Patents

Literature

37results about How to "Overcome looseness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

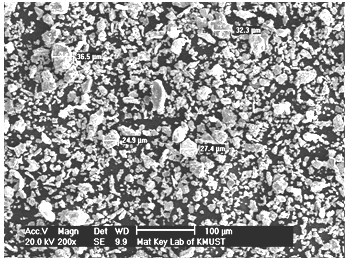

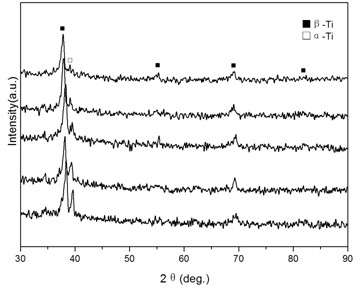

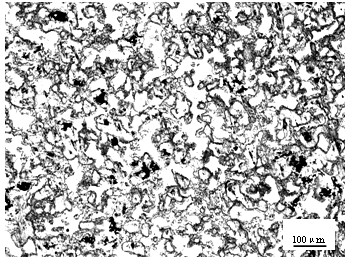

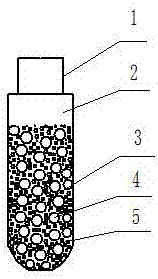

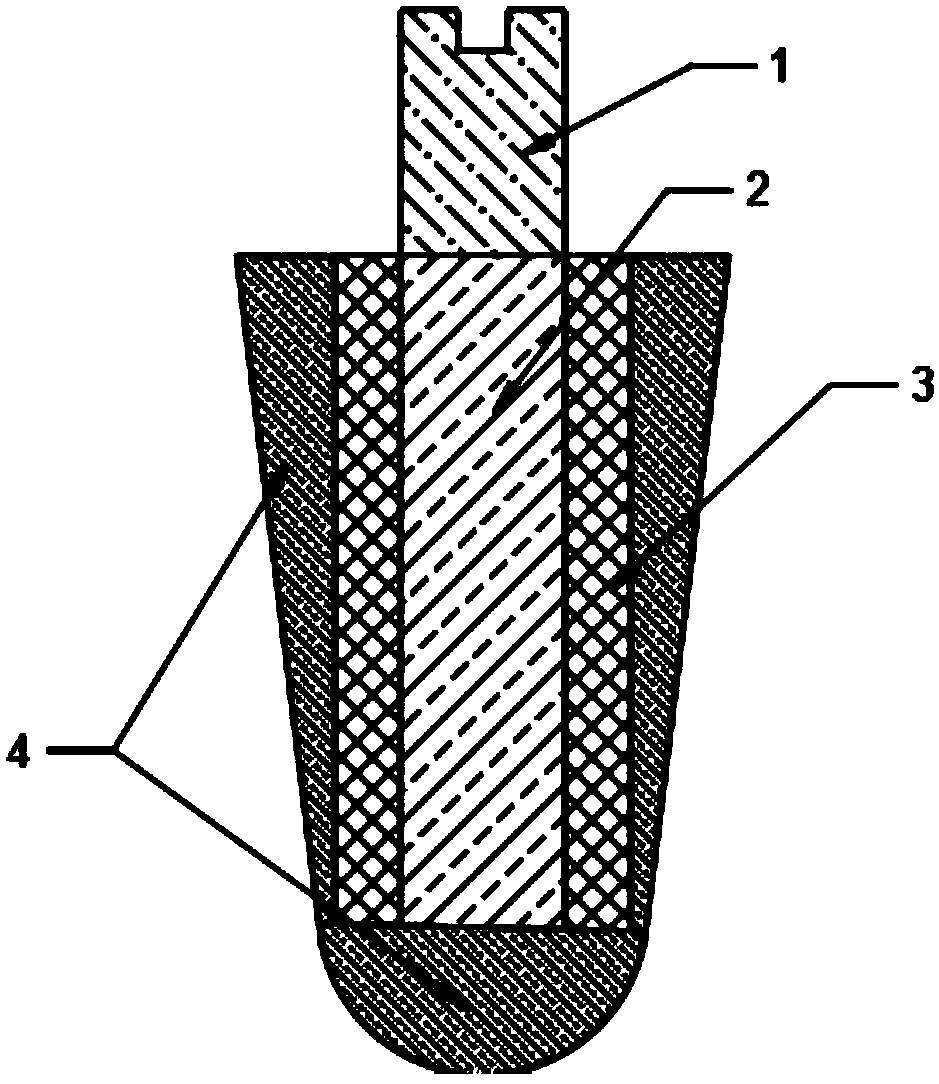

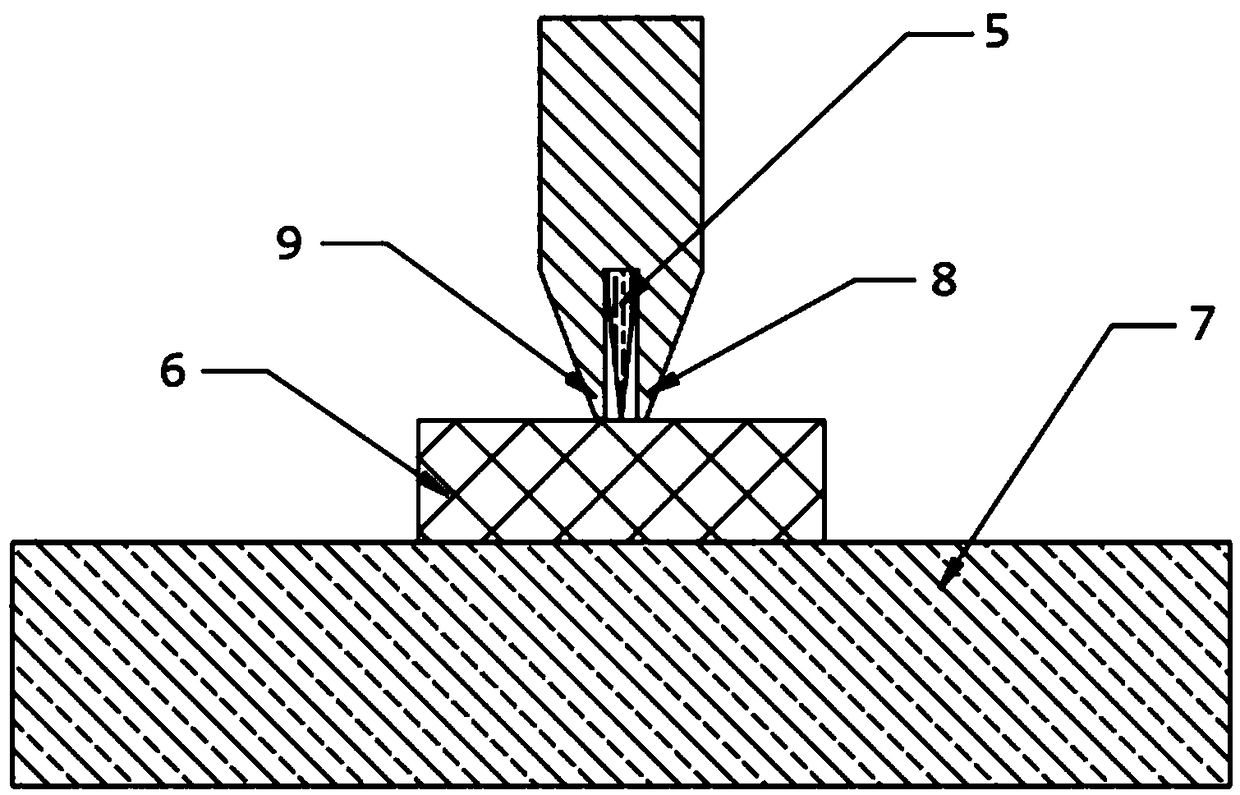

Method for preparing titanium niobium zirconium tin biomedical titanium alloys by discharge plasma sintering

The invention relates to a method for preparing titanium niobium zirconium tin biomedical titanium alloys by discharge plasma sintering, and belongs to the technical field of biomedical material preparation. The method provided by the invention comprises the following steps of: weighing Ti, Nb, Zr and Sn metal powders according to a chemical composition ratio, mixing the powders by a ball mill, putting into a graphite die, then placing into a discharge plasma sintering furnace, applying axial pressure of 10-40MPa, sintering in vacuum with the vacuum degree being 2-6 Pa while the heating rate is 50-100 DEG C / min and the sintering temperature is 950-1100 DEG C, keeping warm for 5-10 min after reaching the sintering temperature, and cooling in furnace to room temperature to obtain the titanium niobium zirconium tin biomedical titanium alloy material. The titanium niobium zirconium tin biomedical titanium alloys prepared by the method has uniform components and microstructure, high density (more than 98%), low elastic modulus (41-50GPa) and the like. In the mean while, the method provided by the invention has advantages of simple process, convenient operation and low cost, and is easy to realize industrial production.

Owner:KUNMING UNIV OF SCI & TECH

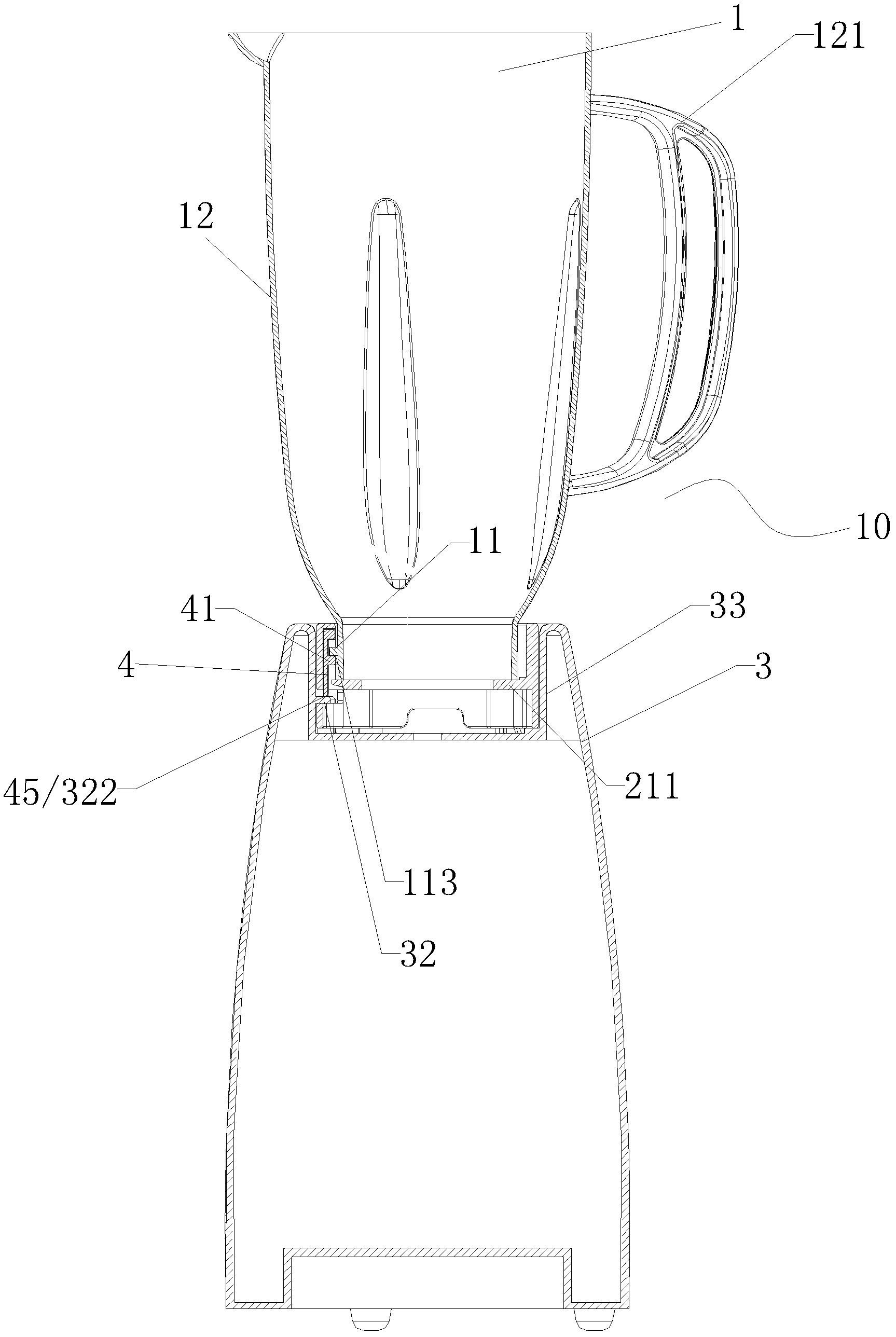

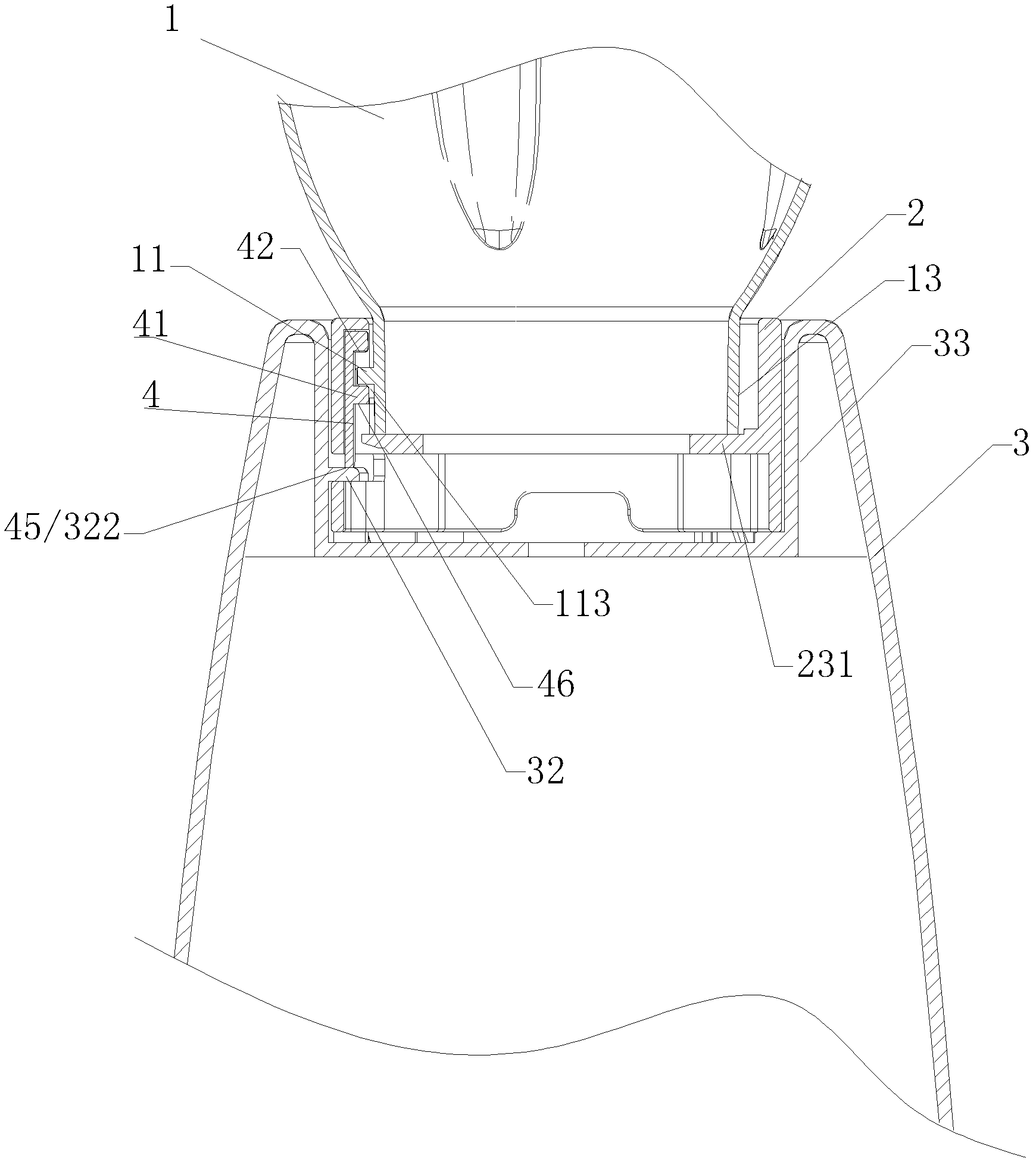

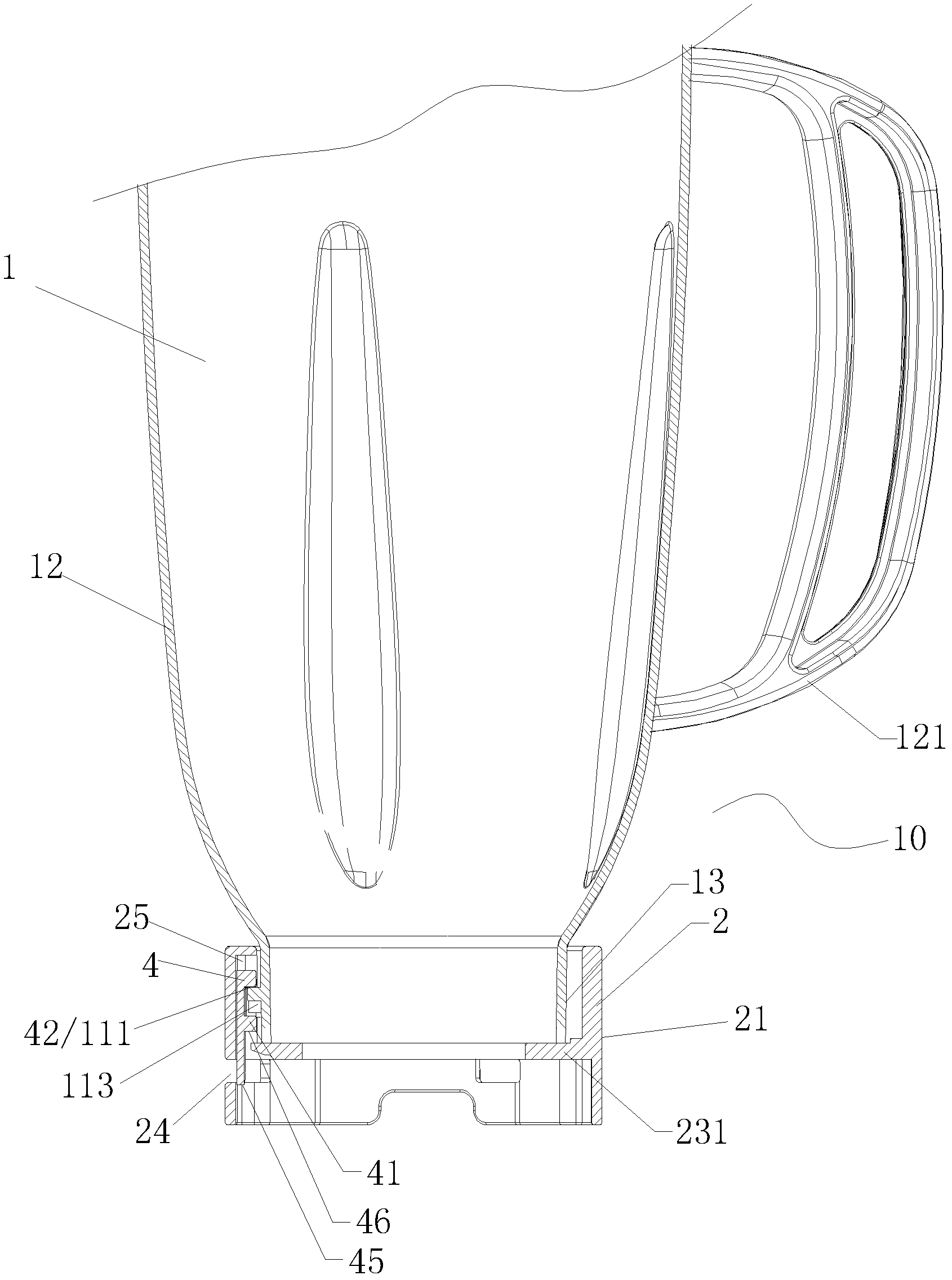

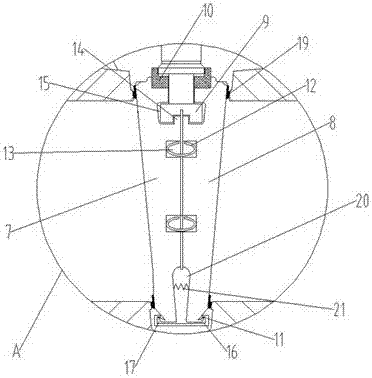

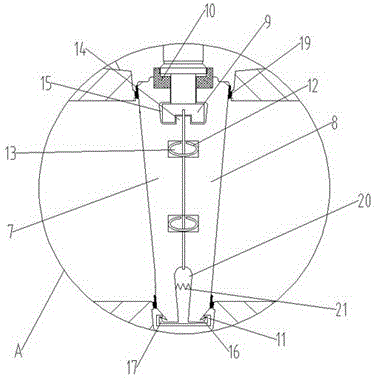

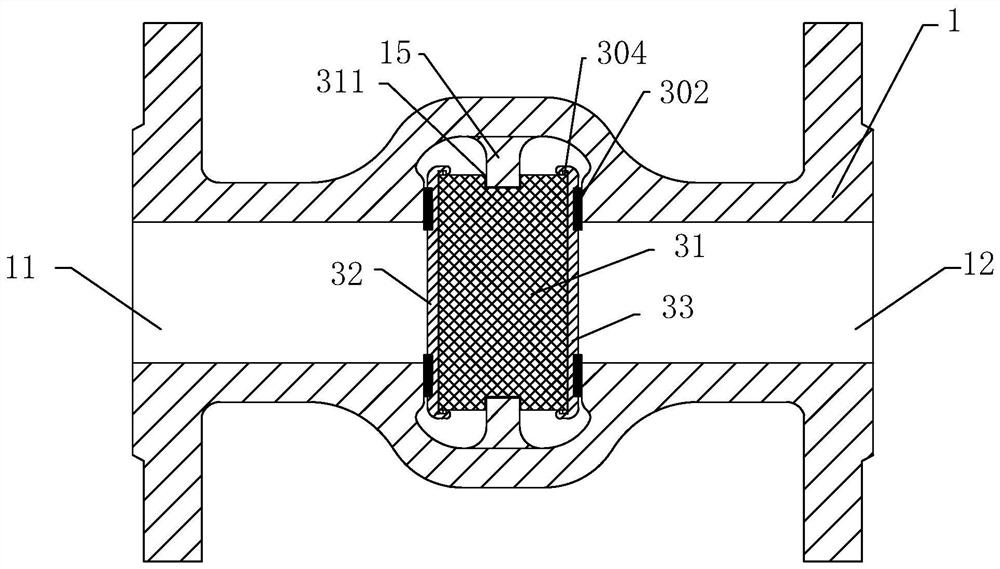

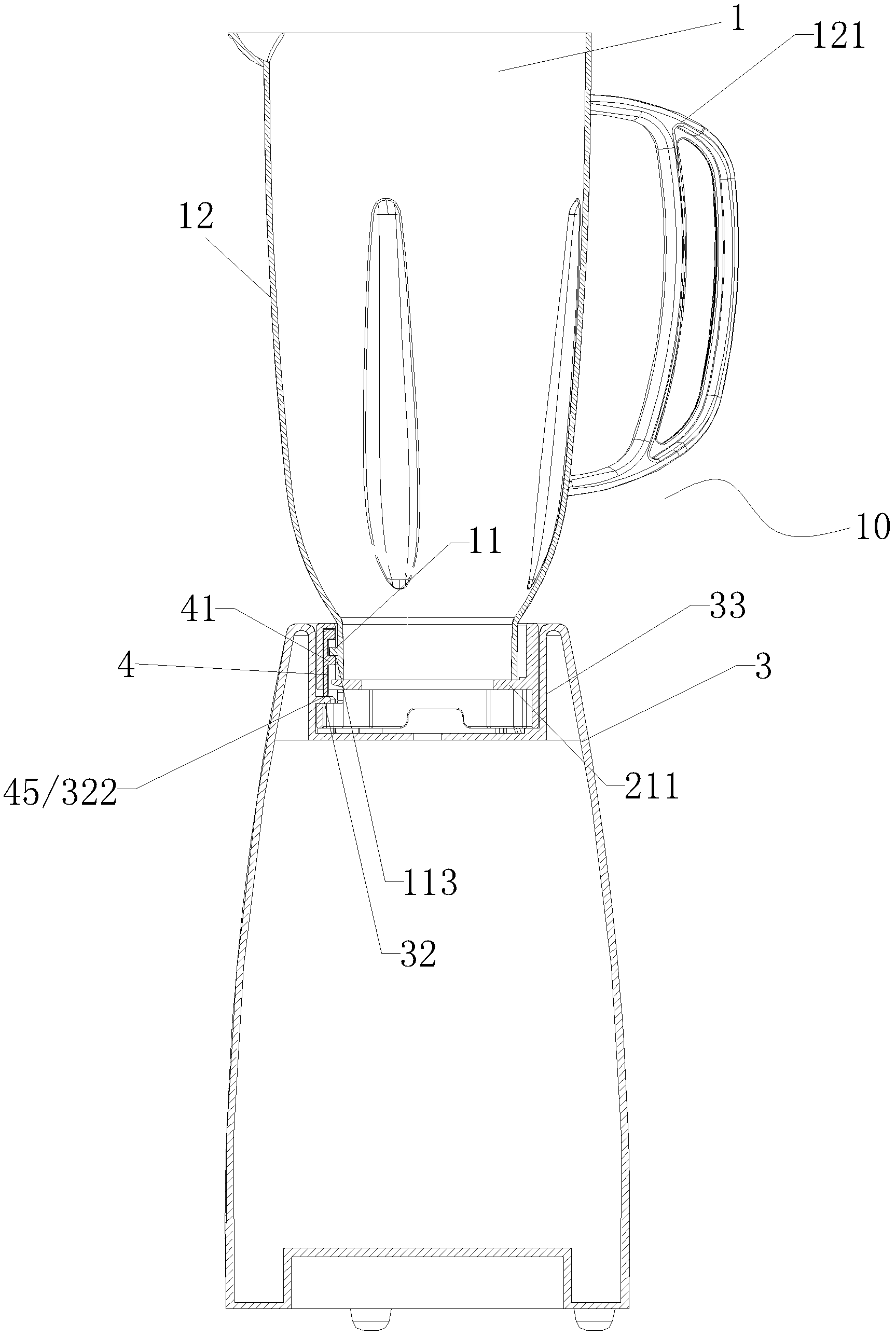

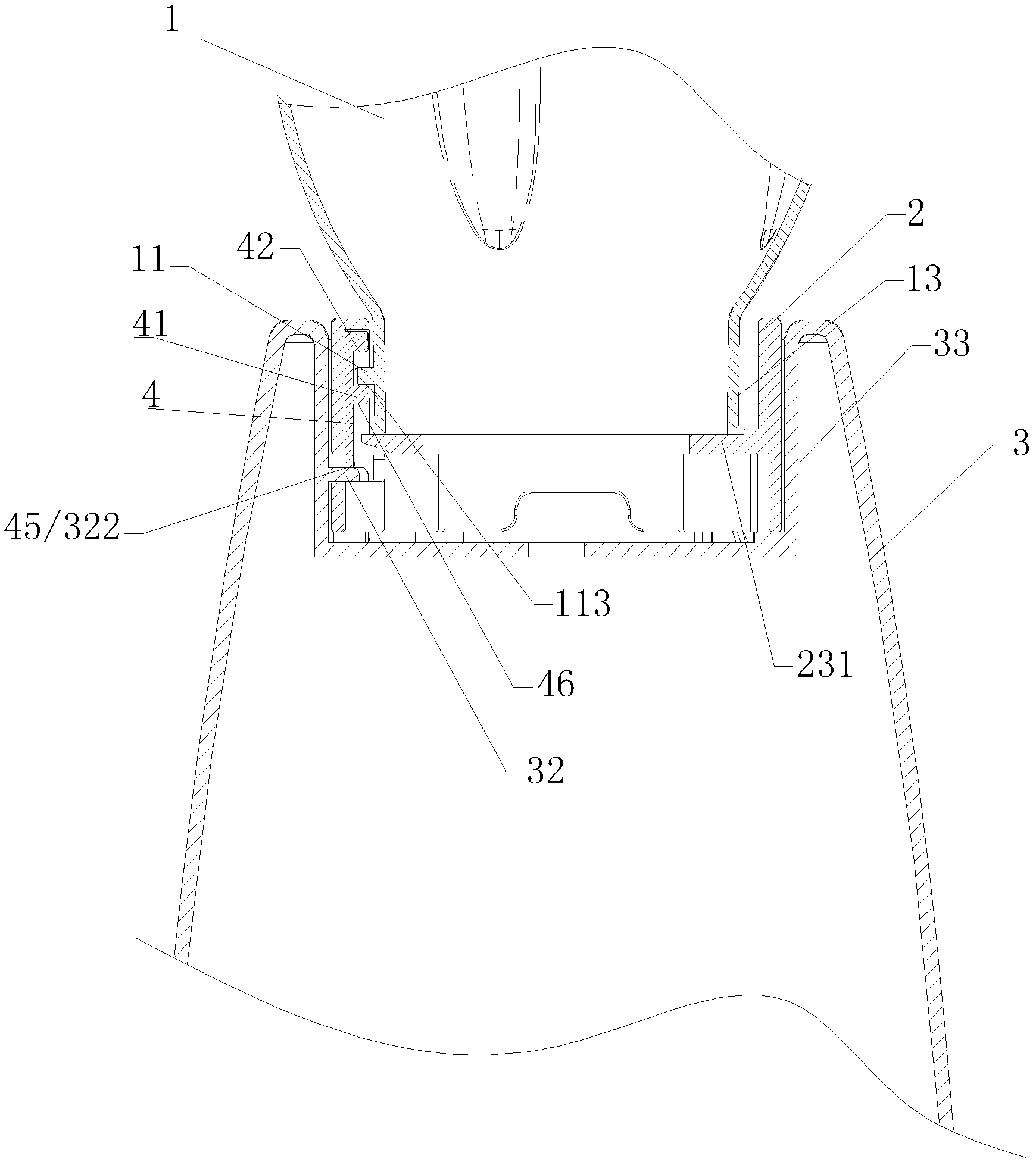

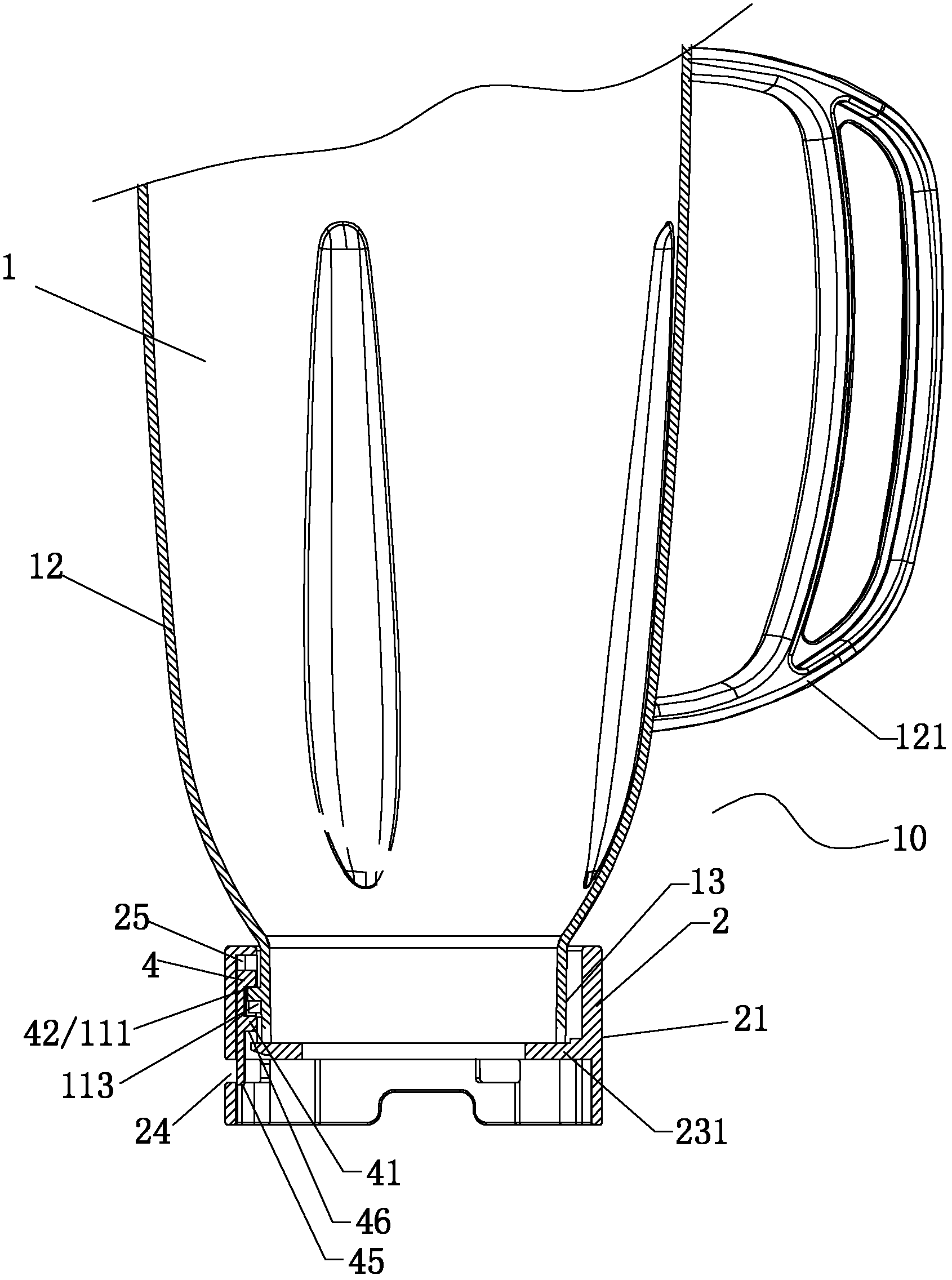

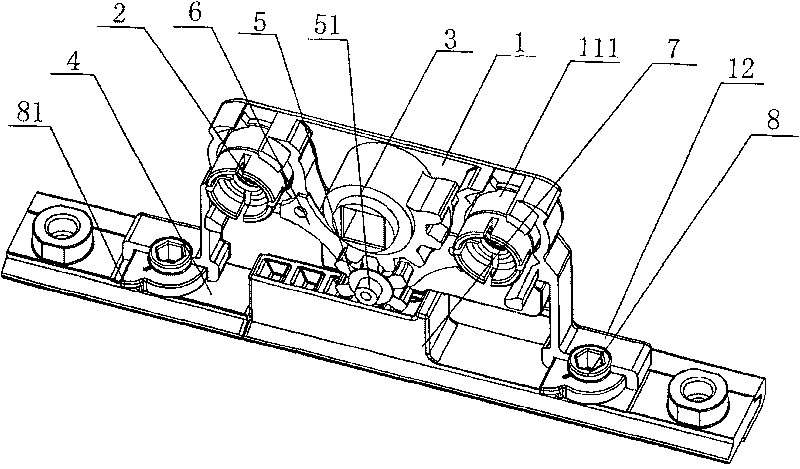

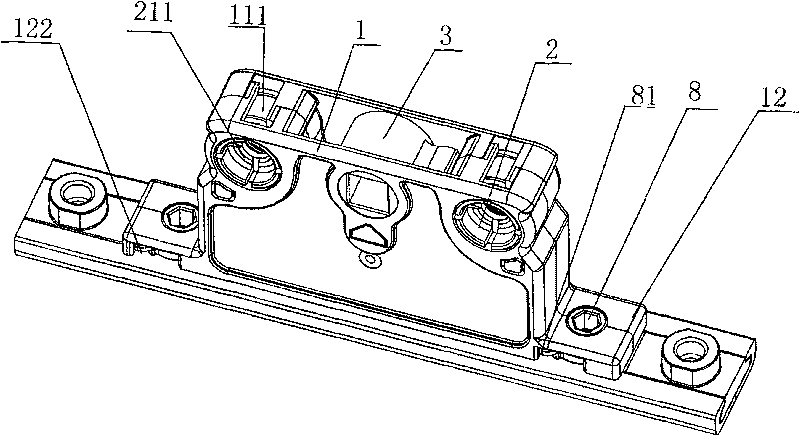

Food processor locking mechanism

The invention provides a food processor locking mechanism which has the anti-loose function, guarantees reliable connection between components and prevents components from loosing. The food processor locking mechanism comprises a first structure part, a second structure part and a connection part, wherein the connection part is respectively in screw connection with the first structure part and the second structure part in a mode convenient to separate, and the first structure part and the connection part can form a first structure assembly. The food processor locking mechanism further comprises a locking block installed on the connection part, wherein the locking block comprises three work positions of an initial position, a first position and a second position. When the connection part is separated from the first structure part and the second structure part, the locking block is arranged at the initial position. When the first structure part and the connection part are in a screw connection state, the locking block leaves a support structure of the connection part to move to the first position to be matched with and fixedly connected with a location structure of the first structure part. When the first structure assembly and the second structure part are in a connection state, the locking block is positioned at the second position.

Owner:ELEC TECH ZHUHAI CO LTD

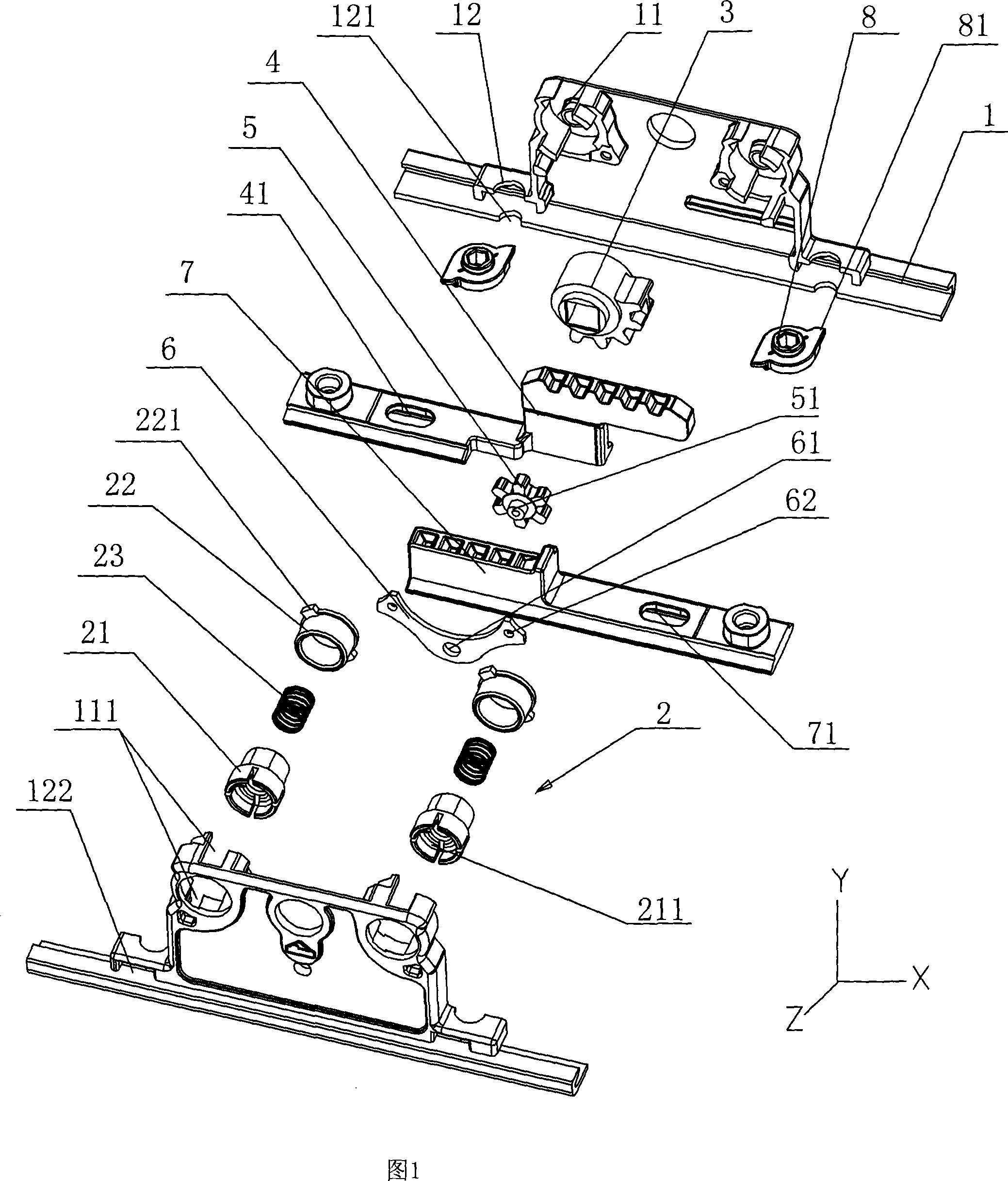

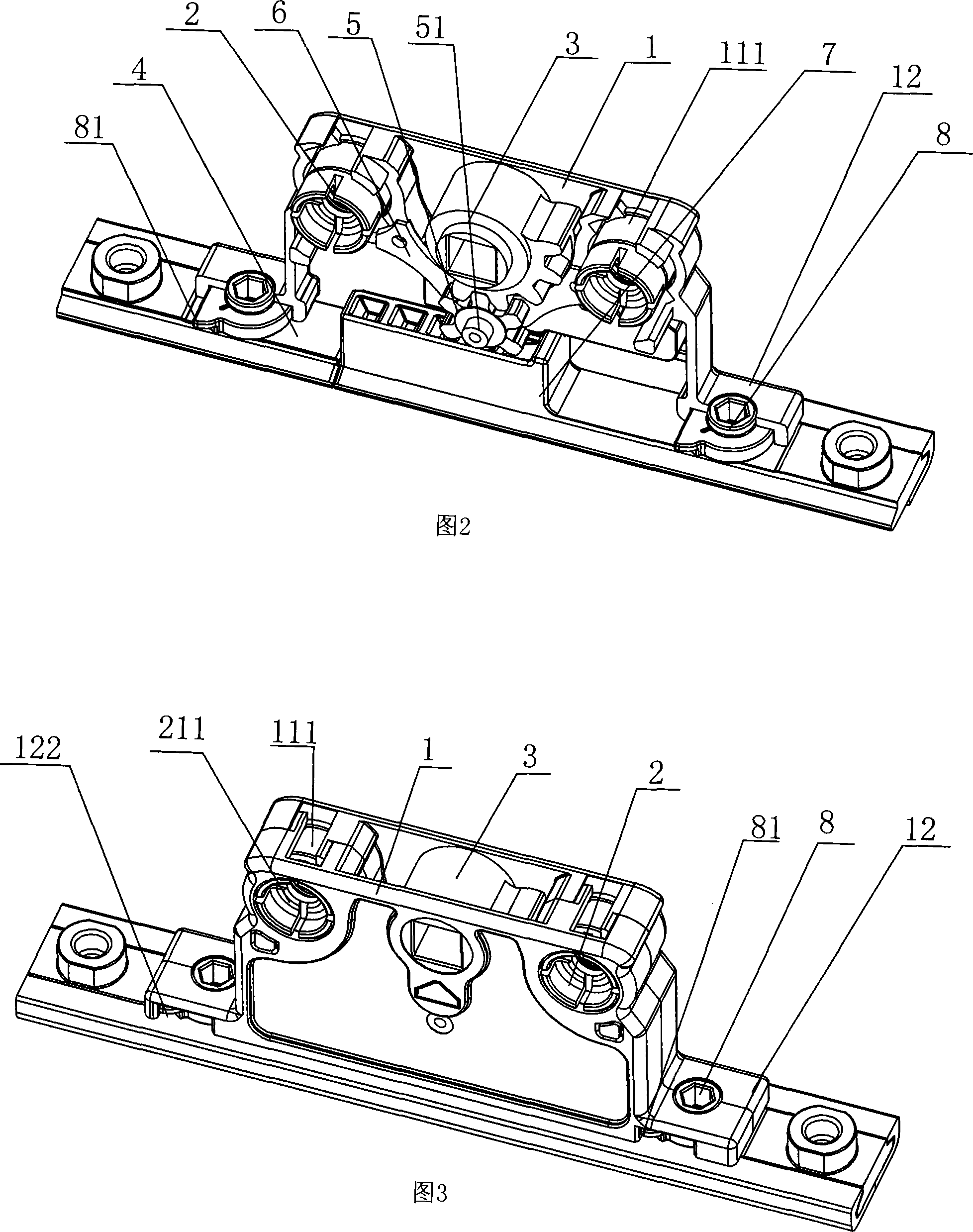

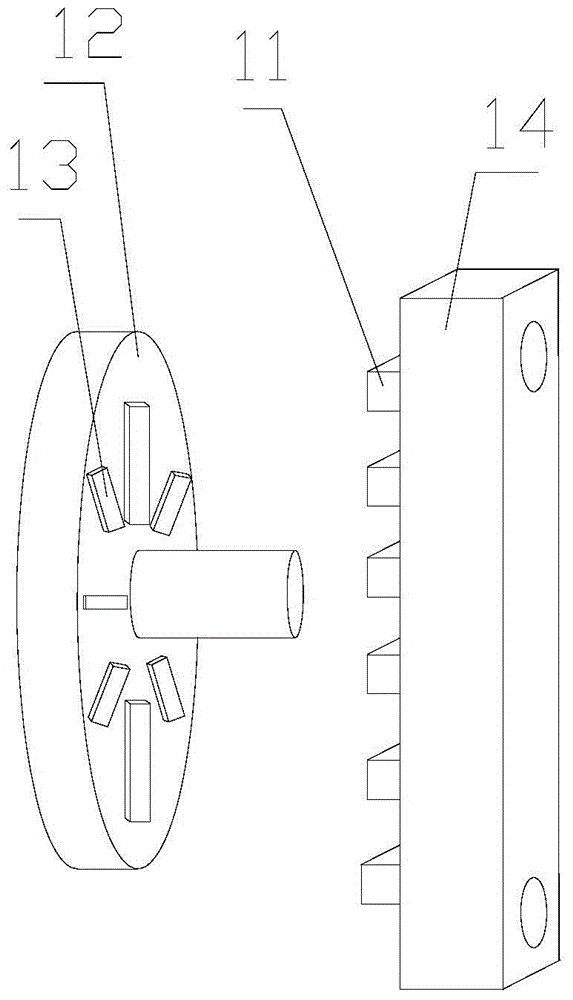

Bidirectional driver of door and window lockset

ActiveCN101245679AUniform bearing forceOvercoming loosenessConstruction fastening devicesCouplingGear wheel

The invention discloses a bidirectional driver for a lock of a door or a window, which comprises a shell; the two sides of the shell are provided with fixing holes in which fixed governing mechanisms are arranged; the interior of the shell is provided with a drive gear, a first drive strip, a reverse drive gear, a drive gear bearing strip and a second drive strip; one end of the central shaft of the reverse drive gear is connected with the shell in coupling, and the drive gear bearing strip is provided with a middle hole and two end holes; the other end of the central shaft of the reverse drive gear is connected in the middle hole of the drive gear bearing strip in coupling; the two end holes of the drive gear bearing strip are socket-jointed with a pin piston integrated with the shell, in this way, the drive gear bearing strip fixes the rotation of the reverse drive gear in two directions; when the reverse drive gear is rotated, the fixing force of the drive gear bearing strip exerted to the reverse drive gear is more uniform, which overcomes the phenomenon that the drive gear bearing strip of a driver is easy to generate looseness when being used for a long time, thus prolonging the service life of the bidirectional driver.

Owner:联程机械(宁波)有限公司

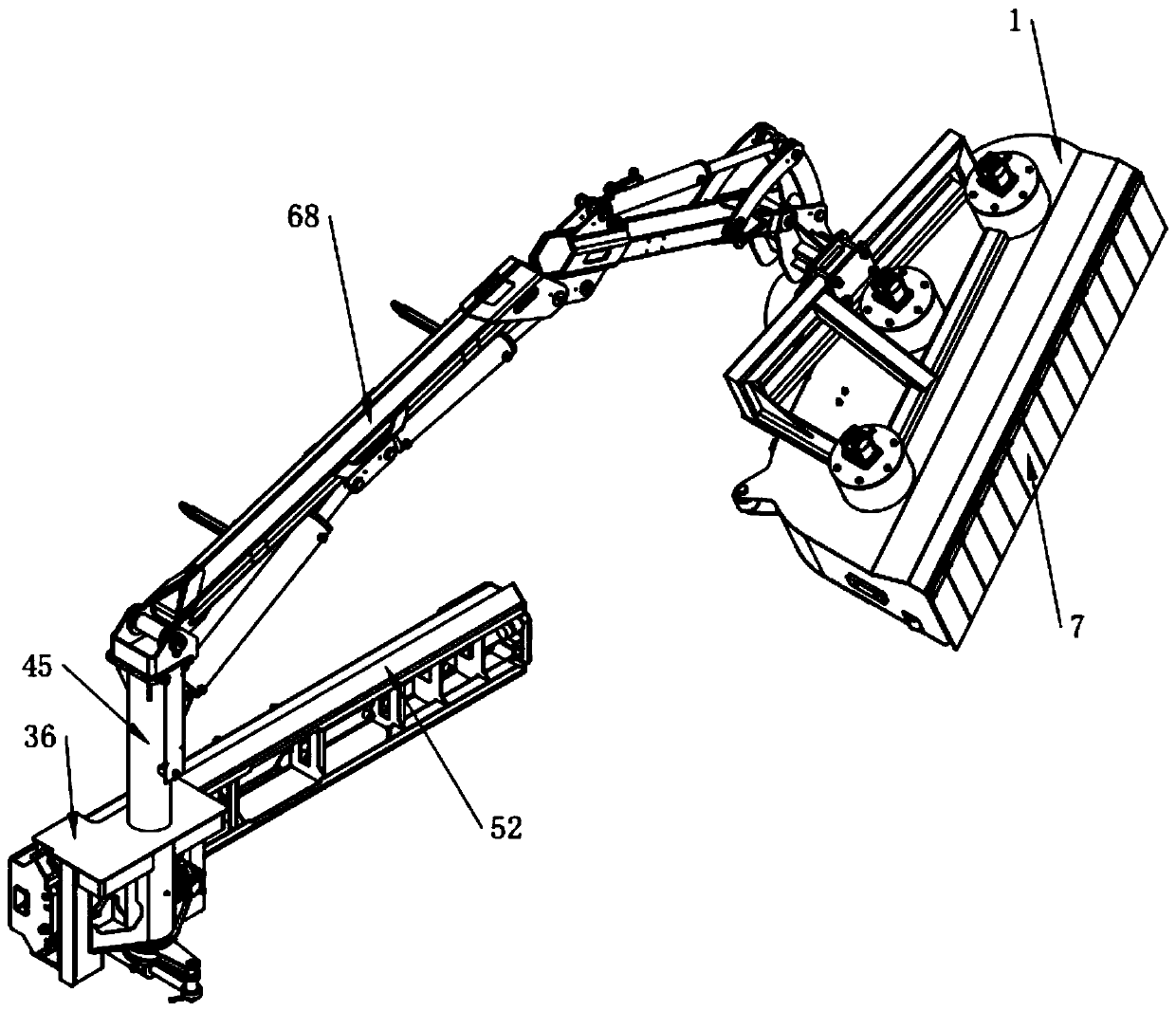

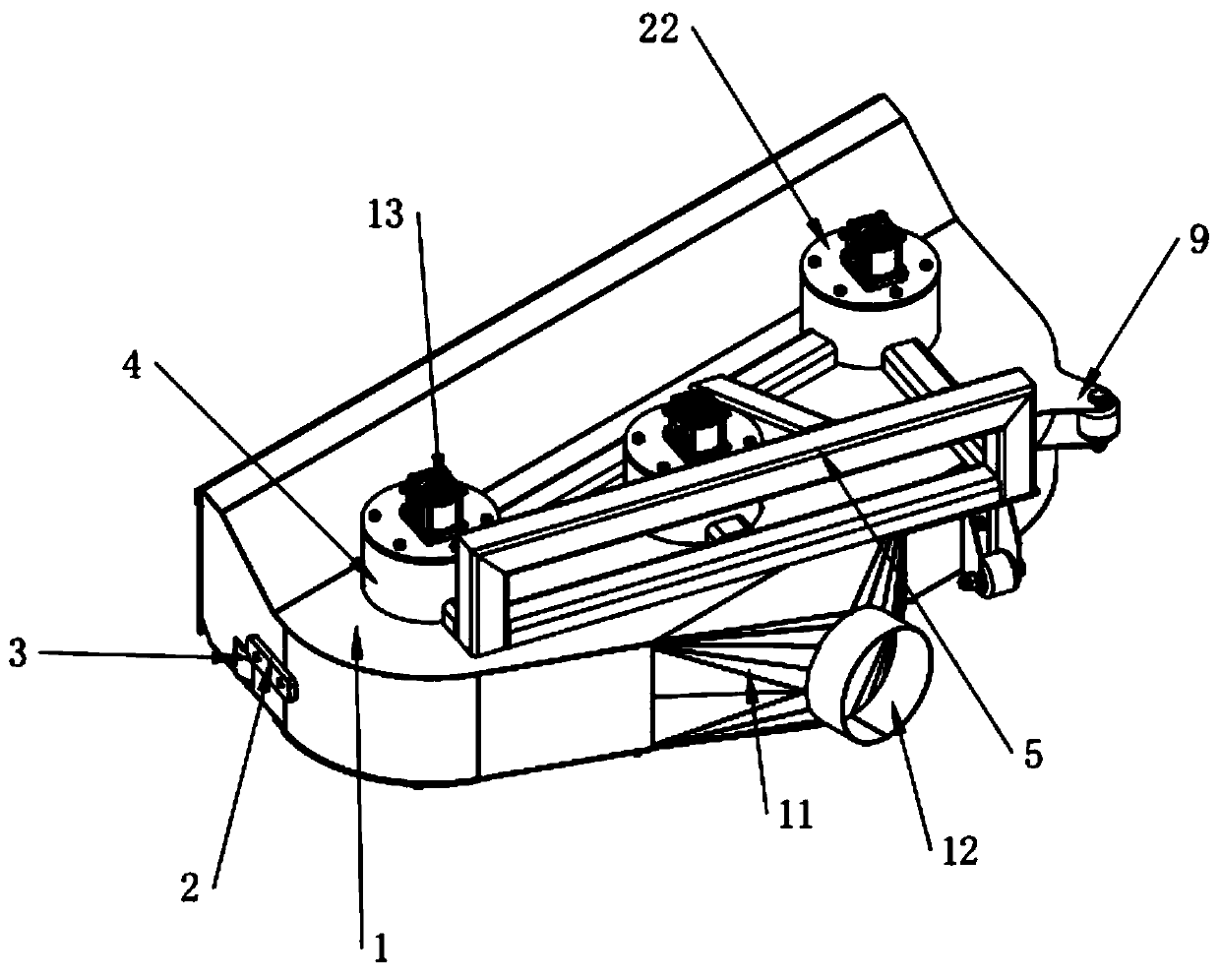

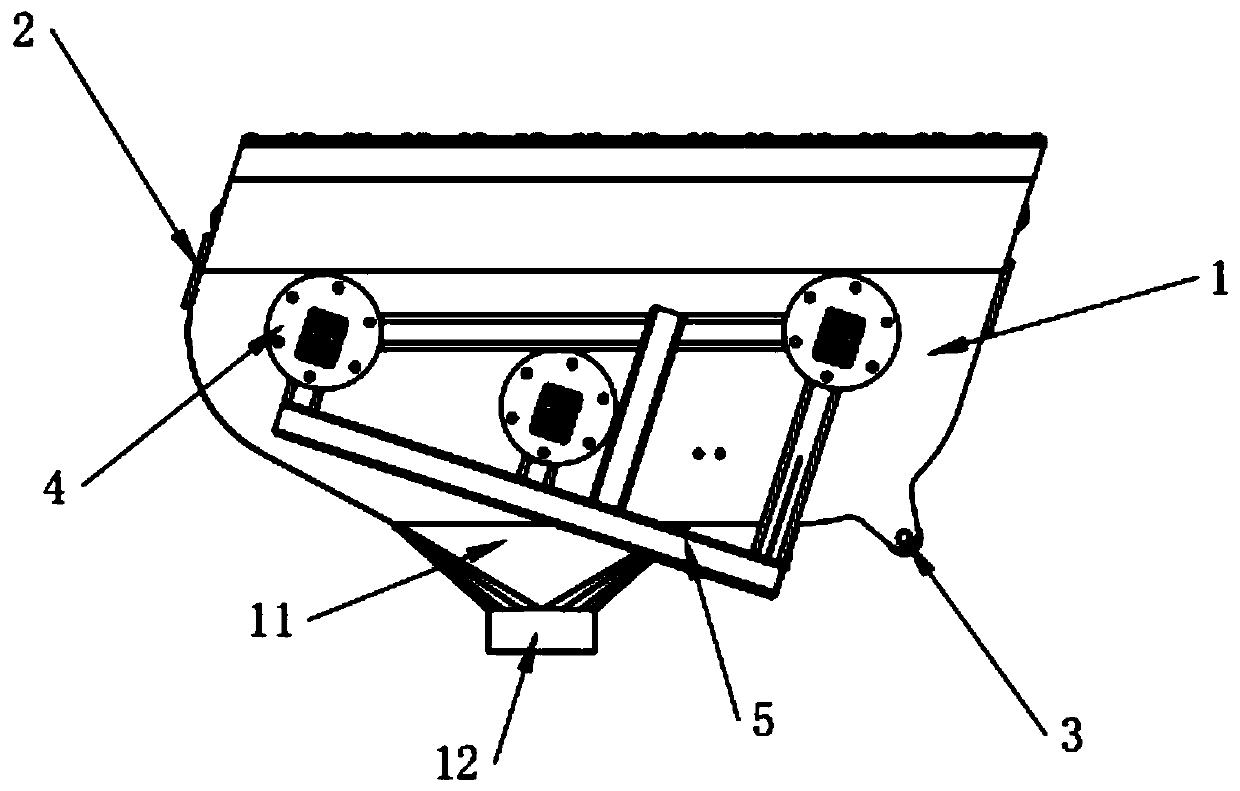

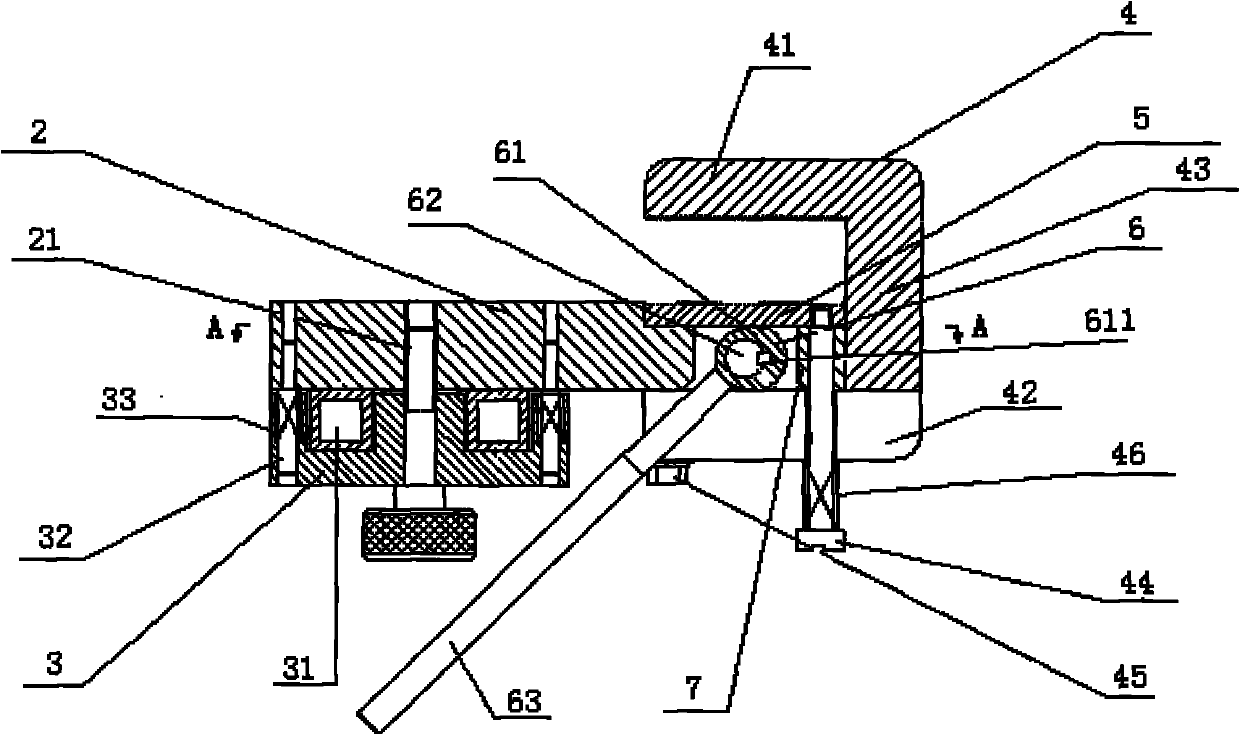

Hedge trimming device assembly

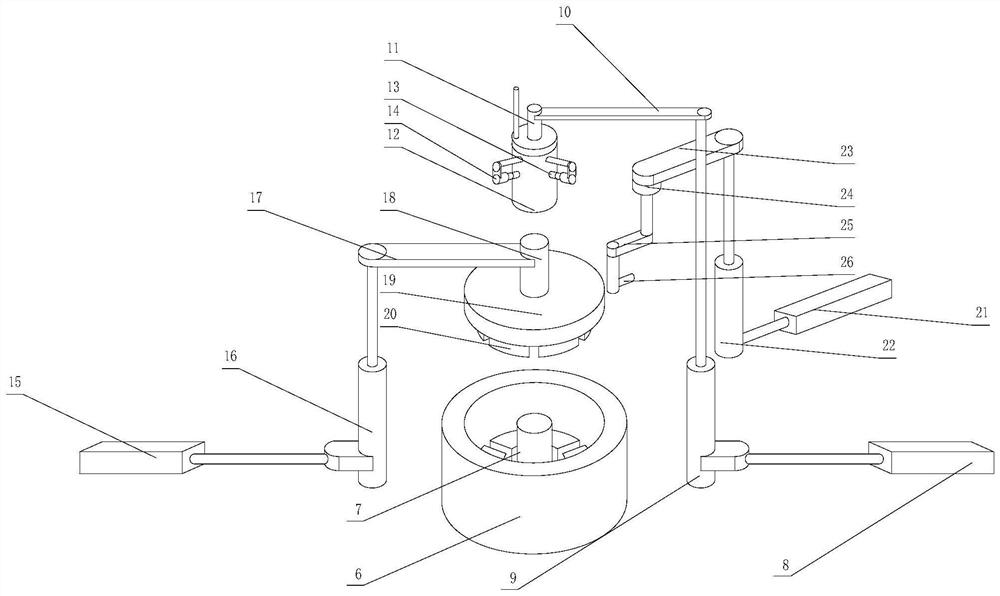

PendingCN110178570ALow maintenanceAvoid open weldingHedge trimming apparatusPlant waste comminutingSteering wheelDriver/operator

The invention discloses a hedge trimming device assembly, and relates to the technical field of hedge trimmer tools. The hedge trimming device assembly comprises a transverse movement mechanism, a steering mechanism and a trimming mechanism; the transverse movement mechanism comprises a transverse movement guide rail and a transverse movement sliding base, a driving chain is fixedly connected to the transverse movement guide rail, and a driving wheel rolling along the surface of the driving chain is installed on the transverse movement sliding base in a reciprocating sliding manner. The hedgetrimming device assembly solves the problems that in a traditional technology, a steering assembly in a trimming device is under the visual field limitation of hedges during steering, and the phenomenon of tooth cracking of a steering wheel is caused; in the movement process of a transverse movement assembly, when the transverse spacings between the hedges and a road surface are different, the operation requirements for drivers are high; a trimming assembly cannot achieve combined trimming since multiple cutters are in single contact with the hedges for cutting, so that the throwing directionof branches is not fixed, and partial power is wasted; the branches are thrown on the high-speed road surface under the rotary cutting function of the cutters, and vehicles driven at high speed are influenced.

Owner:广州交投绿化建设有限公司 +2

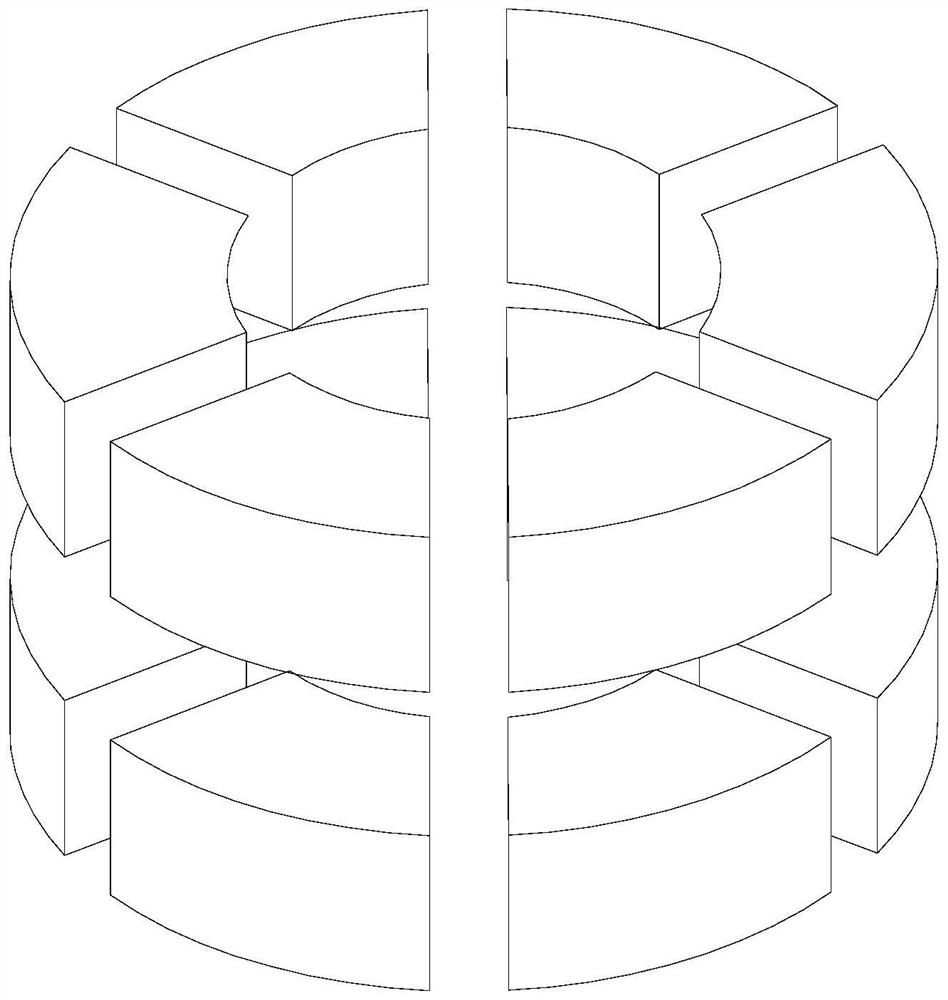

Tooth implant

ActiveCN107280789AEasy to fixLow elastic modulusDental implantsTissue regenerationBone tissueNeck parts

The invention provides an artificial tooth implant. The artificial tooth implant is composed of a body part, a neck part and an abutment, wherein the body part is a porous metal material; the porous metal material is a multi-grade-pore metal material; the multi-grade-pore metal material is composed of all grades of pore cavities which are graded according to the pore diameter size of the material and all grades of cavity walls for forming the pore cavities through surrounding; all grades of the pore cavities are mutually communicated respectively and all grades of the pore cavities are also mutually communicated respectively; the number of grades is two at least. Compared with the fusion time of a traditional artificial tooth implant with a body part which is a porous metal material with single pores, the fusion time between the artificial tooth implant and an adjacent bone tissue is remarkably shortened; the artificial tooth implant is firmly fixed on a gum so that the problems that an interface is not stable and loose are overcome.

Owner:CHONGQING RUNZE PHARM CO LTD

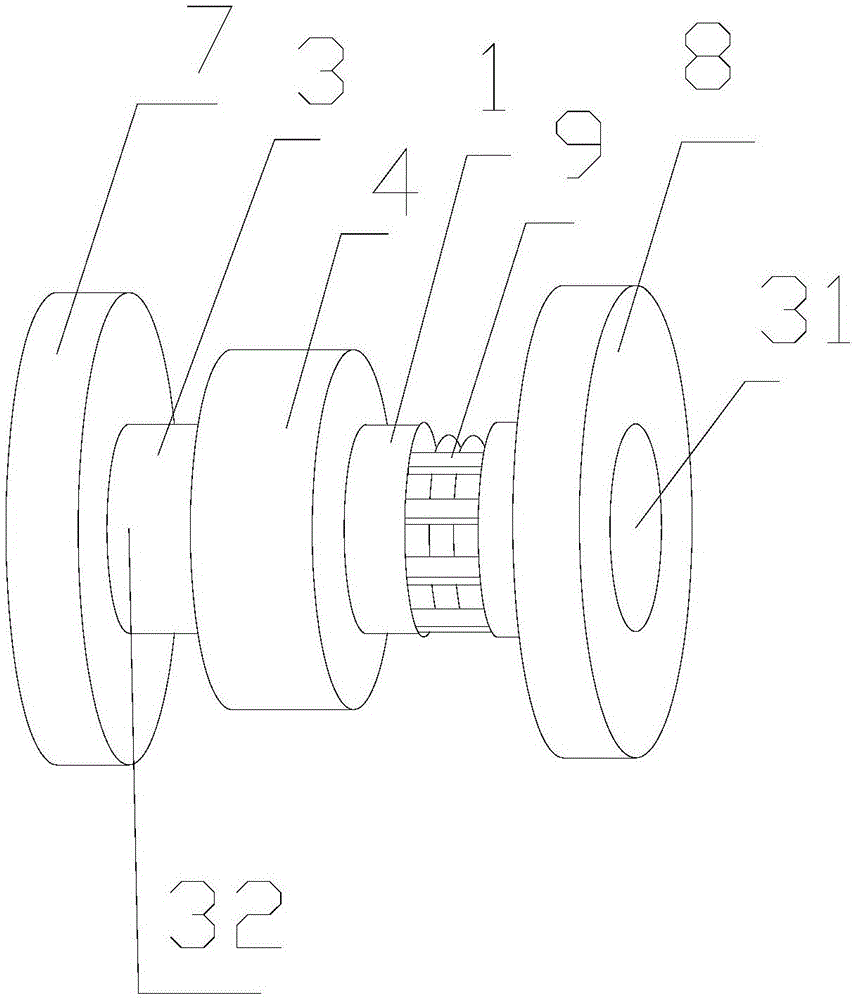

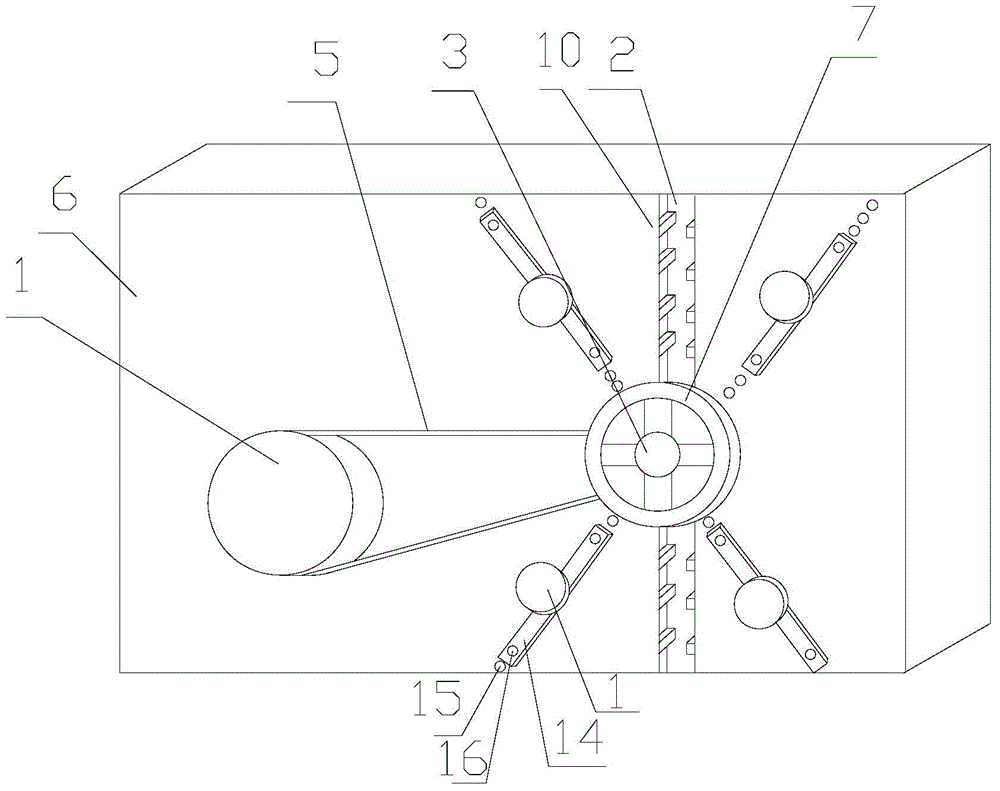

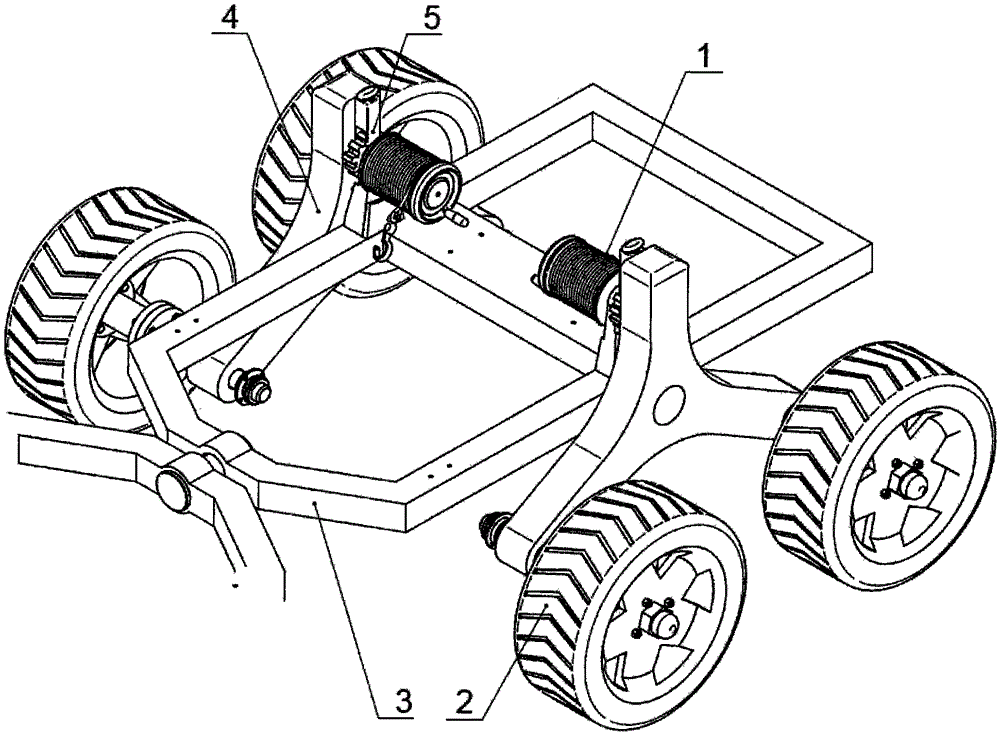

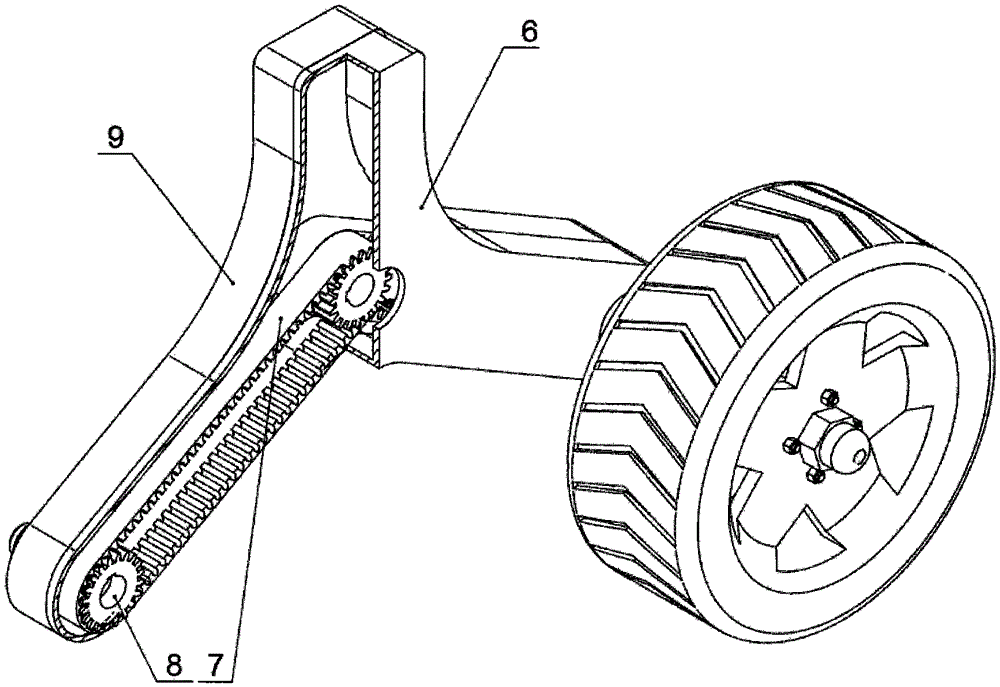

Self pretightening buffering herringbone forest wheel disc

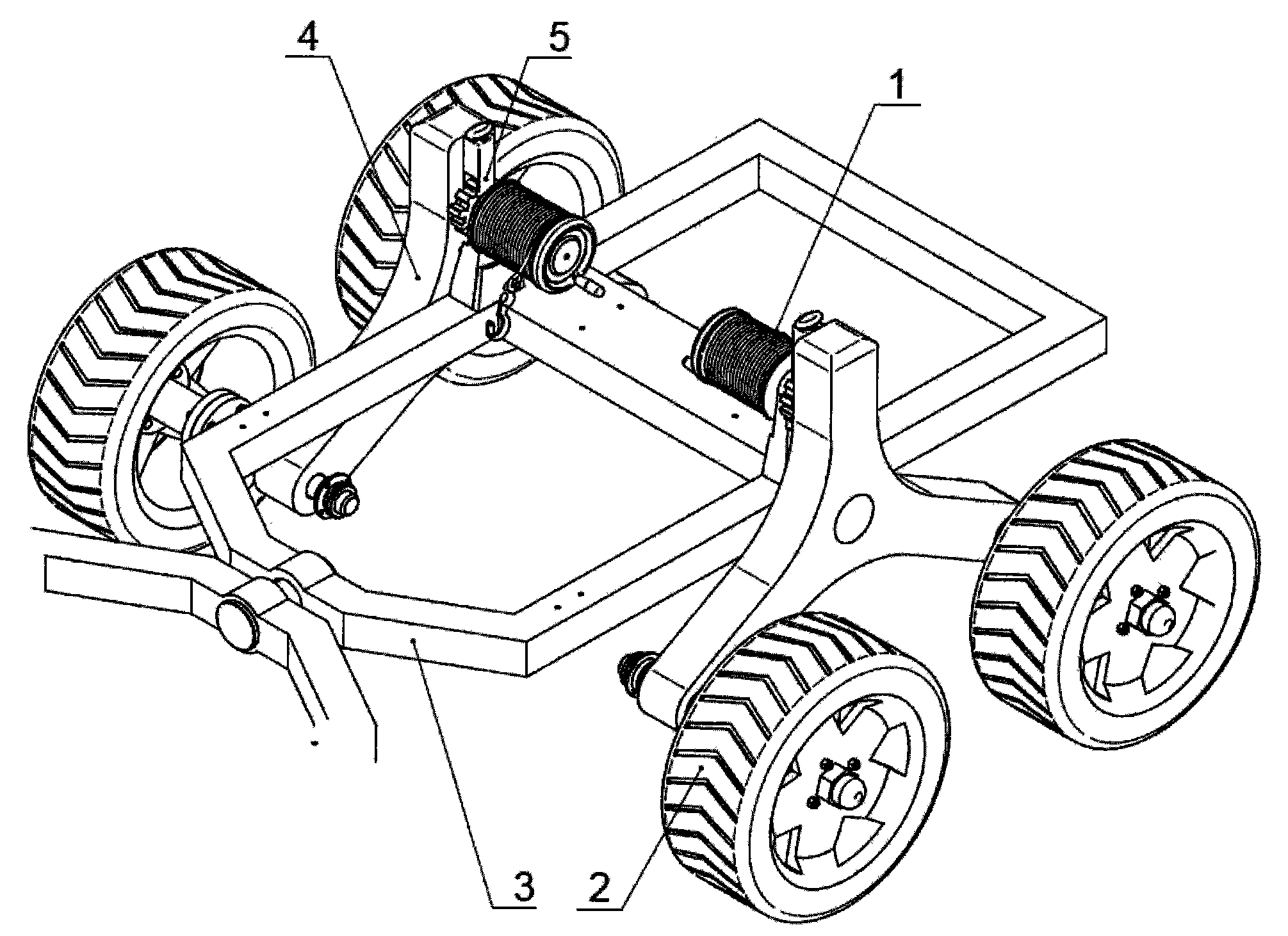

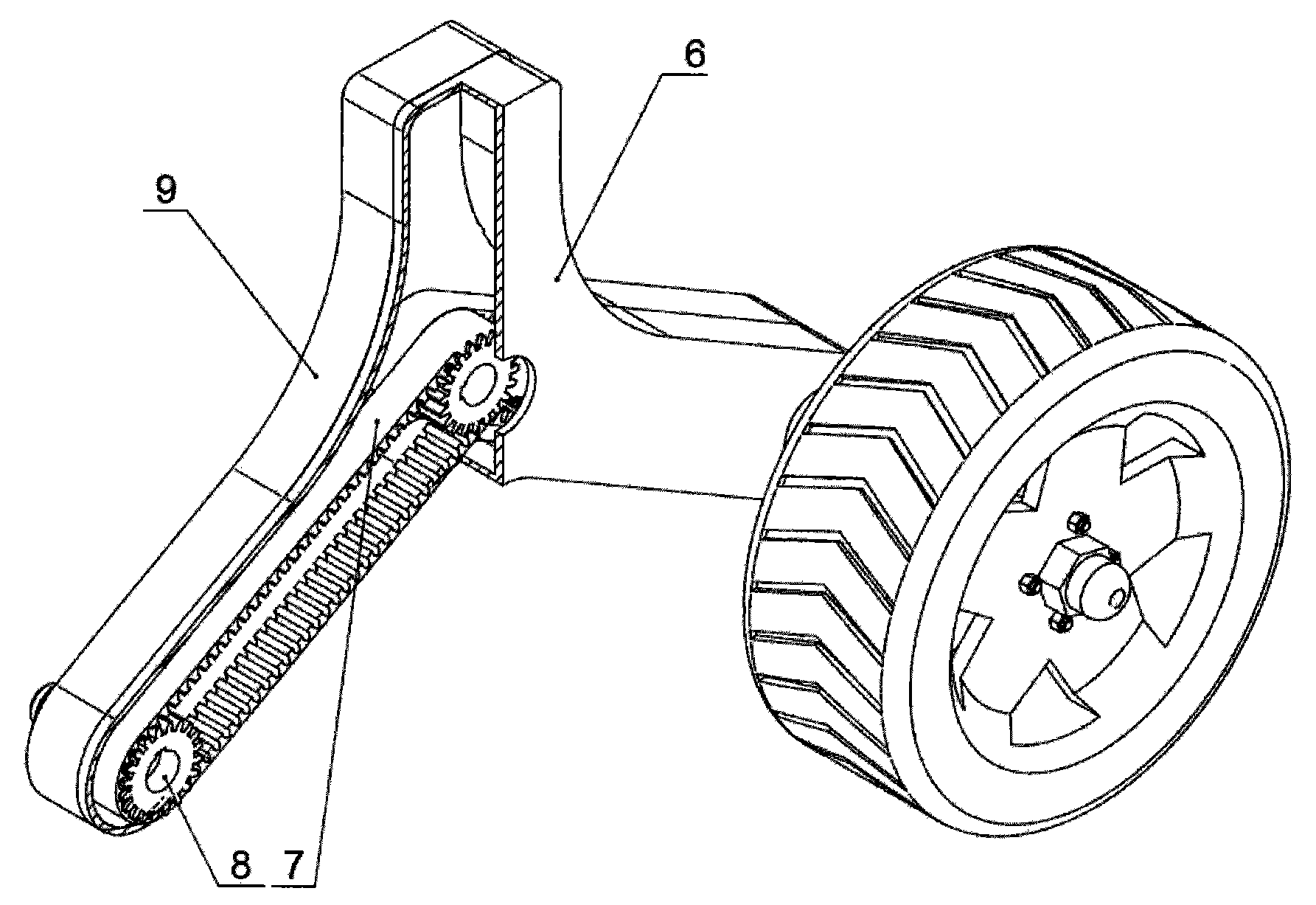

ActiveCN104175805AImprove mobility off-road performanceSimple configurationPivoted suspension armsWheel-axle combinationsMotor driveEngineering

The invention relates to a self pretightening buffering herringbone forest wheel disc and belongs to the technical field of forest vehicle chassis. The forest wheel disc comprises wheels and a base disc. Each wheel comprises a herringbone wheel bone and a self pretightening buffering device. The herringbone wheel bones are installed on two sides of the middle of the base disc, two arms at the bottom are wheel arms, the wheels are installed on the end portions of the wheel arms, a top single arm is a traction arm, and the self pretightening buffering devices are installed on the traction arm. A wheel bone outer casing and a wheel bone inner casing are installed in a matching mode to form an enclosed casing. Direct gears are installed on the end portions of the inner sides of the wheel arms of the two casings, direct gears are coaxially installed in the middle of the inner sides of the two casings, and the gears are in meshing transmission through a tooth-shaped meshing belt. The self pretightening buffering device achieves a self pretightening buffering function, achieves wheel arm high-amplitude swinging and restrains the borne materials in the vehicle cross-country running process. The wheel disc can improve the motor-driven country crossing performance of forest vehicles, simplify the vehicle whole structure and improve the vehicle carrying performance.

Owner:BEIJING FORESTRY UNIVERSITY

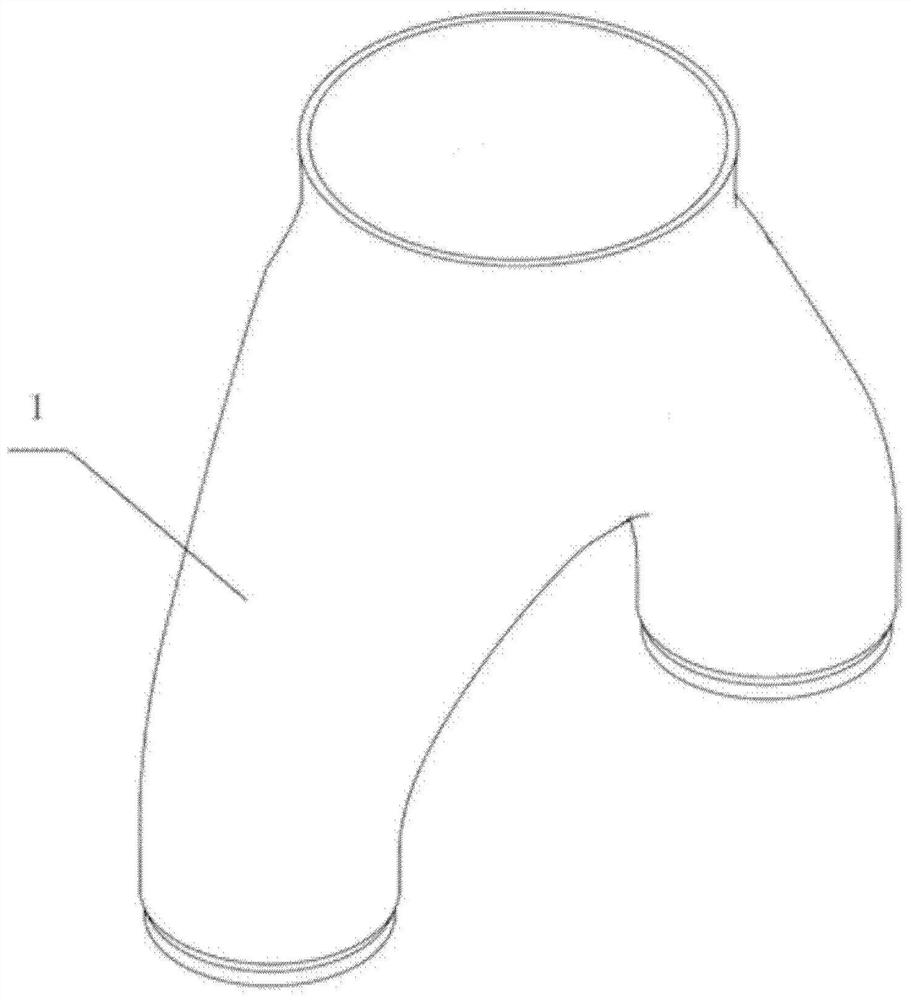

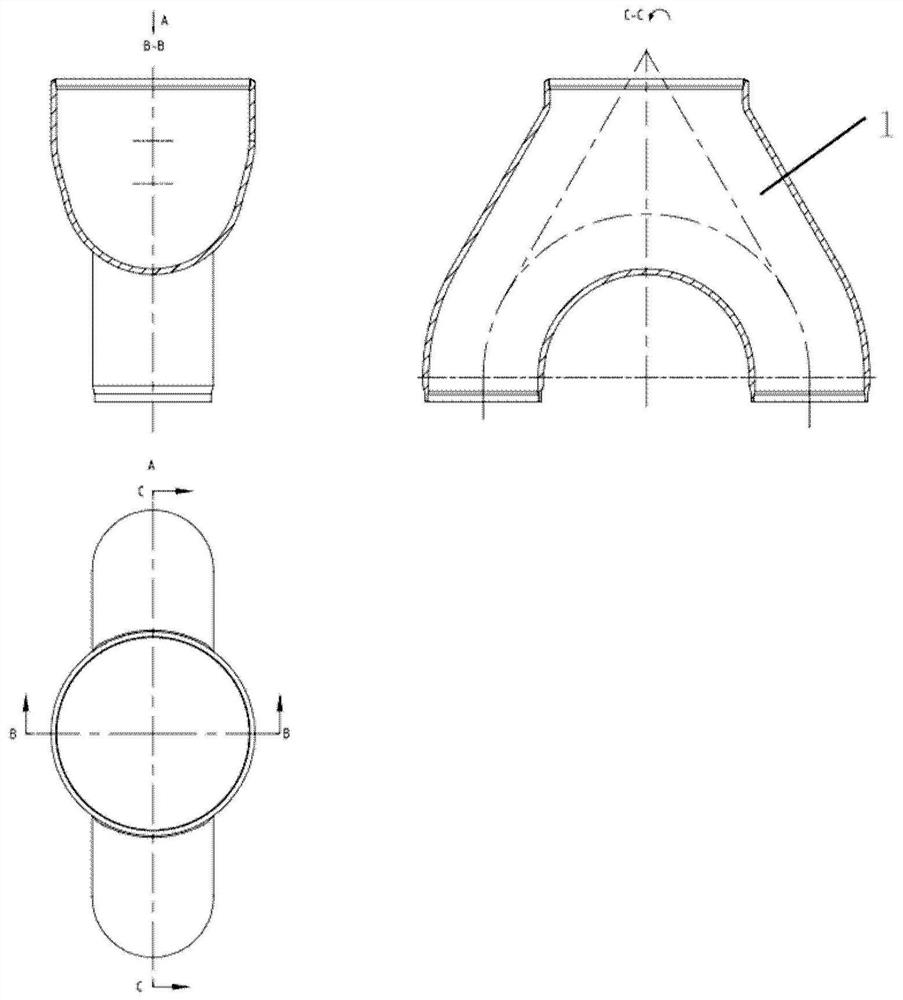

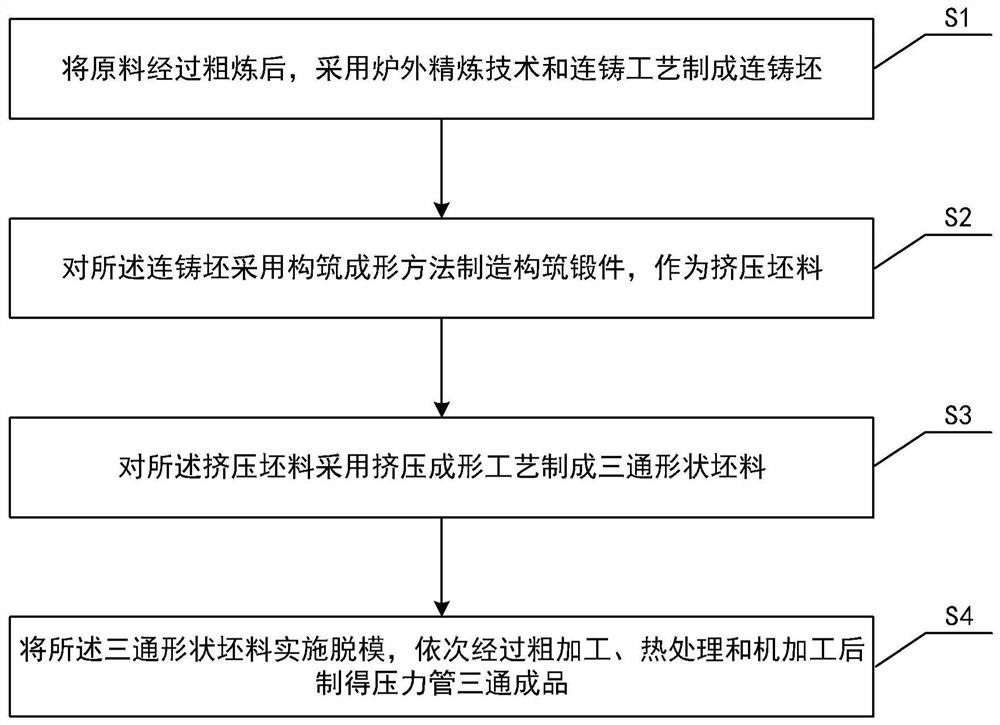

Manufacturing method of pressure pipe tee joint

ActiveCN112846672ALow Cycle Fatigue PropertiesMeet the service environmentNuclear energy generationLow-cycle fatigueMaterials science

The invention provides a method for manufacturing a pressure pipe tee joint. The method comprises the following steps that 1, after raw materials are roughly smelted, a continuous casting blank is manufactured by adopting an external refining method and a continuous casting process; 2, a construction forge part is manufactured from the continuous casting blank by adopting a construction forming method to serve as an extrusion blank; 3, the extrusion blank is manufactured into a tee-joint-shaped blank by adopting an extrusion forming process; and 4, after the tee-joint-shaped blank is demolded, rough machining, heat treatment and machining are conducted in sequence, and then a pressure pipe tee joint finished product is obtained. By means of the manufacturing method, it can be guaranteed that a tee joint material has the characteristics of matched obdurability, uniform structure, intergranular corrosion resistance and high and low cycle fatigue, and the complex service environment and failure mode of the pressure pipe tee joint are met. Moreover, according to the method, a weldless fast reactor integrated tee joint forming process is adopted for the first time, so that the problem that obvious size effect exists in the solidification process of a large-section steel ingot of a forge part with a complex structure is solved, and the phenomena of segregation, looseness and coarse grains of the steel ingot are overcome.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

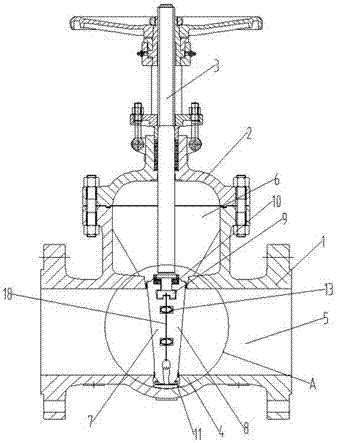

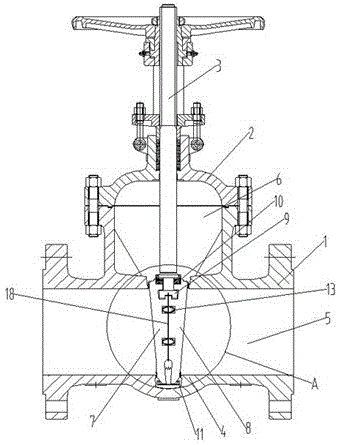

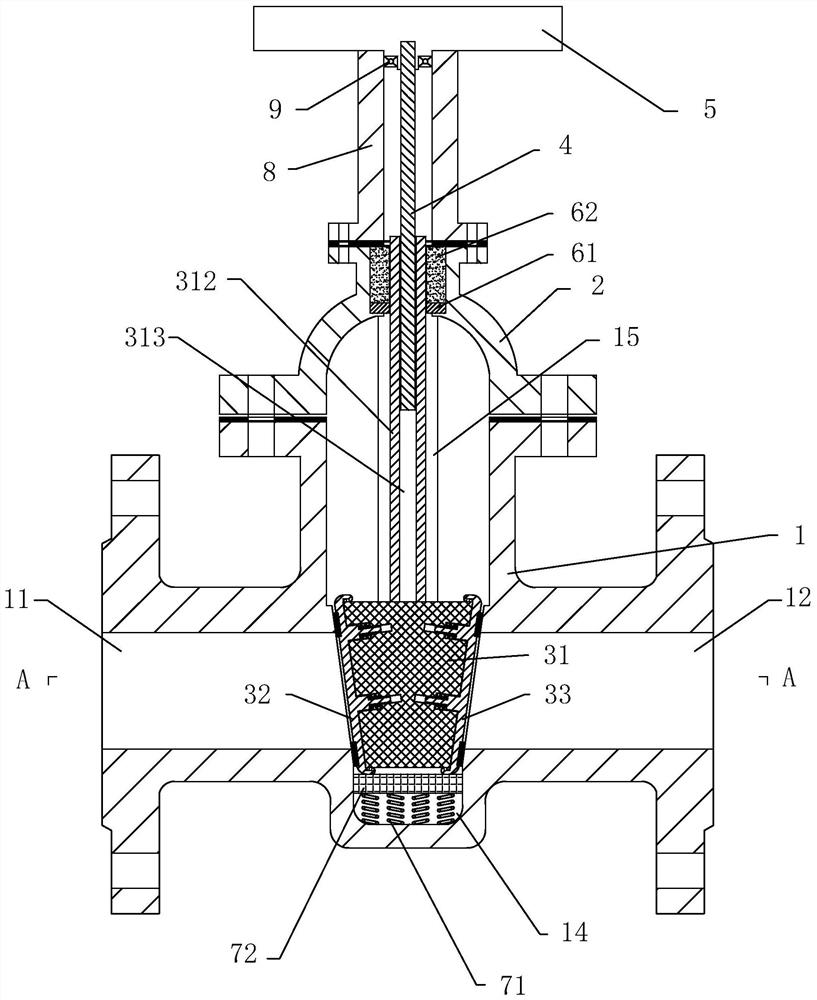

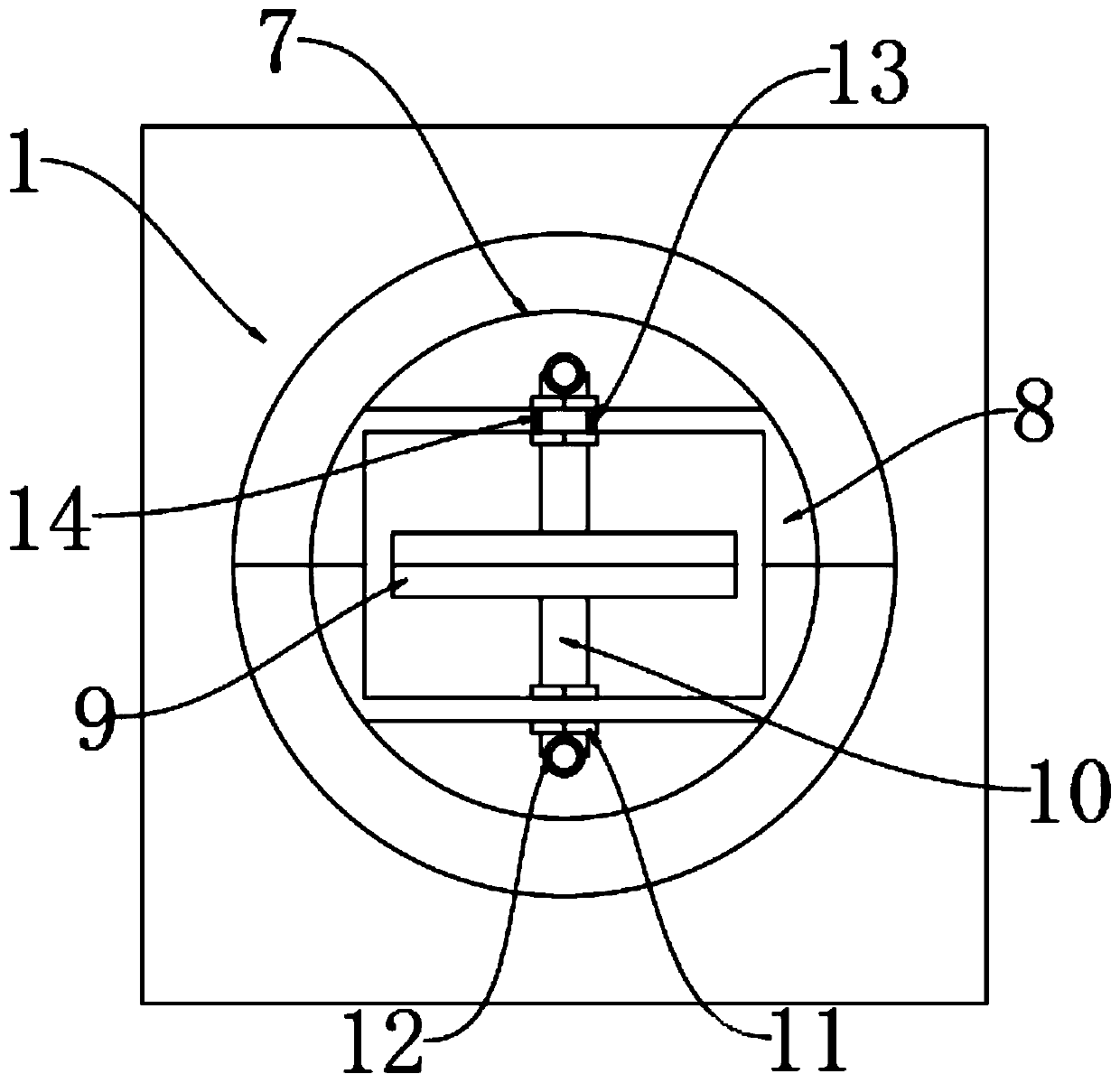

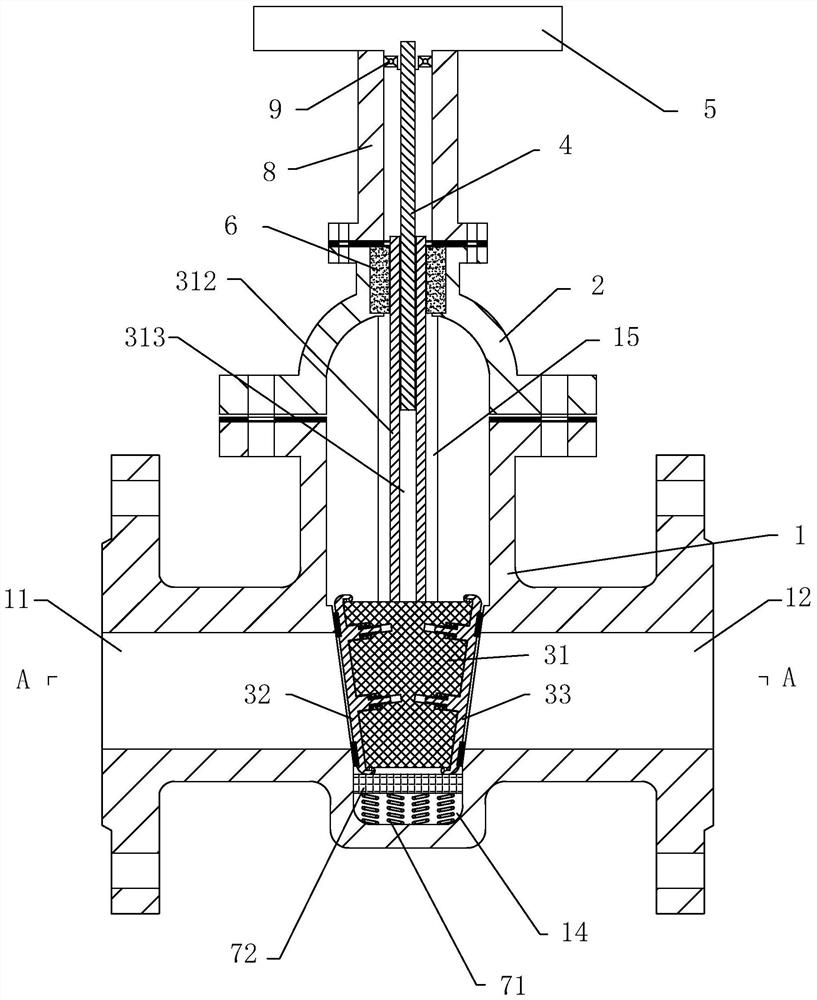

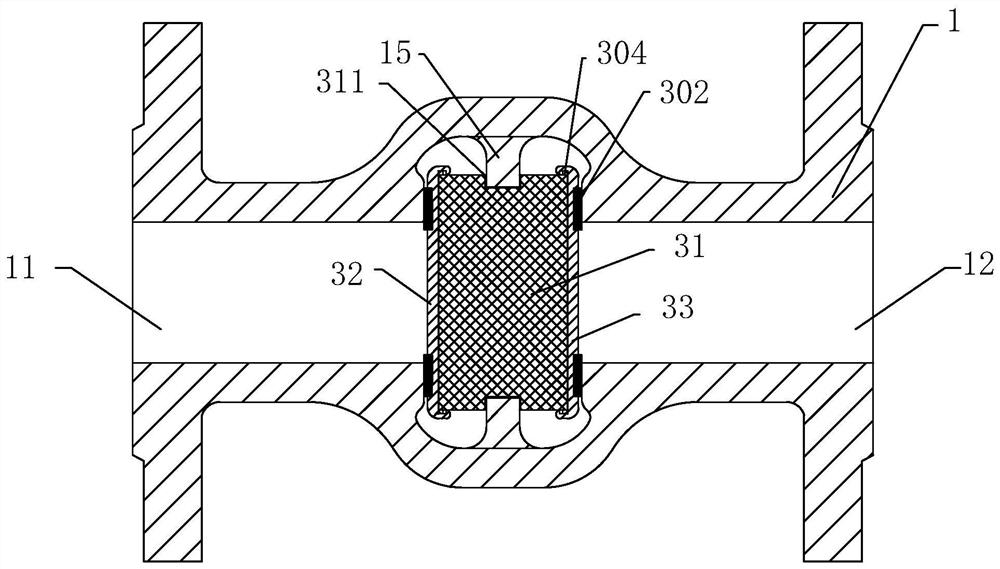

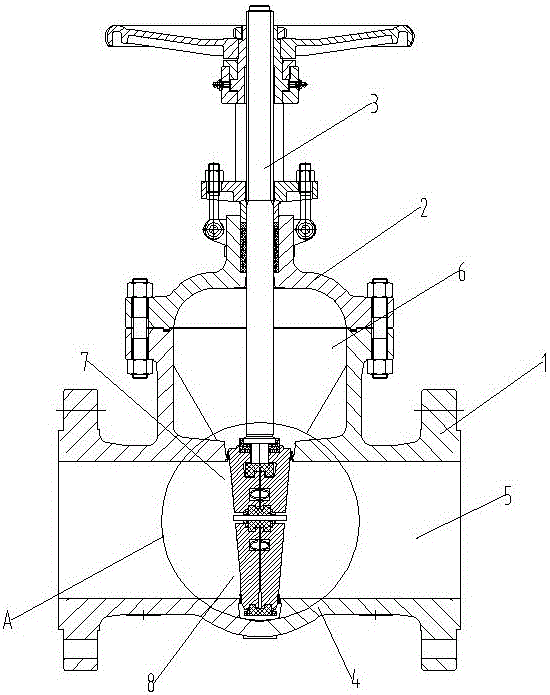

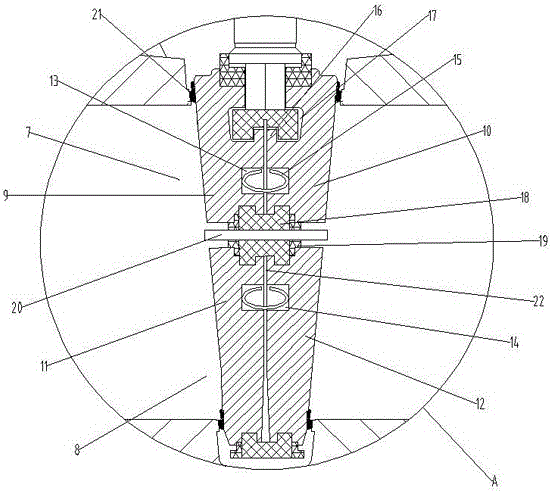

gate

ActiveCN105065699BOvercome loosenessOvercoming the problem of insufficient sealingSlide valveLeft valveGate valve

The invention discloses a gate valve with a good airtightness effect. Springs arranged between a traditional left valve plate and a traditional right valve plate are replaced by elastic metal rings, and therefore the defect that the left valve plate and the right valve plate get loose due to the fact that the springs lose efficacy after long-time use can be effectively overcome. Due to the facts that the elastic metal rings abut against the inner walls of accommodating cavities and open upwards, it is guaranteed that the elastic metal rings can exert pressure in the axis direction of a flow channel all the time, and the problem that airtightness is not enough due to abrasion of a valve seat or a sealing face is solved due to the fact that elastic force is exerted on the left valve plate and the right valve plate continuously. Moreover, a valve plate sleeve and a clamping sleeve are used for limiting and fixing the left valve plate and the right valve plate, the fixing mode is simple and reliable, and compared with a traditional gate valve, the airtightness is good, and the service life is long.

Owner:FLUOROSEAL SPECIALTY VALVES SUZHOU

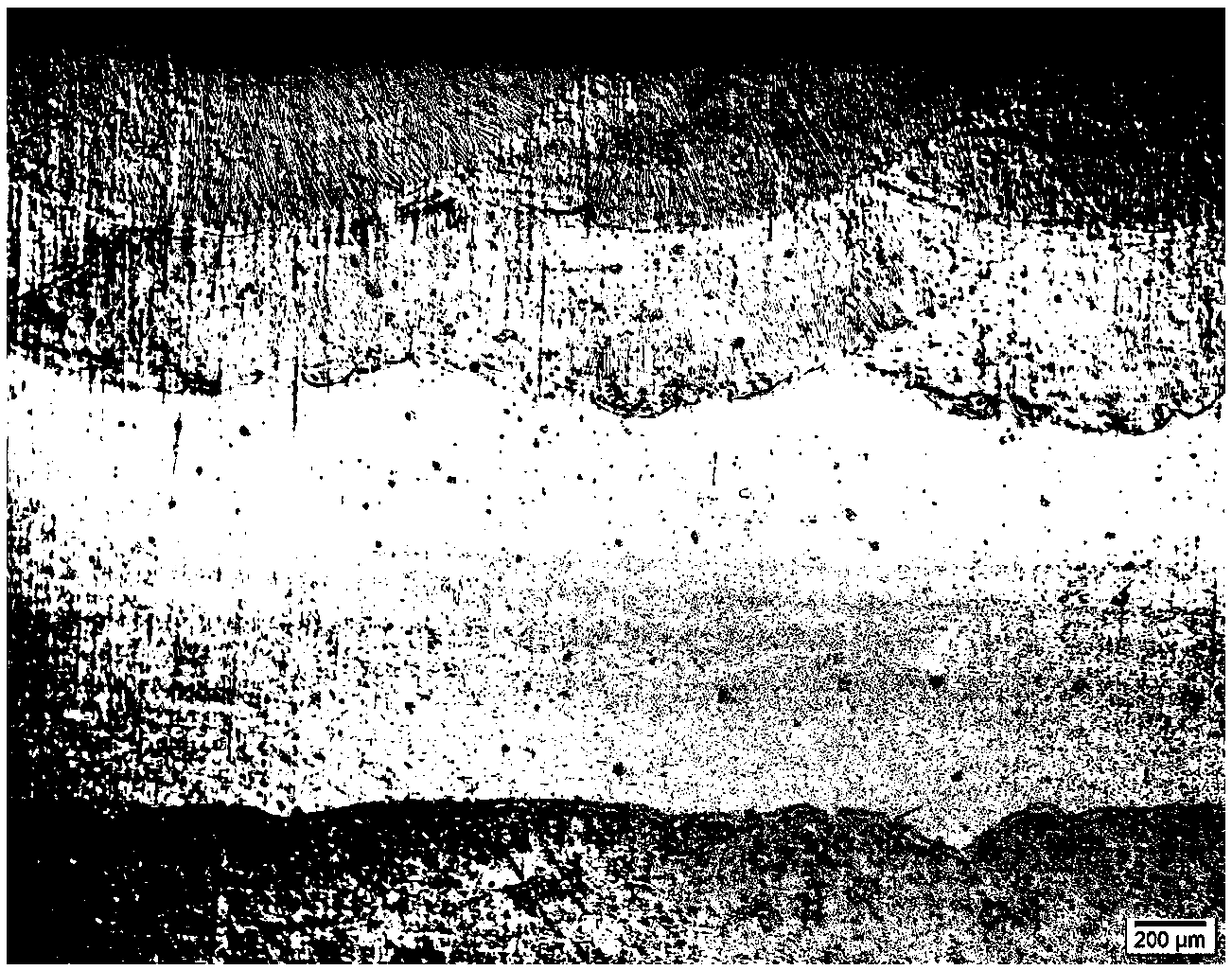

Integrated cast steel supporting roller

The invention relates to an improvement on a material and a quenching mode for an integrated cast steel supporting roller. The integrated cast steel supporting roller is characterized by consisting of a supporting roller body and a mandrel cast steel material, wherein the mandrel cast steel material comprises the following components in percentage by weight: 0.4 to 0.6 percent of C, 0.3 to 0.6 percent of Si, less than or equal to 0.03 percent of P, less than or equal to 0.02 percent of S, less than or equal to 0.3 percent of Ni, 4.8 to 5.2 percent of Cr, 0.5 to 0.7 percent of Mo, 0.1 to 0.2 percent of V, 0.1 to 0.2 percent of Ti, 0.005 to 0.1 percent of B, 0.01 to 0.03 percent of Ca, 0.6 to 0.9 percent of Mn and the balance of iron and inevitable impurities; and the roller body is quickly heated by adopting a differential temperature furnace in heat treatment, and quenching is performed after the temperature of a working layer reaches the quenching requirement. The defects that the conventional 50Cr5MoV cast blank grains are thick, loose and not compact are overcome; and the tissue grains of the obtained supporting roller are fine, the issue is bainite, and the supporting roller basically has no pearlite tissue, so the strength, toughness and quenching capacity of the supporting roller are improved, and the service life is prolonged. The working layer is subjected to effective thorough quenching by differential temperature quick quenching, so the service life of the working layer of the supporting roller is prolonged; the mandrel tissue of the inner layer is not changed, and the quenching basically does not affect the performance of the mandrel, so the strength of the mandrel is ensured, and the mandrel has high strong toughness; and the whole service life of the supporting roller is prolonged by 30 percent compared with that of the conventional 50Cr5MoV supporting roller.

Owner:宜兴市国昌轧辊有限公司

Gate valve

ActiveCN105065699AOvercoming loosenessOvercoming the problem of insufficient sealingSlide valveEngineeringValve seat

The invention discloses a gate valve with a good airtightness effect. Springs arranged between a traditional left valve plate and a traditional right valve plate are replaced by elastic metal rings, and therefore the defect that the left valve plate and the right valve plate get loose due to the fact that the springs lose efficacy after long-time use can be effectively overcome. Due to the facts that the elastic metal rings abut against the inner walls of accommodating cavities and open upwards, it is guaranteed that the elastic metal rings can exert pressure in the axis direction of a flow channel all the time, and the problem that airtightness is not enough due to abrasion of a valve seat or a sealing face is solved due to the fact that elastic force is exerted on the left valve plate and the right valve plate continuously. Moreover, a valve plate sleeve and a clamping sleeve are used for limiting and fixing the left valve plate and the right valve plate, the fixing mode is simple and reliable, and compared with a traditional gate valve, the airtightness is good, and the service life is long.

Owner:FLUOROSEAL SPECIALTY VALVES SUZHOU

Method for preparing functionally-graded dental implant by metal 3D printing

InactiveCN108926399ASolve the release problemOvercome loosenessDental implantsAdditive manufacturing apparatusFunctionally graded materialStress shielding

A method for preparing a functionally-graded dental implant by metal 3D printing is characterized in that a tooth root made from a functionally graded material and an abutment part made from a singlematerial are sequentially printed by a laser melting precipitation (LMP) technology based on a three-dimensional model of the dental implant. The integral molding of the tooth root and the abutment solves fretting wear caused by poor mechanical combination and micro-leakage caused by loosening; and the stress shielding phenomenon caused by the high modulus of traditional Ti6Al4V alloy tooth rootsand release of toxic elements Al and V are effectively alleviated, and the integration of the tooth root and the abutment can effectively guarantee the mechanical stability and the biomechanical stability of the root-abutment combination.

Owner:SHANGHAI JIAO TONG UNIV

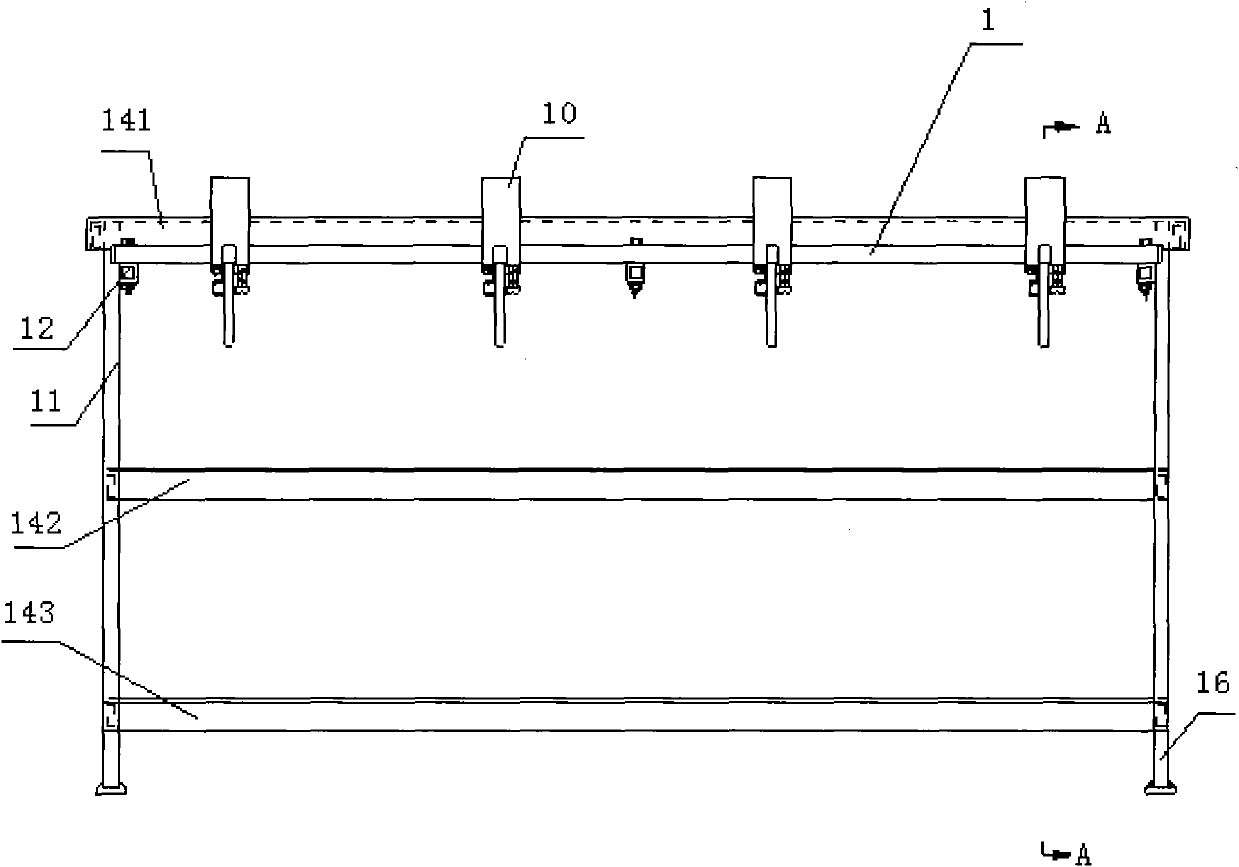

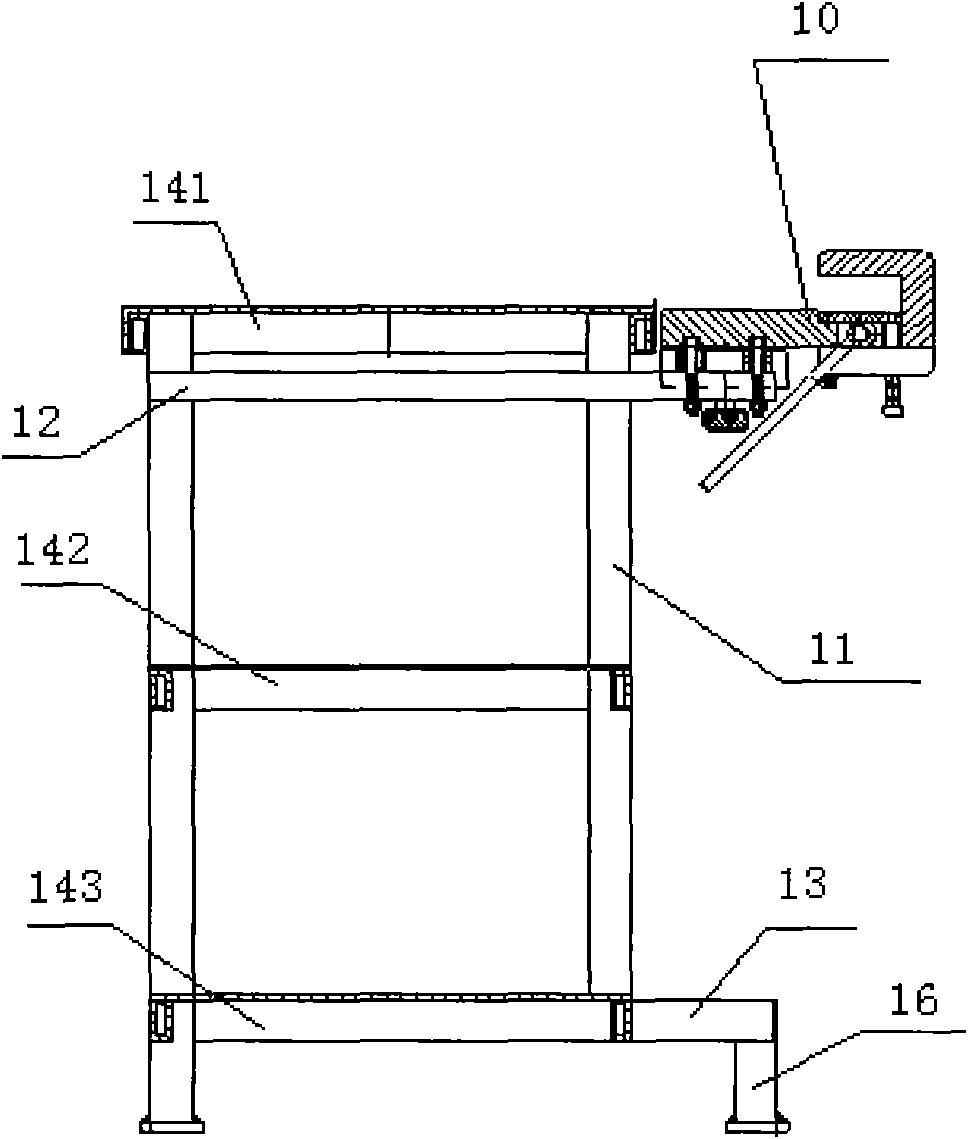

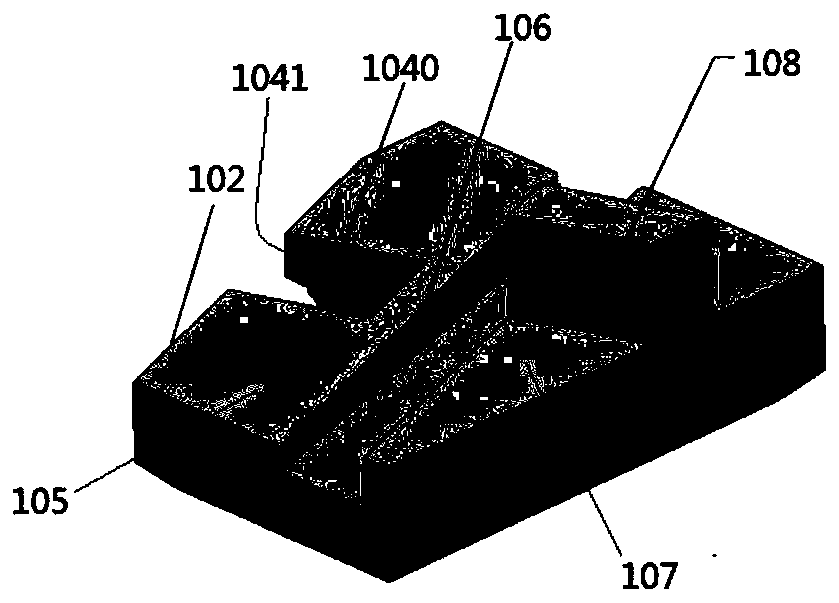

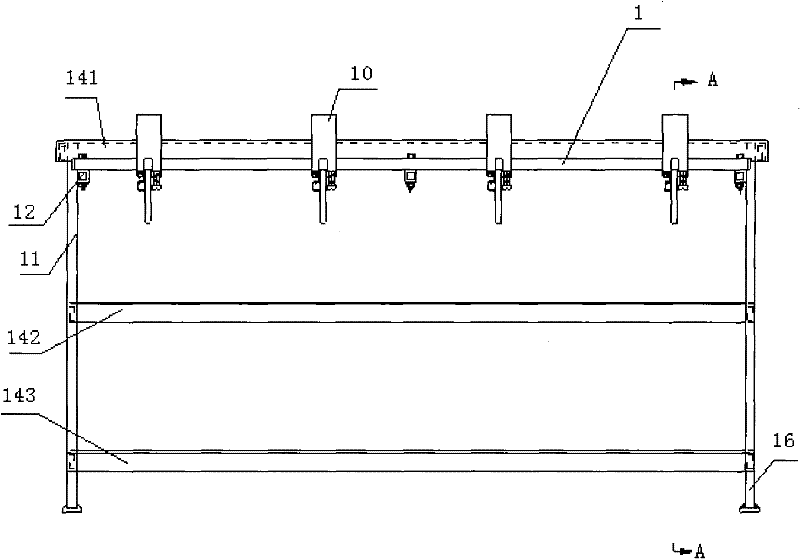

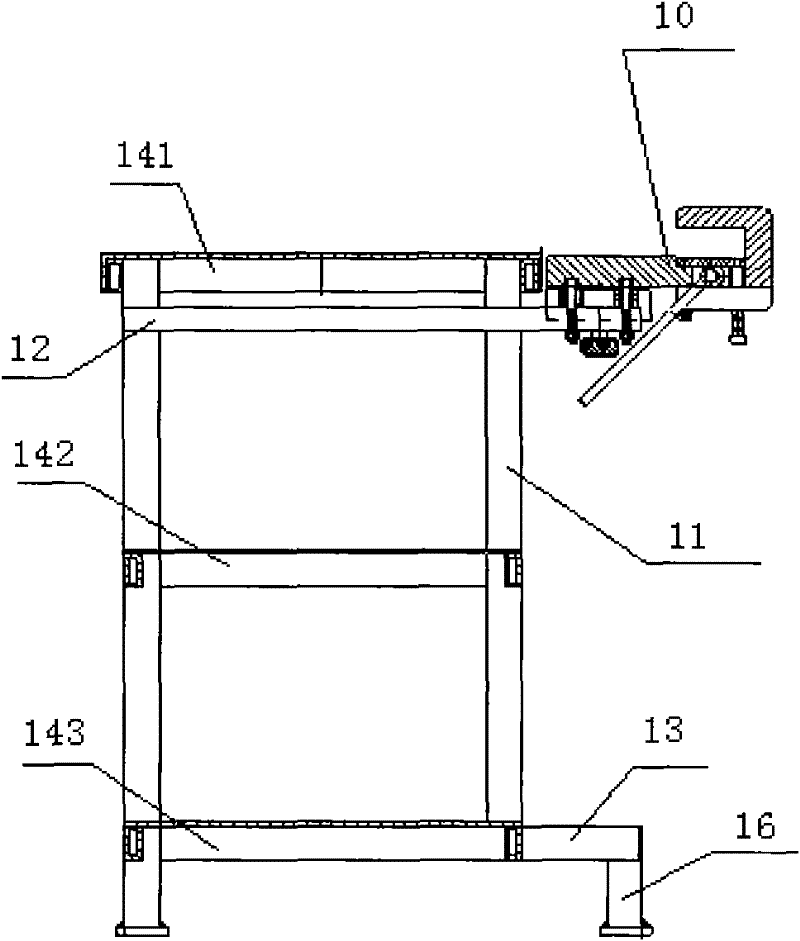

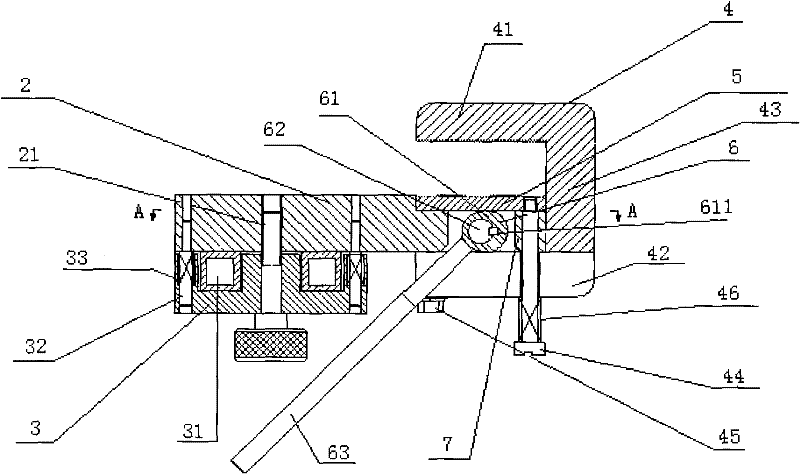

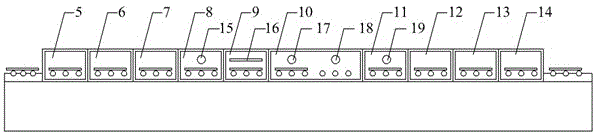

Device for cutting insulation support for transformer body

The invention discloses a device for cutting an insulation support for a transformer body, comprising a workbench body. The workbench body comprises a workbench surface, four rectangular tubes which are arranged under the workbench surface to support the workbench surface, three cantilevers which are fixed on the workbench body and bulge out of the workbench surface, two guide rails which are arranged on the cantilevers in parallel and four moving guide plates which can move and be fixed by passing through the two guide rails. The device improves the working efficiency and can conveniently finishing cutting the insulation support for the transformer body and save time and labor, and the cut insulation support has flat paperboard, thus greatly improving the production quality and the production efficiency. The jig saw is held by both hands so that the jig saw is stable with force, and both hands are not contacted with the paperboard of the insulation support, thus avoiding the possibility that the jig saw is liable to hurting own hands in the original cutting mode.

Owner:SHANGHAI ZHIXIN INTELLIGENT ELECTRIC CO LTD +2

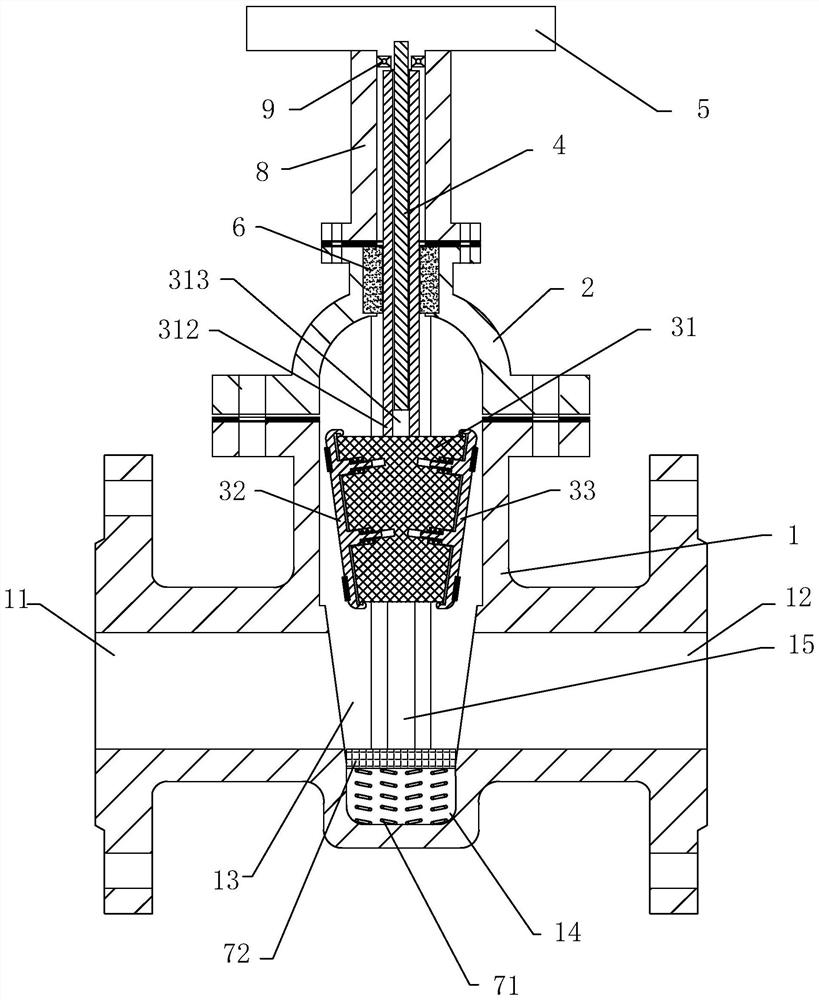

High-airtightness fire gate valve

PendingCN112283378AOvercome failureExcellent safety and service lifeSpindle sealingsSlide valvePhysicsStructural engineering

The invention relates to the field of gate valves, in particular to a high-airtightness fire gate valve which comprises a valve body, a valve deck, a flashboard assembly, a valve rod and a hand wheel.The valve body is provided with a feeding port and a discharging port, a flow channel is formed between the feeding port and the discharging port, the flashboard assembly is arranged in the flow channel, a flashboard groove is formed in the bottom of the flow channel, the lower end of the valve rod is connected with the flashboard assembly, the upper end of the valve rod is connected with the hand wheel, the flashboard assembly comprises a guide block, a left flashboard assembly body and a right flashboard assembly body, the left flashboard assembly body and the right flashboard assembly bodyare arranged on the two sides of the guide block, a guide column is arranged at the upper end of the guide block, a guide groove is formed in the guide column, internal threads are formed in the guide groove, the lower end of the valve rod is spirally arranged in the guide groove, an extending sleeve is arranged at the upper end of the valve deck, the guide column penetrates through the valve deck to stretch into the extending sleeve, the hand wheel is arranged at the upper end of the extending sleeve, a sealing scraping block and sealing filler are arranged on the side face, in contact withthe guide column, of the valve deck, and an annular protruding strip is arranged on the face, in contact with the guide column, of the sealing scraping block. The high-airtightness fire gate valve mainly solves the problem that in the prior art, sealing filler of the gate valve is prone to polluting a conveying medium.

Owner:祥安消防科技有限公司

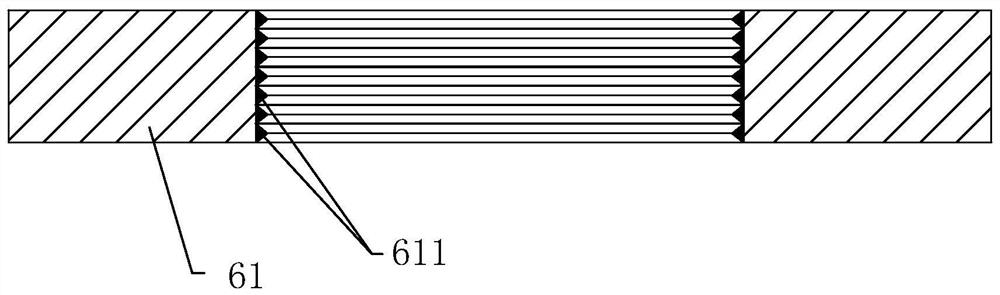

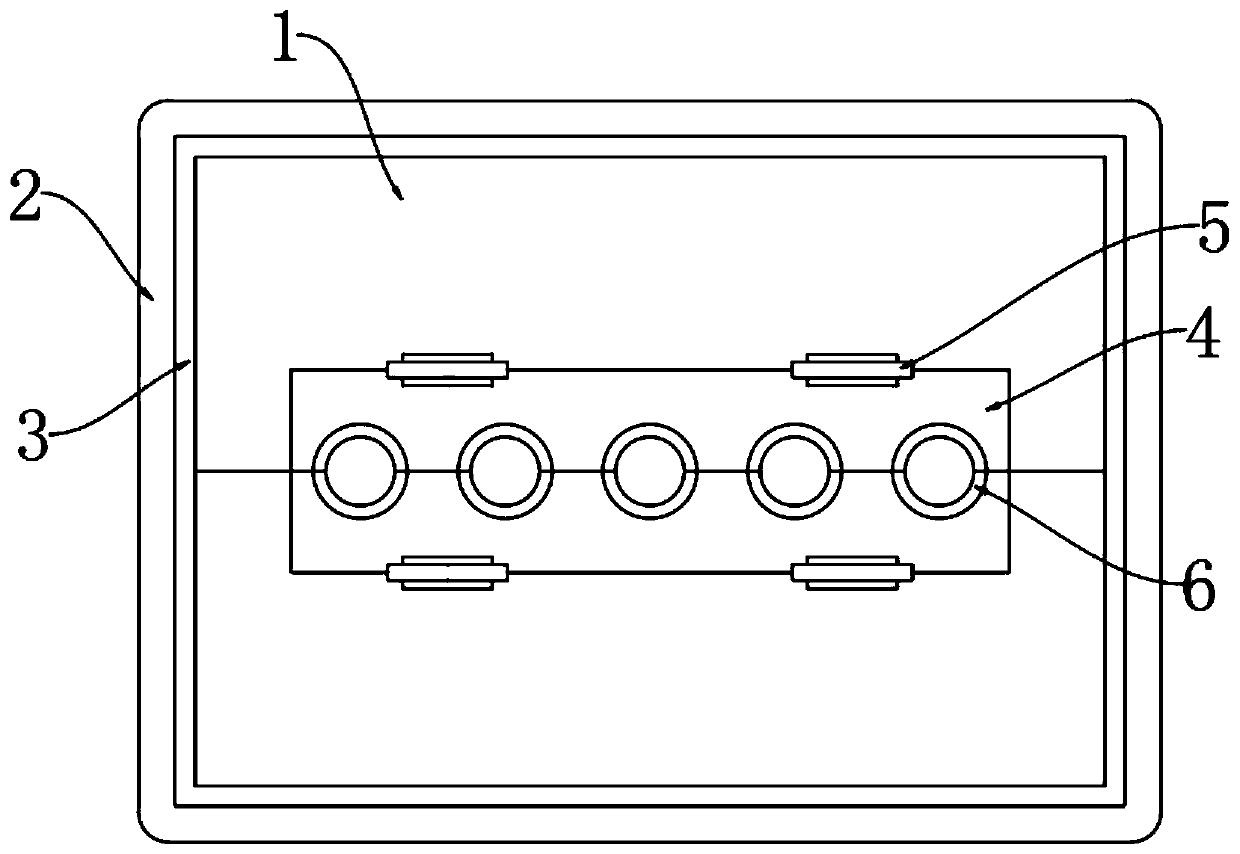

Ethernet cable connection clamping groove

InactiveCN110932027AOvercome loosenessOvercome sheddingEngagement/disengagement of coupling partsAdhesive beltStructural engineering

The invention discloses an Ethernet cable connecting clamping groove, relates to the technical field of Ethernet cables, and aims to solve the problems that two network cables connected with each other are easily influenced by external factors in the using process of the existing Ethernet cable, so that loosening and falling off are caused. The number of the network cable clamping plates is two. The two network cable clamping plates are bundled and connected through an adhesive tape; outer sheaths are arranged on the outer walls of the two network cable clamping plates; the two network cable clamping plates are symmetrically distributed relative to the horizontal line of the outer sheath; sealing plates are arranged on the front end surface and the rear end surface of the network cable clamping plate; the sealing plate is rotatably connected with the network cable clamping plate through a hinge, five cable inlet holes are formed in the sealing plate, five line channels are formed in the network cable clamping plate, the five line channels are communicated with the five cable inlet holes respectively, and a fastening mechanism is arranged in the center of each line channel.

Owner:SUZHOU AINAGE INFORMATION TECH CO LTD

Bidirectional sealing gate valve

PendingCN112268123AAffect blockingEasy to transportSlide valveValve housingsEngineeringSolid particle

The invention relates to the field of gate valves, in particular to a bidirectional sealing gate valve. The bidirectional sealing gate valve comprises a valve body, a valve cover, a gate plate assembly, a valve rod and a hand wheel, wherein the valve cover is arranged at the top of the valve body through a bolt, the valve body is provided with a feeding port and a discharging port which are coaxially arranged, a flow channel is formed between the feeding port and the discharging port, the gate plate assembly is arranged in the flow channel, a gate plate groove is formed in the bottom of the flow channel, the lower end of the valve rod penetrates into the valve body from the valve cover and is connected with the gate plate assembly, the upper end of the valve rod is connected with the handwheel, the gate plate assembly comprises a guide block, a left gate plate assembly and a right gate plate assembly, the left gate plate assembly and the right gate plate assembly are arranged on the two sides of the guide block, each of the left gate plate assembly and the right gate plate assembly comprises a gate plate which is arranged in parallel with the corresponding wedge-shaped surface, the gate plates can move relative to the guide block through elastic assemblies, a limiting sealing assembly is arranged between the periphery of each gate plate and the guide block, and an elastic baffle plate assembly is arranged in the gate plate groove. According to the bidirectional sealing gate valve, the problem that a gate valve in the prior art is not suitable for conveying a medium containing solid particle impurities, so that the sealing effect is poor is mainly solved.

Owner:沪航科技集团有限公司

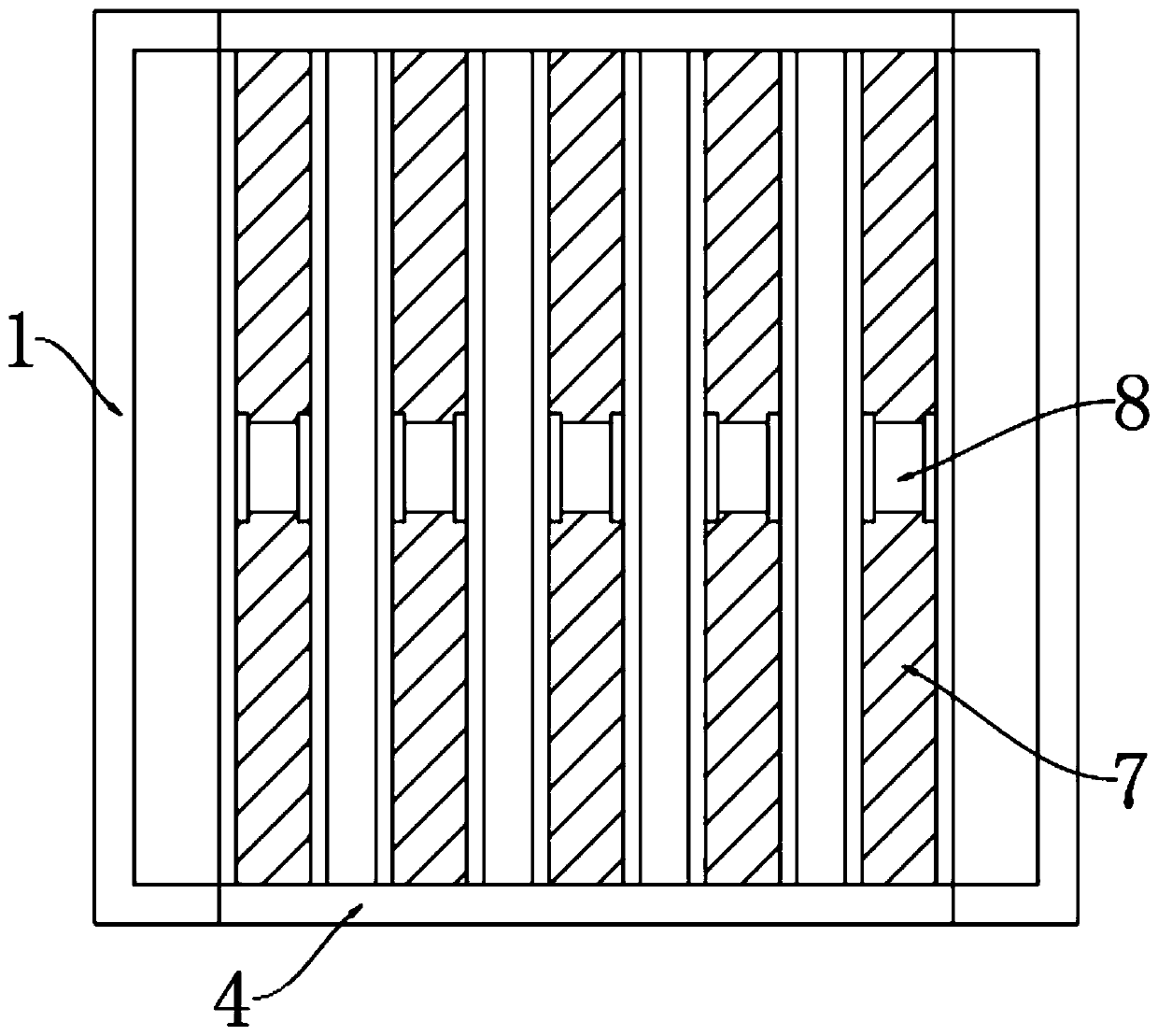

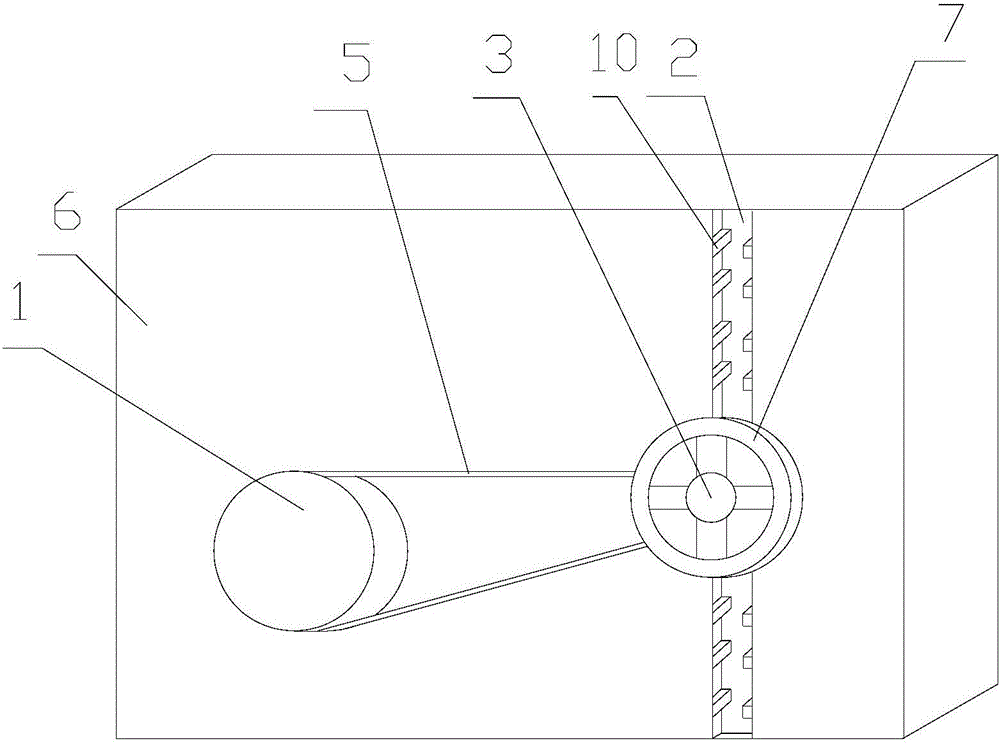

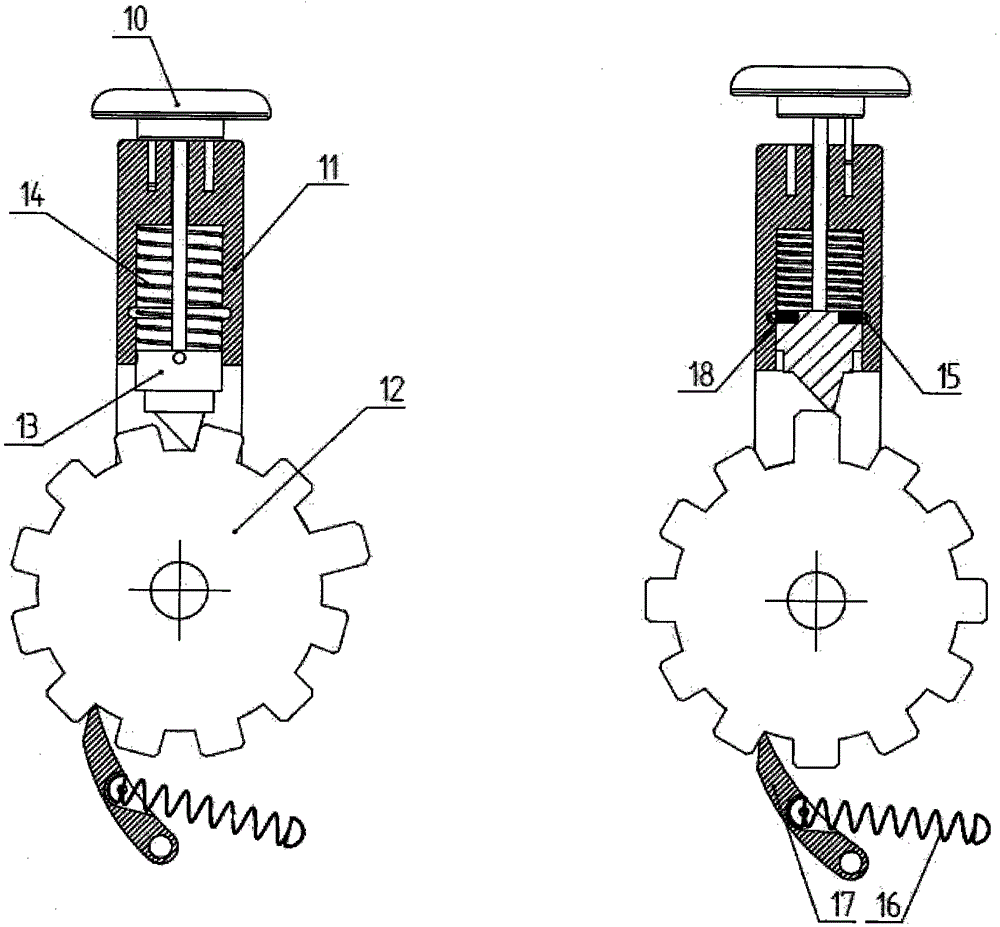

Regulators for textile machines

ActiveCN104878511BOvercome loosenessRealize the function of tightening the beltLoomsEngineeringLeather belt

Owner:江苏瑞斯特针纺有限公司

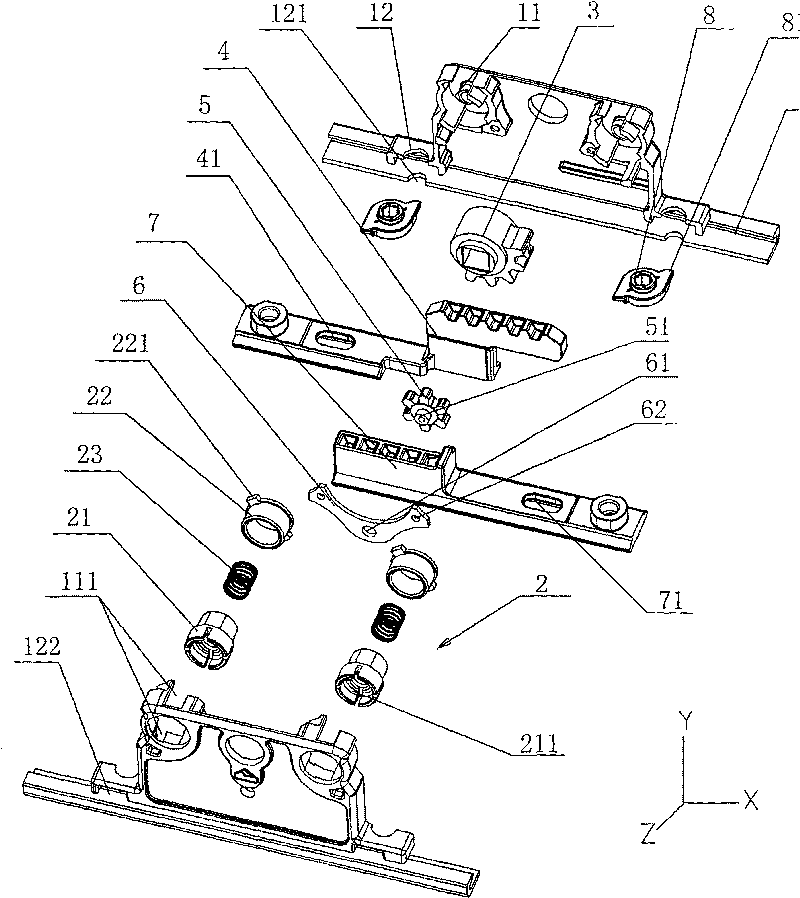

Food processor locking mechanism

ActiveCN103099550BAvoid reverse rotationOvercome loosenessKitchen equipmentCross connectionLocking mechanism

The invention provides a food processor locking mechanism which has the anti-loose function, guarantees reliable connection between components and prevents components from loosing. The food processor locking mechanism comprises a first structure part, a second structure part and a connection part, wherein the connection part is respectively in screw connection with the first structure part and the second structure part in a mode convenient to separate, and the first structure part and the connection part can form a first structure assembly. The food processor locking mechanism further comprises a locking block installed on the connection part, wherein the locking block comprises three work positions of an initial position, a first position and a second position. When the connection part is separated from the first structure part and the second structure part, the locking block is arranged at the initial position. When the first structure part and the connection part are in a screw connection state, the locking block leaves a support structure of the connection part to move to the first position to be matched with and fixedly connected with a location structure of the first structure part. When the first structure assembly and the second structure part are in a connection state, the locking block is positioned at the second position.

Owner:ELEC TECH ZHUHAI CO LTD

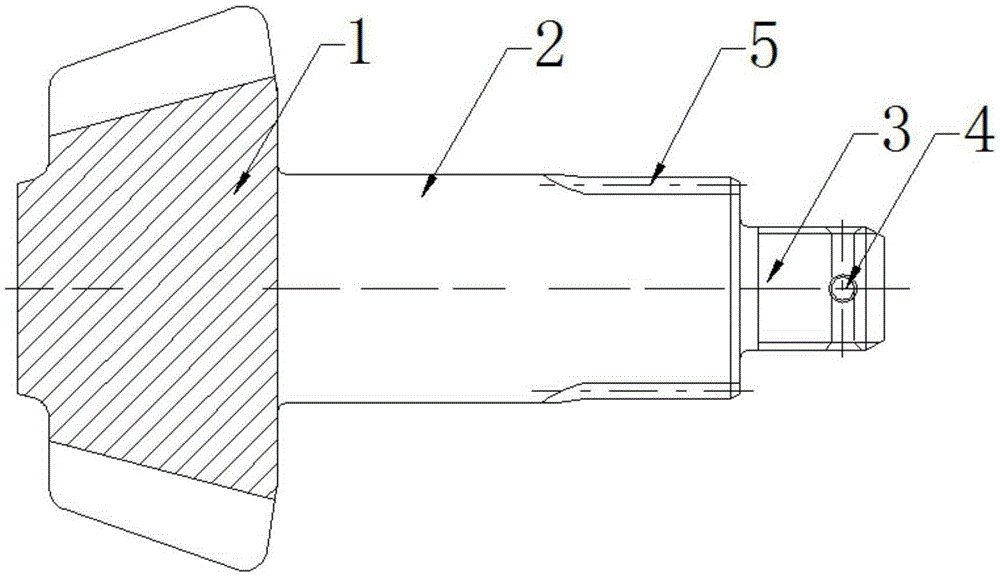

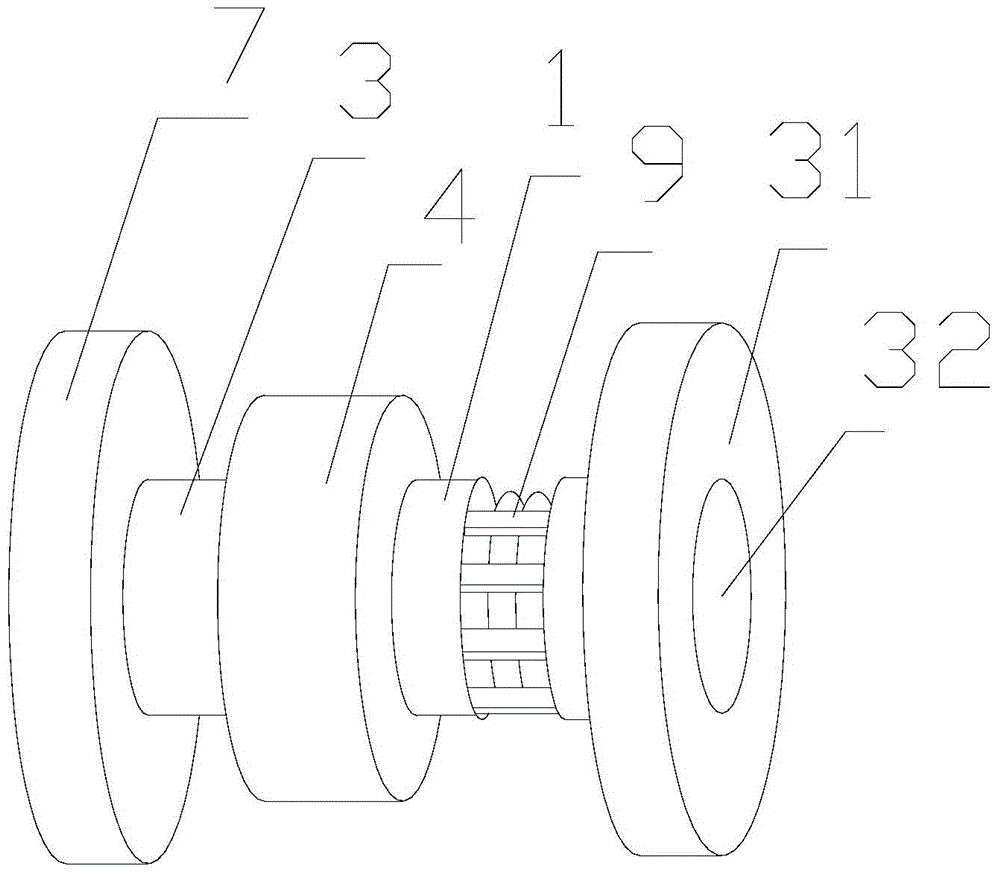

Bevel gear

InactiveCN105333100AStable installationOvercome loosenessPortable liftingGearing elementsEngineeringMechanical efficiency

The invention discloses a bevel gear. The bevel gear is characterized in that the bevel gear comprises a gear tooth part (1), a gear shaft part (2) and a screw part (3); the gear tooth part (1), the gear shaft part (2) and the screw part (3) are sequentially connected and integrally designed; at least six locking pin holes (4) are evenly formed in the outer wall of the screw part (3) in the circumferential direction; the locking pin holes (4) are all perpendicular to the axis of the screw part (3), and every two locking pins holes (4) are communicated with each other. The bevel gear has the beneficial effects that the gear can be firmly installed; the situation that the gear is prone to looseness in the transmission process due to a long service cycle of the gear is avoided, so that the transmission process is more stable, the mechanical efficiency is improved, and the safety performance of equipment is improved.

Owner:CHONGQING SHOUYE MACHINERY MFG

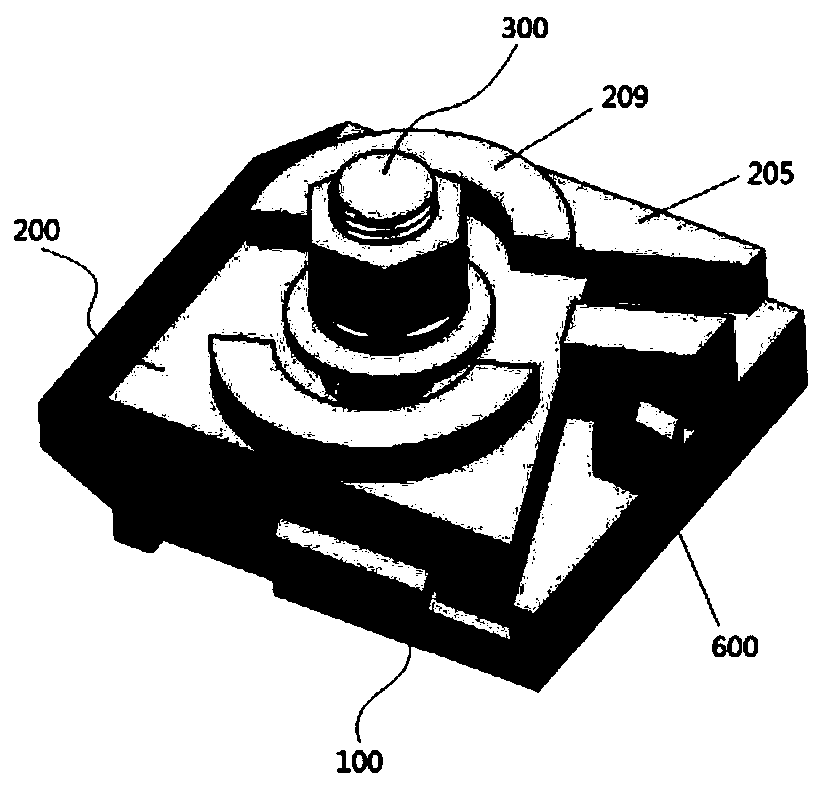

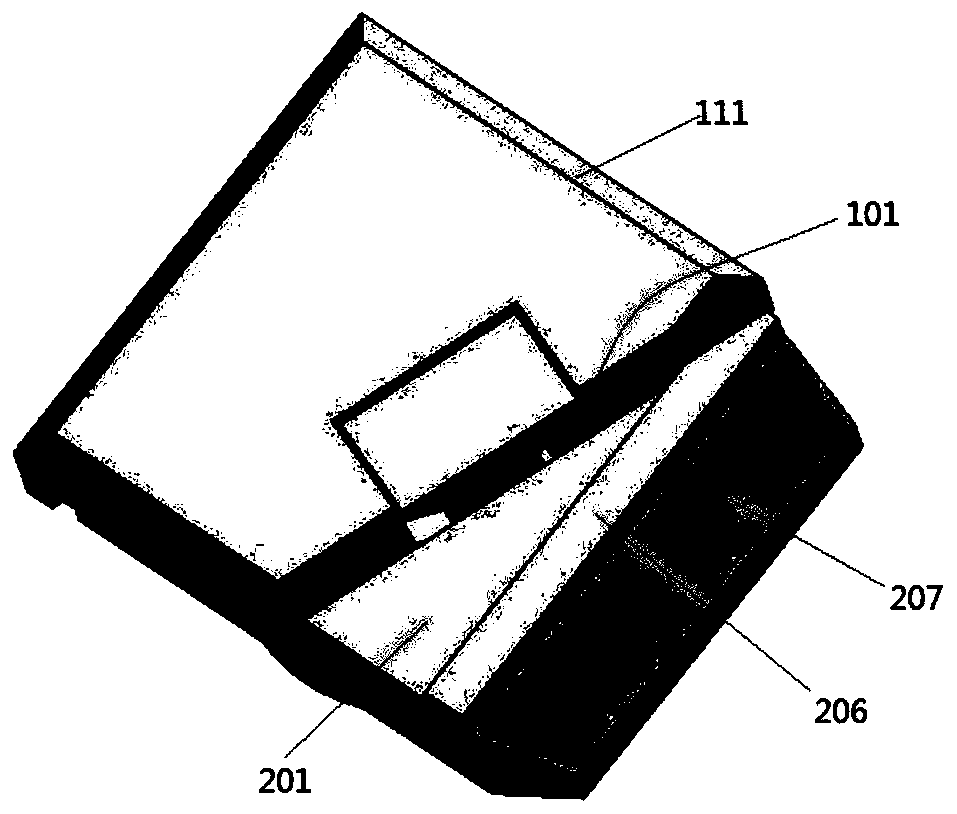

Rail press and rail

The embodiment of the application provides a rail press and a rail. The rail press comprises a fixed base and an upper cover, the upper cover covers the fixed base, first locking member enabling the fixed base and the upper cover to achieve two-way anti-retreating self-locking in the sided direction and a bucket-shaped bolt member penetrating through the upper cover and the fixed base in the perpendicular direction and fixing the upper cover and the fixed base are configured between the fixed base and the upper cover, and a gradual contraction mounting hole matched with the bucket-shaped boltmember is formed in the fixed base. The rail press can solve the problems such as loosening, falling off, rail displacement and change of gauge of the rail press due to the huge lateral force passed to the rail in the operation process of lifting transport equipment, meanwhile, the problems of high difficulty of the user maintenance and the high maintenance cost are further solved, and the requirements of the rails such as various heavy-duty, large lifting transport equipment and coke oven four large vehicles are met.

Owner:林州市宏阳工业设备有限公司

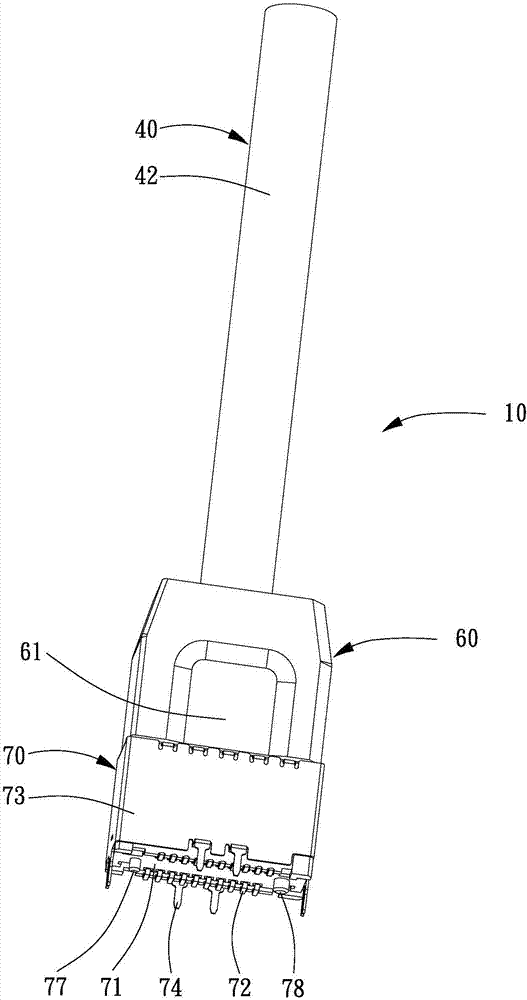

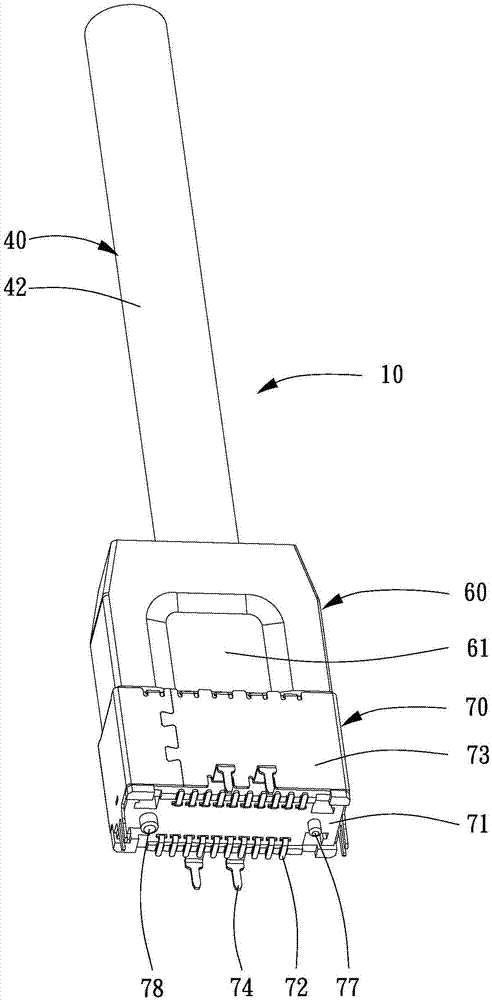

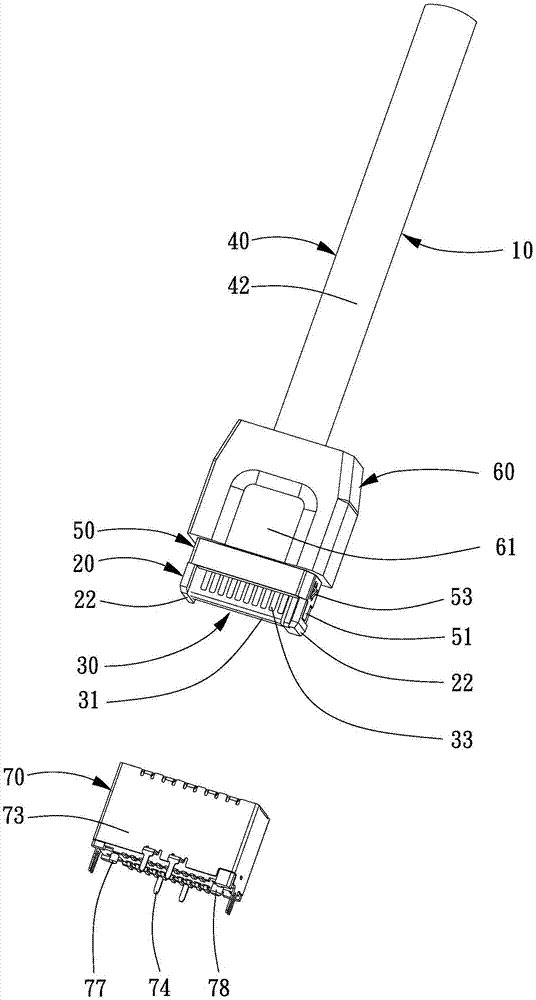

Internal Type-C connector assembly and male connector thereof

PendingCN107508061AEnsure electrical connection stabilityExtended service lifeSecuring/insulating coupling contact membersTwo-part coupling devicesElectrical connectionEngineering

The invention relates to an internal Type-C connector assembly, and the connector assembly is used for the connection of mainboard elements. The connector assembly comprises a male connector and a female connector matched with the male connector. The male connector comprises a plug buckle part and a PCB passing through the plug buckle part. The plug buckle part comprises two substrates, a first pin and a second pin which are respectively connected with two opposite ends of each substrate, and a plurality of fixed parts passing through the substrates. The PCB comprises a PCB female board, a plurality of bonding pads and a plurality of gold fingers, wherein the bonding pads and gold fingers are respectively disposed on two opposite surfaces of the PCB female board. The connector assembly is simple in structure, is reasonable in design, employs a connection structure of the PCB and the gold fingers, and guarantees the electrical connection stability of the male connector. Meanwhile, the gold fingers are integrated on the PCB, thereby solving a loosening problem after long-time use, avoiding poor contact, guaranteeing the quality of a product, and effectively prolonging the service life of the male connector.

Owner:DONGGUAN MINGJI ELECTRONICS

Device for cutting insulation support for transformer body

The invention discloses a device for cutting an insulation support for a transformer body, comprising a workbench body. The workbench body comprises a workbench surface, four rectangular tubes which are arranged under the workbench surface to support the workbench surface, three cantilevers which are fixed on the workbench body and bulge out of the workbench surface, two guide rails which are arranged on the cantilevers in parallel and four moving guide plates which can move and be fixed by passing through the two guide rails. The device improves the working efficiency and can conveniently finishing cutting the insulation support for the transformer body and save time and labor, and the cut insulation support has flat paperboard, thus greatly improving the production quality and the production efficiency. The jig saw is held by both hands so that the jig saw is stable with force, and both hands are not contacted with the paperboard of the insulation support, thus avoiding the possibility that the jig saw is liable to hurting own hands in the original cutting mode.

Owner:SHANGHAI ZHIXIN INTELLIGENT ELECTRIC CO LTD +2

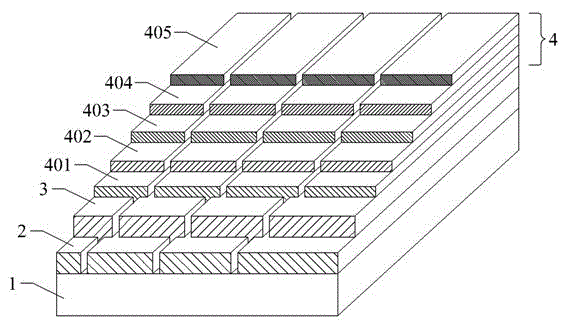

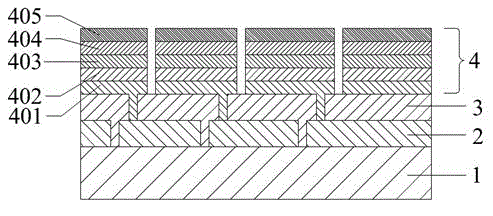

Film solar energy battery and manufacturing method thereof

InactiveCN103943696ASolve Adhesion ProblemsImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationAlloyEngineering

The invention belongs to the technical field of a solar energy battery, and relates to a film solar energy battery and a manufacturing method thereof, for solving the technical problems of welding performance of the back electrode of a film solar energy battery, adhesive force among each film layer and the like. The film solar energy battery is composed of multiple internally series-connected photoelectric units, comprises a front electrode, a photoelectric conversion layer and a back electrode which are sequentially stacked on a substrate, and is characterized in that the back electrode is of a multi-layer structure composed of a transparent conductive layer, a transition layer, a first reflection layer, a second reflection layer and a welding enhancement protective layer. The reflection layer of the back electrode is composed of two membranes, i.e., a silver membrane and an aluminum membrane, and the thickness of the silver membrane is smaller than the thickness of the aluminum membrane, so that the production cost can be effectively reduced; and the aluminum membrane is provided with a nickel copper film layer or a nickel-vanadium alloy film layer so that the back electrode can be protected, and the welding performance of the back electrode can also be improved.

Owner:SHEN ZHEN TRONY SCI & TECH DEV CO LTD

Novel sluice valve

The invention discloses a novel sluice valve with a good sealing effect. Compared with a conventional sluice valve, the novel sluice valve disclosed by the invention is good in sealing performance and long in service life. An upper valve plate set is connected to a lower valve plate set by connecting pieces so as to ensure that when a valve rod moves up and down, an upper sealing surface and a lower sealing surface are maintained at the best state; although the upper sealing surface and the lowing sealing surface are different in abrasion loss, the upper sealing surface and the lowing sealing surface do not interfere each other; the abrasion losses of the upper sealing surface and the lower sealing surface are compensated by respective elastic metal rings, and therefore, the upper sealing surface and the lower sealing surface have the best sealing effect. Springs between conventional valve plates are replaced by the elastic metal rings so as to effectively overcome a phenomenon that after the springs become invalid due to long-term usage, loosening occurs between the two valve plates.

Owner:FLUOROSEAL SPECIALTY VALVES SUZHOU

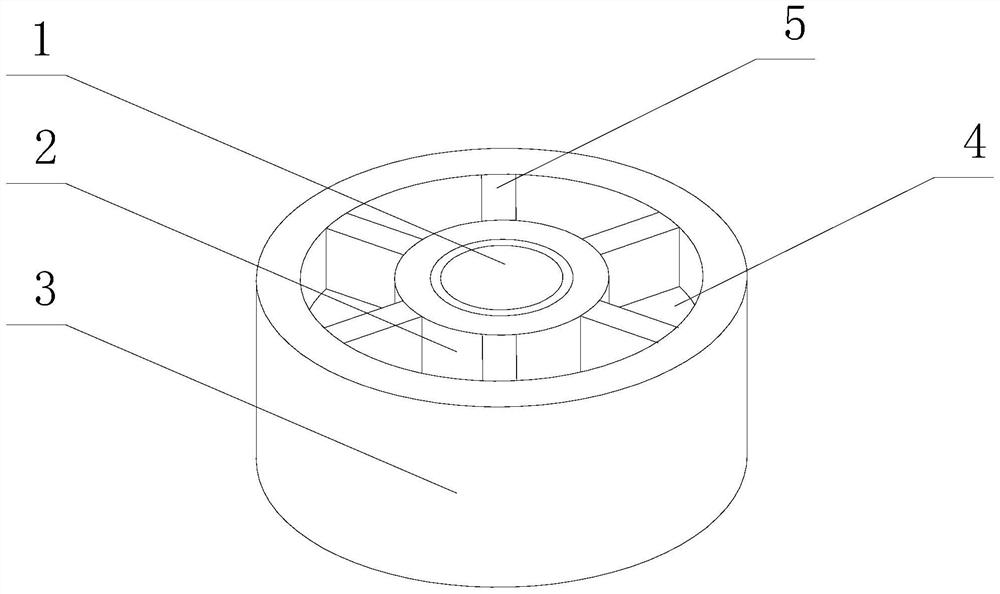

Composite MC nylon steel core wheel casting equipment

PendingCN114393759ALarge expansion coefficientSmall expansion coefficientDomestic articlesStructural engineeringUltimate tensile strength

The composite MC nylon steel core wheel casting equipment comprises a casting tank, a limiting barrel, a cover plate and two occupying units, and a cylinder is fixed to the bottom wall of a cavity; the output end of the first horizontal moving device is connected with a first lifting device, the output end of the first lifting device is connected with a first connecting plate, a first connecting rod is arranged on the first connecting plate, the bottom end of the first connecting rod is connected with the top wall of a limiting cylinder, and a sliding rod driving device is fixed to the outer wall of the limiting cylinder; the output end of the sliding rod driving device is connected with a sliding rod, the sliding rod penetrates through the side wall of the limiting cylinder, and a feeding hole is formed in the top wall of the limiting cylinder; the output end of the second horizontal moving device is connected with a second lifting device, the output end of the second lifting device is connected with a second connecting plate, a second connecting rod is arranged on the second connecting plate, and the bottom end of the second connecting rod is connected with a cover plate; the composite nylon wheel cast by the device is high in strength, wear-resistant and stable in matching with a bearing, and vibration and noise in operation are reduced.

Owner:扬州艾克斯新材料科技有限公司

Bidirectional driver of door and window lockset

ActiveCN101245679BUniform bearing forceOvercome loosenessBuilding locksConstruction fastening devicesGear wheelCoupling

The invention discloses a bidirectional driver for a lock of a door or a window, which comprises a shell; the two sides of the shell are provided with fixing holes in which fixed governing mechanismsare arranged; the interior of the shell is provided with a drive gear, a first drive strip, a reverse drive gear, a drive gear bearing strip and a second drive strip; one end of the central shaft of the reverse drive gear is connected with the shell in coupling, and the drive gear bearing strip is provided with a middle hole and two end holes; the other end of the central shaft of the reverse drive gear is connected in the middle hole of the drive gear bearing strip in coupling; the two end holes of the drive gear bearing strip are socket-jointed with a pin piston integrated with the shell, inthis way, the drive gear bearing strip fixes the rotation of the reverse drive gear in two directions; when the reverse drive gear is rotated, the fixing force of the drive gear bearing strip exertedto the reverse drive gear is more uniform, which overcomes the phenomenon that the drive gear bearing strip of a driver is easy to generate looseness when being used for a long time, thus prolongingthe service life of the bidirectional driver.

Owner:联程机械(宁波)有限公司

Elastic anti-skidding finger type toothbrush

InactiveCN110393364AOvercome loosenessGuaranteed cleanlinessBrush bodiesBristleBiochemical engineering

The invention provides an elastic anti-skidding finger type toothbrush, and belongs to the field of articles for daily life. The elastic anti-skidding finger type toothbrush comprises a fixed sectionand a work section, wherein the fixed section is a round barrel, an anti-separating convex ring is arranged on the inner wall of the round barrel, the height of the anti-separating convex ring is 0.1-0.3 cm, and the width of the anti-separating convex ring is 0.3-0.5 cm; friction salient points are arranged on the outer wall of the round barrel; a connecting primary ring is arranged on the fixed section, a connecting sub ring is arranged on the work section, a clamping groove is arranged in the inner wall of the connecting primary ring, a clamping boss is arranged on the outer wall of the connecting sub ring, and the clamping groove in the connecting primary ring corresponds to the clamping boss on the connecting sub ring; the fixed section and the work section are fixed to form a whole through the connecting primary ring and the connecting sub ring; and a bristle plate is arranged on the work section, and bristles are arranged on the bristle plate. The product is complete in functiondesign, low in manufacturing and use costs, easy and simple to operate, and very suitable for promotion and use within the industry.

Owner:毕研群

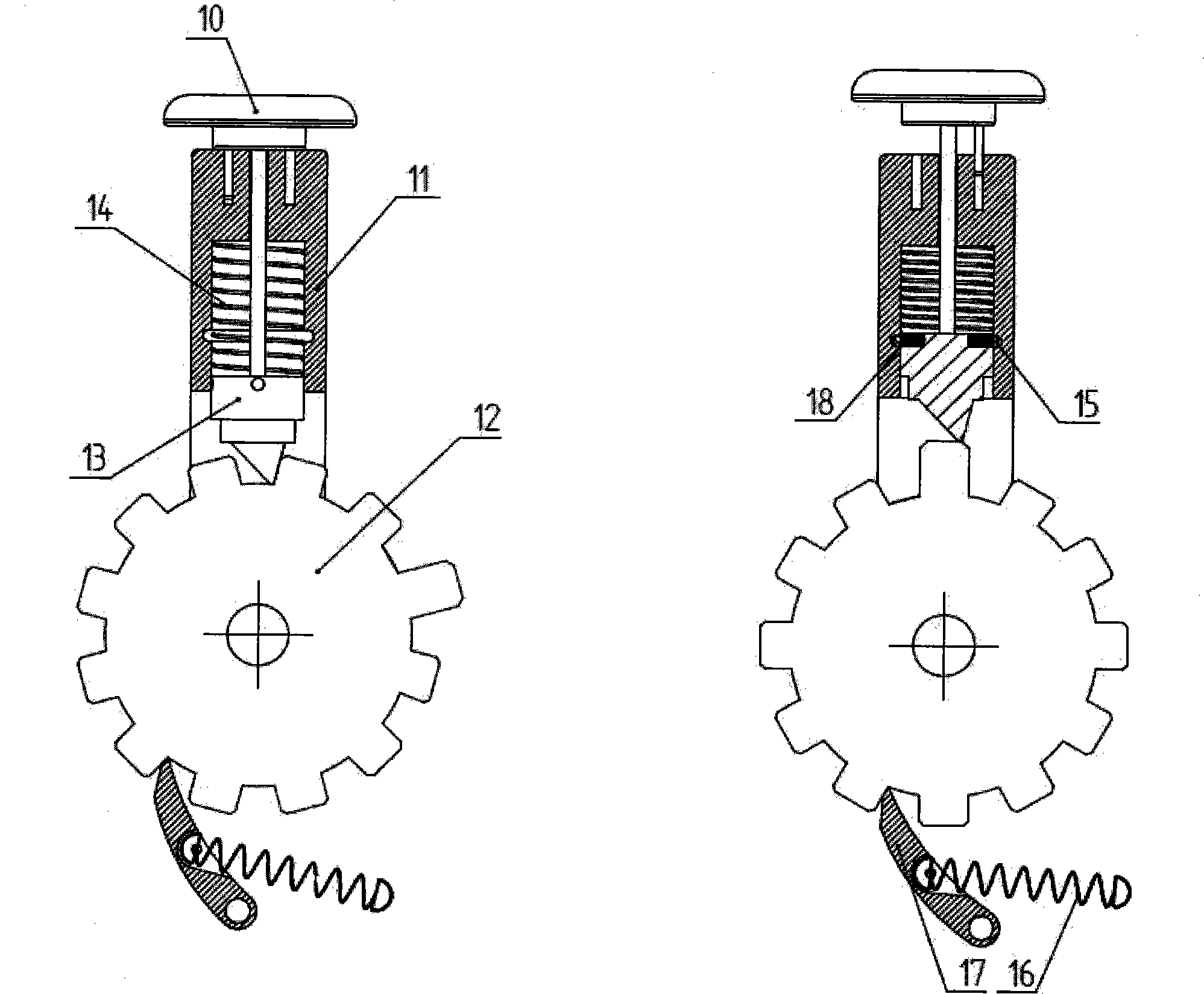

Adjusting and locking device for textile machine

The invention discloses an adjusting and locking device for a textile machine. The adjusting and locking device for the textile machine comprises a base, a rotating wheel, a first rotating plate, a belt, a groove, an indented rod, a plurality of stopping rods and a plurality of second rotating plates, wherein the rotating wheel, the first rotating plate, the belt, the groove, the indented rod, the stopping rods and the second rotating plates are arranged on the base; outer tooth grains are arranged on the side surface of a first end of the indented rod along the length direction; the first end of the indented rod is tapped in the groove; inner tooth grains which are matched with the outer tooth grains are arranged on the inner surface of the groove; the indented rod rotates so as to move along the length direction of the groove; the first rotating plate sleeves the indented rod in a rotating manner; two ends of the belt respectively sleeve the rotating wheel and the first rotating plate so that the rotating wheel and the first rotating plate rotate synchronously; upper tooth grains are arranged on the side surface of each stopping rod; lower tooth grains which are matched with the upper tooth grains are arranged on an end surface of each rotating plate so that the second rotating plates can rotate to drive the stopping rods to move along the length direction; and one ends of the stopping rods face the side surface of the indented rod. By the adjusting and locking device, the textile machine can be adjusted and locked.

Owner:江苏森清环保科技有限公司

A Herringbone Forest Roulette with Self-pretensioning and Buffering

ActiveCN104175805BImprove mobility off-road performanceSimple configurationPivoted suspension armsWheel-axle combinationsMotor driveHigh amplitude

The invention relates to a self pretightening buffering herringbone forest wheel disc and belongs to the technical field of forest vehicle chassis. The forest wheel disc comprises wheels and a base disc. Each wheel comprises a herringbone wheel bone and a self pretightening buffering device. The herringbone wheel bones are installed on two sides of the middle of the base disc, two arms at the bottom are wheel arms, the wheels are installed on the end portions of the wheel arms, a top single arm is a traction arm, and the self pretightening buffering devices are installed on the traction arm. A wheel bone outer casing and a wheel bone inner casing are installed in a matching mode to form an enclosed casing. Direct gears are installed on the end portions of the inner sides of the wheel arms of the two casings, direct gears are coaxially installed in the middle of the inner sides of the two casings, and the gears are in meshing transmission through a tooth-shaped meshing belt. The self pretightening buffering device achieves a self pretightening buffering function, achieves wheel arm high-amplitude swinging and restrains the borne materials in the vehicle cross-country running process. The wheel disc can improve the motor-driven country crossing performance of forest vehicles, simplify the vehicle whole structure and improve the vehicle carrying performance.

Owner:BEIJING FORESTRY UNIVERSITY

Self-disinfecting type finger toothbrush sleeve with massage function

The invention provides a self-disinfecting type finger toothbrush sleeve with a massage function, and belongs to the field of articles for daily life. The self-disinfecting type finger toothbrush sleeve is characterized by comprising a fixed section and a work section, wherein the fixed section is a round barrel, a connecting primary ring is arranged on the fixed section, a connecting sub ring isarranged on the work section, a clamping groove is arranged in the inner wall of the connecting primary ring, a clamping boss is arranged on the outer wall of the connecting sub ring, and the clampinggroove in the connecting primary ring corresponds to the clamping boss on the connecting sub ring; the fixed section and the work section are fixed to form a whole through the connecting primary ringand the connecting sub ring; a bristle plate is arranged on the work section, and hollow bristles are arranged on the bristle plate; and a vibration massager is arranged between the work section andthe fixed section, the vibration massager comprises a vibration motor and a vibration pushing block, and the vibration motor is connected with the vibration pushing block through three or more connecting springs. For the self-disinfecting type finger toothbrush sleeve with the massage function, a brush head of a toothbrush can be conveniently and rapidly replaced, the integral replacement is not needed, and the targeted disinfecting and vibration massage are carried out on the oral cavity while teeth are brushed.

Owner:毕研群

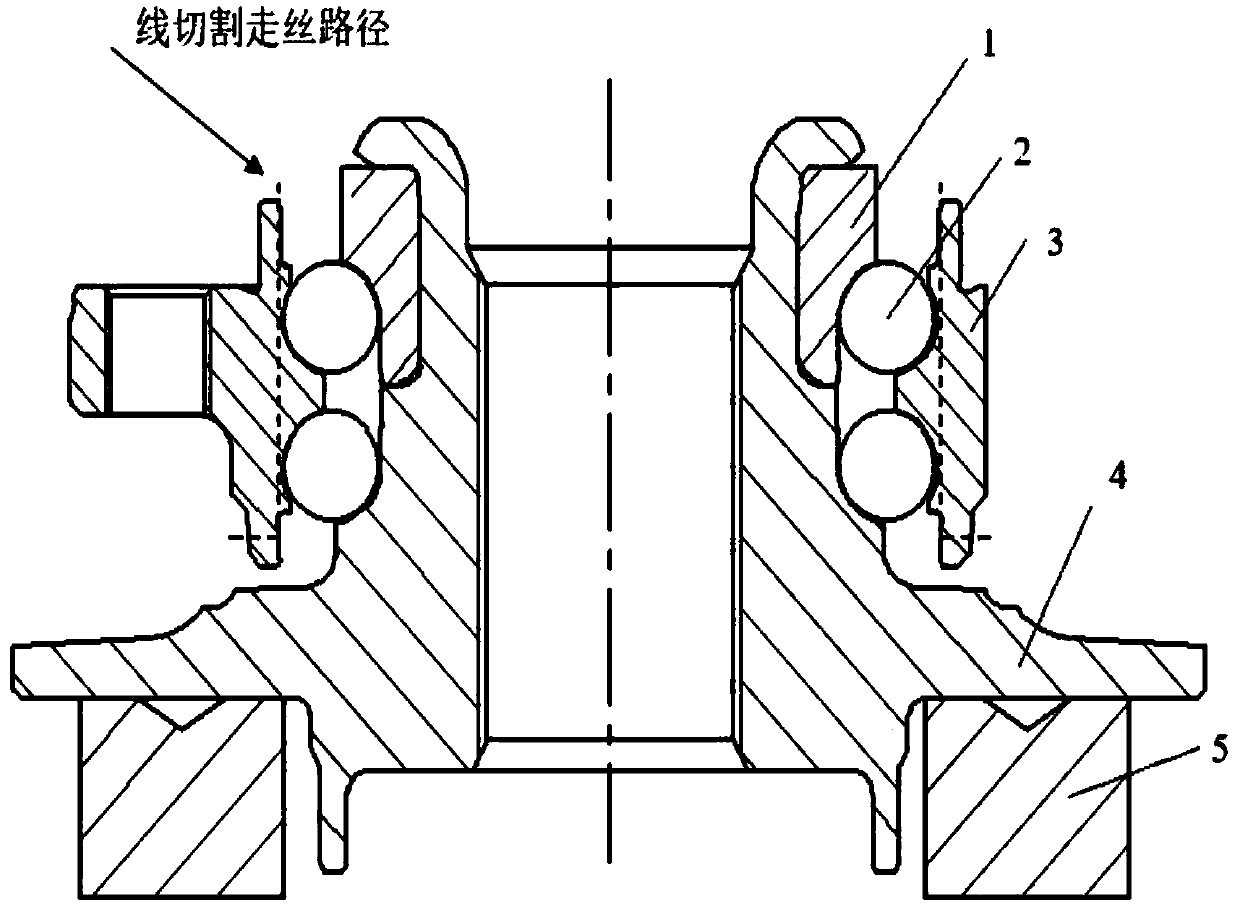

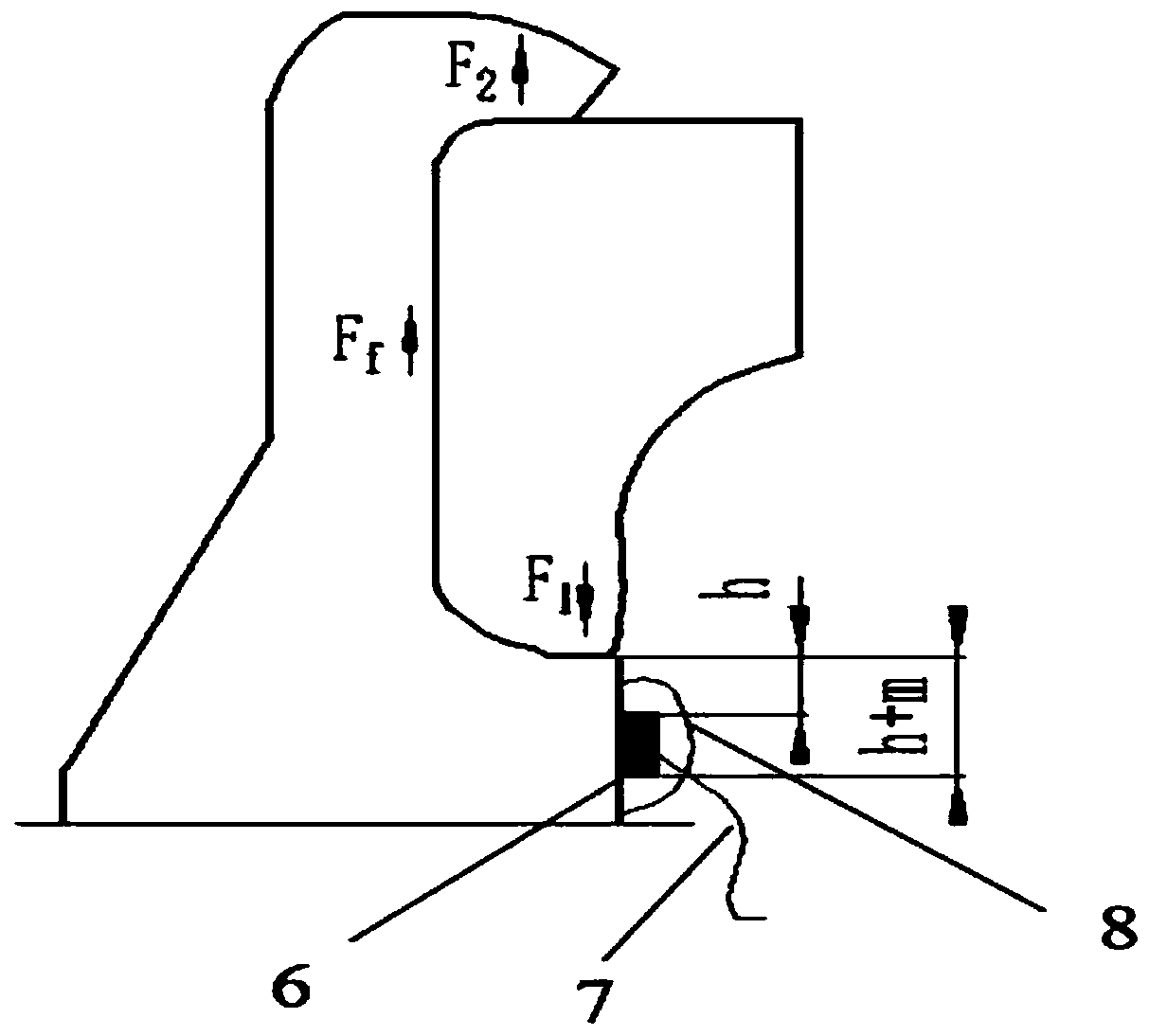

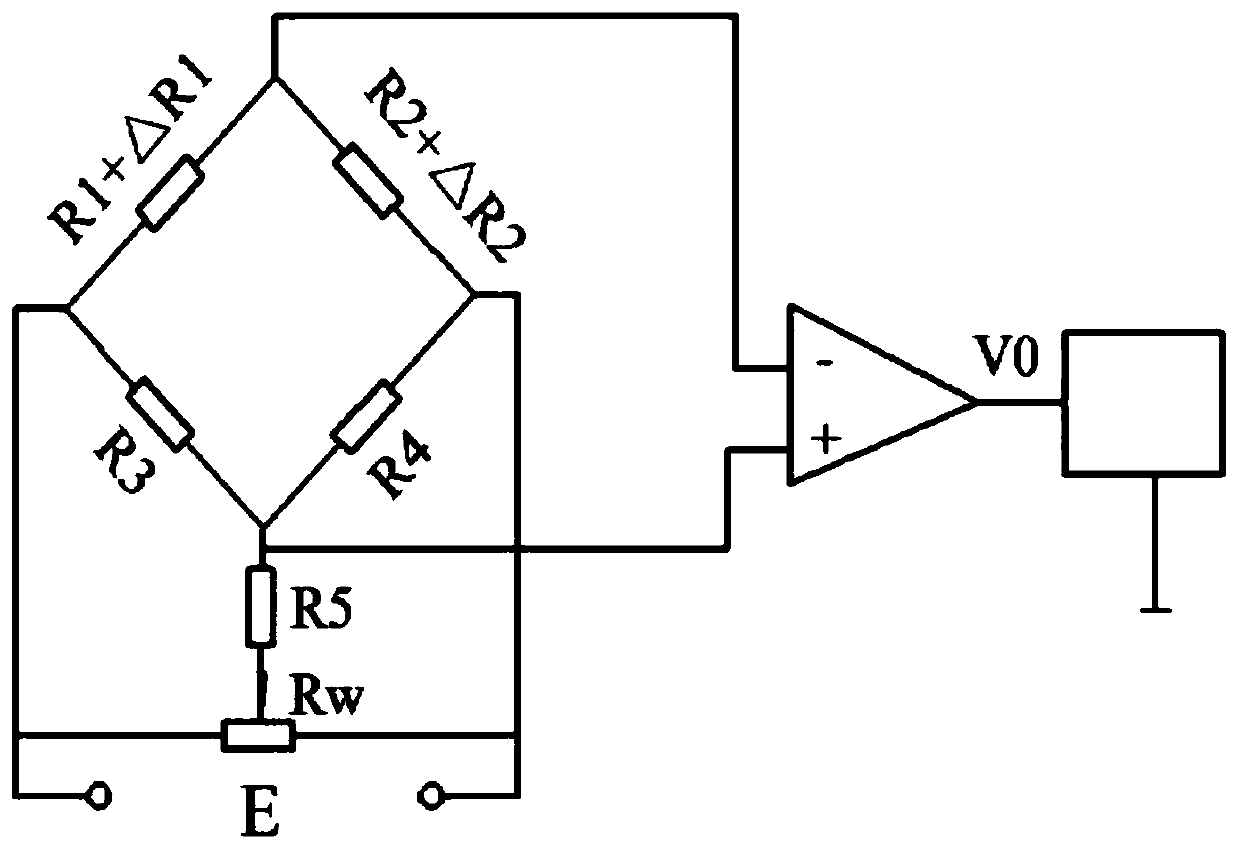

A wheel hub bearing swing grinding riveting pre-tightening force detection method

ActiveCN111595500AOvercome loosenessOvercome the resultForce measurementApparatus for force/torque/work measurementStrain gaugeStrain measurement

The invention relates to the technical field of wheel hub bearing pre-tightening force measurement methods, and discloses a wheel hub bearing swing grinding riveting pre-tightening force detection method, which comprises the following steps: 1, disassembling a riveted wheel hub bearing, cutting an outer flange of the riveted wheel hub bearing, removing a steel ball and the outer flange, and reserving an inner ring and an inner flange; and 2, symmetrically adhering two strain gauges below the shaft shoulder of the inner flange in the step 1, forming a strain gauge group by the two strain gauges, and forming a measuring circuit by the strain gauge group and a strain measuring instrument. According to the wheel hub bearing swing grinding riveting pre-tightening force detection method, a strain gauge does not need to be connected in the riveting process, and the problems that the strain gauge is likely to be loosened due to overlarge strain in the riveting process, and the measurement result is abnormal are solved; besides, the calibration is corrected by considering the influence of the friction force on the result, the strain caused by the lower axial force and the upper axial forceat the strain gauges separately is obtained through simulation, and a strain correction coefficient is introduced, so that the detection precision is improved.

Owner:HUBEI NEW TORCH SCIENCE & TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com