Bevel gear

A technology of bevel gears and axles, applied to bevel gears. field, to achieve the effect of firm installation, stable transmission process, and improved mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

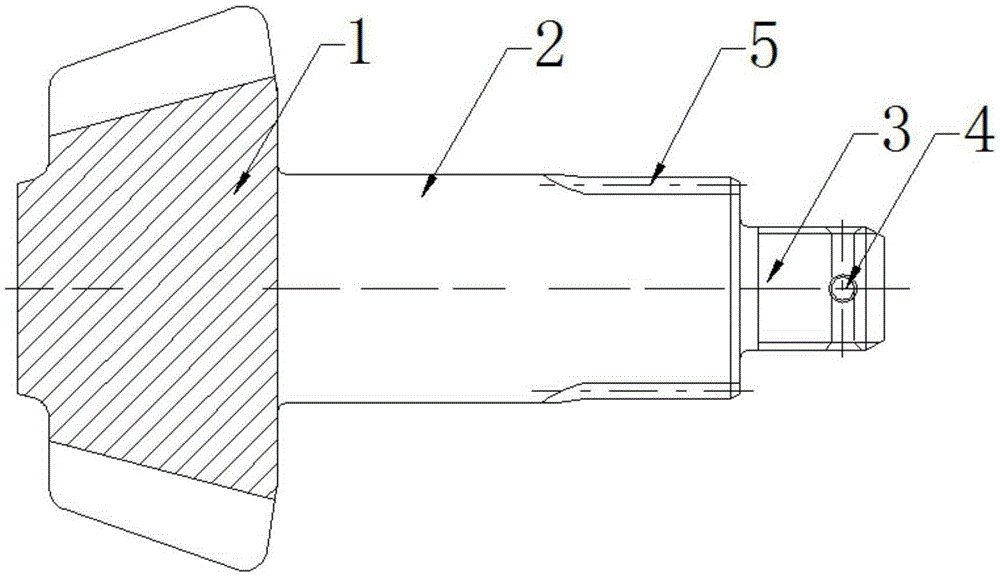

[0016] From figure 1 It can be seen that a bevel gear includes a gear tooth part 1, a wheel shaft part 2 and a screw part 3, and the gear tooth part 1, the wheel shaft part 2 and the screw part 3 are sequentially connected and designed as a whole, and on the outer wall of the screw part 3 There are at least 6 locking pin holes 4 uniformly arranged along the circumferential direction, and the locking pin holes 4 are all perpendicular to the axis line of the screw part 3, and the two are connected;

[0017] From figure 1 It can also be seen that the locking pin hole 4 is close to the end of the screw part 3; a spline 5 is provided on the axle part 2.

[0018] Preferably, the hole diameter of the locking pin hole 4 is 5 mm to 7 mm, and in this embodiment, the hole diameter is 6 mm.

[0019] The worki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com