High-safety reinforcing device for geotechnical engineering side slope

A high-security, ruggedized device technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

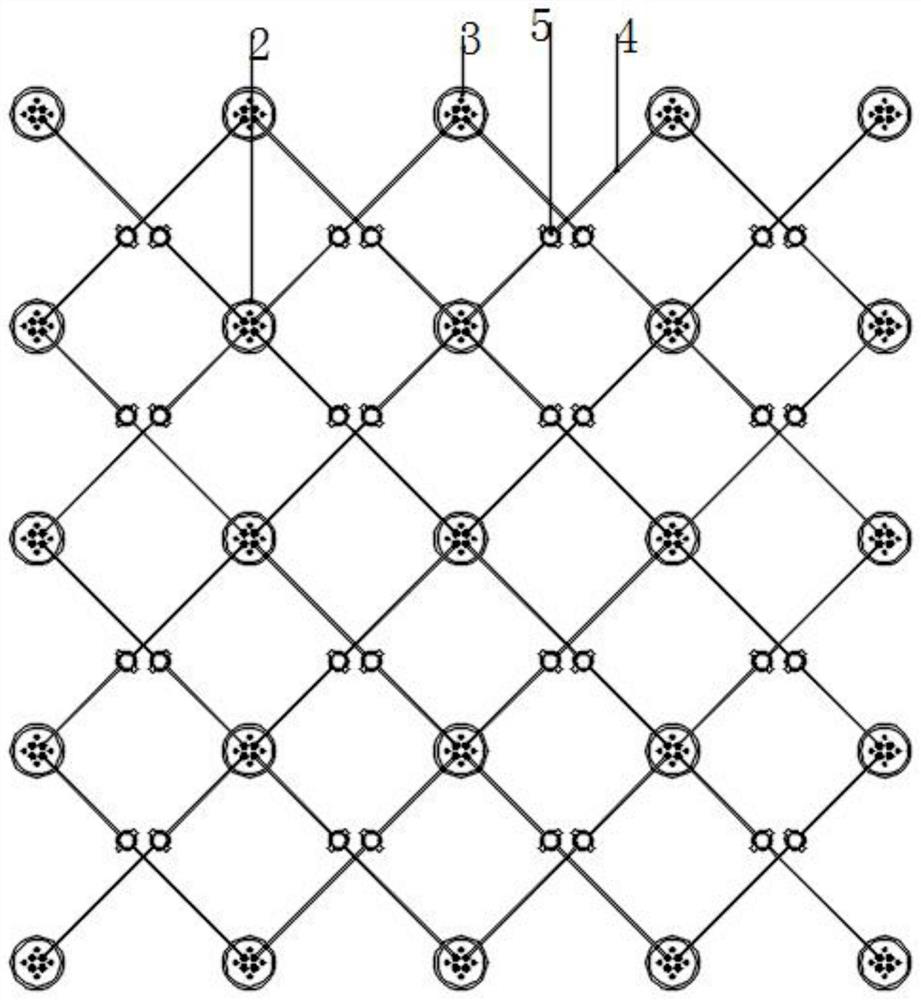

[0053] A high-safety reinforcement device for geotechnical engineering slopes, comprising a slope body 1, an anchoring mechanism 2, a rope head fixing mechanism 3, a steel wire rope 4 and a tensioning mechanism 5;

[0054] Mounting grooves 11 are arrayed on the inclined surface of the slope body 1, and an anchoring groove 12 is provided at the bottom of the mounting groove 11;

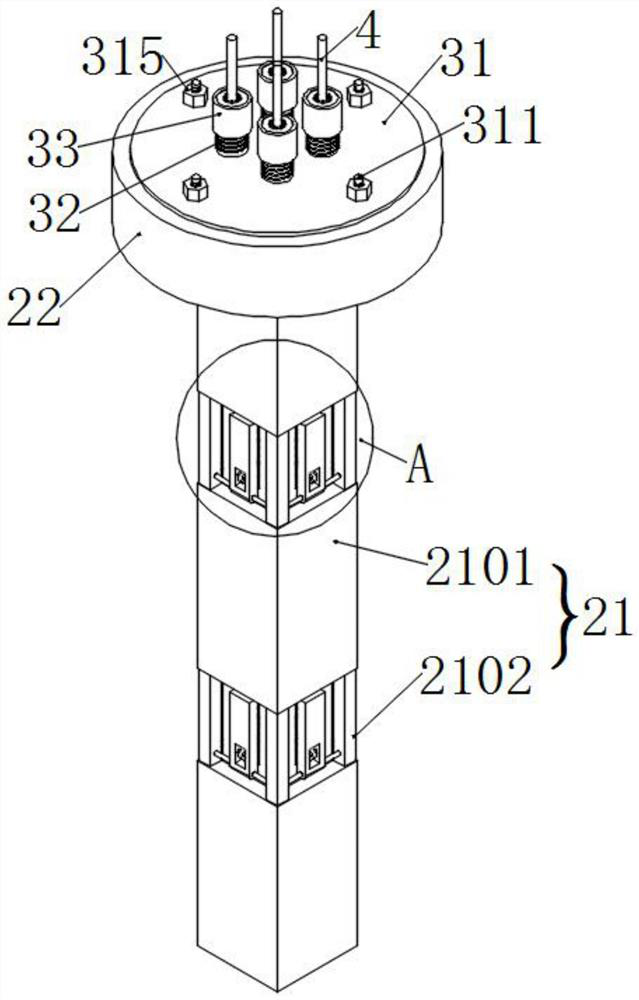

[0055] The anchoring mechanism 2 includes an anchoring cylinder 21 and an installation frame 22; the anchoring cylinder 21 and the installation frame 22 are respectively fixed in the anchoring groove 12 and the installation groove 11;

[0056] The rope head fixing mechanism 3 is arranged in the installation frame 22, and the wire rope 4 is fixedly connected between the two rope head fixing mechanisms 3 at the diagonal position;

[0057] The tensioning mechanism 5 is arranged on the wire rope 4 , and the tensioning mechanism 5 is used for tensioning the wire rope 4 .

[0058] In this example:

[0059]...

Embodiment 2

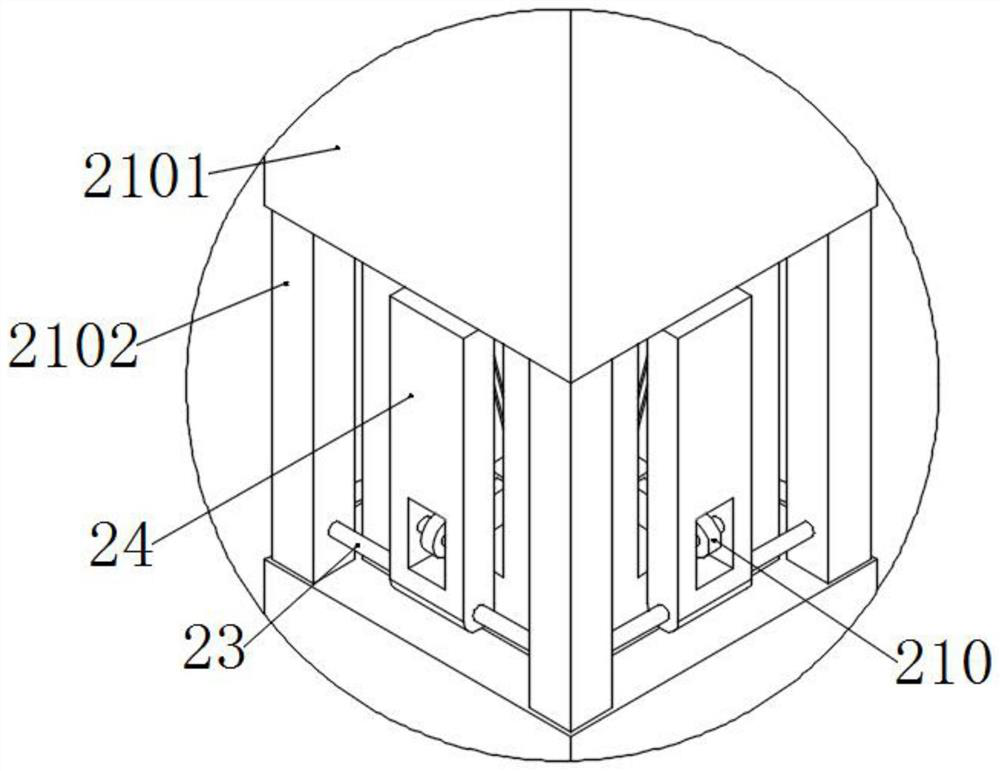

[0062] On the basis of Embodiment 1, the detailed technical features of the anchoring mechanism 2 are disclosed in this embodiment.

[0063] The anchoring cylinder 21 includes a plurality of cylinders 2101 arranged at intervals in the vertical direction. The cross-section of the cylinders 2101 is square. The four corners of the two adjacent cylinders 2101 are connected by a set of connecting rods 2102. The first rotating shaft 23 is indirectly fixed, and the first rotating shaft 23 is rotatably connected with the opening plate 24. The position corresponding to each group of connecting rods 2102 in the anchoring cylinder 21 is slidably connected with the opening seat 25, and each side of the opening seat 25 is opened. There is a right-angled triangle opening slot 26, the inclined surface of the opening slot 26 is inclined downward along the direction pointing to the center of the opening seat 25, and a guide slot 27 is opened on the inclined surface of the opening slot 26. The ...

Embodiment 3

[0078] On the basis of Embodiment 2, this embodiment discloses the detailed technical features of the rope head fixing mechanism 3

[0079] The rope head fixing mechanism 3 includes a cover plate 31, a plug sleeve 32 and a fixed sleeve 33; the cover plate 31 is detachably connected to the installation frame 22, and the plug sleeves 32 are fixed in the cover plate 31 and have four rectangular arrays. The outer wall of 32 is provided with a second inner thread 34, the top of the insert sleeve 32 is also fixed with a group of fixed fins 35 evenly around the circumference, and the outer side of the fixed fins 35 is inclined downward along the direction away from the center of the insert sleeve 32. The fixed sleeve 33 The inner wall of the bracket is provided with a second external thread 36 that engages with the second internal thread 34 , an abutment seat 37 is fixed on the top of the inner cavity of the fixing sleeve 33 , and an abutment hole 38 is opened in the center of the abu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com