Built-in rotation speed measurement device of supercharger

A technology of speed measurement and supercharger, which is applied to measurement devices, linear/angular velocity measurement, speed/acceleration/shock measurement, etc., can solve the problems of low measurement accuracy, unsuitable for long-term use, inconvenient installation of measurement devices, etc. Simple, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

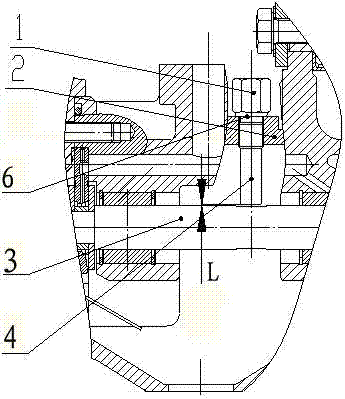

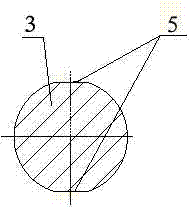

[0020] like figure 1 As shown, a built-in speed measurement device for a supercharger includes a speed sensor 1, a bearing body 2, and a speed sensor 3 is a rotating shaft. The speed sensor 1 is provided with a speed sensor center 4, and the speed sensor 1 is connected to the bearing body 2. A positioning plane 6 is set at the position, and the bearing body 2 is closely positioned through the positioning plane 6, and a detection platform 5 is set on the rotational speed test piece 3 (such as figure 2 ), the detection platform 5 is set on two symmetrical planes on both sides of the rotating shaft, the speed sensor 1 and the bearing body 2 are connected by M10 X 1 fine thread, and suspended at a certain distance above the speed tested part 3, And face the detection platform 5 on the rotational speed tested part 3, the measurement gap L between the rotational speed sensor center 4 on the rotational speed sensor 1 and the detection platform 5 is 0.5-1.2 mm.

Embodiment 2

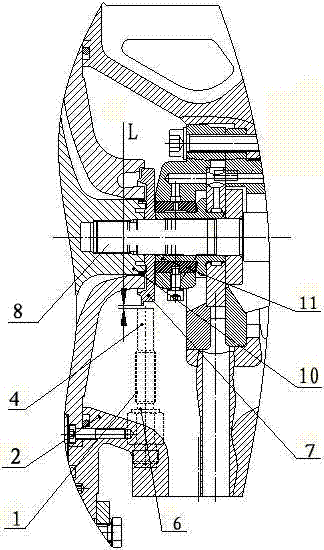

[0022] like image 3 As shown, a turbocharger built-in speed measurement device includes a speed sensor 1, a bearing body 2, a positioning plane 6 is provided at the connection between the speed sensor 1 and the bearing body 2, and the speed measured part 3 includes a shaft cover 7 and a rotating shaft 8. The shaft cover 7 is tightly fitted on the rotating shaft 8. The shaft cover 7 is sandwiched between the compressor impeller 10 and the bearing sleeve 11, and the axial clamping force ensures its firm positioning and connection. The detection platform 5 is two symmetrical The boss plane 9 (as Figure 4 ), set on the shaft cover 7, the speed sensor 1 is provided with a speed sensor center 4, the speed sensor 3 is provided with a detection platform 5, the speed sensor 1 and the bearing body 2 are connected by a fine thread of M12 X 1.25, And it is closely positioned by the positioning plane 6; and it is suspended at a certain distance above the speed tested part 3, and is faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com