems that the existing harness connector of the automatic transmission can not fix after being placed into a box, the fixation of the harness connector needs additional clamp plates or clamp springs, and the assembly process is complex, and can reduce the matching diameter of the harness connector of the automatic transmission with the box. Moreover, the harness connector with the barbs can be fixedly installed very conveniently.

Owner:SHANGHAI LAIMU ELECTRONICS

A protective cover plate at the input and output ends of a battery disconnecting unit and a high-voltage distribution box

InactiveCN109066924ANo need to disassembleNo need for dismantlingBatteries circuit arrangementsElectric powerElectrical batteryStructural engineering

The invention discloses a protective cover plate at the input and output ends of a battery disconnecting unit, comprising a protective cover, wherein one end of the protective cover is rotatably connected with the upper case of a distribution box, and the other end is connected with the lower case of the distribution box through a locking mechanism. The invention also provides a high-voltage distribution box adopting the protective cover plate, comprising a protective cover, an upper case, a lower case and a battery disconnecting unit. The input and output ends of the battery disconnecting unit are arranged at the surface recess of the lower case, and the protective cover covers the input and output ends of the battery disconnecting unit. The invention can enable the user to disassemble and assemble conveniently when installing the input and output point copper bar, and the operation is convenient and saves man-hour.

Owner:常州是为电子有限公司

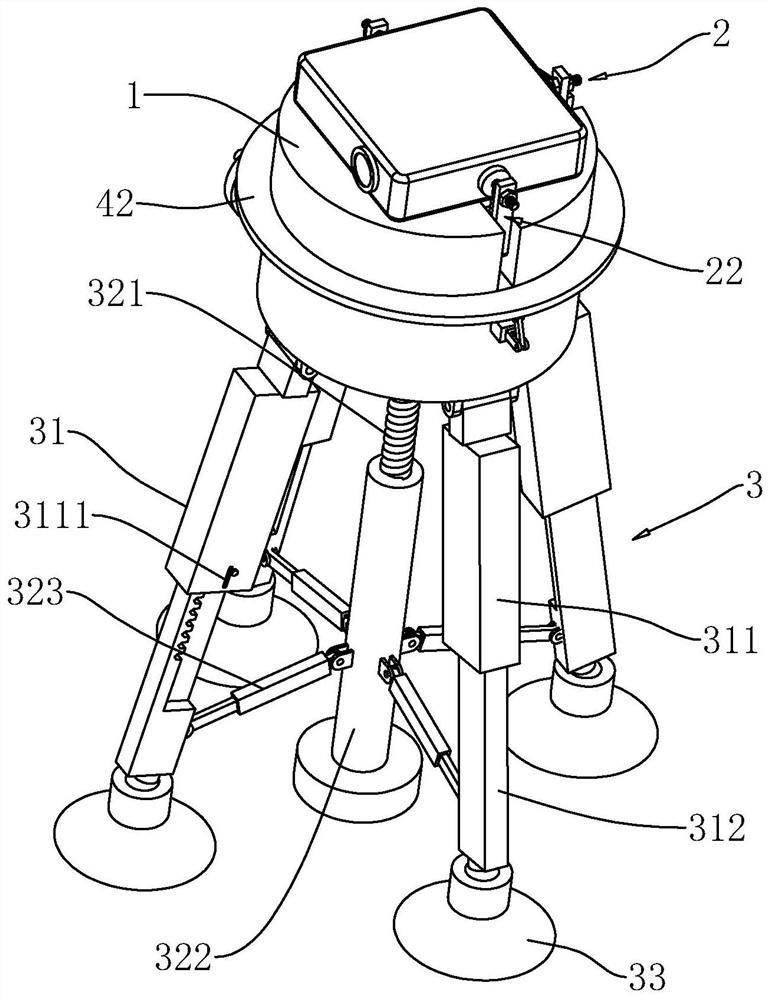

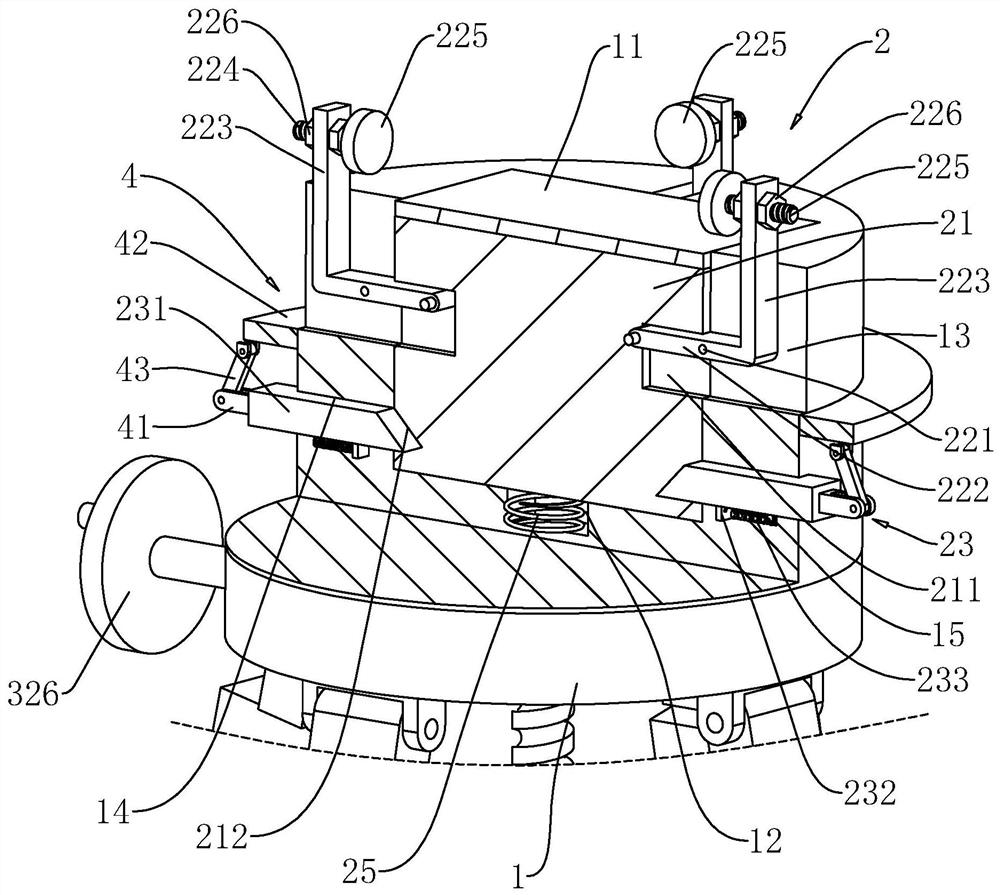

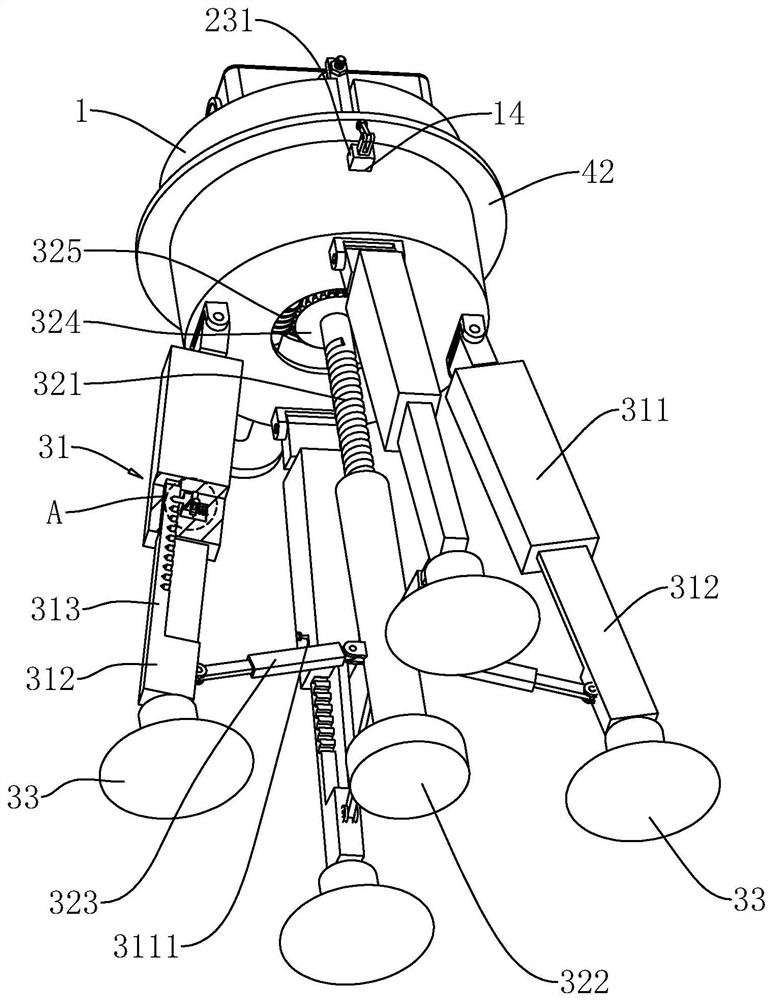

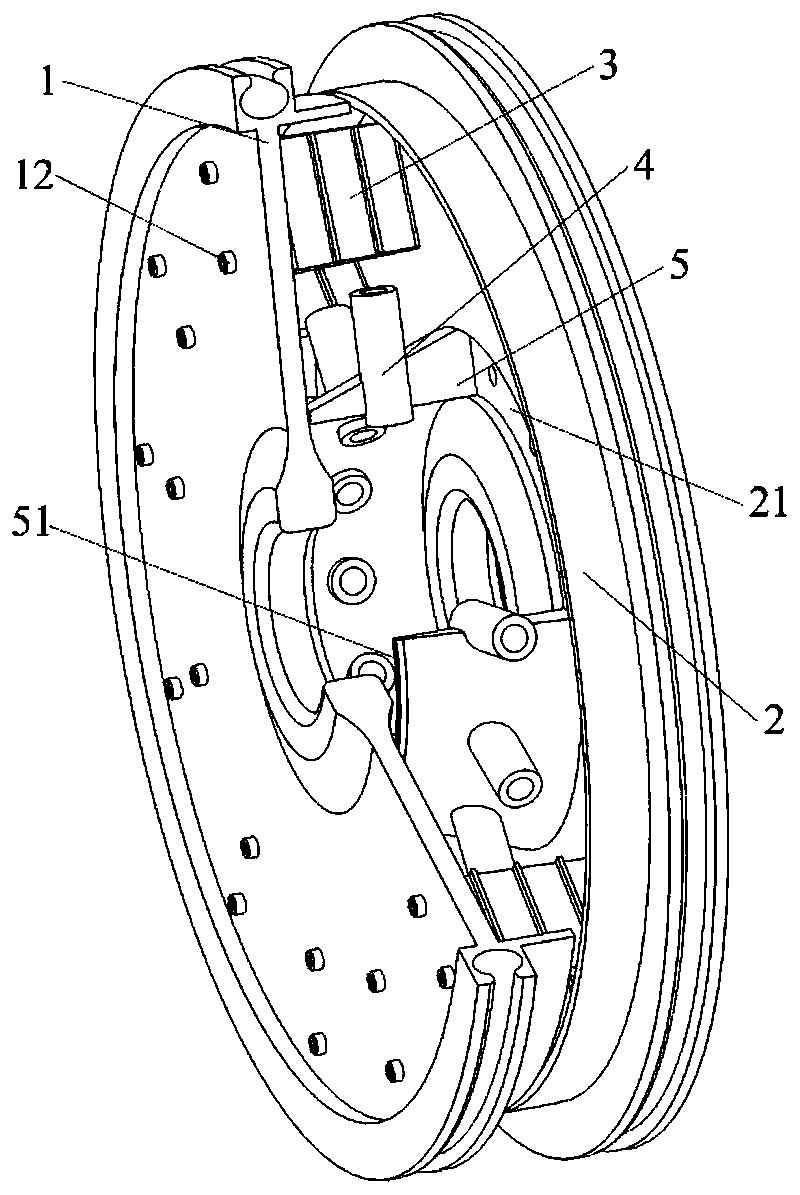

Portable support frame for digital projector

ActiveCN112483846AThe fixing method is simple and reliableEasy to operateStands/trestlesSupport planeProjector

The invention relates to a portable support frame for a digital projector. The portable support frame comprises a support block and a support device; the support block is provided with a clamping device; a sliding groove is formed in the upper end face of the support block; a containing groove is formed in the bottom of the sliding groove; movable grooves are formed in the upper end face of the support block; the multiple movable grooves are formed in the circumferential direction of the sliding groove at intervals; the clamping device comprises a driving block arranged in the sliding groove in a sliding mode, clamping parts arranged in the movable grooves in a rotating mode and a fixing assembly arranged on the support block; a limiting groove is formed in one side of the driving block; the clamping part comprises pin shafts fixed in the movable grooves, first rods rotationally arranged on the pin shafts and second rods vertically fixing the sides, away from the driving block, of thefirst rods; the ends, away from the second rods, of the first rods are movably arranged in the limiting groove; the upper ends of the second rods are attached to the outer side wall of the projector;a reset spring is arranged in the containing groove; and the two ends of the reset spring are fixed to the lower end face of the driving block and the bottom of the containing groove correspondingly.The portable support frame has the effect of being capable of improving the installation stability of the projector.

Owner:BEIJING YUNLOOK CULTURE MEDIA CO LTD

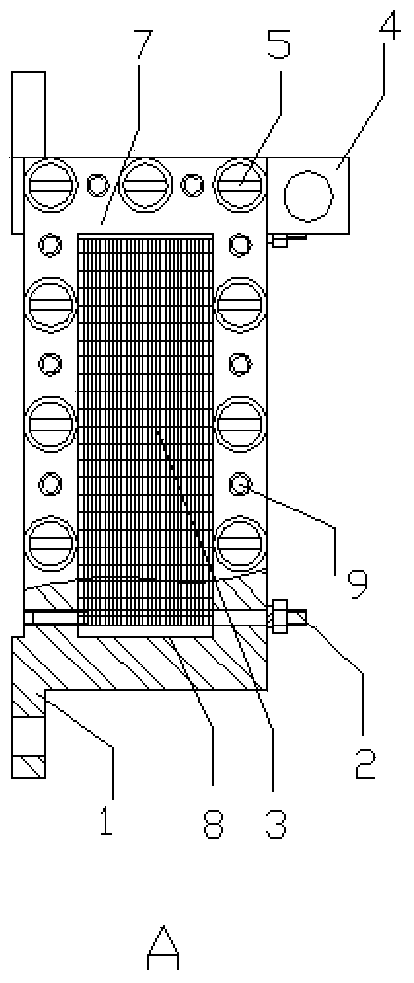

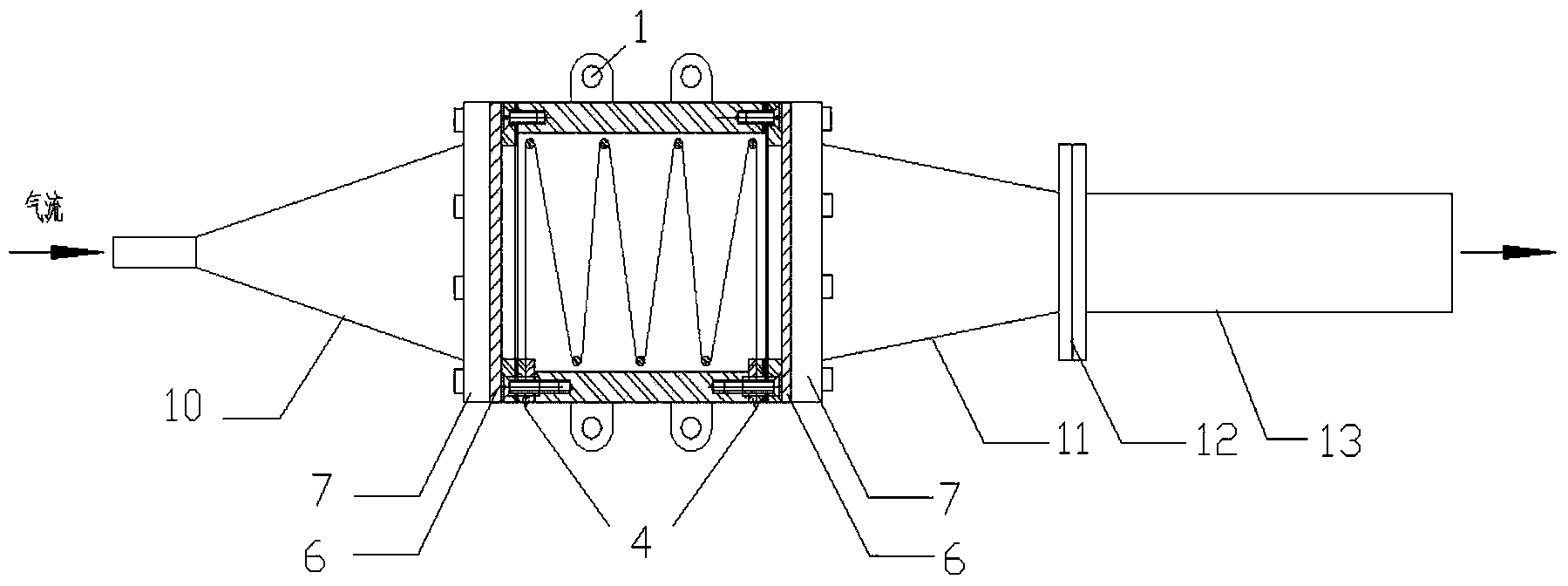

Contra-rotating gas compressor structure and composite type anti-whirling device structure suitable for contra-rotating gas compressor air entraining system

ActiveCN110469540AMake up for the defect of easy vibrationImprove stabilityPump componentsPumpsGas compressorSystem stability

The invention discloses a contra-rotating gas compressor structure and a composite type anti-whirling device structure suitable for a contra-rotating gas compressor air entraining system. The composite type anti-whirling device structure is characterized in that a first-stage gas compressor wheel disc and a second-stage gas compressor wheel disc reversely rotate in a coaxial manner, the contra-rotating gas compressor structure is formed, and outer edge check rings of the first-stage gas compressor wheel disc and the second-stage gas compressor wheel disc form the air inlet slot of the contra-rotating gas compressor air entraining system; fin type anti-whirling devices are evenly distributed on the high radius position along the circumference, and fixed to the first-stage gas compressor wheel disc, and tubular anti-whirling devices are evenly distributed on the low radius position along the circumference, and mounted on the second-stage gas compressor wheel disc through a tubular anti-whirling device holder. Through the composite type anti-whirling device structure of the high-radius fin type anti-whirling devices and the low-radius tubular anti-whirling devices, the airflow pressure losses of the contra-rotating gas compressor air entraining system can be effectively reduced, the system stability and reliability are greatly improved, meanwhile, the fixed manner is simple and reliable, mounting is convenient, and later-period maintenance and repair can be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Hydraulic pump

InactiveCN106678011ARealize adjustment changesReduce settingsPump testingPositive displacement pump componentsElastic componentHydraulic pump

The invention discloses a hydraulic pump. The hydraulic pump comprises a direct current motor; an armature core of the direct current motor is connected with a motor rotating shaft through a flat key; one or more hydraulic pump plunger cavities are formed in the armature core; all the hydraulic pump plunger cavities are arranged annularly with the motor rotating shaft as the center; the front ends of the hydraulic pump plunger cavities are provided with a swash plate fixed to a front end cover of the direct current motor; plungers slidably connected with the hydraulic pump plunger cavities are slidably connected with an annular slipping boot track on the swash plate through slipping boots at the front ends of the plungers; the rear ends of the hydraulic pump plunger cavities are provided with a thrust plate fixed to a rear end cover of the direct current motor; a pressing, sealed and connection structure is arranged between the armature core provided with the hydraulic pump plunger cavities and the thrust plate, specifically, a spring stopping block is arranged on the part, close to the front end of the armature core, of the motor rotating shaft, and an elastic component is arranged between the spring stopping block and the armature core so that oil passing openings in the right ends of the hydraulic pump plunger cavities can be in close fit with two waist-form flow allocation windows of the thrust plate. The hydraulic pump has the characteristics of being compact in structure, small in size, little in component configuration quantity and the like.

Owner:石家庄市液压有限责任公司

Bearing head and polishing device with same

ActiveCN111251177AConvenient air pressure controlSimple structureLapping machinesGrinding feed controlPhysicsEngineering

The invention relates to the technical field of semiconductor manufacturing process polishing, in particular to a bearing head and a polishing device with the same. The bearing head comprises a body made of a non-flexible material, wherein a plurality of concave cavities are formed in the end, close to a wafer to be polished, of the body, and a vent hole connected with an air source is formed in each concave cavity; and a flexible film is fixedly connected to the end and is suitable for making contact with the wafer to be polished. According to the bearing head, the body is made of the non-flexible material, so that a plurality of concave cavities are conveniently formed in the body; the vent holes connected with the air source are formed in the concave cavities, so that the air pressure of each concave cavity is conveniently controlled; due to the fact that the flexible film is fixedly connected to the end part, close to the wafer to be polished, of the body and is in contact with thewafer to be polished, the compactness between the flexible film and the wafer to be polished is guaranteed; and due to the fact that independent control over all the cavities is guaranteed by directly forming the cavities in the body made of the non-flexible material to be matched with the flexible film without independently arranging sealing mechanisms among all the cavities, and therefore the structure and the process manufacturing of the bearing head simpler.

Owner:北京晶亦精微科技股份有限公司

a shoe washing machine

ActiveCN104921686BThe fixing method is simple and reliableEasy to cleanFootwear cleanersPulp and paper industryDrive motor

Owner:望江县雷创科技有限公司

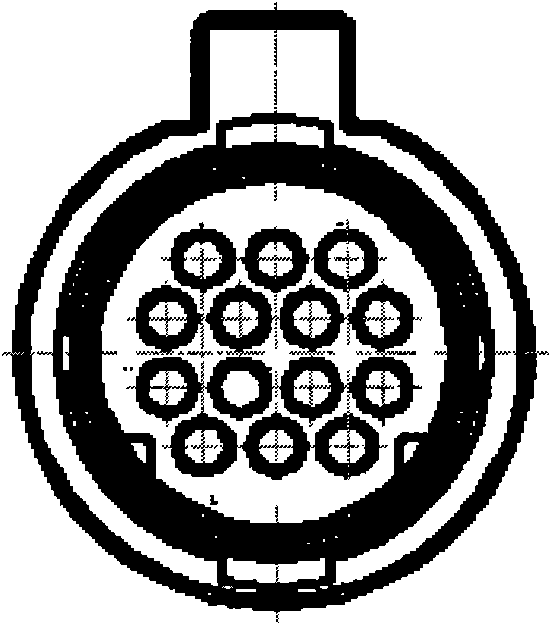

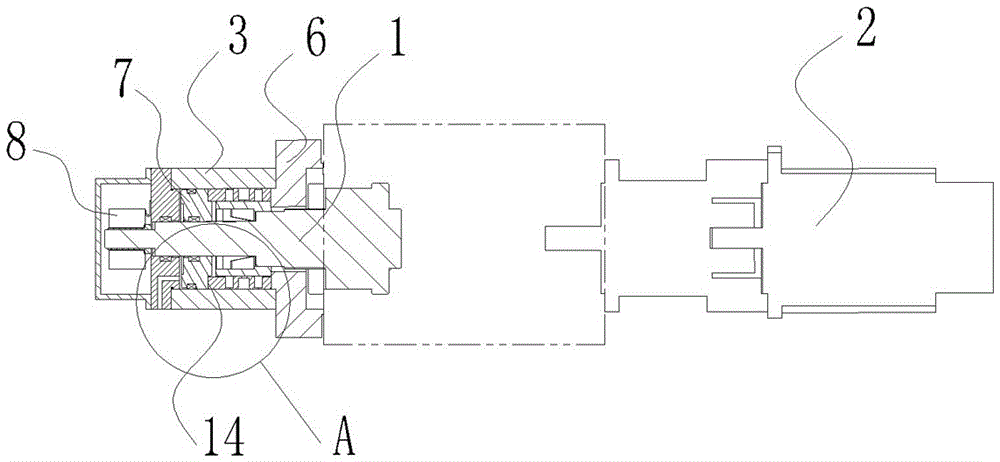

Optical fiber beam expansion connector

InactiveCN101907749AReduce alignment errorsImprove delivery qualityCoupling light guidesEngineeringCollimator

The invention relates to an optical fiber beam expansion connector, comprising a connector casing which is provided with an optical fiber collimator mounting hole; an optical fiber collimator is arranged in the optical fiber collimator mounting hole; the wall of the optical fiber collimator mounting hole directly contacts and fits to the optical fiber collimator; and the insertion end of the optical fiber beam expansion connector and an adapter connector is the front end. In the invention, the connector casing is provided with the optical fiber collimator mounting hole in which the optical fiber collimator is arranged, the outer periphery surface of the optical fiber collimator directly contacts and fits to the wall of the optical fiber collimator mounting hole, and no part is arranged between the optical fiber collimator and the optical fiber collimator mounting hole, so that the integrated error of the product is small, the centring error between the optical fiber collimator and an adapted optical collimator is small, and the transitive quality of optical signals is high.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

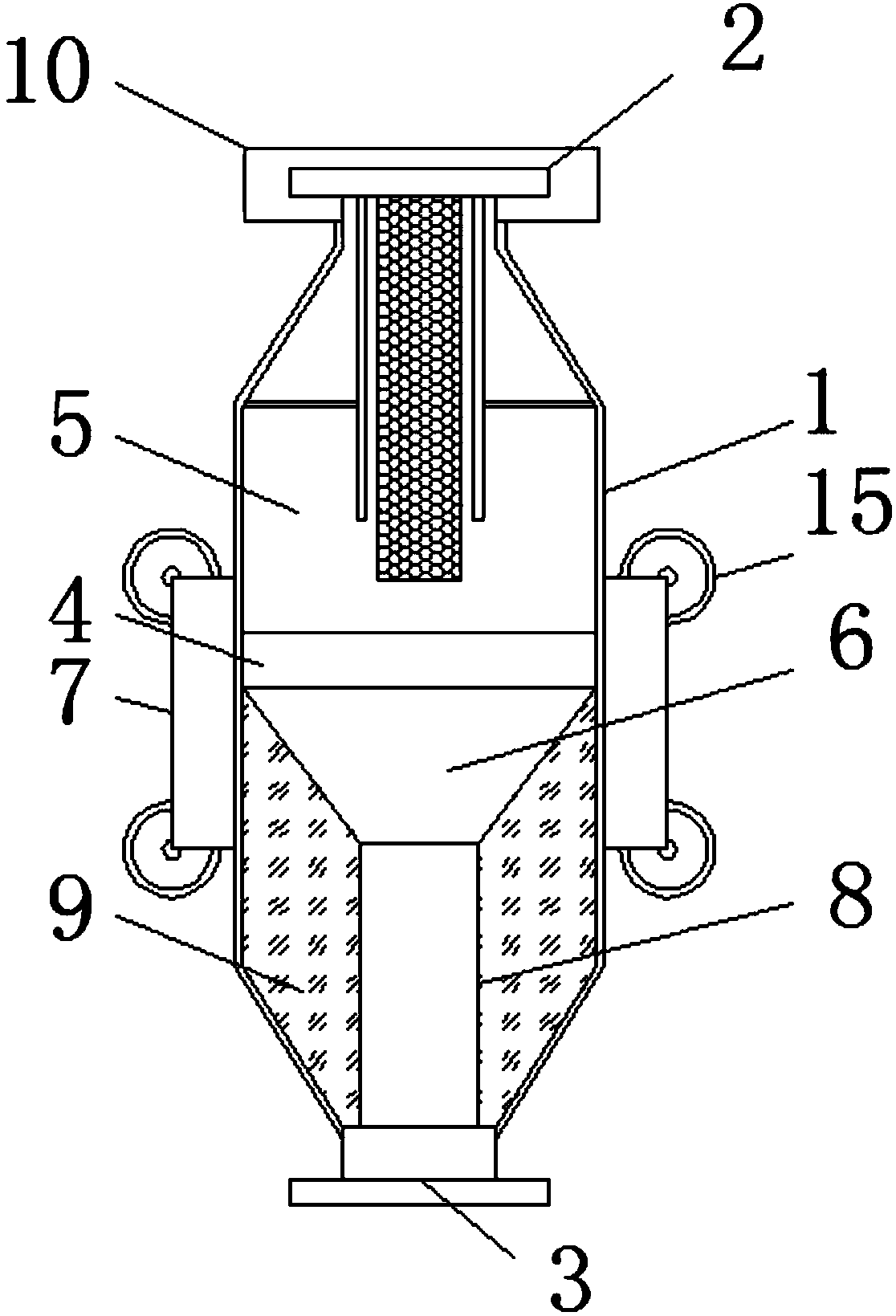

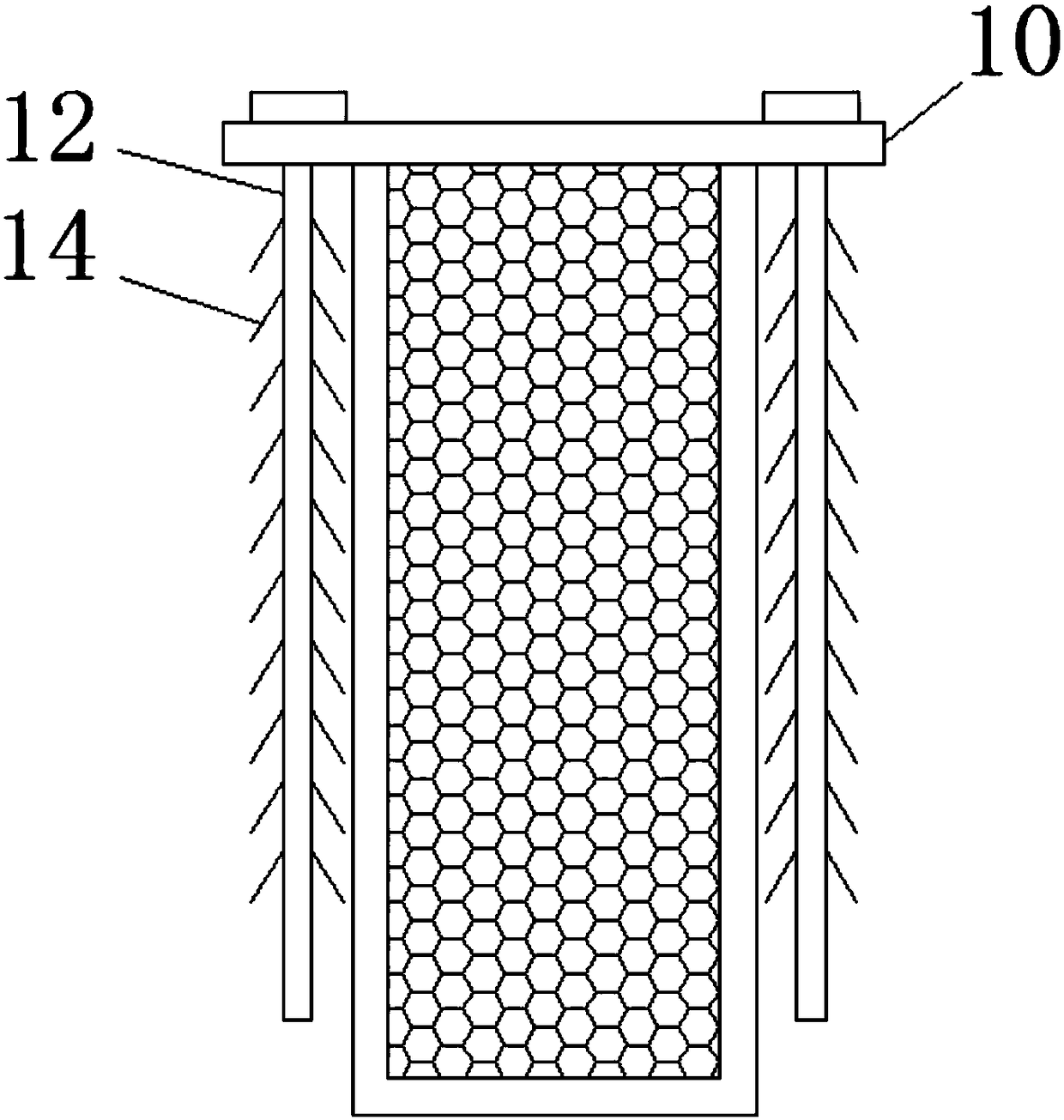

Blockage-preventing and convenient-mounting type silencer

InactiveCN108397893AEasy to installAvoid damageNoise suppressionCleaning using toolsForeign matterEngineering

The invention relates to the technical field of air conditioning equipment, and discloses a blockage-preventing and convenient-mounting type silencer. The silencer comprises an outer silencer body, wherein an air inlet is formed in the upper surface of the outer silencer body, and an air outlet is formed in one end, far away from the air inlet, of the outer silencer body; a separating plate is fixedly connected to the middle part of the inner wall of the outer silencer body and is used for separating the outer silencer body into an upper empty chamber and a lower empty chamber; the upper emptychamber is positioned above the separating plate. According to the blockage-preventing and convenient-mounting type silencer, foreign matters at the air inlet can be effectively intercepted through anet barrel, so that the foreign matters can be prevented from entering the silencer to damage the silencer; the net barrel can be washed through a washing brush; a user can slide the washing brush ona slide rail and rotate to crush the net barrel; the net barrel is manufactured through stainless steel, so that the corrosion resistance is ensured, and the rust preventing capacity is high; and moreover, the net barrel is clamped above the air inlet and is fixed through an air chuck; the fixing manner is simple and reliable; and the user can conveniently mount, and the time is saved.

Owner:SUZHOU YIXINHE ELECTRONICS CO LTD

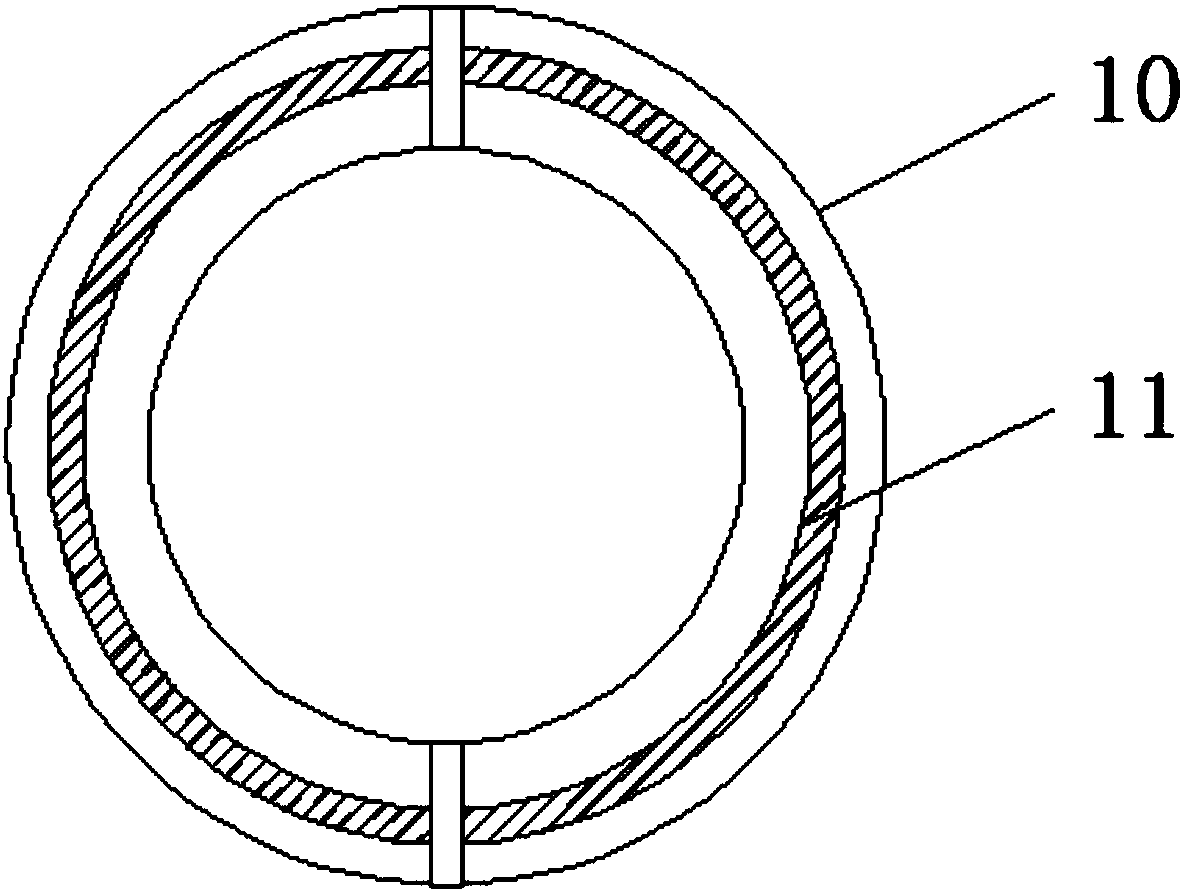

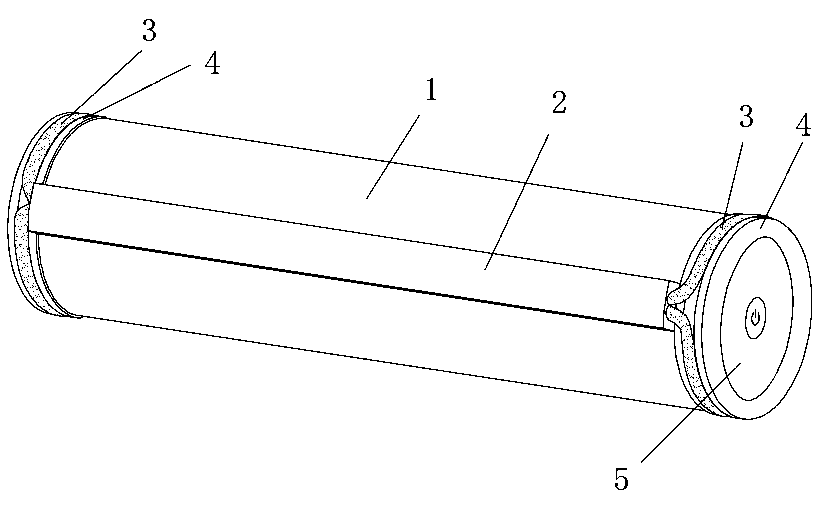

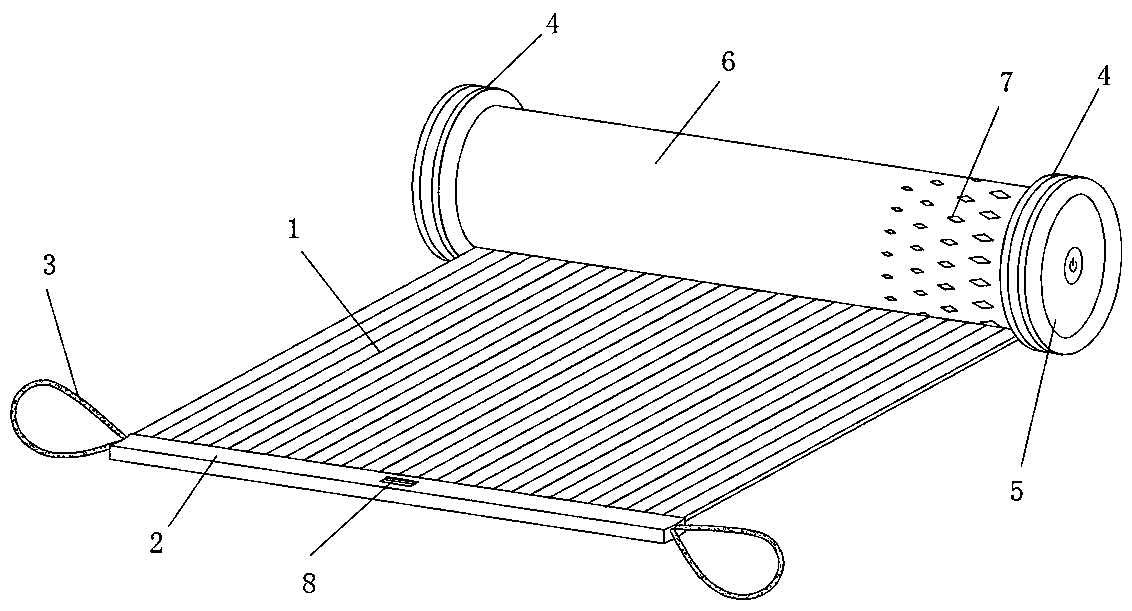

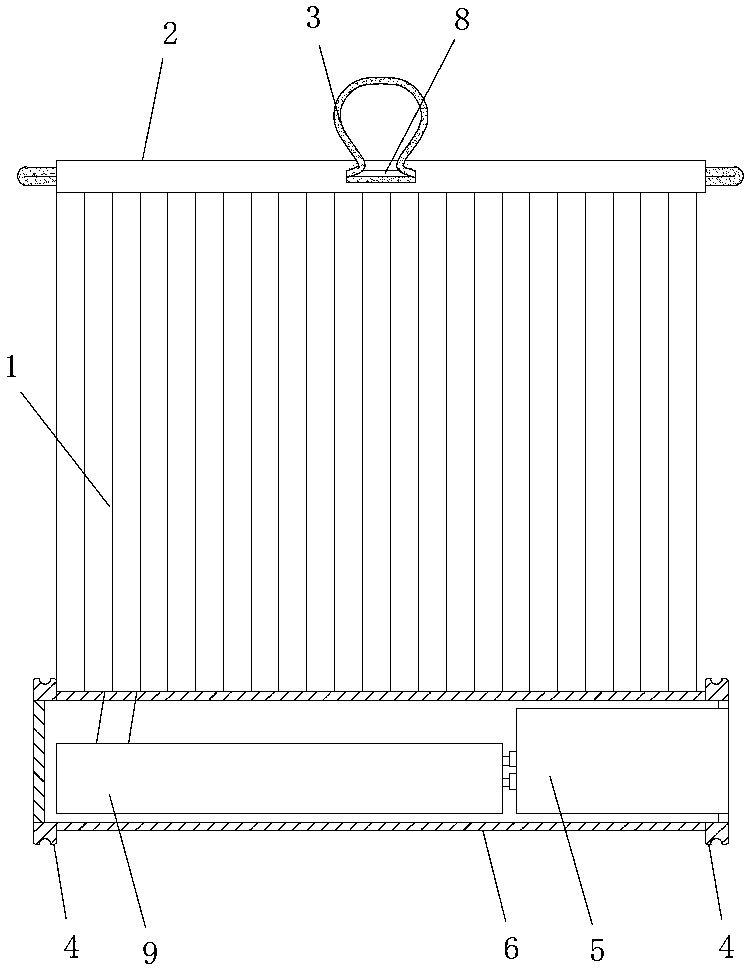

Outdoor solar reel

PendingCN109067347ASmall size limitThe fixing method is simple and reliablePhotovoltaicsPhotovoltaic energy generationSolar cellConductor Coil

The invention relates to an outdoor solar reel, which solves the problem that the size of a flexible solar cell panel is limited and the surface is easy to be damaged due to the existing solar reel peripheral housing. The device has a cylinder core, the cylindrical surface of the cylinder core is wound with a flexible solar cell panel, one end of the flexible solar cell panel is fixed on the outerwall of the cylinder core and is connected with a battery in the cylinder core, The other end is provided with a fixing strip, wherein elastic ropes are pierced through the fixing strip, the elasticropes are pierced out from both ends of the fixing strip and form a collar, the two ends of the cylinder core are provided with fixing parts, the fixing parts are provided with an annular groove, andwhen the flexible solar cell panel is in a rewinding state, the elastic ropes installed in the collar at both ends of the fixing strip are sleeved in the annular groove respectively. The fixing methodof the invention is simple and reliable, and the elastic rope can be pulled out in the middle of the fixing strip and used as a hanging rope suspension; Winding is open, thereby reducing the possibility of scratches; The length of flexible solar panels is adjustable to a certain extent.

Owner:浙江尚越新能源开发有限公司

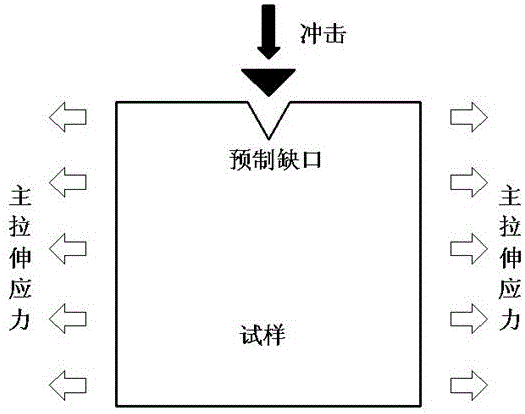

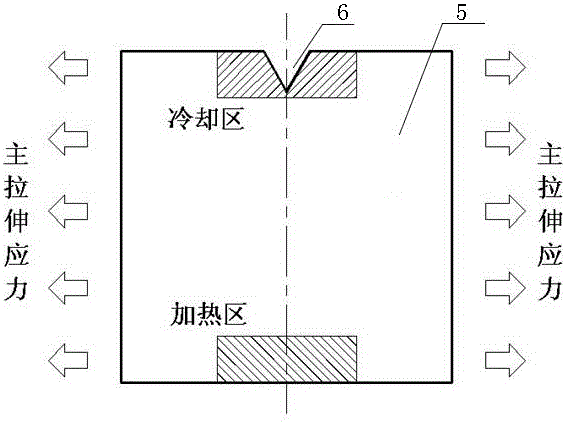

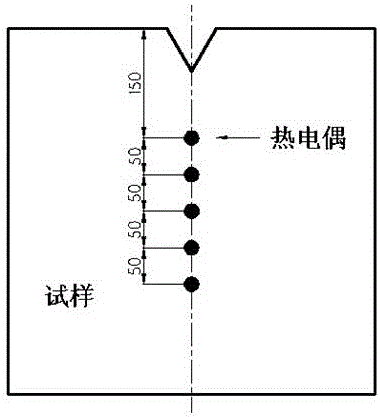

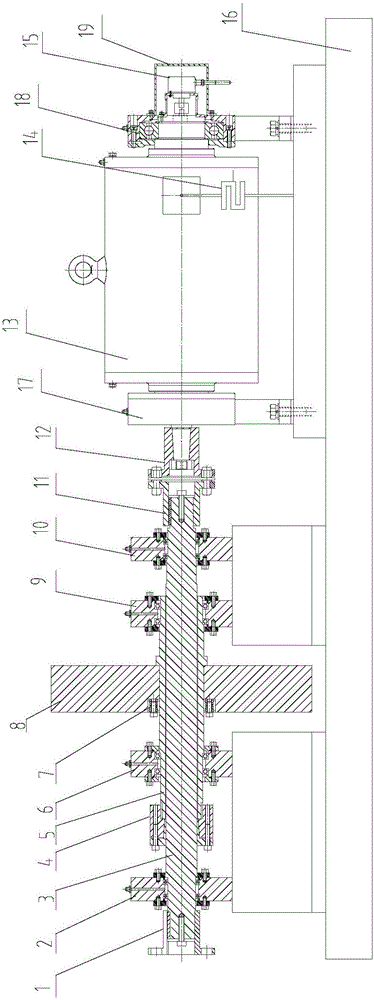

Method for establishing gradient temperature field

ActiveCN106769381ASmooth openingEnsure consistencyPreparing sample for investigationEngineeringMechanical engineering

The invention relates to a cryogenic device used by a method for establishing a gradient temperature field. The cryogenic device used by the method consists of two same low-temperature blocks, a top block having a width the same as that of a sample, and a fastening mechanism, wherein the top block is arranged between the two low-temperature blocks, and the two low-temperature blocks are symmetrically arranged at a V-shaped nick; the fastening mechanism is used for clamping the top block so as to enable the top block to be jointed with the surfaces of two sides of the sample; the surfaces of one sides, jointed with the sample, of the low-temperature blocks are respectively provided with a concave-shaped cryostat; long-strip-shaped parts at the lower ends of the cryostats are used for cooling a V-shaped groove. The method can meet the demands of smoothly starting the cracking of brittle cracks at the nick part and establishing the gradient temperature field, and lays a foundation for the validity test of a crack-arrest property.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Floating motor type engine transient dynamic test two-purpose dynamometer and two-purpose method thereof

ActiveCN106124103ASimple structureReduce volumeWork measurementTorque measurementDrive shaftElectric machine

The invention discloses a floating motor type engine transient dynamic test two-purpose dynamometer. The floating motor type engine transient dynamic test two-purpose dynamometer comprises a foundation, a first transmission shaft bearing support, a second transmission shaft bearing support, a first motor bearing support and a second motor bearing support, wherein the first transmission shaft bearing support and the second transmission shaft bearing support are equipped with a transmission shaft, the transmission shaft is sleeved with a flywheel shaft, the transmission shaft is connected with a transmission shaft and flywheel shaft connector, the flywheel shaft is connected with an inertia flywheel through a flywheel tension sleeve, a dynamometer motor is arranged between the first motor bearing support and the second motor bearing support, an output shaft of the dynamometer motor departing from the transmission shaft is connected with an encoder, and a casing of the dynamometer motor is provided with a pull pressure transducer. The invention further discloses a two-purpose method of the floating motor type engine transient dynamic test two-purpose dynamometer. The floating motor type engine transient dynamic test two-purpose dynamometer is convenient to realize, realizes low cost, is convenient to mount and use, has complete functions, has high work reliability and stability, has high strong practicality and is convenient for popularization and use.

Owner:中检西部检测有限公司

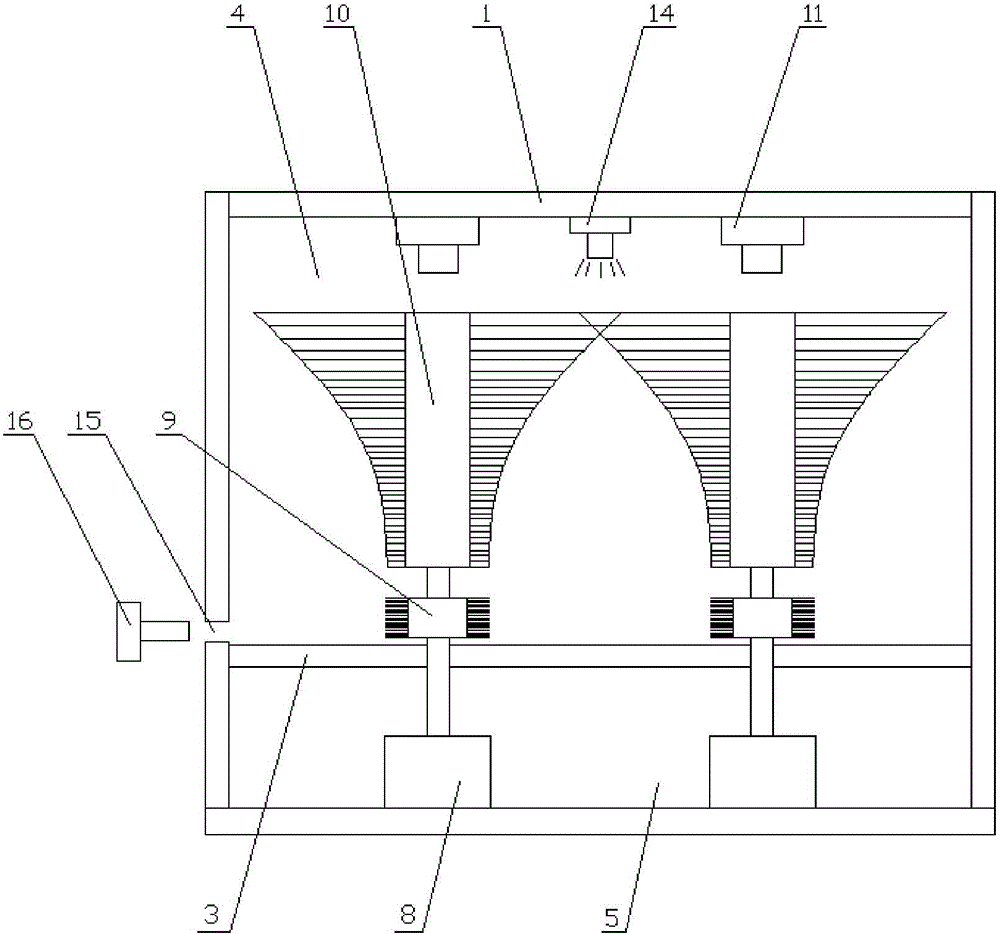

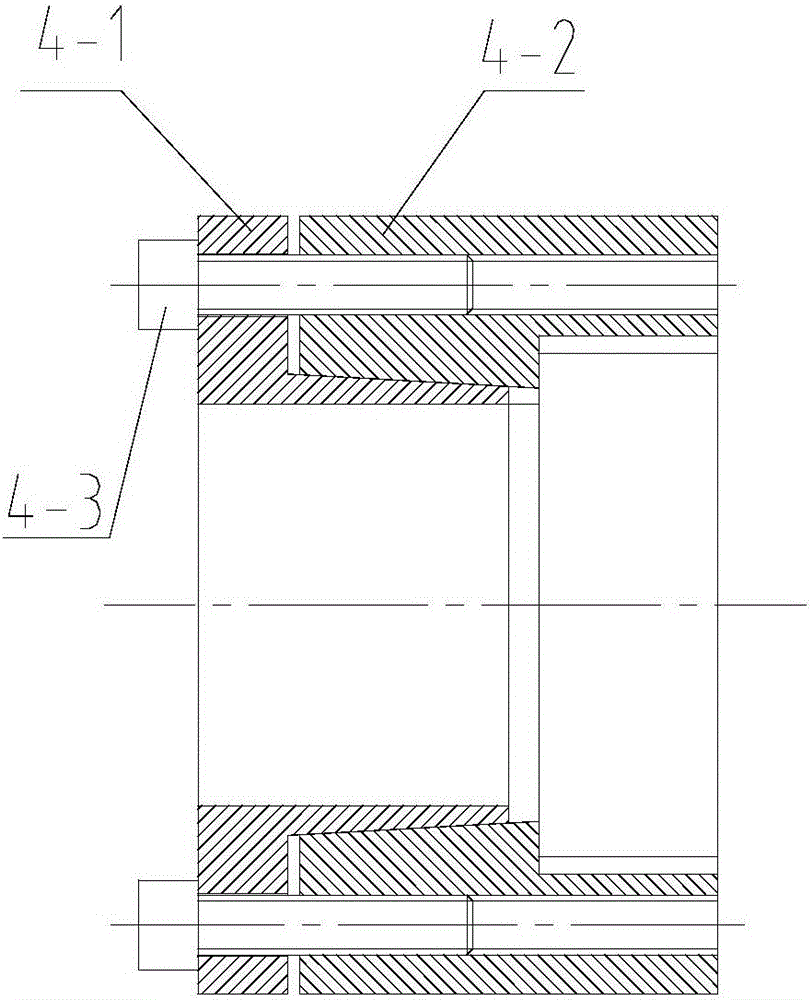

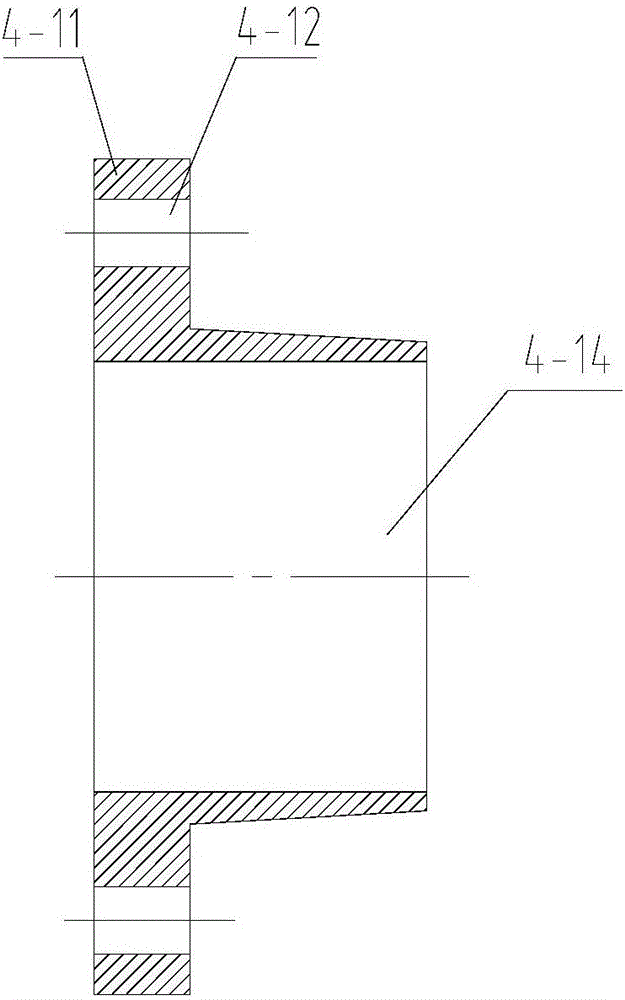

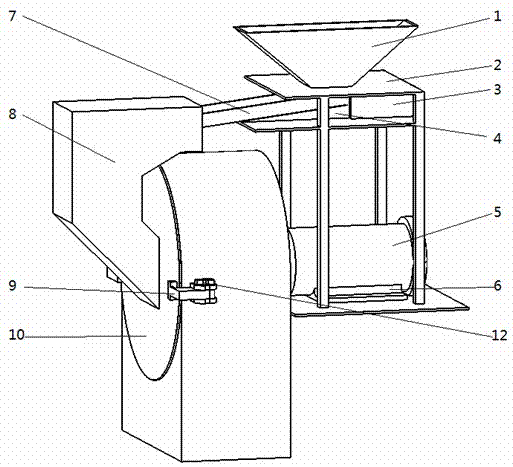

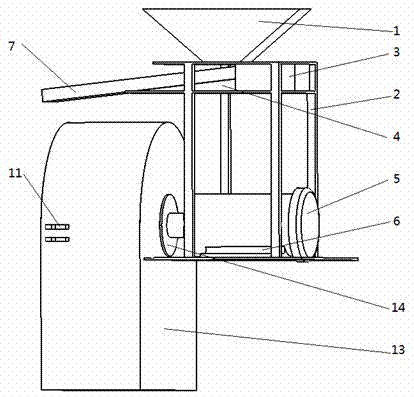

Special-purposed pulverizer for coal mine fire extinguishing high hygrophanous resin, and application method thereof

The invention discloses a special-purposed pulverizer for a coal mine fire extinguishing high hygrophanous resin and an application method thereof. The invention is characterized in that: a material canister is fixed on a main rack, an outlet at the lower part of the material canister is connected with a chute feeder, a guide rail is fixed on the main rack, one end of the chute feeder is fixed with an electromagnetic device, the chute feeder is connected with the guide rail through a dovetail, the other end of the chute feeder is connected with the upper end of the feeding channel, the lower end of the feeding channel is connected with a through hole on a baffle plate, the baffle plate is fixed on a crushing chamber, subordinate blades are annularly arranged on the upper part of the crushing chamber, screen meshes are annularly arranged on the lower part of the crushing chamber, a motor is fixed on the main rack through a motor fixing rack, an output shaft of the motor is fixed on a flange of the crushing chamber, the terminal of the output shaft is fixed with a circular disc, several main blades are distributed around the circular disc. According to the invention, vibration feeding is adopted for feeding a stable and uniform way, and overload damage can be prevented though controlling of the motor current; the main blades and the subordinate blades have stronger flexibility to reduce the wearing of blades; the subordinate blades are annularly and densely arranged such that the crushing efficiency and quality can be enhanced; the screen meshes are convenient to be changed for different meshes of crushing.

Owner:ZHEJIANG WEILONG POLYMER MATERIAL +1

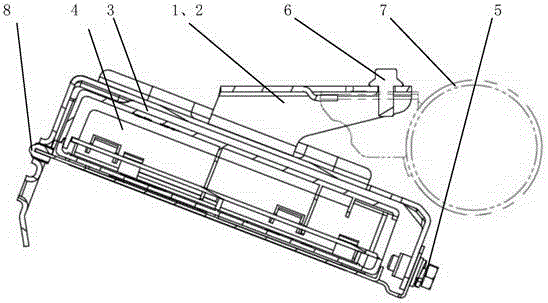

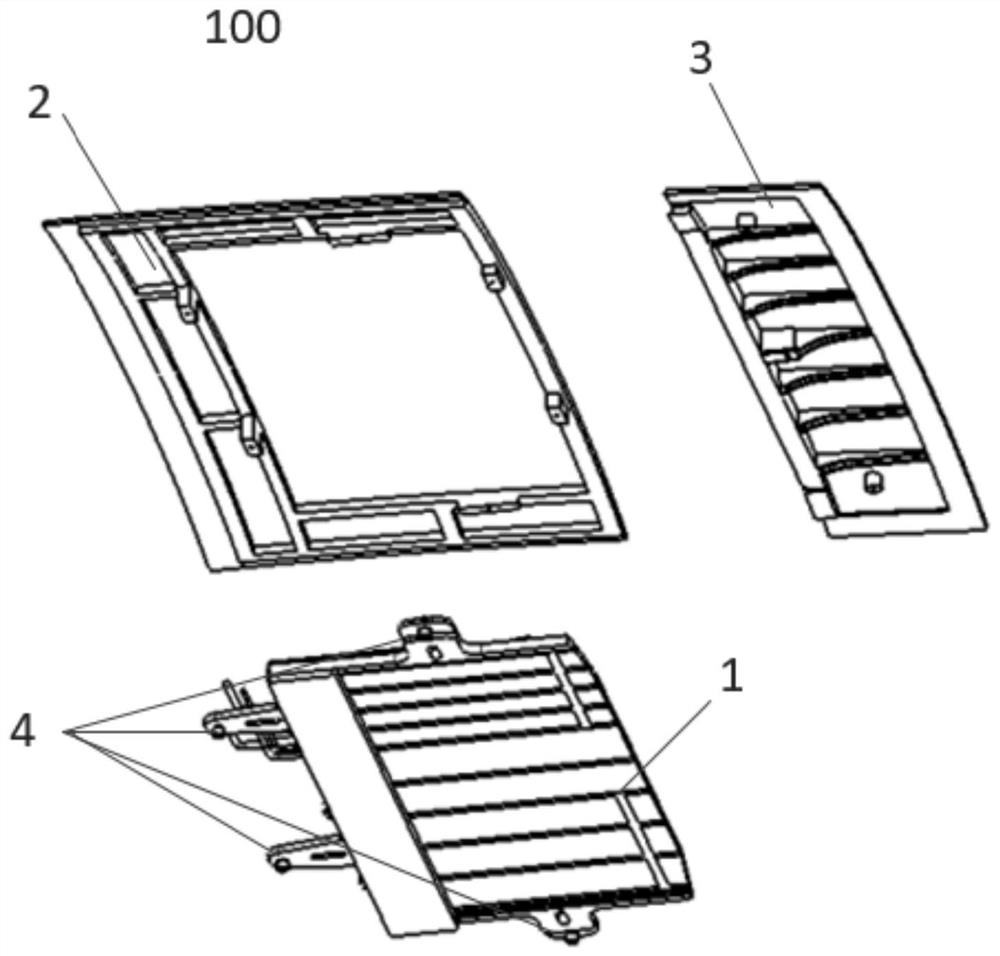

Wind guide plate and air conditioner with wind guide plate

Owner:GREE ELECTRIC APPLIANCES INC

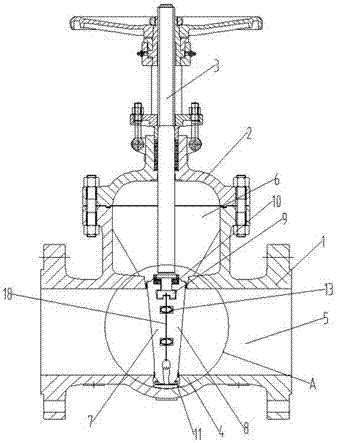

Easy-to-clean intelligent cooking equipment

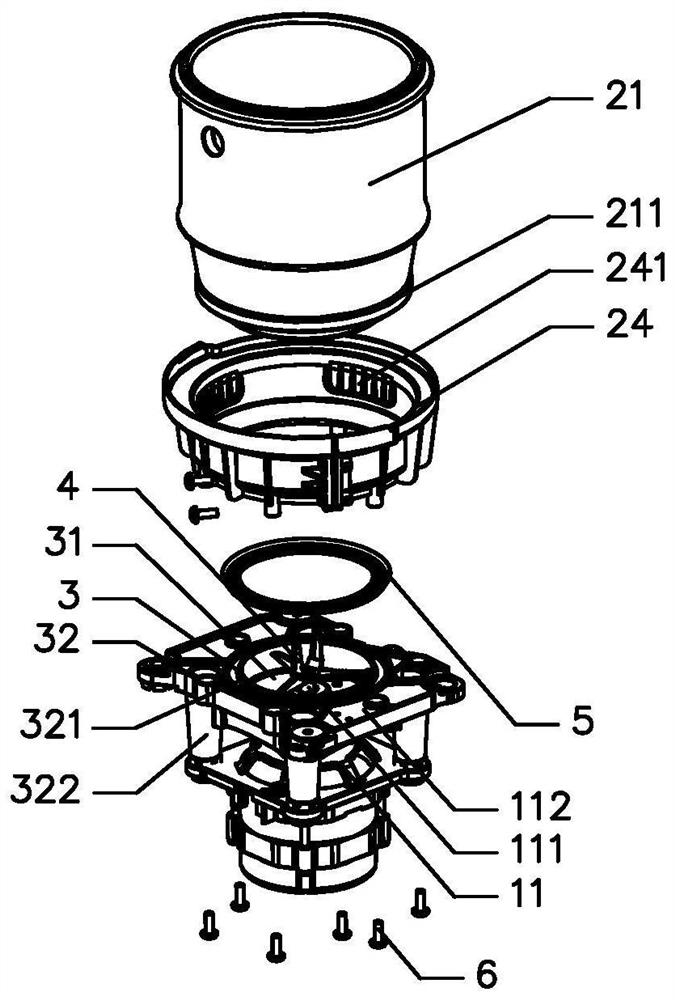

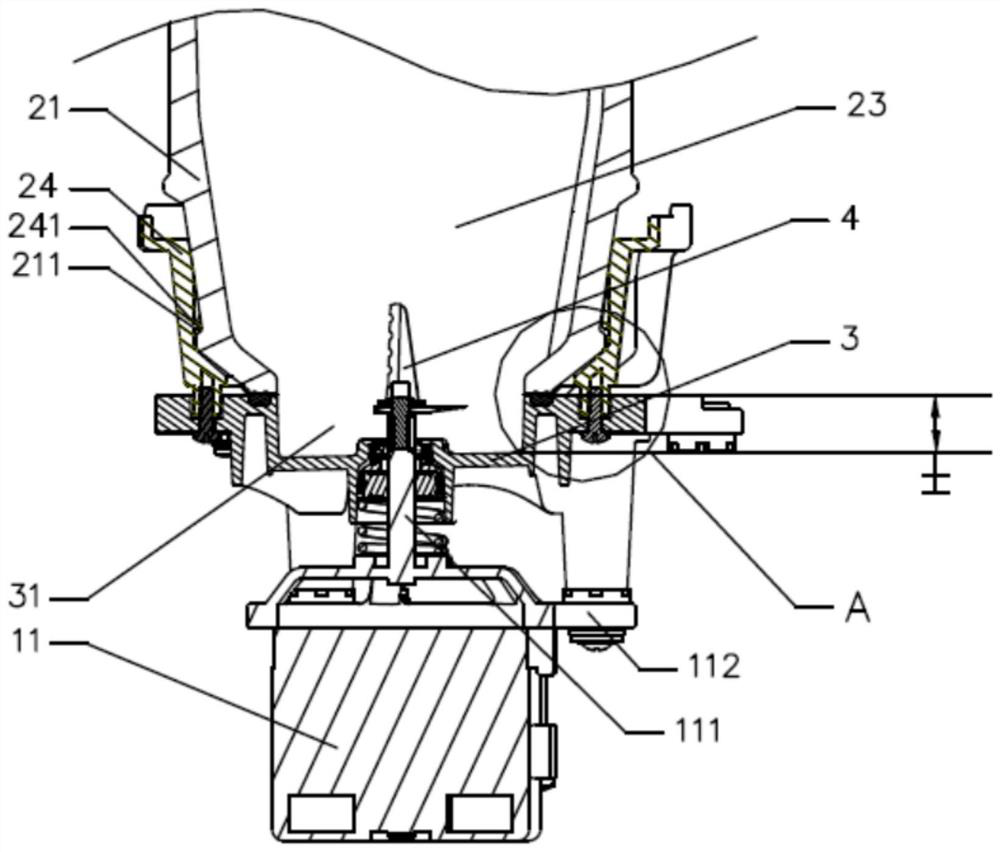

PendingCN110279286AKeep clean and hygienicEasy to disassembleCooking-vessel lids/coversCooking insertsCouplingDrive shaft

The invention discloses easy-to-clean intelligent cooking equipment. The easy-to-clean intelligent cooking equipment comprises a cover body and a seat body, and a stirring member is arranged on the cover body; a drive device is arranged on a connection arm, and the drive device drives the stirring member to perform stirring action through a transmission mechanism; and the transmission mechanism comprises a drive shaft, a coupling shaft and a planet wheel assembly, wherein the drive shaft is arranged on the connection arm and rotates on the fixed axis of the connection arm driven by the drive device; the coupling shaft is connected with the drive shaft and is driven to rotate in a coaxial line mode with the drive shaft; the planet wheel assembly is used for driving the stirring member to enable the own axis to rotate and revolute around the axis of the coupling shaft, and the planet wheel assembly comprises a fixed cover, a movable cover, a sun wheel and two planet wheels; and the coupling shaft penetrates through the fixed cover and the movable cover, the movable cover is driven to rotate relative to the fixed cover, the coupling shaft and the movable cover are locked and connected through a locking piece in the direction of the axle of the coupling shaft and the movable cover, the coupling shaft is in transmission connection with the movable cover in the peripheral direction of the coupling shaft and the movable cover through an occlusion structure, and after the locking piece is dismantled, the planet wheel assembly can be separated from the coupling shaft. The easy-to-clean intelligent cooking equipment is easy to clean and use.

Owner:机智过人(北京)智能科技有限公司

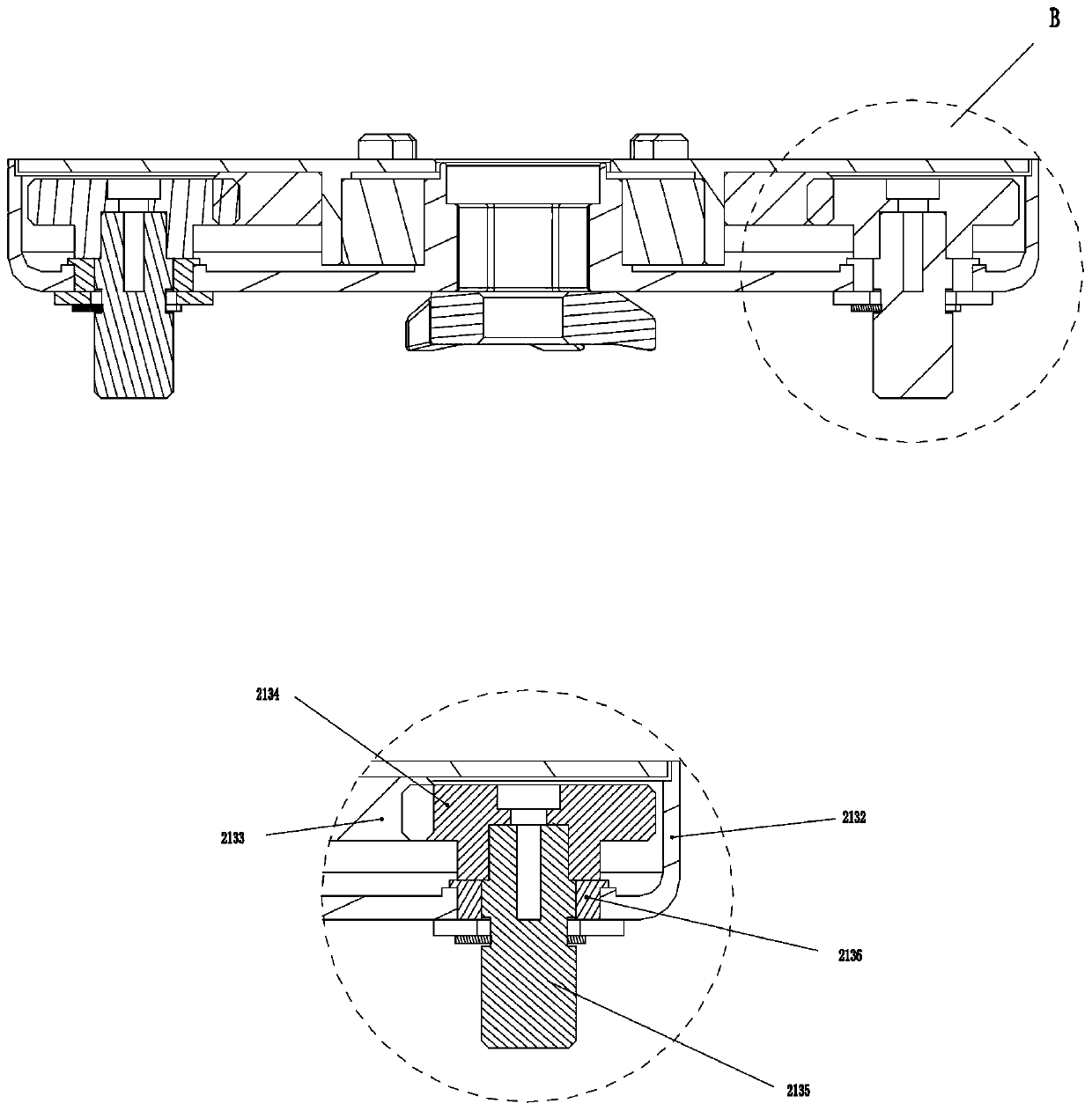

gate

ActiveCN105065699BOvercome loosenessOvercoming the problem of insufficient sealingSlide valveLeft valveGate valve

The invention discloses a gate valve with a good airtightness effect. Springs arranged between a traditional left valve plate and a traditional right valve plate are replaced by elastic metal rings, and therefore the defect that the left valve plate and the right valve plate get loose due to the fact that the springs lose efficacy after long-time use can be effectively overcome. Due to the facts that the elastic metal rings abut against the inner walls of accommodating cavities and open upwards, it is guaranteed that the elastic metal rings can exert pressure in the axis direction of a flow channel all the time, and the problem that airtightness is not enough due to abrasion of a valve seat or a sealing face is solved due to the fact that elastic force is exerted on the left valve plate and the right valve plate continuously. Moreover, a valve plate sleeve and a clamping sleeve are used for limiting and fixing the left valve plate and the right valve plate, the fixing mode is simple and reliable, and compared with a traditional gate valve, the airtightness is good, and the service life is long.

Owner:FLUOROSEAL SPECIALTY VALVES SUZHOU

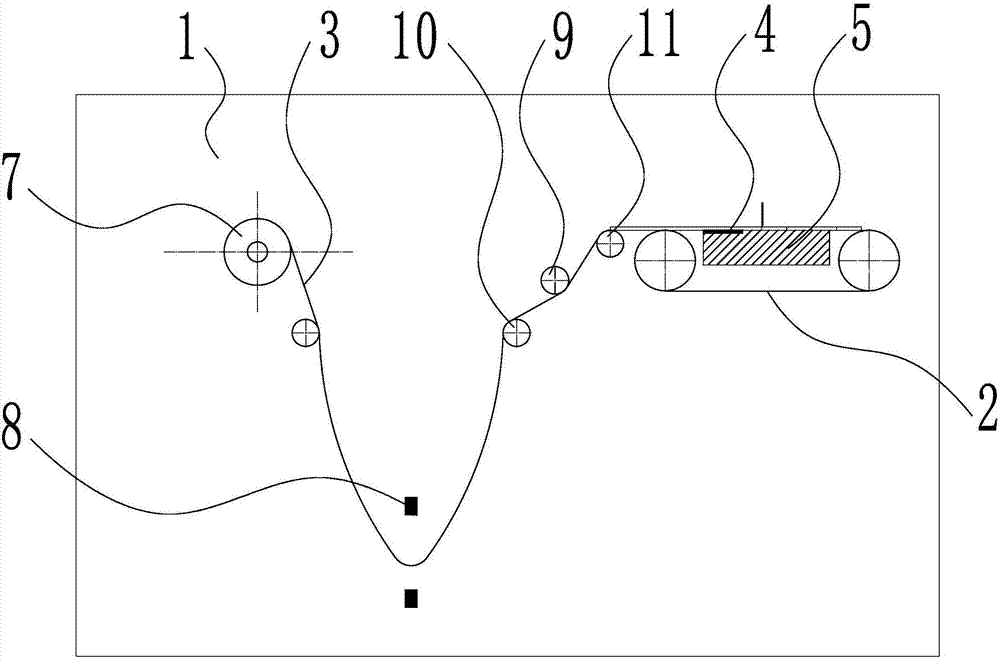

Automatic slicing machine for slitting ultrathin flexible magnetic sheets

InactiveCN107953465ANo deformationPrevent and avoid breakingFine working devicesEngineeringProduction quality

The invention relates to an automatic slicing machine, in particular to an automatic slicing machine for slitting ultrathin flexible magnetic sheets. The automatic machine is simple in structure, highin cutting efficiency, and good in quality. The automatic cutting machine solves the technical problems of low cutting efficiency, low accuracy of sizes of ultrathin flexible magnetic sheets, poor production quality, and low qualification rate due to completely pure manual operation. The automatic cutting machine includes a closed workshop and a conveyor arranged in the closed workshop, and the input end of the conveyor is tiled with an ultrathin-flexible-magnetic-sheet raw material belt; a horizontal strong magnetic sheet is arranged below the input end, corresponding to the ultrathin-flexible-magnetic-sheet raw material belt, of the conveyor; the ultrathin-flexible-magnetic-sheet raw material belt is absorbed and fixed on the conveyor and move towards to an output end following the conveyor; and a slicing device is arranged above the conveyor, and the ultrathin-flexible-magnetic-sheet raw material belt can be continuously cut in segmentation mode by the cutting device.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Transformer oil storage tank supporting structure

InactiveCN104332285AThe fixing method is simple and reliableEnsure safetyTransformers/inductances coolingBiochemical engineeringFuel tank

The invention relates to the field of a transformer auxiliary device, in particular to a transformer oil storage tank supporting structure. The transformer oil storage tank supporting structure comprises a transformer oil tank, two ring clamps, a support column and a lock column; one end of the support column is connected with the ring clamps through a flange, a fixed head is arranged on the other end of the support column, a through hole is respectively, axially and perpendicularly formed on the fixed head and the support column, a clamping rib is arranged on the inner wall of the through hole, the transformer oil tank is provided with an installation clamping hole and a fixed hole which is perpendicular to the installation clamping hole, a fixed hole is also arranged in the fixed hole and correspondently inserted into the installation clamping hole, and the fixed hole is fixed in the installation clamping hole by embedding the support column into the fixed hole. The transformer oil storage tank supporting structure has beneficial effects that by adopting the fixing way of the lock column and support column, the oil storage tank is convenient to install and dismount.

Owner:CHONGQING WANGBIAN ELECTRIC GRP CORP

Small quick heater

The invention discloses a small quick heater which comprises a shell, insulating layers, insulating studs, a heating net, electrodes and asbestos gaskets, wherein the heating net is fixed on the insulating studs on the two sides of a channel of the shell in a tensioned mode to enable a multi-layer grid structure to be formed in the channel, the electrodes are arranged at the two ends of the shell respectively to fasten the heating net, the power supply ends of the electrodes and flanges are fastened to the shell through insulating screws, the insulating layers are arranged between the electrodes and the shell, the asbestos gaskets are arranged between the electrodes and the flanges, and the heating net is electrified and heated through the electrodes to achieve reliable power supply. According to the small quick heater, multi-layer folding wire mesh is adopted to serve as a heating element, the wire mesh is arranged perpendicular to the liquid flowing direction in a single-layer or multi-layer mode, and by means of the characteristics that the contact area between liquid and the heating element is large and heat exchange is strong, the efficiency of heat exchange between the liquid and the heating element is high. The heater is used for quick heating of liquid working media in a channel under the condition that non-conducting liquid is still or moves, and especially suitable for quick heating of liquid with small flow.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

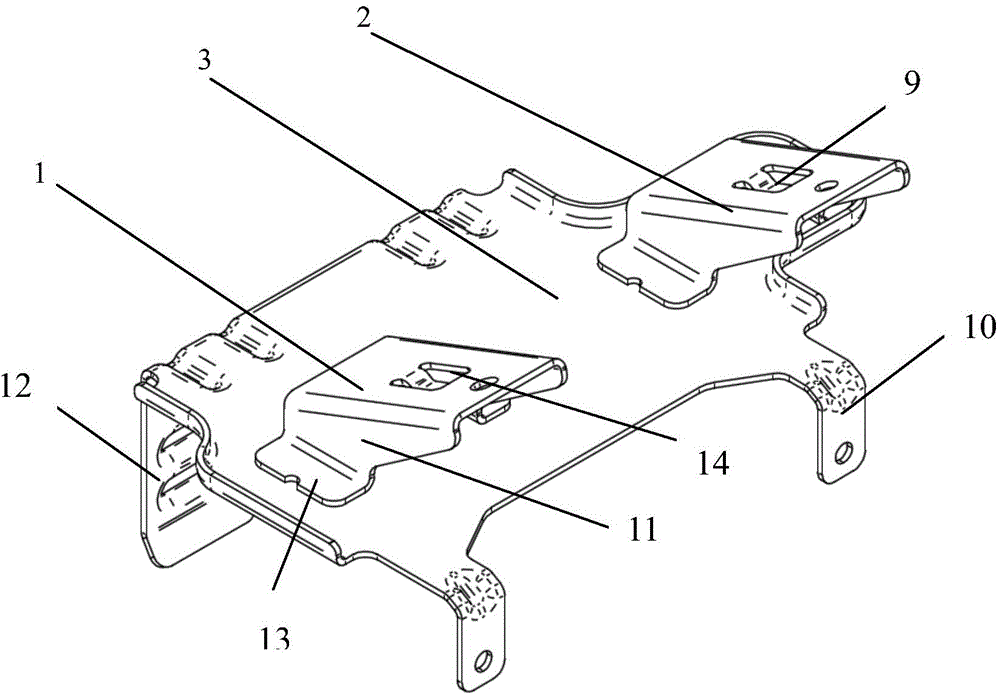

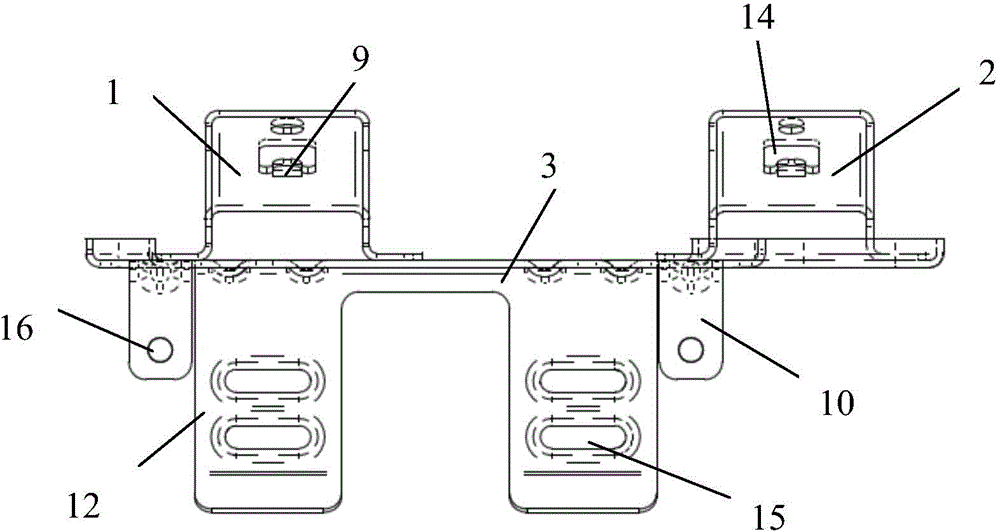

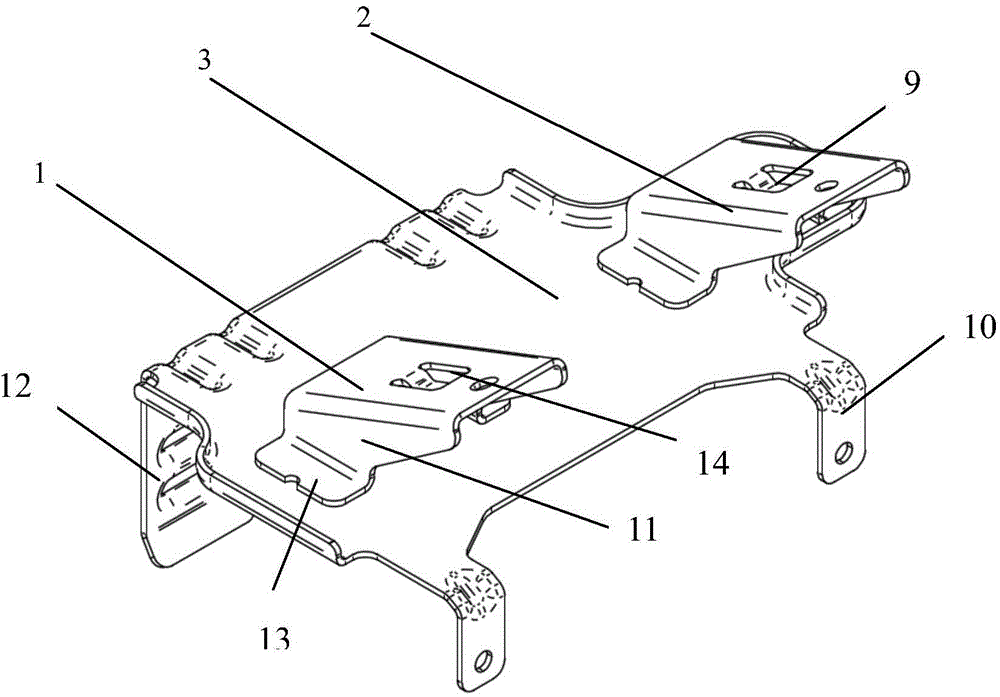

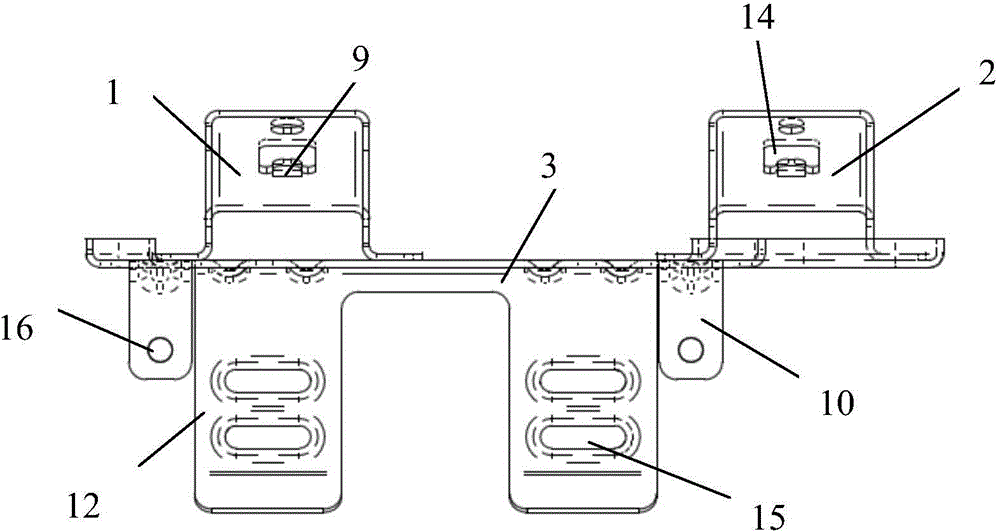

Bracket for automobile controller

The invention relates to a bracket for an automobile controller. The bracket comprises a bracket body, a left upper bracket and a right upper bracket, wherein the left upper bracket and the right upper bracket are fixed on the bracket body; and two bulged structures which are bent to form approximate right angles with the body are arranged on each lateral side of two side edges of the bracket body and used for mounting the controller. Two points are designed on the controller bracket, so that the bracket can be fixed on a pipe beam of an automobile body and connected through bolts; and two limit devices are arranged on bracket mounting support feet, so that mounting points don't bear the weight of the bracket and the controller directly, and fixation can be more reliable.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

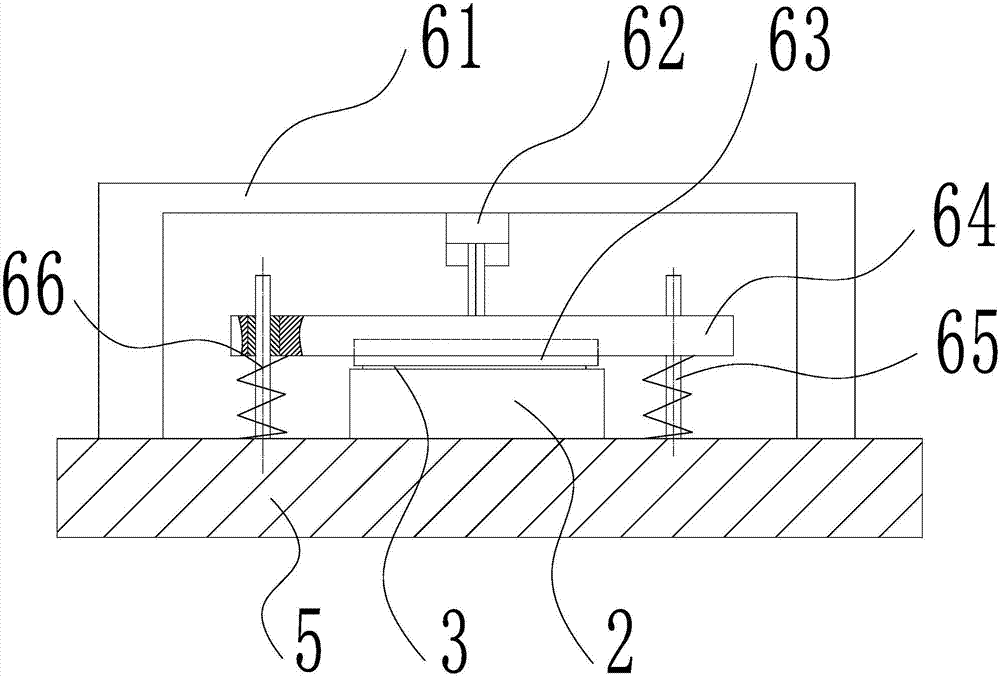

A stamping device for reinforcing steel plate of washing machine

ActiveCN109226406BEffectively fixedAvoid offsetMetal-working feeding devicesPositioning devicesHydraulic cylinderLaundry washing machine

The invention discloses a stamping device of a washing machine reinforcing steel plate. The device comprises a base, wherein the top of the base is symmetrically, vertically and fixedly provided withsupporting columns, the tops of the supporting columns are horizontally and fixedly provided with a top plate, the top center of the top plate is fixedly provided with a hydraulic cylinder, a piston rod on the bottom of the hydraulic cylinder vertically and slidably penetrates through the top plate and is fixedly provided with a pushing mounting column, the bottom of the pushing mounting column ishorizontally and fixedly provided with an abutting plate, the bottom of the pushing mounting column is provided with a mounting groove, the bottom center of the abutting plate is provided with a riveting groove, a threaded pressing column vertically and slidably penetrates through the top of the abutting plate, the top end of the threaded pressing column extends to the inner portion of the mounting groove and is sleeved with a first gear and a second gear in a sleeved mode, and the bottom end of the threaded pressing column extends to the inner portion of the riveting groove and is fixedly provided with a stamping head. The stamping device of the washing machine reinforcing steel plate has the advantages that the structure is reasonable, the operation is concise, the fixing mode is simpleand firm, power output is stable and strong, and the stability of stamping is improved.

Owner:CHUZHOU XIEZHONG HOUSEHOLD ELECTRICAL APPLIANCE FITTINGS

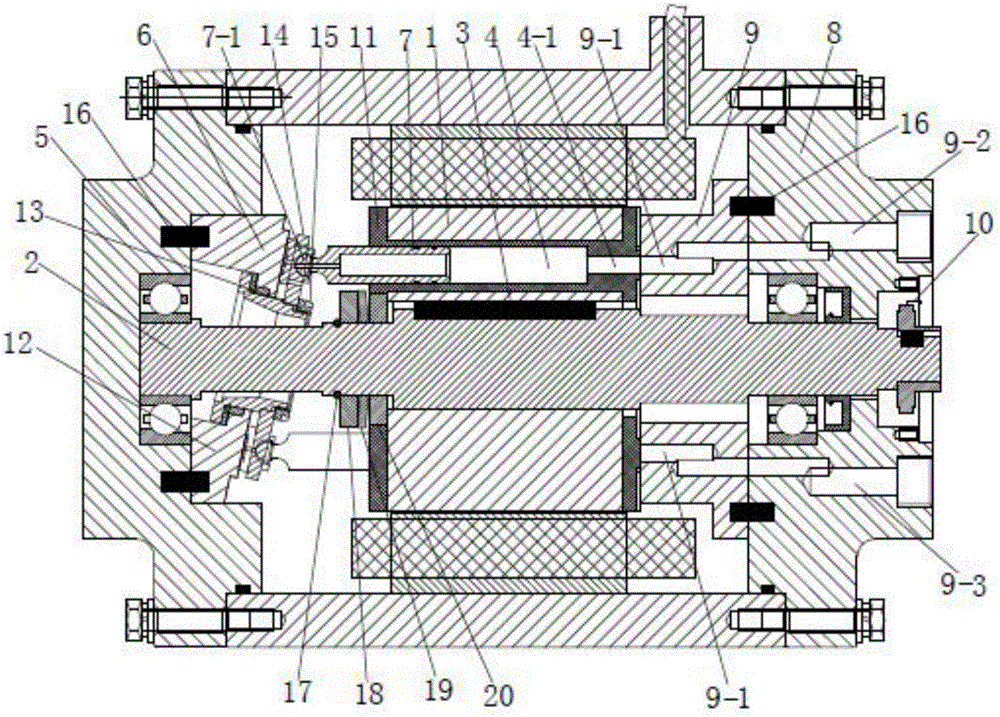

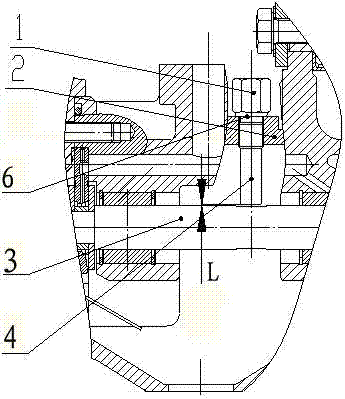

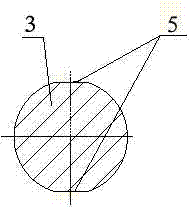

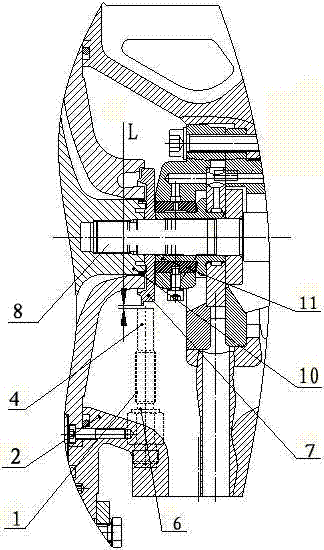

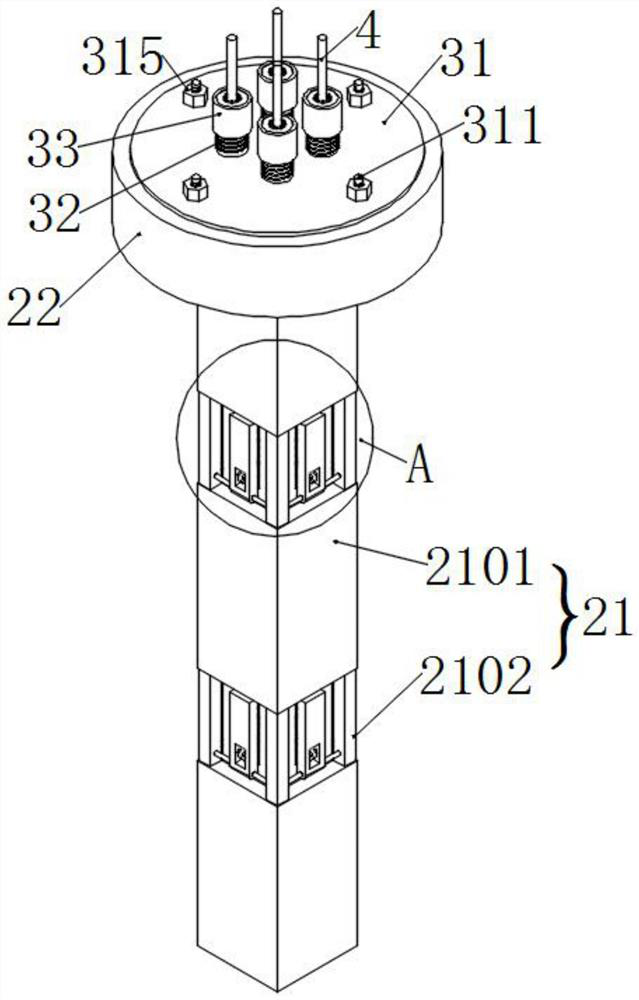

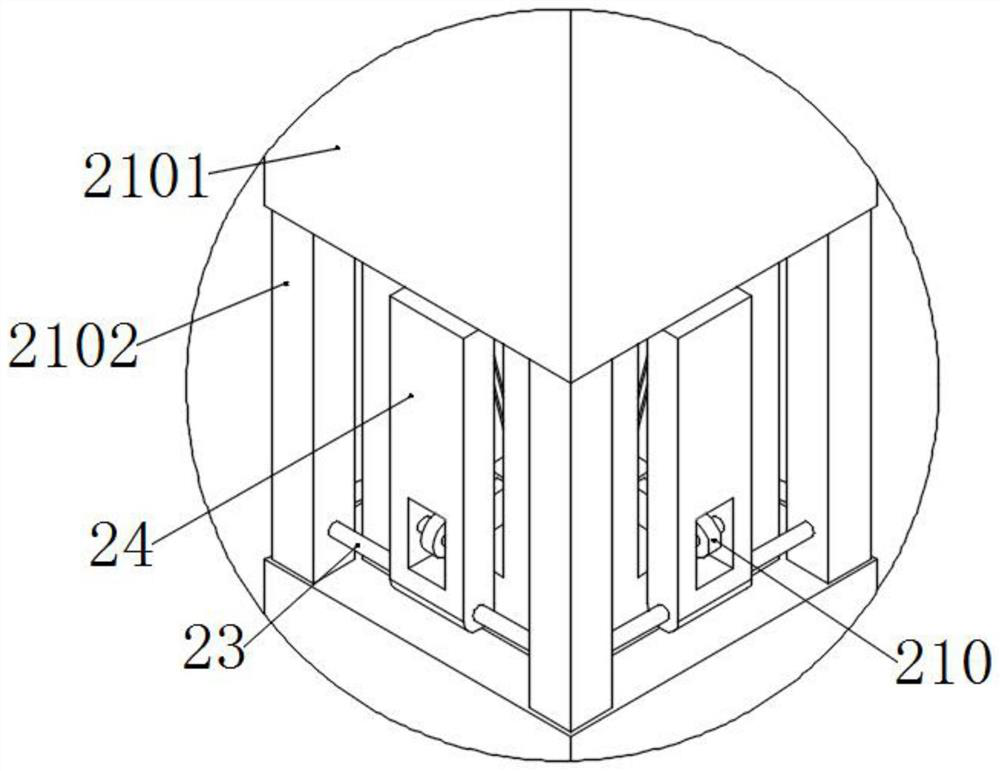

Built-in rotation speed measurement device of supercharger

InactiveCN103901223AGuaranteed reliabilitySimple structureLinear/angular speed measurementMechanical engineeringPhysics

The invention relates to a built-in rotation speed measurement device of a supercharger. The device comprises a rotation speed sensor (1), a bearing body (2) and a piece (3) with the rotation speed to be measured, wherein the rotation speed sensor (1) is provided with a rotation speed sensor center (4), the piece (3) with the rotation speed to be measured is provided with a measurement platform (5), and the rotation speed sensor (1) is connected with the bearing body (2) through fine threads and suspended at a position a certain distance above the piece (3) with the rotation speed to be measured and right faces the measurement platform (5) on the piece (3) with the rotation speed to be measured to form a measurement gap L. Because the rotation speed sensor is firmly fastened to the bearing body of the supercharger, the device is simpler in structure, and accordingly it is guaranteed that the sensor can be reliably used for a long time.

Owner:大同北方天力增压技术有限公司

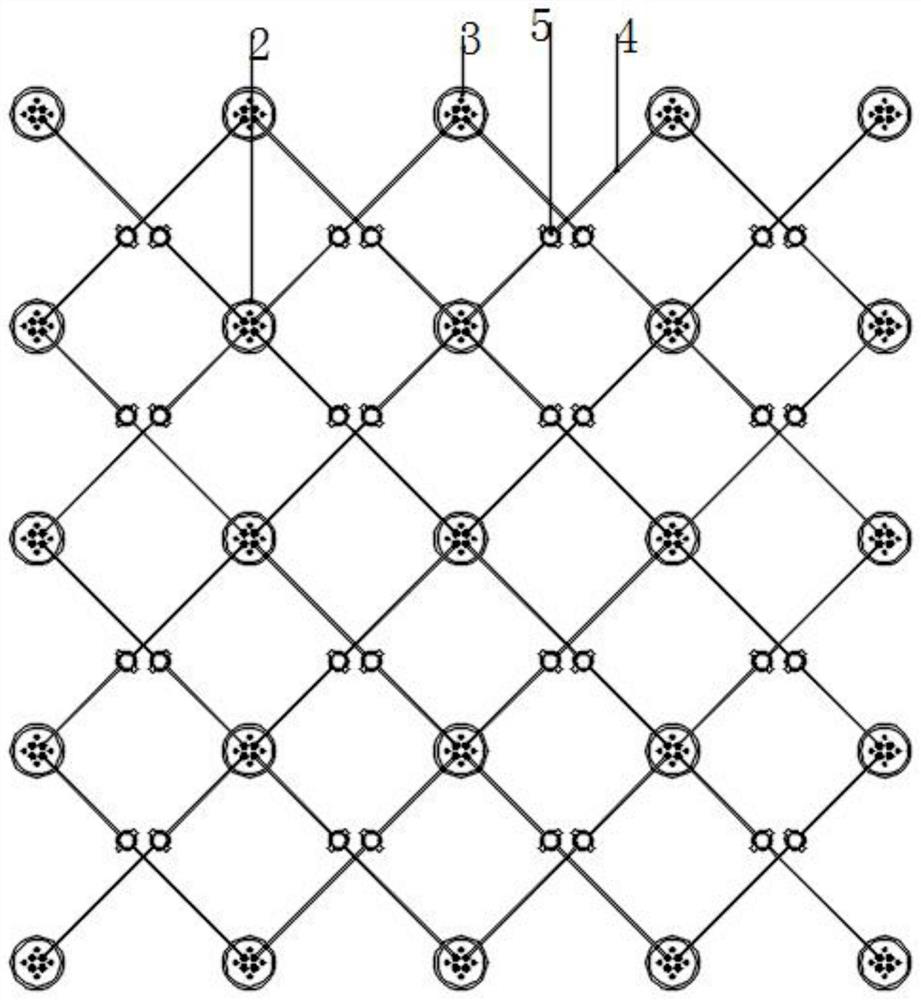

High-safety reinforcing device for geotechnical engineering side slope

PendingCN114575360AThe fixing method is simple and reliablePrevent looseningClimate change adaptationExcavationsSoil scienceLandslide

The high-safety reinforcing device comprises a slope body, an anchoring mechanism, a rope head fixing mechanism, a steel wire rope and a tensioning mechanism and has the beneficial effects that the anchoring mechanism is stably fixed in the slope body, the two ends of the steel wire rope are fixed through the rope head fixing mechanism, and the steel wire rope is woven into a net shape; local landslide and collapse on a slope body can be avoided, the steel wire ropes are independently fixed, so that the steel wire ropes are convenient to fix, the steel wire ropes are mutually independent, the net woven by the steel wire ropes cannot integrally fall off due to looseness of a single steel wire rope, during maintenance, only the falling or broken steel wire ropes need to be replaced, and the maintenance cost is reduced. The whole device is more convenient to maintain, after the steel wire rope is fixed, the steel wire rope can be tensioned through the tensioning mechanism, and the whole device is more reliable and safer.

Owner:成都睿思达工程设计咨询有限公司

Rotary shaft feedback detection hydraulic locking system

ActiveCN103801983BAvoid wear and tearThe fixing method is simple and reliableAutomatic control devicesGrinding drivesControl systemCylinder block

The invention discloses a rotating shaft feedback detection hydraulic locking system, provides a locking system with large locking torque, high positioning accuracy, and can accurately identify and feedback the position of the box body, and solves the problem of box body positioning accuracy in the prior art Low, the position of the cabinet cannot be adjusted and corrected and other technical problems. It includes a mandrel and a servo motor connected to one end of the mandrel. The middle part of the mandrel rotates and connects to the box. The other end of the mandrel opposite to the servo motor is sleeved with a cylinder connected to the box. The corresponding core in the cylinder A wear-resistant sleeve is fixed on the shaft, and the wear-resistant sleeve is covered with a corrugated sleeve. The inner end of the corrugated sleeve is connected to the box body, and the outer end extends to the outside of the wear-resistant sleeve, and is slidably connected to the mandrel corresponding to the outer end of the corrugated sleeve. There is a piston, the piston is driven by the power unit and pushes the corrugated sleeve inwards to compress it so that the cylinder body is tightened and fixed on the wear-resistant sleeve, and an encoder that can automatically identify the position of the box relative to the mandrel is installed on the mandrel. The controller is connected to the servo motor through the control system.

Owner:陈小青 +1

A food processor with good cleaning effect

ActiveCN110731711BGuaranteed to workGuaranteed stabilityVessels with intergral heatingElectric machineryEngineering

The invention provides a food processing machine with a good cleaning effect. The food processing machine comprises a machine body, a motor, a crushing device, a crushing cup body and a crushing cup cover, wherein the crushing cup body comprises a glass cup body, a metal disc and a cup body support, wherein openings are formed in the upper part and the lower part of the glass cup body respectively; the metal disc is mounted at the opening in the lower part of the glass cup body in a sealing mode; the crushing cup cover is arranged at the opening in the upper part of the glass cup body in a covering mode; the crushing cup cover, the glass cup body and the metal disc are enclosed to form a pulping cavity; the crushing device is arranged in the pulping cavity; the upper port of the metal discis provided with a mounting skirt; the thickness of the mounting skirt is 2.5 mm to 6 mm; the opening in the lower part of the glass cup body is in butt joint with the mounting skirt of the metal disc; a sealing ring is arranged between the opening in the lower part of the glass cup body and the mounting skirt; the sealing ring is used for sealing the gap between the glass cup body and the metaldisc; and the inner side wall of the glass cup body is aligned with the inner side wall of the metal disc at the butt joint of the glass cup body and the metal disc, and the alignment deviation is notmore than 2 mm. Therefore, the food processing machine is easy to automatically clean.

Owner:JOYOUNG CO LTD

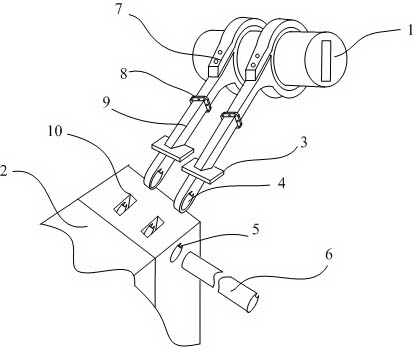

Inflatable laparoscope device placer

InactiveCN104706429AAvoid deformationPrecise positioningSuture equipmentsInternal osteosythesisEngineeringAssistive equipment

The invention provides an inflatable laparoscope device placer, belonging to the field of medical treatment auxiliary equipment. The inflatable laparoscope device placer comprises a bag, a bonding component and a connecting piece, wherein the bag is provided with an opening, and the bonding component is located in the bonding component and is fixedly connected with the inner wall of the bag; the bonding component comprises a plurality of inflatable positioning rings for being fixedly inserted by a laparoscope device, the center lines of the positioning rings face to the opening, and the positioning rings are distributed at intervals and are sequentially communicated; the connecting piece is connected with the bonding component or the bag and is used for fixing the placer to a fixture. The inflatable laparoscope device placer is simple in structure and convenient to use, the time and the labor are saved during operation, and the laparoscope device is good in positioning effect and is convenient to fetch and place.

Owner:杨璐 +4

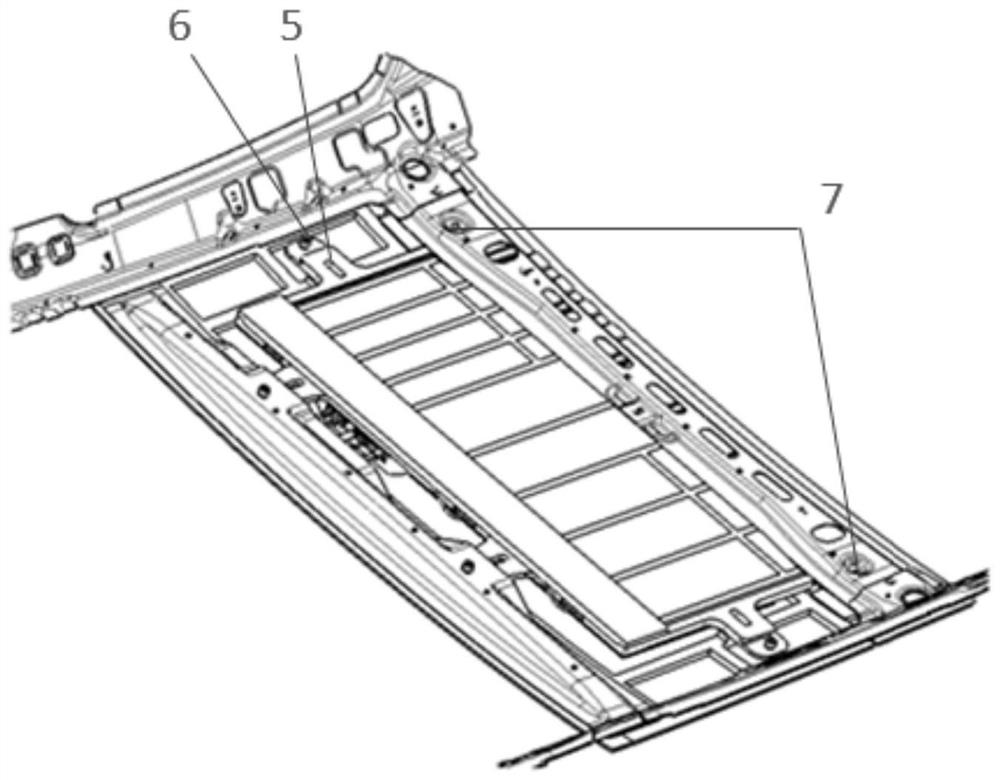

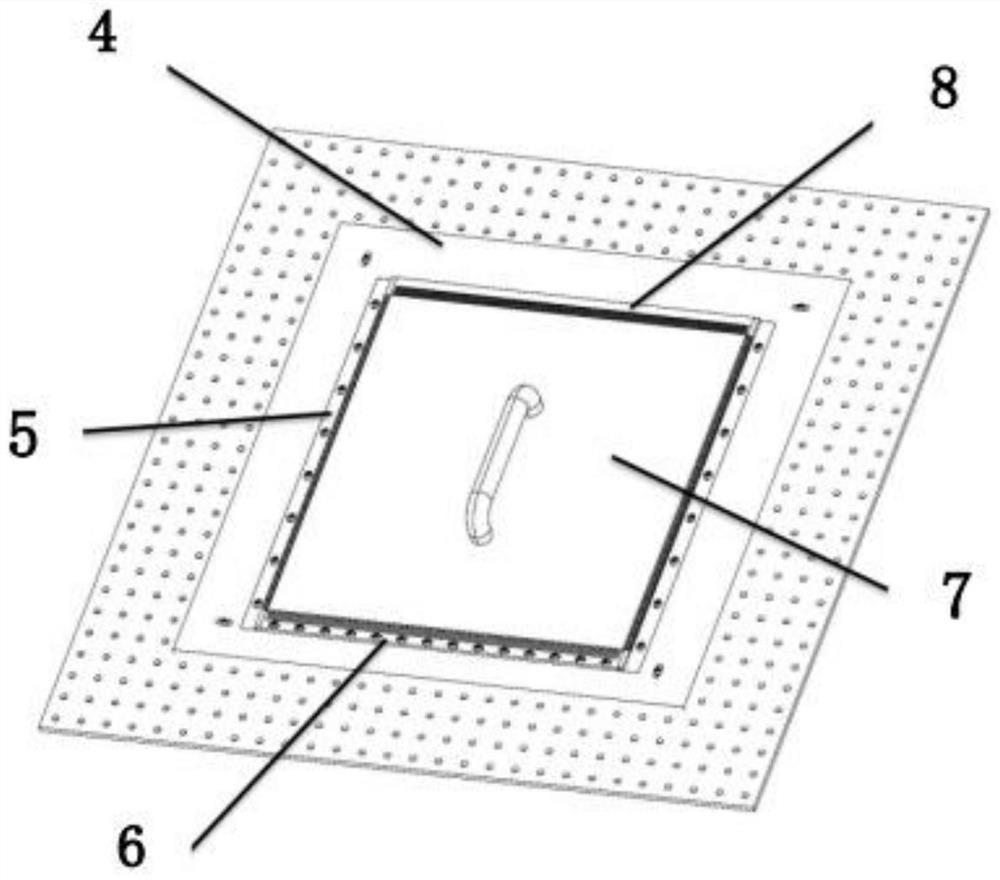

Vehicle-mounted communication module assembly device, vehicle body top cover and vehicle

PendingCN113997870AReduce bend over assembly timeImprove comfortAntenna arraysAntenna adaptation in movable bodiesIn vehicleMechanical engineering

The invention discloses a vehicle-mounted communication module assembly device, a vehicle body top cover and a vehicle. The vehicle-mounted communication module assembly device comprises a satellite communication module and an antenna housing, wherein the satellite communication module comprises at least one connecting block, the connecting block comprises a first connecting piece and a second connecting piece, the satellite communication module is connected with the antenna housing through the first connecting piece, and the satellite communication module is connected with the vehicle body top cover main body through the second connecting piece. The satellite communication module, the antenna housing and the heat dissipation plate are integrally mounted on the roof, so that the assembly steps are simplified, the assembly time is shortened, and the assembly efficiency is improved; and the workload of assembly personnel or robots is reduced, assembly tools and clamps are reduced, and the cost is reduced.

Owner:ZHEJIANG ZEEKR INTELLIGENT TECH CO LTD +2

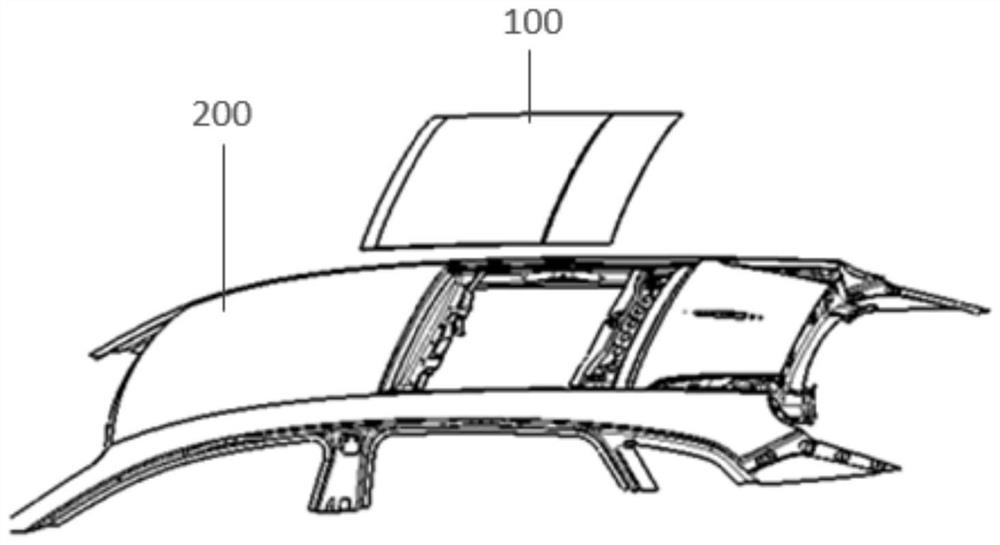

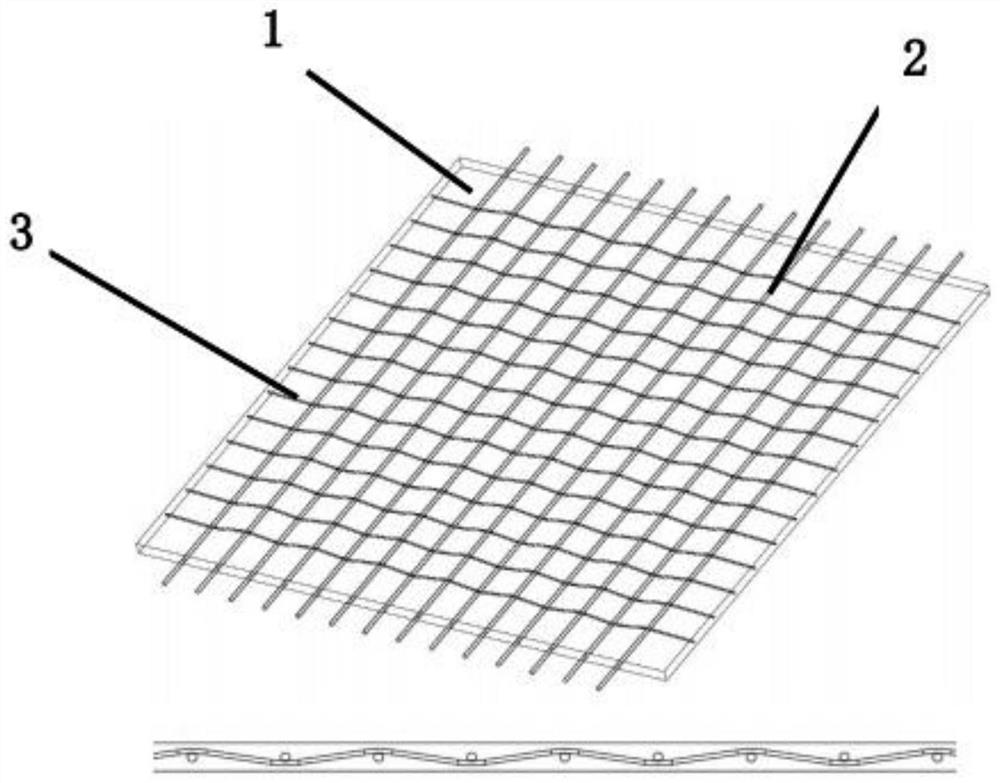

Flexible composite skin and manufacturing method and tool structure thereof

ActiveCN111674541AReduce cell aspect ratioImprove structural stabilityFinal product manufactureFuselage bulkheadsStructural engineeringManufacturing engineering

The invention provides a flexible composite skin and a manufacturing method and a tool structure thereof, and belongs to the technical field of aviation, thereby solving a problem that an existing flexible skin is poor in stability and bearing performance. The composite skin comprises a flexible rubber base body, an embedded supporting structure and a fiber reinforcement body. The embedded supporting structure and the fiber reinforcement body are shaped in the flexible rubber base body in parallel, the embedded supporting structure and the fiber reinforcement body are arranged in a mutually perpendicular and overlapped mode, and uniform and independent grid units are formed in the flexible rubber base body. The manufacturing tool structure comprises a metal bottom plate, fiber bundle moldplates, a supporting rod mold plate, a gland plate and a sliding block mold. The metal bottom plate is fixedly connected with a pair of fiber bundle mold plates, the supporting rod mold plate is fixedly installed on the upper surface of the metal bottom plate, the supporting rod mold plate is connected with the pair of fiber bundle mold plates to form a rectangular rail, and the sliding block moldslides along the rectangular rail. The flexible composite skin and the manufacturing method and the tool structure thereof are mainly used for variable sweepback wing quadrilateral shearing module units.

Owner:HARBIN INST OF TECH

Bracket for automobile controller

ActiveCN103552523AScalableThe fixing method is simple and reliableElectric/fluid circuitEngineeringBolt connection

The invention relates to a bracket for an automobile controller. The bracket comprises a bracket body, a left upper bracket and a right upper bracket, wherein the left upper bracket and the right upper bracket are fixed on the bracket body; and two bulged structures which are bent to form approximate right angles with the body are arranged on each lateral side of two side edges of the bracket body and used for mounting the controller. Two points are designed on the controller bracket, so that the bracket can be fixed on a pipe beam of an automobile body and connected through bolts; and two limit devices are arranged on bracket mounting support feet, so that mounting points don't bear the weight of the bracket and the controller directly, and fixation can be more reliable.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com