Patents

Literature

191results about How to "Guaranteed installation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

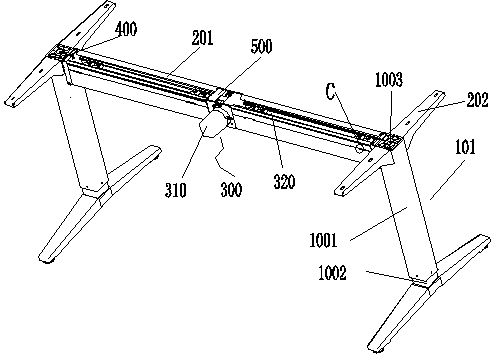

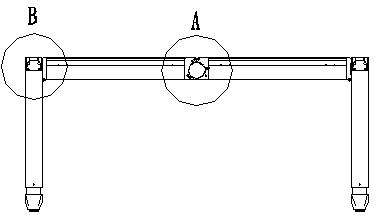

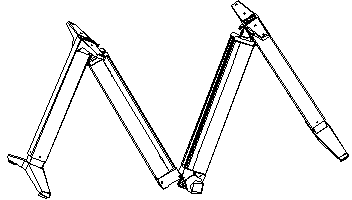

Foldable support for lifting table or chair

ActiveCN103315519AHigh sensitivityProtection securityDismountable chairsFoldable chairsEngineeringMechanical engineering

The invention discloses a foldable support for a lifting table or chair. The foldable support comprises a lifting mechanism, a pair of transverse beams arranged symmetrically and a driving mechanism for driving the lifting mechanism to lift. The lifting mechanism comprises a pair of lifting columns arranged correspondingly. The lifting columns are hinged with the ends of the transverse beams through a first connecting device, and are folded around the first connecting device. The transverse beams are hinged through a second connecting device, and are folded around the second connecting device. The invention further discloses a lifting table or chair with the foldable support. The lifting table or chair comprises a panel and a support arranged under the panel. The columns and the transverse beams can be folded, so that occupied space is reduced during transportation, package size is small, and storage and transportation are easy; when a user assembles the lifting table, only need to follow the instructions, and assembling effect can be guaranteed.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

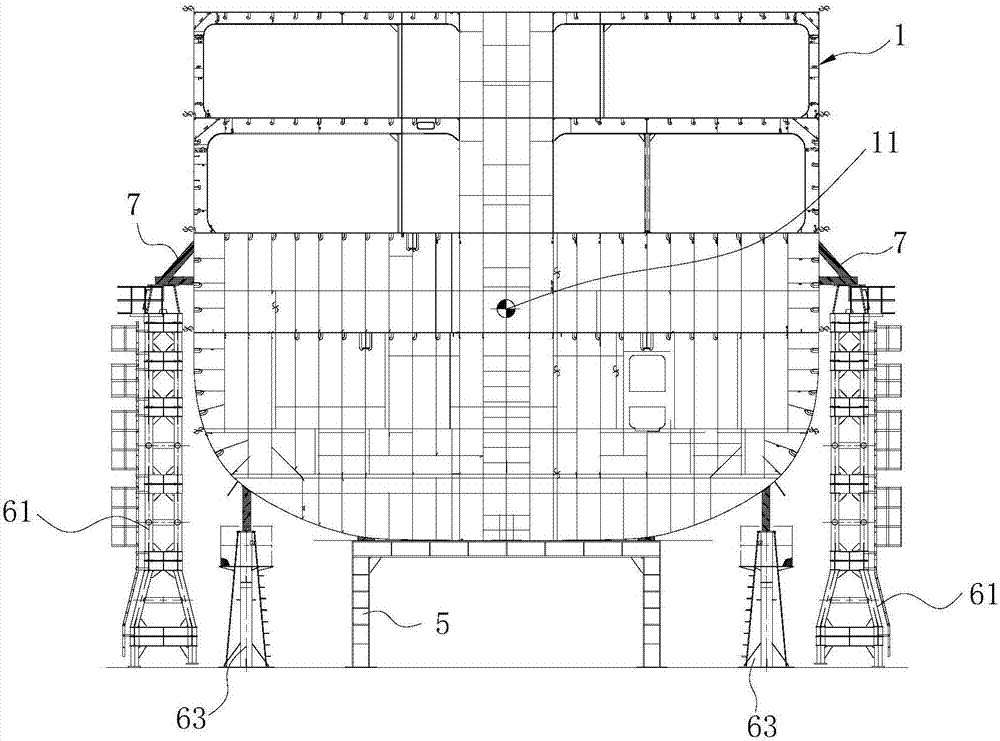

Flipper block construction method

ActiveCN107323609AShorten the construction periodReduce installation difficultyVessel designingEngineeringSupport plane

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

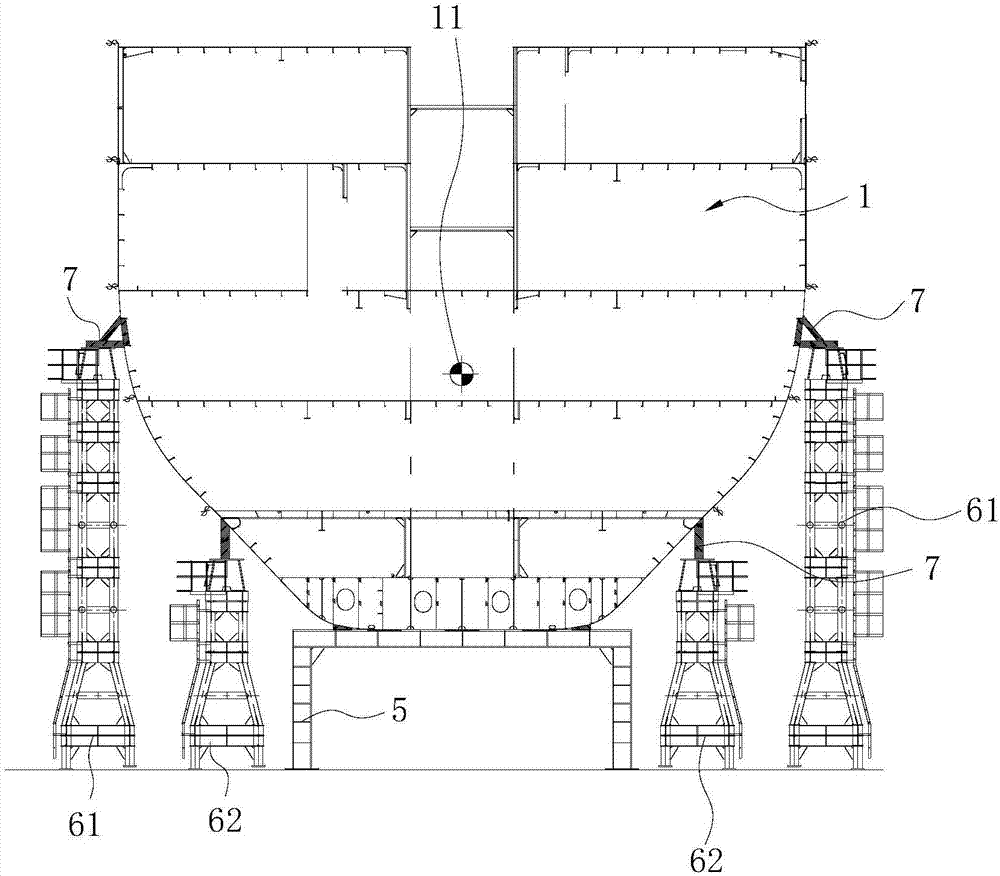

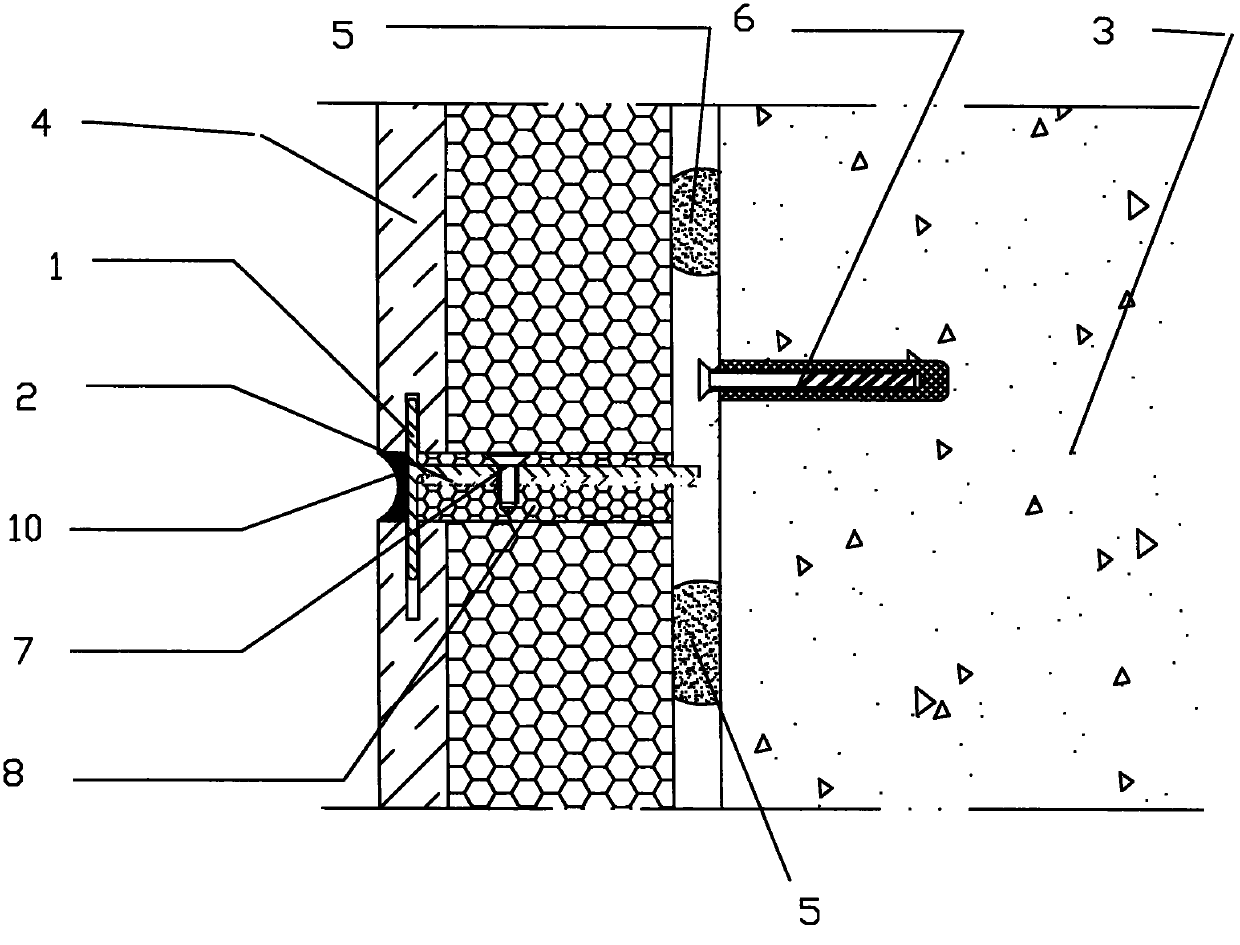

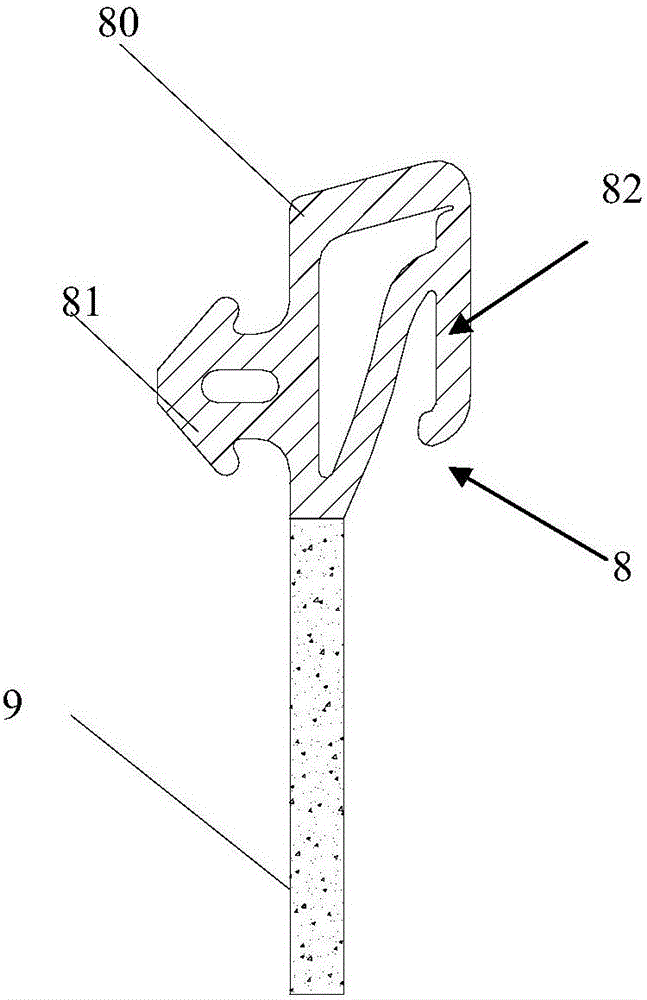

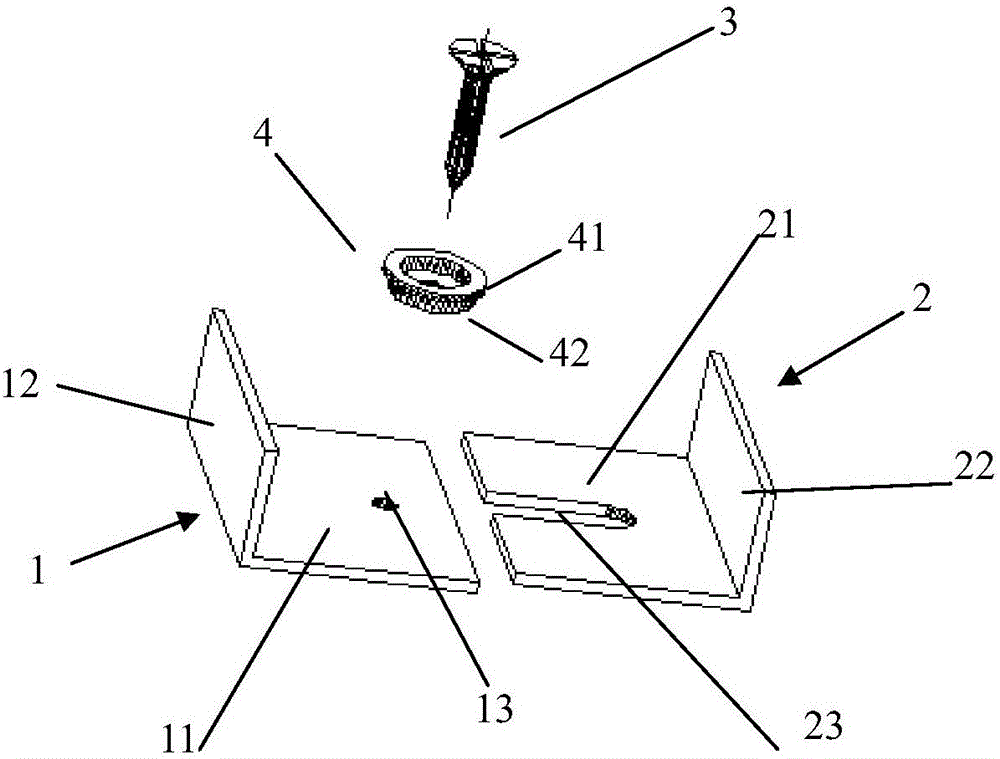

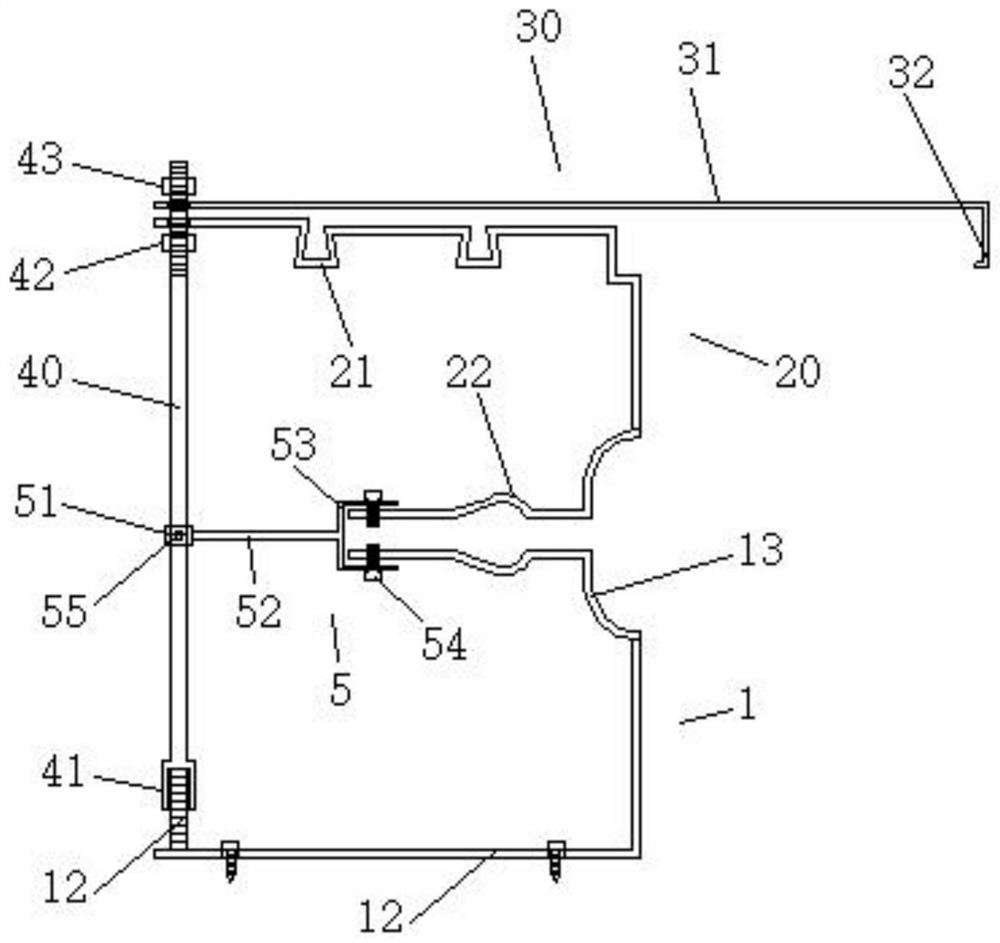

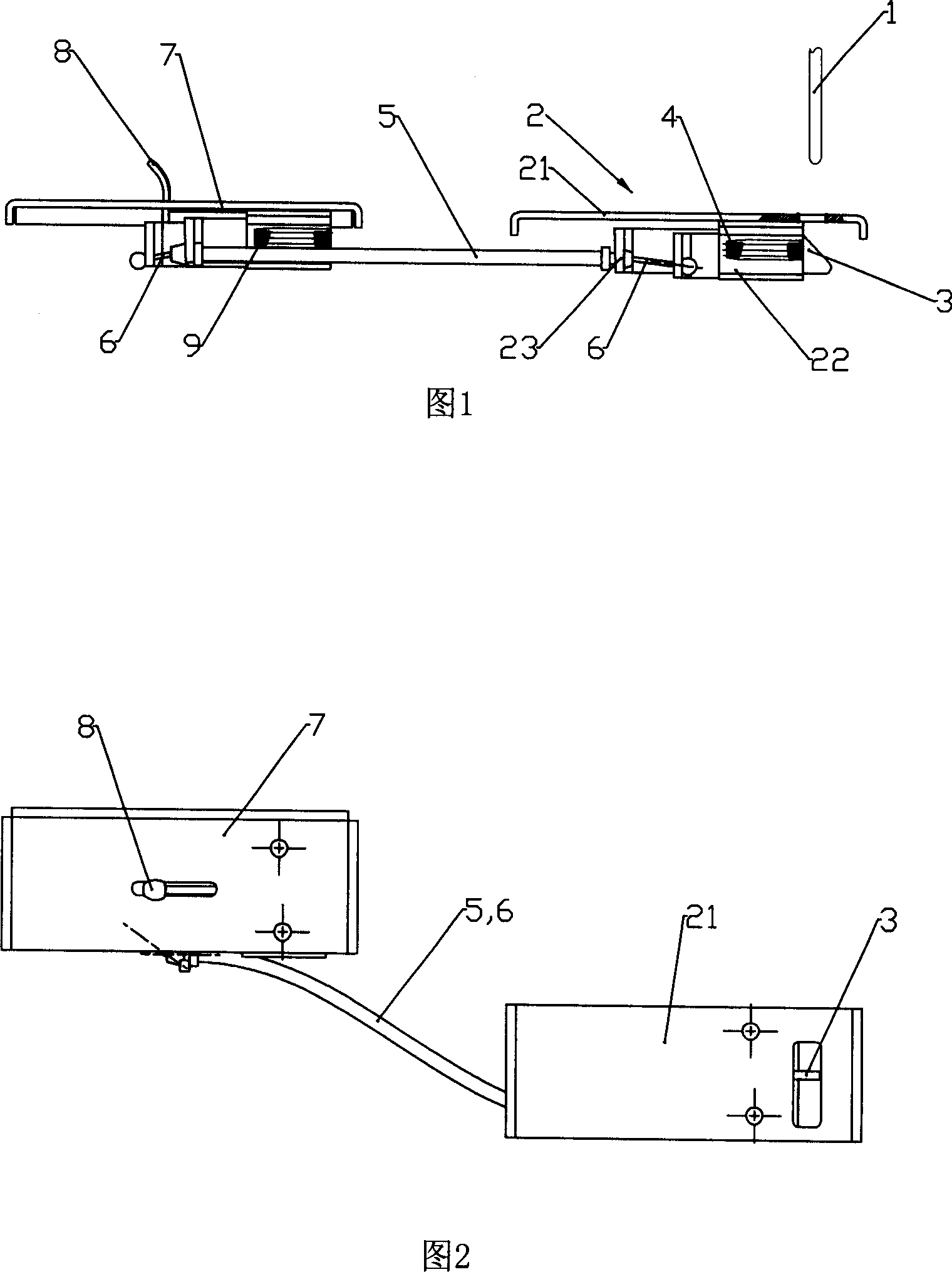

Wall panel connection device and wall surface construction method using same

InactiveCN102363999AEnsure the amount of fasteningSafe and reliableCovering/liningsSurface constructionFastener

The invention discloses a wall panel connection device in wall panel surface construction and a wall surface construction method using the wall panel connection device and belongs to the field of building engineering. The wall panel connection device comprises a member 1 and a member 2, wherein the cross section of the member 1 is reverse-T-shaped, a left plane can be connected with a wall panel, and a plurality of through holes are formed in a right plane; the cross section of the member 2 is reverse-L-shaped, the plurality of through holes are formed in the right plane, the right plane can be connected with a building foundation wall, and the plurality of through holes are formed in the left plane; and the right plane of the member 1 and the left plane of the member 2 are overlapped with each other and matched with the wall panel in thickness. The wall surface construction method comprises the following steps of: respectively fixing the member 2 and the member 1 on the building foundation wall and the wall panel; and tightly connecting the member 2 and the member 1. By adoption of the invention, during installation, the fastening amount of the members (fasteners) and panels can be guaranteed; with the three-dimensional adjustability of the member 1 and the member 2, an installation position can be determined; safety and reliability are guaranteed; and quickness and convenience for installation and high efficiency are realized.

Owner:GUANGDONG SOBEN GREEN NEW MATERIAL CO LTD

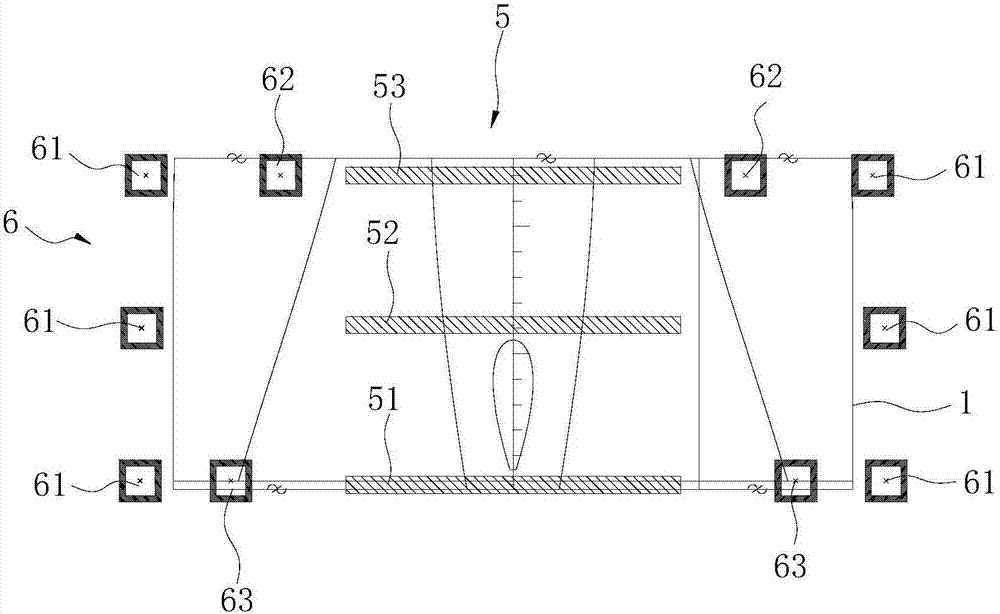

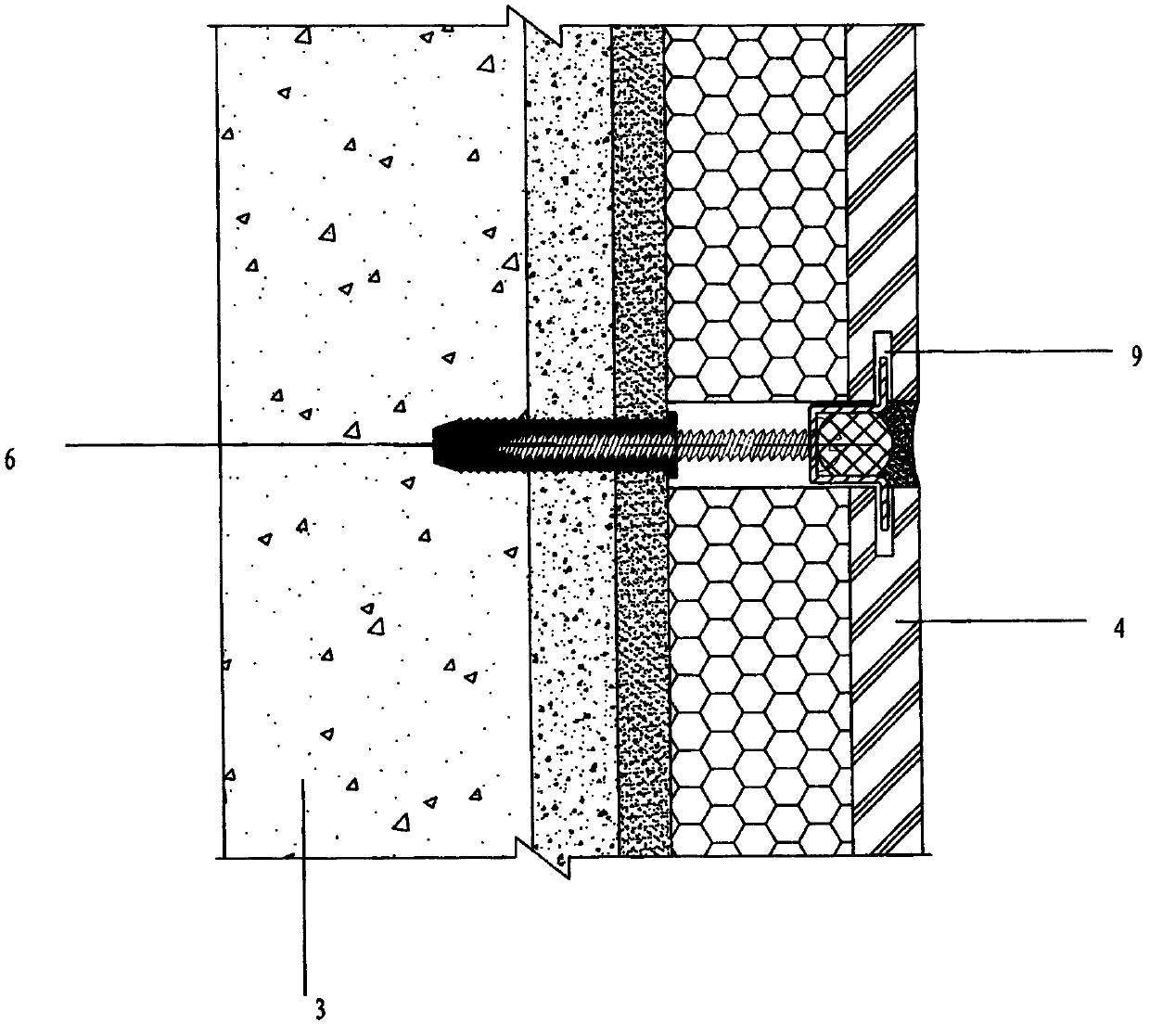

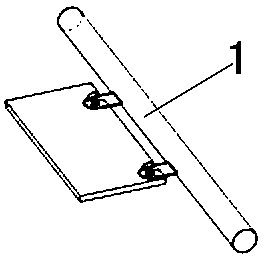

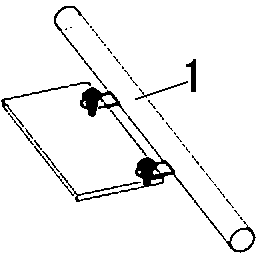

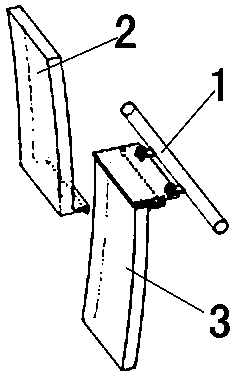

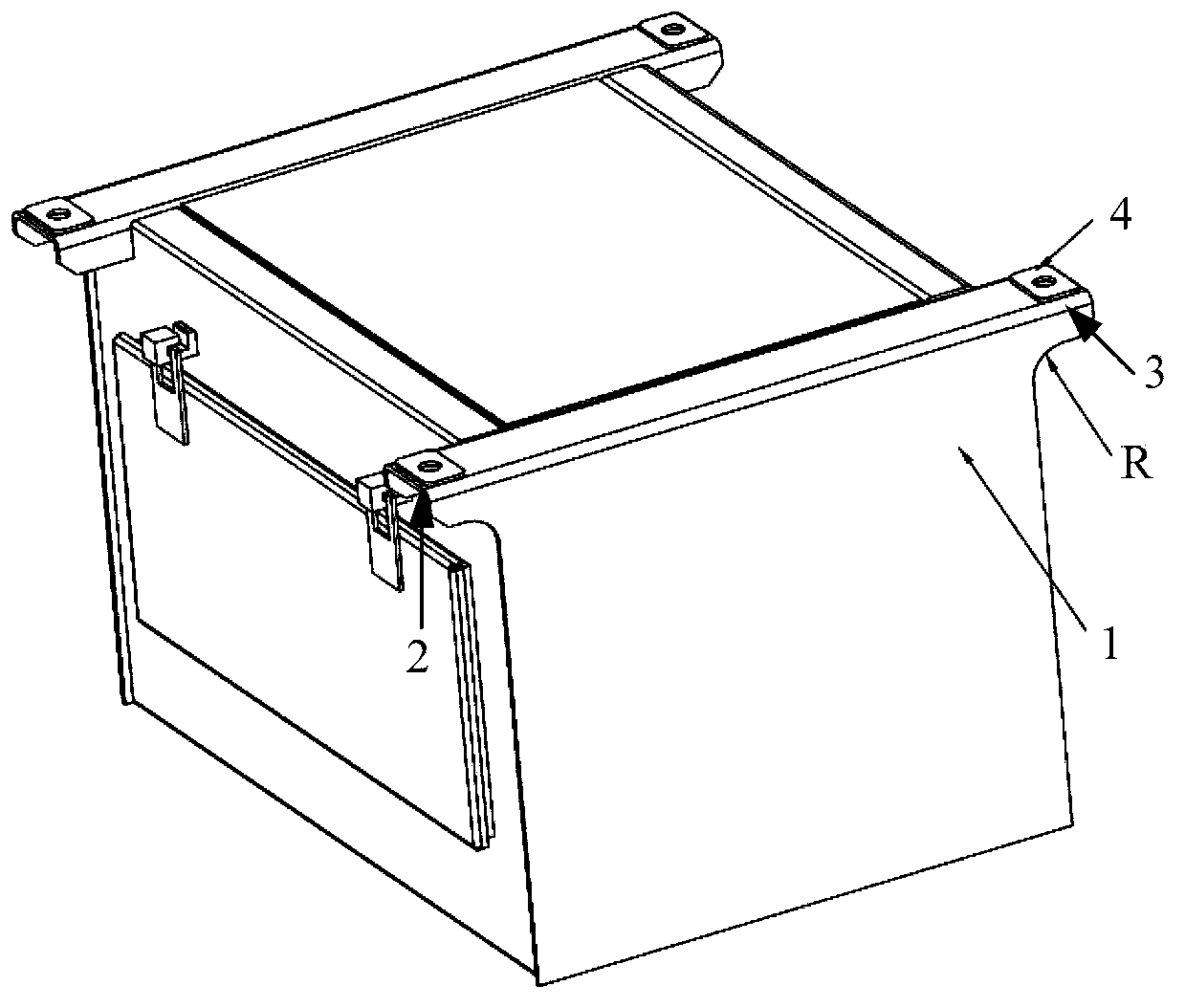

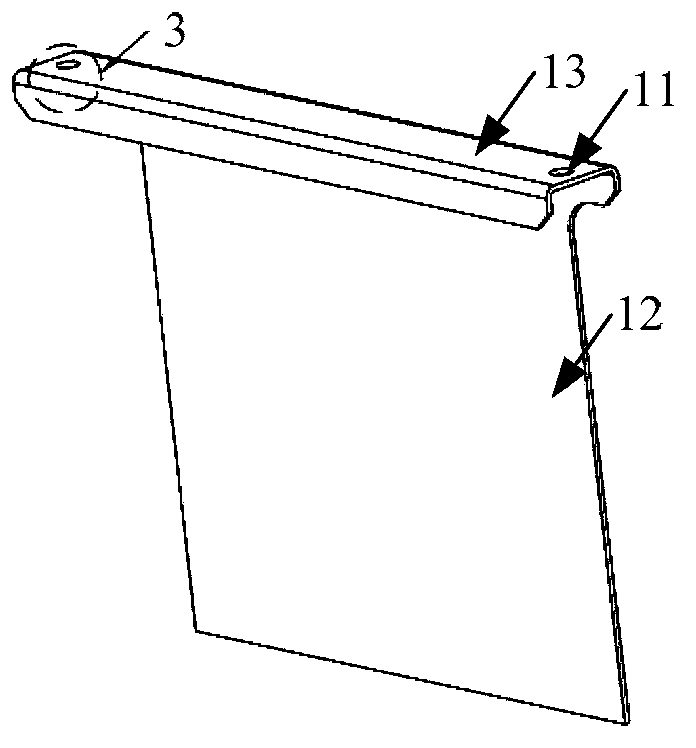

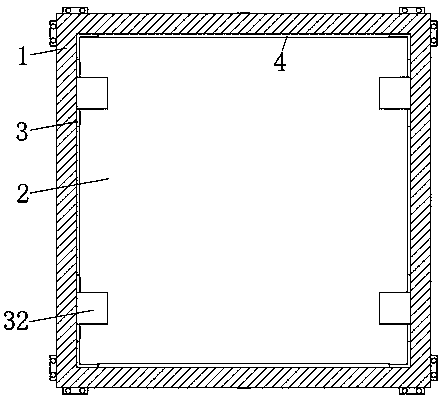

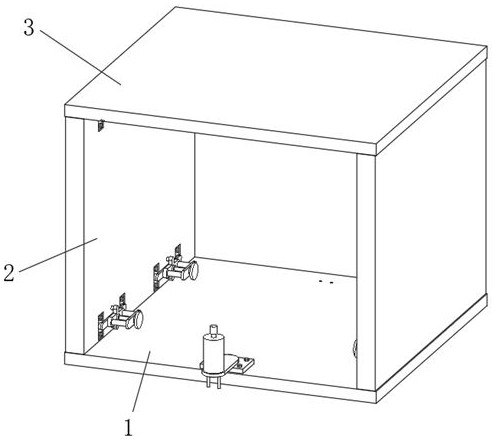

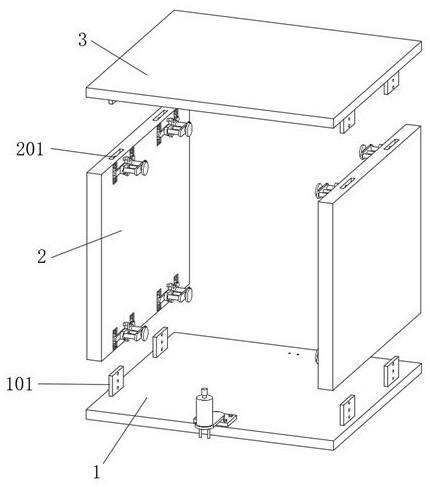

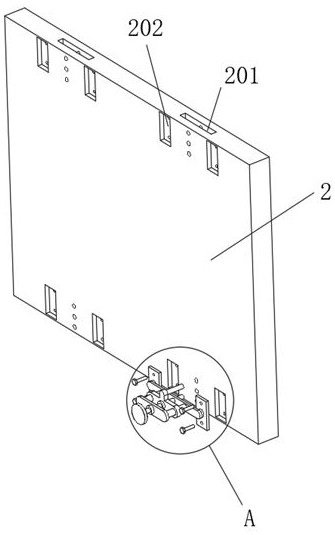

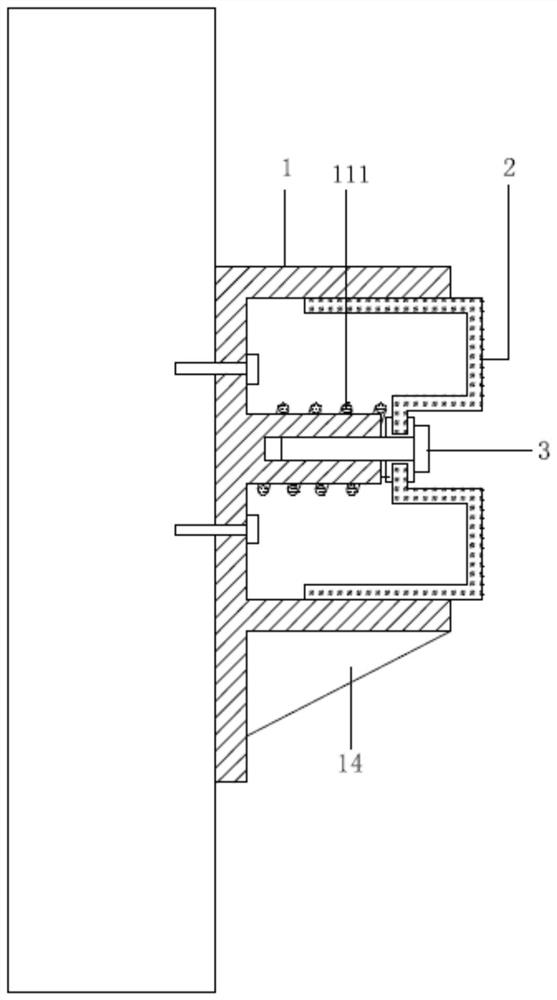

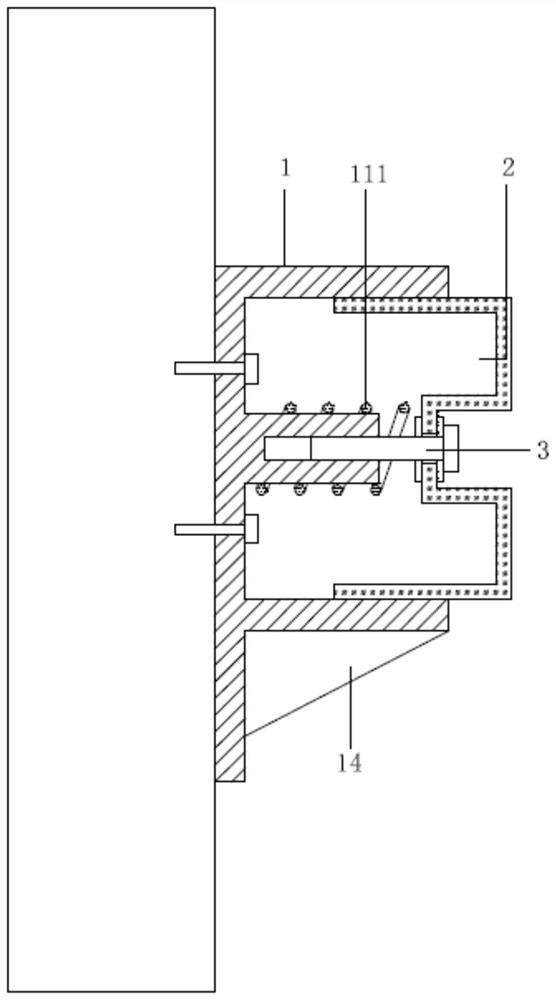

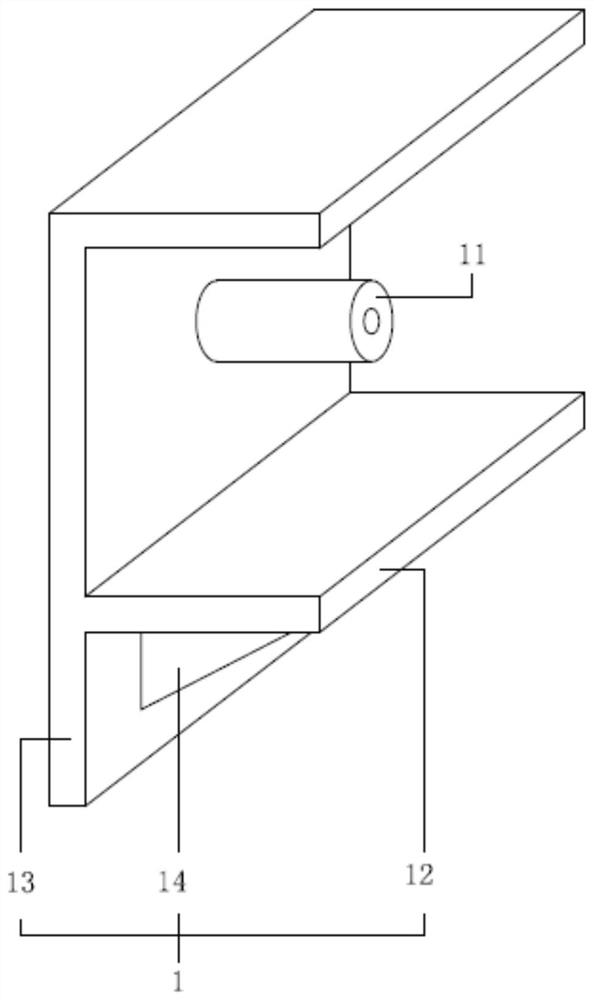

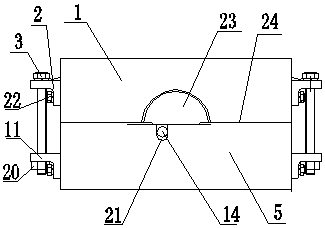

Special-shaped GRG block partition limiting installation structure and splicing method thereof

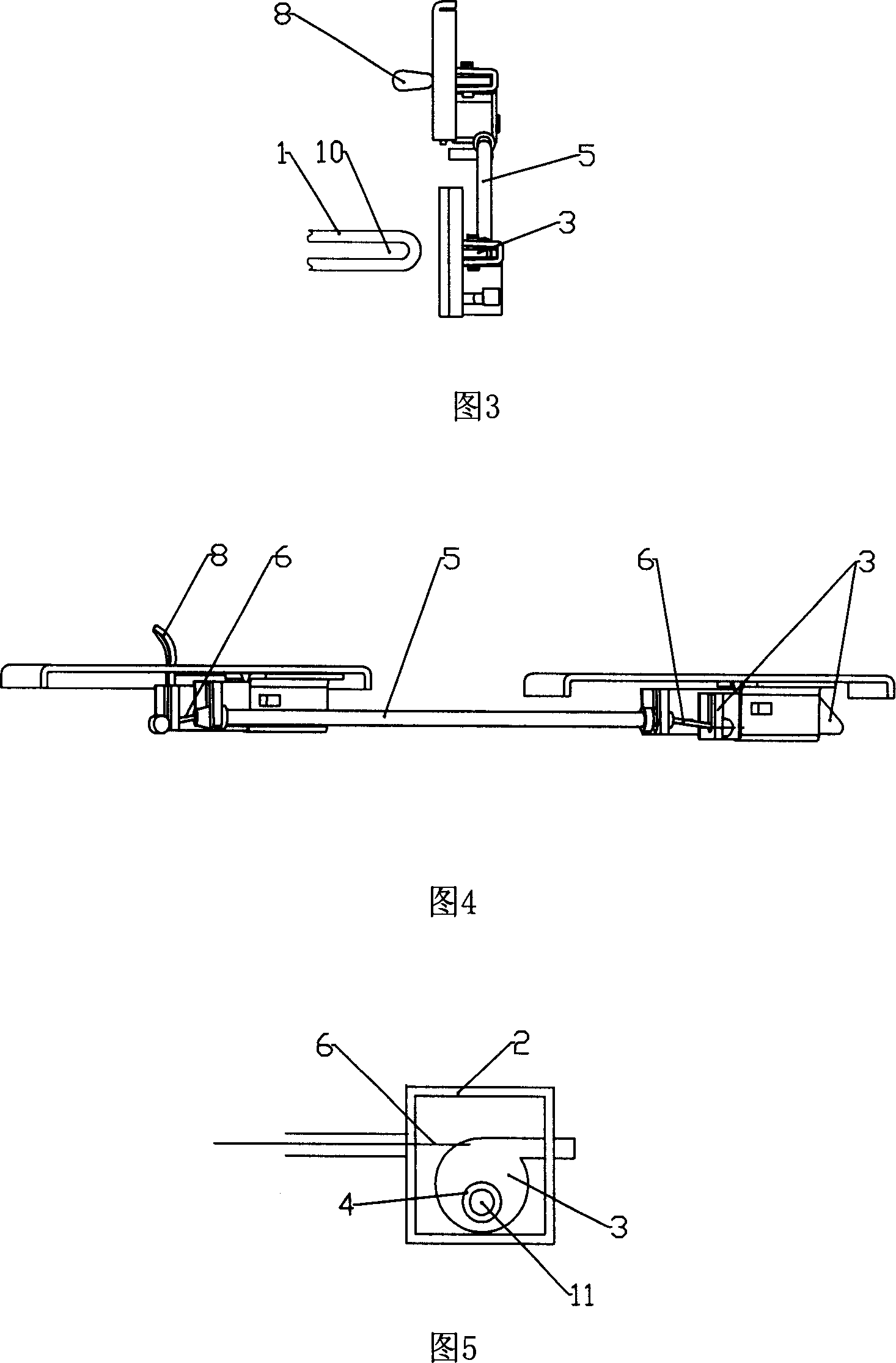

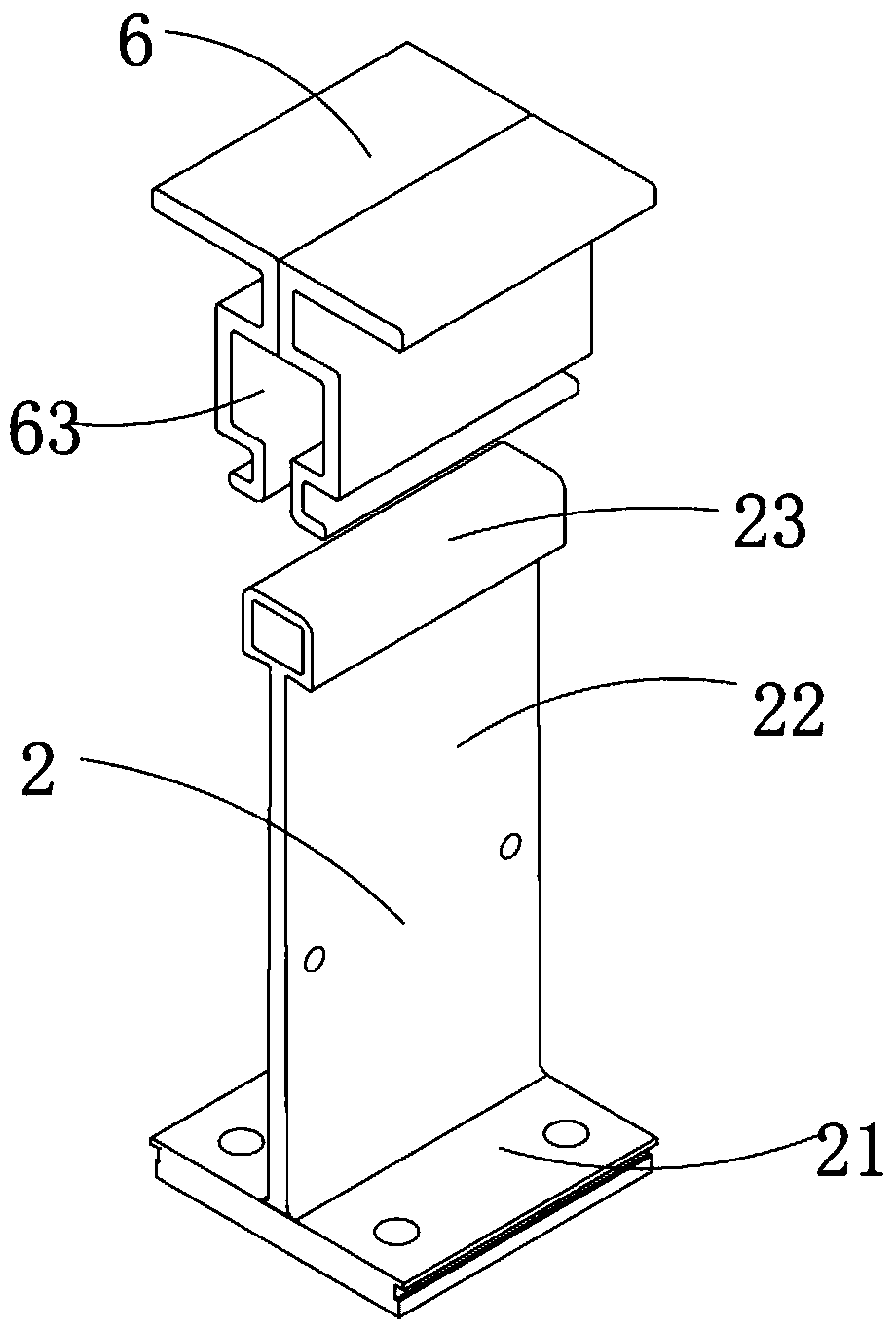

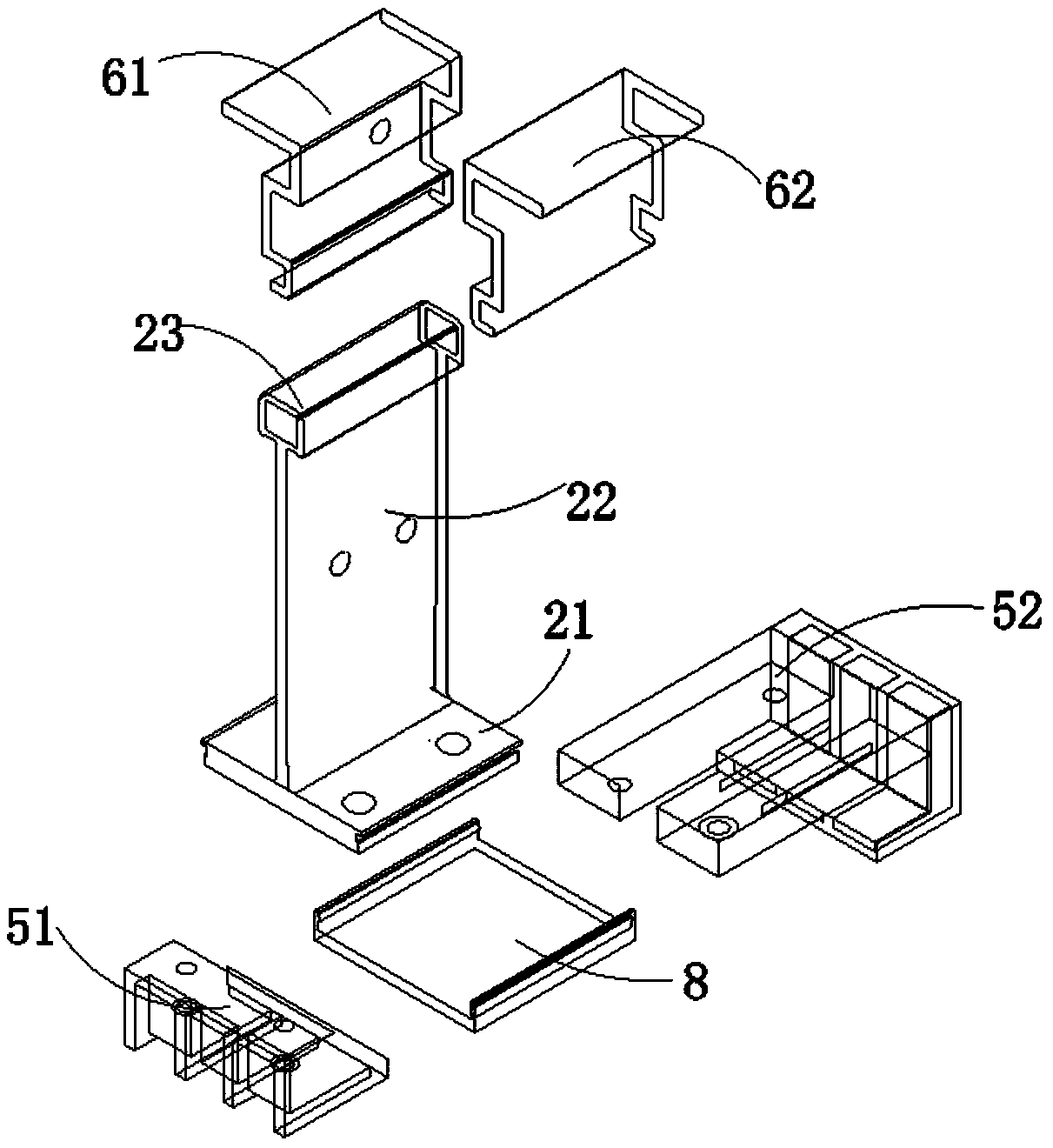

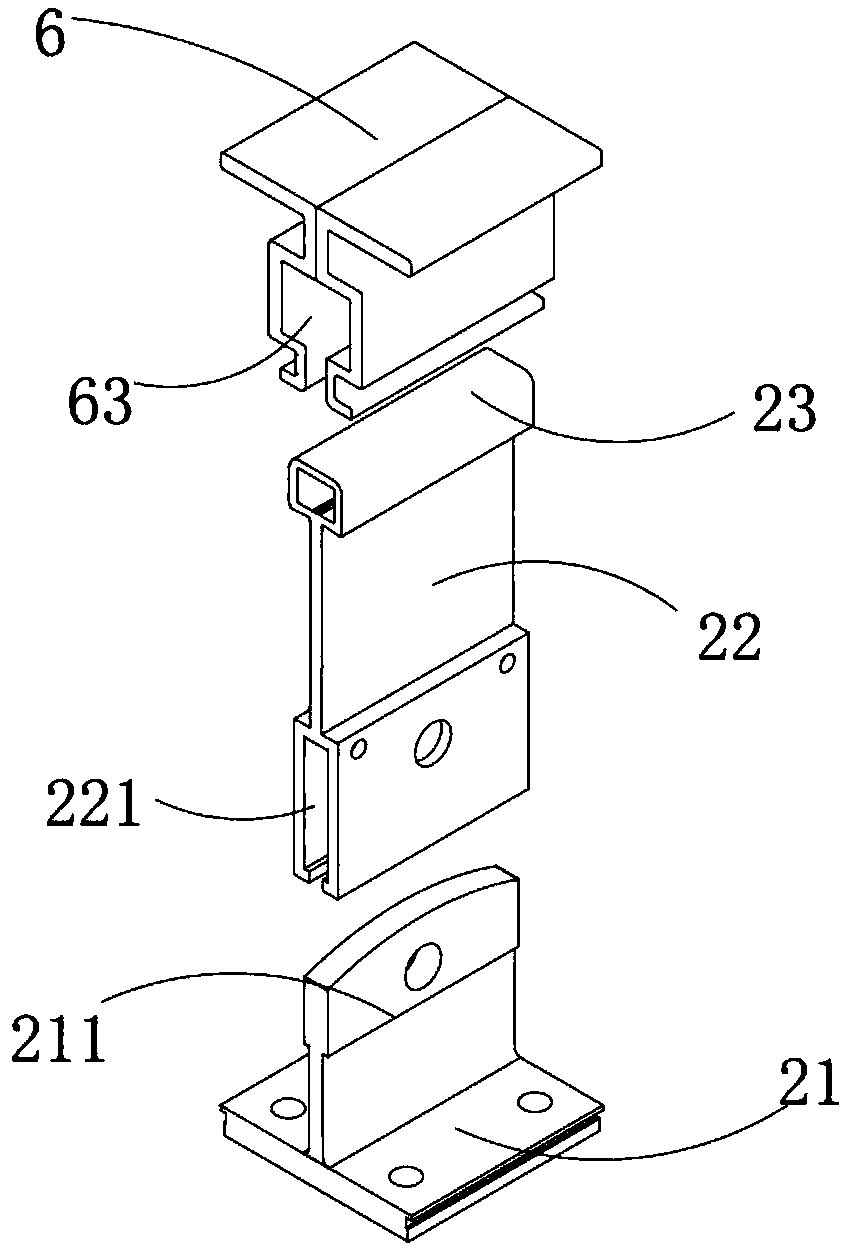

ActiveCN103967247AGuaranteed installation effectSolve the problem that the installation quality is difficult to controlCovering/liningsSteel frameInstallation Error

The invention discloses a special-shaped GRG block partition limiting installation structure. The special-shaped GRG block partition limiting installation structure comprises a fixing steel frame (1), upper GRG plates (2) and lower GRG plates (3). The upper GRG plates (2) and the lower GRG plates (3) are mutually and correspondingly spliced to form structural units; the structural units are installed side by side, the back face of each structural unit is fixed to the fixing steel frame (1), and the fixing steel frame (1) is installed on an inner steel frame structure. The invention further discloses a splicing method of the special-shaped GRG block partition limiting installation structure. According to the special-shaped GRG block partition limiting installation structure and the splicing method of the special-shaped GRG block partition limiting installation structure, the problem that installation quality of large-area special-shaped GRG is difficult to control is solved, the quality problems such as installation errors and dislocation are solved, and the overall installation effect of the GRG is guaranteed.

Owner:GOLD MANTIS CONSTR DECORATION

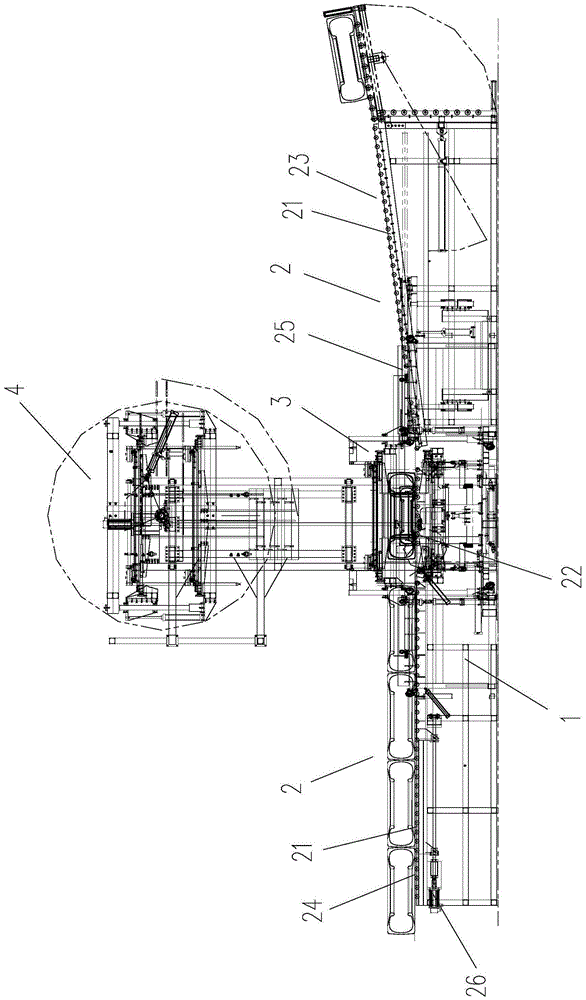

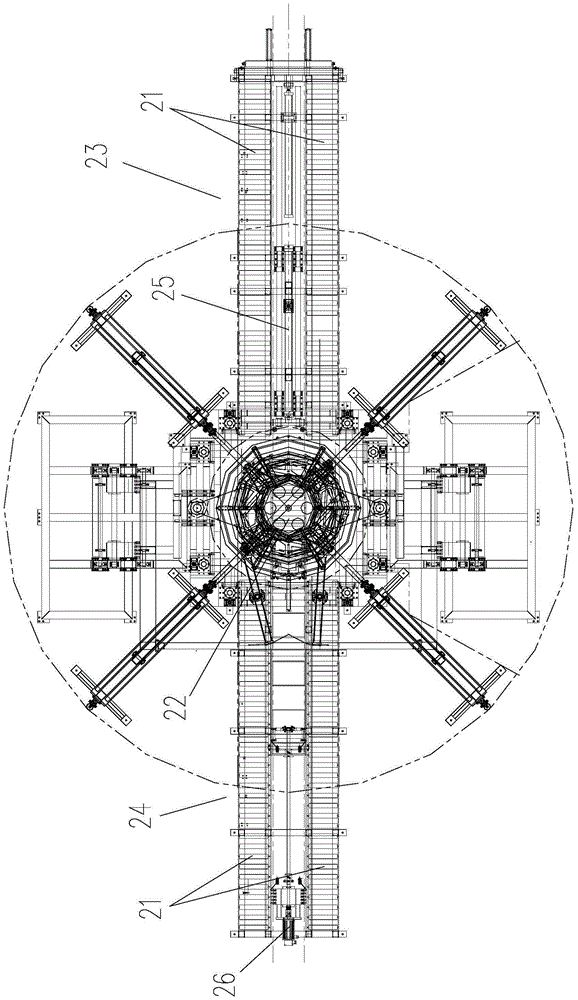

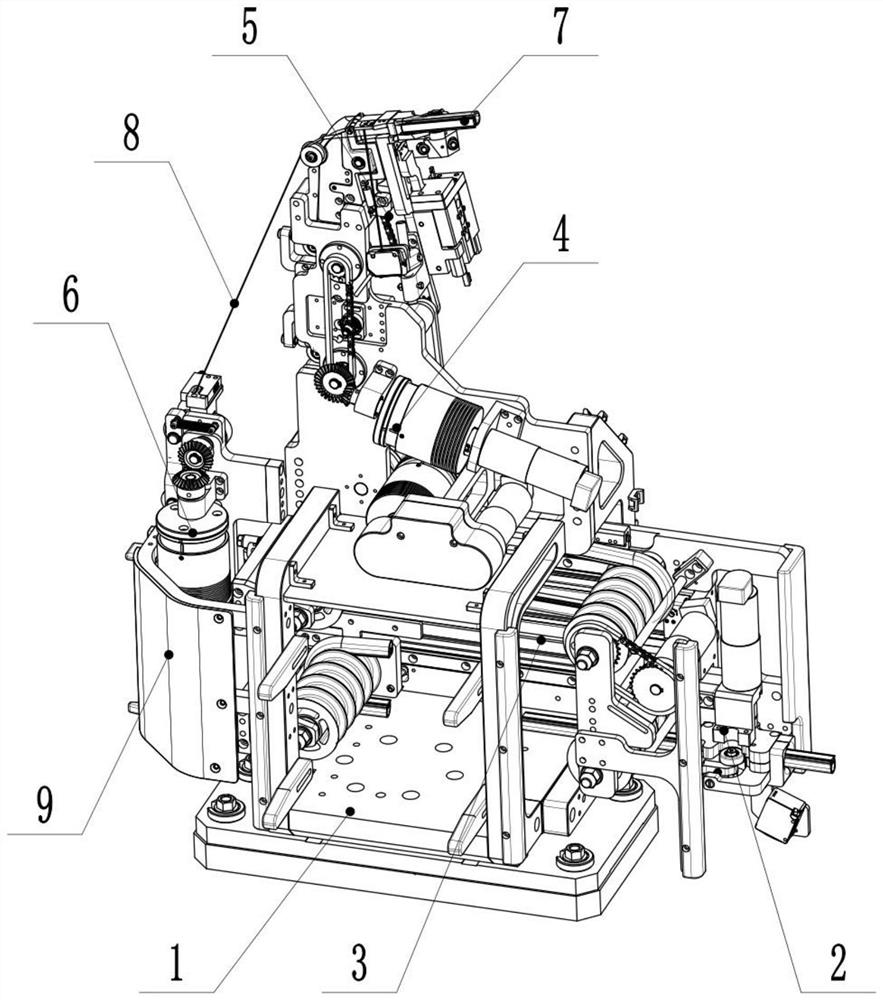

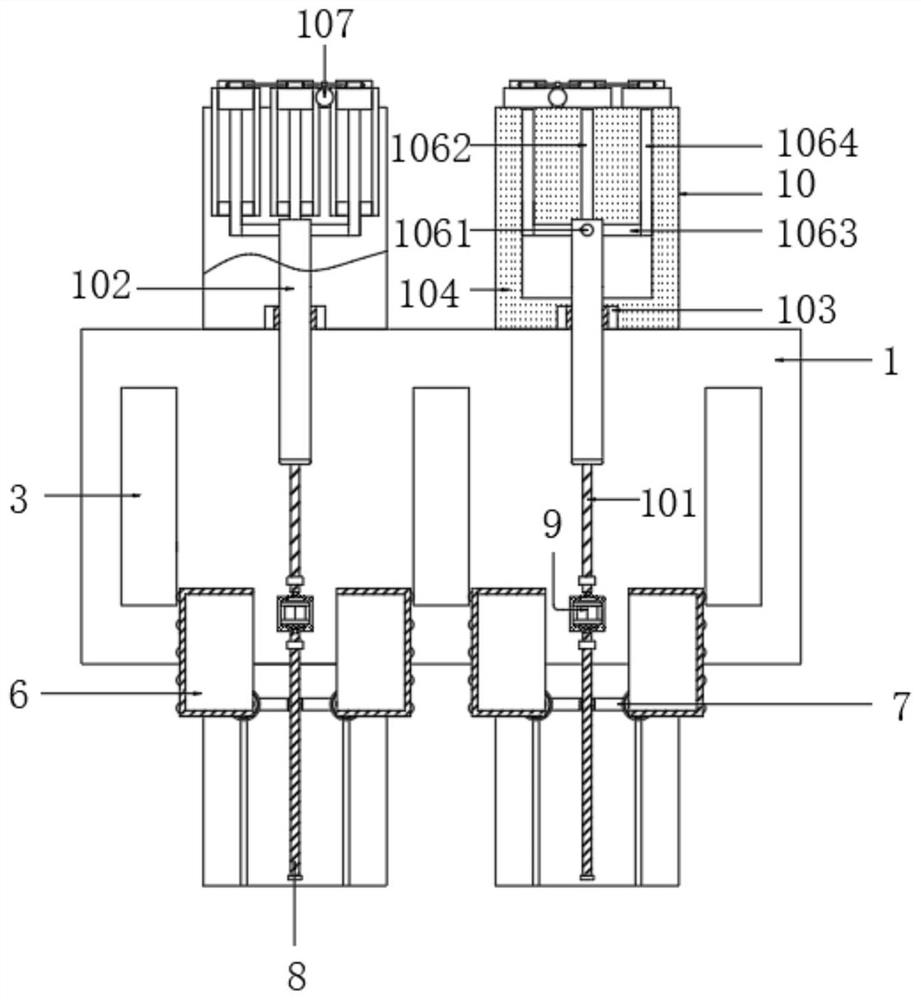

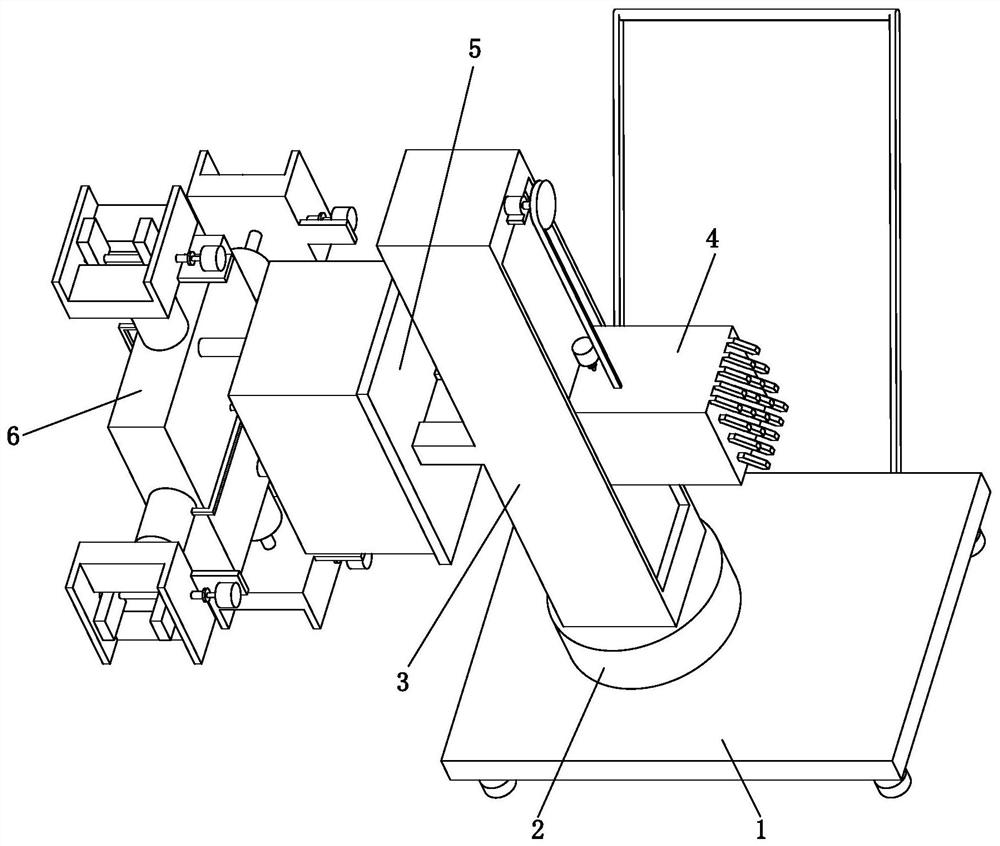

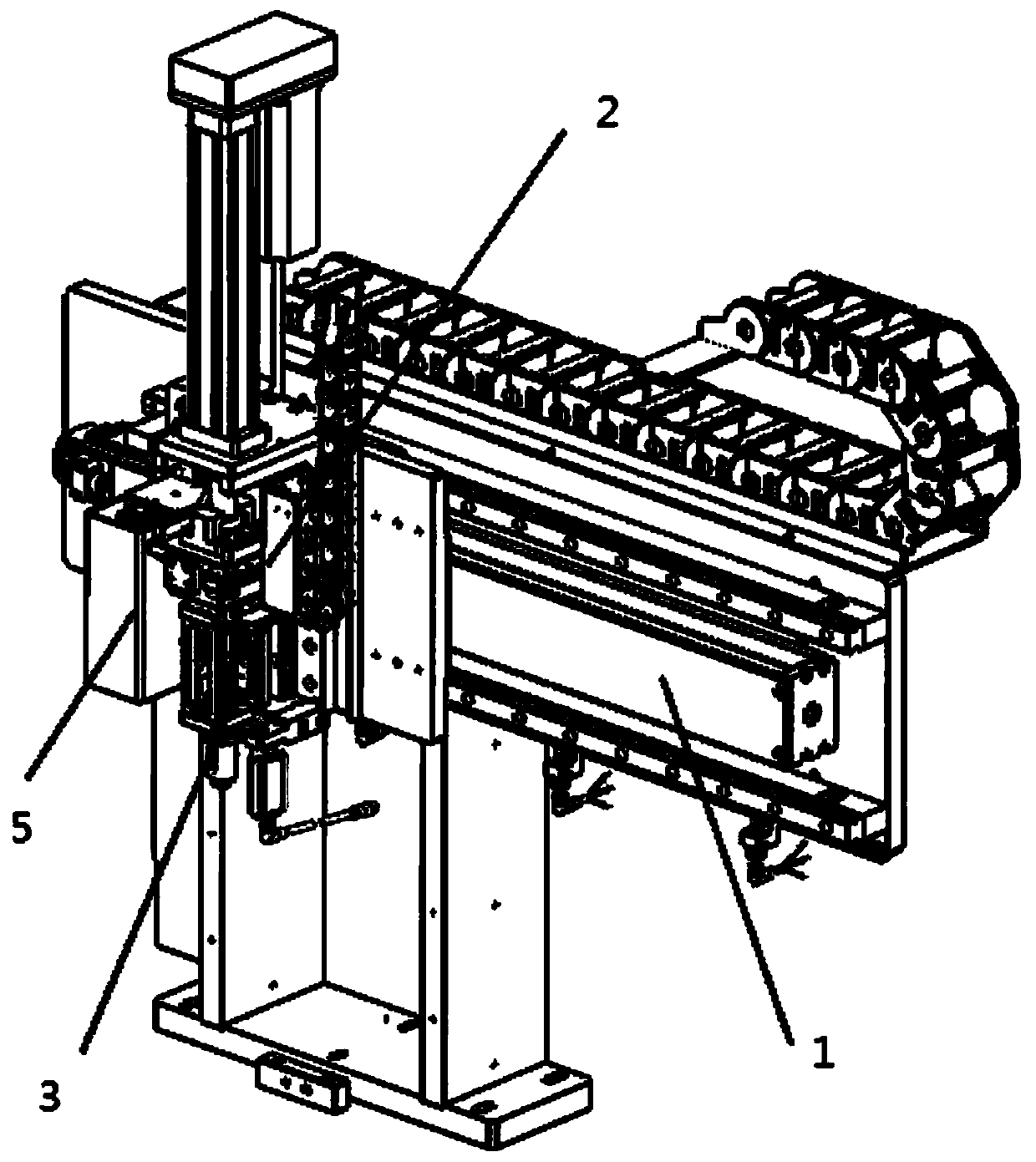

Tyre's inner tire mat belt installing machine

ActiveCN105196807ASimple structureReduce the probability of misfitsTyre repairingEngineeringFill device

A tyre's inner tire mat belt installing machine comprises a frame, on which a tyre conveying device, a tyre flaring device and tyre filling device. The tyre flaring device is positioned at the middle part of the tyre conveying device. The tyre filling device is positioned above the tyre flaring device. The tyre's inner tire mat belt installing machine has a relatively simple structure. Tyre flaring and filling of inner tire mat belts can be simultaneously carried out at only a station. Probability of matching errors between working procedures during the working process is reduced, occupation space of equipment is also saved. Accuracy requirement is low, and long-term stable and efficient operation can be realized.

Owner:青岛胜迈自动化科技有限公司

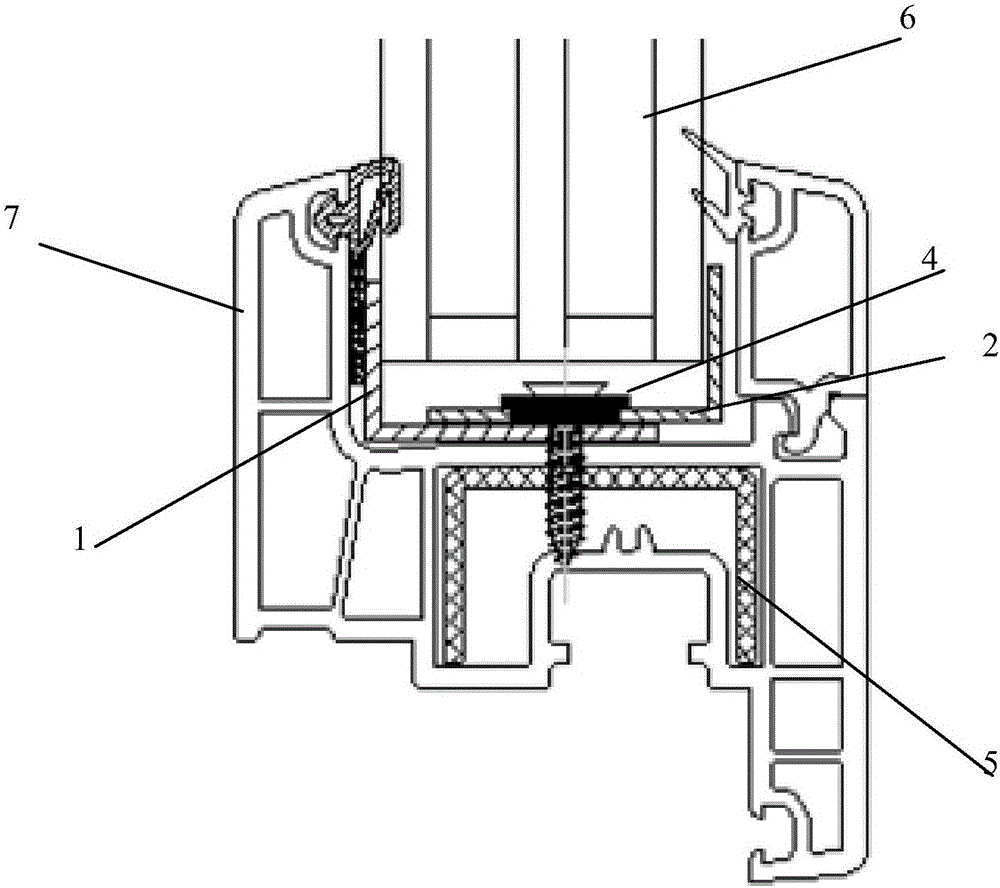

Plastic-steel fire resisting window

InactiveCN106223814AAvoid deformationGuaranteed installation effectFireproof doorsSealing arrangementsEngineeringCo extrusion

The invention discloses a plastic-steel fire resisting window. The plastic-steel fire resisting window comprises a PVC profile material, glass, a glass fastening device and a sealing part. The sealing part comprises a sealing rubber strip which is molded through co-extrusion and a high-temperature expansion strip made of a fireproof high-temperature expansion material, and the high-temperature expansion strip is located on the lower portion of the sealing rubber strip; the glass fastening device comprises an L-shaped fixed plate, an L-shaped movable plate, a fixing screw and a cushion cover. According to the plastic-steel fire resisting window, the whole glass fastening device is made of iron or steel, a fastening mechanism positioning the lower end of the glass is formed by the L-shaped fixed plate fixedly connected with a steel lining and the L-shaped movable plate matched with the cushion cover arranged on the L-shaped fixed plate, the fastening mechanism is resistant to high temperature and not prone to deformation, and therefore it is effectively guaranteed that safety protection is provided in time under the conditions that external plastic steel is melted, and the glass is softened. According to the plastic-steel fire resisting window, the high-temperature expansion rubber strip and the sealing rubber strip are molded through co-extrusion and installed at a time when door window machining is conducted.

Owner:TIANJIN ZHONGCAI PROFILES

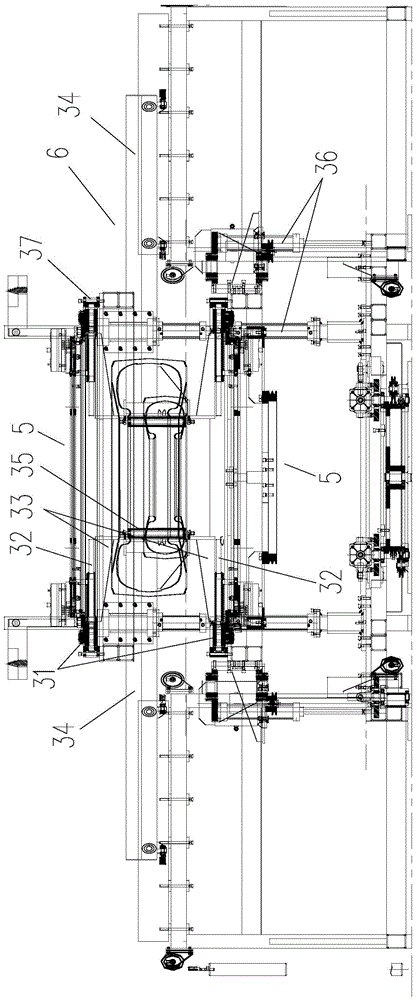

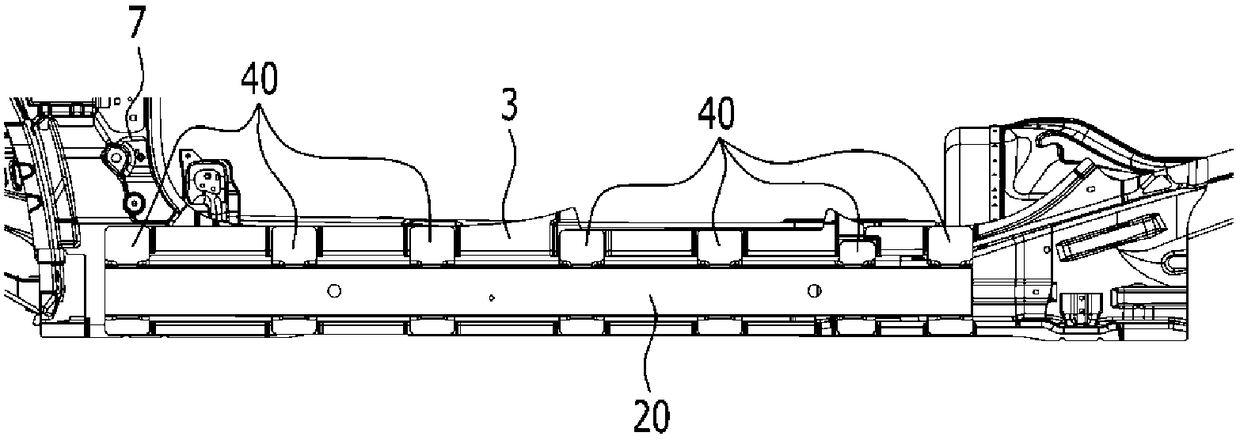

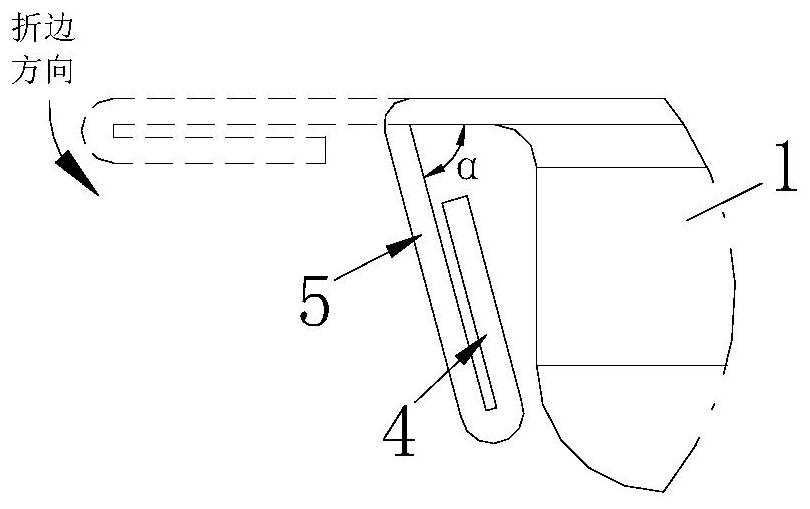

Vehicle door sealing strip pasting and mounting system and pasting method

The invention relates to the field of vehicle production auxiliary processing, in particular to a vehicle door sealing strip pasting and mounting system and a pasting method. The pasting and mounting system comprises a connecting plate unit, a feeding unit, a buffering unit, a material conveying unit, a discharging unit and a protective belt recycling unit. Sealing strips enter the pasting and mounting system from the feeding unit and pass through the buffering unit, and buffering storage materials are formed in the buffering unit. On one hand, the buffering storage materials are conveyed outwards by the buffering unit, and on the other hand, the buffering storage materials are pulled upwards by the material conveying unit, so that the sealing strips are conveyed to the discharging unit. At the discharging unit, the protective belts of the sealing strips are peeled off, the pasting faces of the sealing strips are attached to a vehicle door, and the protective belts are guided to be collected by the protective belt recycling unit. According to the pasting and mounting system, the sealing strip installing and rolling steps are synchronously processed, the installing efficiency is improved, it is guaranteed that the vehicle door sealing strip pasting speed and the rolling head discharging speed are the same, the sealing strips are prevented from being stretched in the installing process, and the sealing strip and vehicle door pasting firmness is guaranteed.

Owner:长春涵智科技有限公司 +1

Mounting and fixing device of pipe gallery deformation joint water-stop belt and construction method

ActiveCN111980062APrevent deviationGuaranteed installation effectArtificial islandsUnderwater structuresEnvironmental geologyStructural engineering

The invention discloses a mounting and fixing device of a pipe gallery deformation joint water-stop belt and a construction method, and belongs to the technical field of construction of the pipe gallery deformation joint water-stop belt. The device is provided with a lower bearing support, an upper bearing support, a press bracket, a supporting part and a bearing bracket, wherein the upper bearingsupport and the lower bearing support are used for limiting the position of a medium-buried water-stop belt, the supporting part is used for connecting the upper bearing support with the lower bearing support and adjusting the spacing between the upper bearing support and the lower bearing support, the bearing bracket is used for connecting the upper bearing support and the lower bearing supportto compress the medium-buried water-stop belt and guarantee the accurate mounting position of the medium-buried water-stop belt, meanwhile, the press bracket located at the top compresses a back binding type water-stop belt along the supporting part to prevent the back binding type water-stop belt from floating upwards, and the mounting effect of the medium-buried water-stop belt and the back binding type water-stop belt is protected comprehensively and effectively.

Owner:CHINA MCC17 GRP

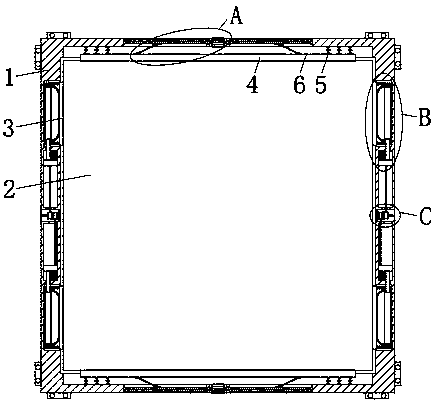

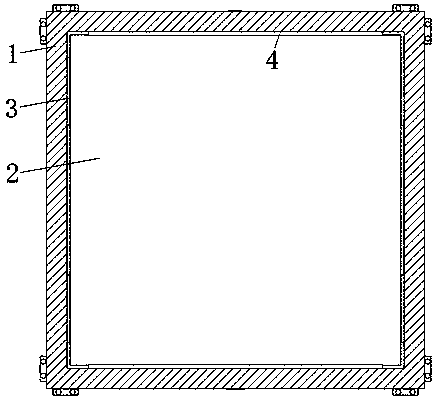

Cabinet used for converter, converter and rail vehicle

ActiveCN104143899AImprove structural rigidityPlay a sealing roleSupports/enclosures/casingsPower conversion systemsBiomedical engineering

The invention provides a cabinet used for a converter, the converter and a rail vehicle. The cabinet used for the converter comprises a wallboard assembly and skin, wherein the wallboard assembly comprises a plurality of first wallboards and a plurality of second wallboards, and the first wallboards and the second wallboards define a cavity in an enclosed mode; the first wallboards and the second wallboards are wrapped with the skin. Lugs extending outwards are integrally formed at the two ends of each first wallboard and are wrapped with the skin, each lug is provided with a first installation hole, and the skin is provided with second installation holes corresponding to the first installation holes. According to the cabinet, the lugs and a cabinet body are integrated, the structural strength of the cabinet is improved, the service life of the skin is prolonged and hoisting installation performance of the cabinet is improved.

Owner:CHINA CNR CORPORATION

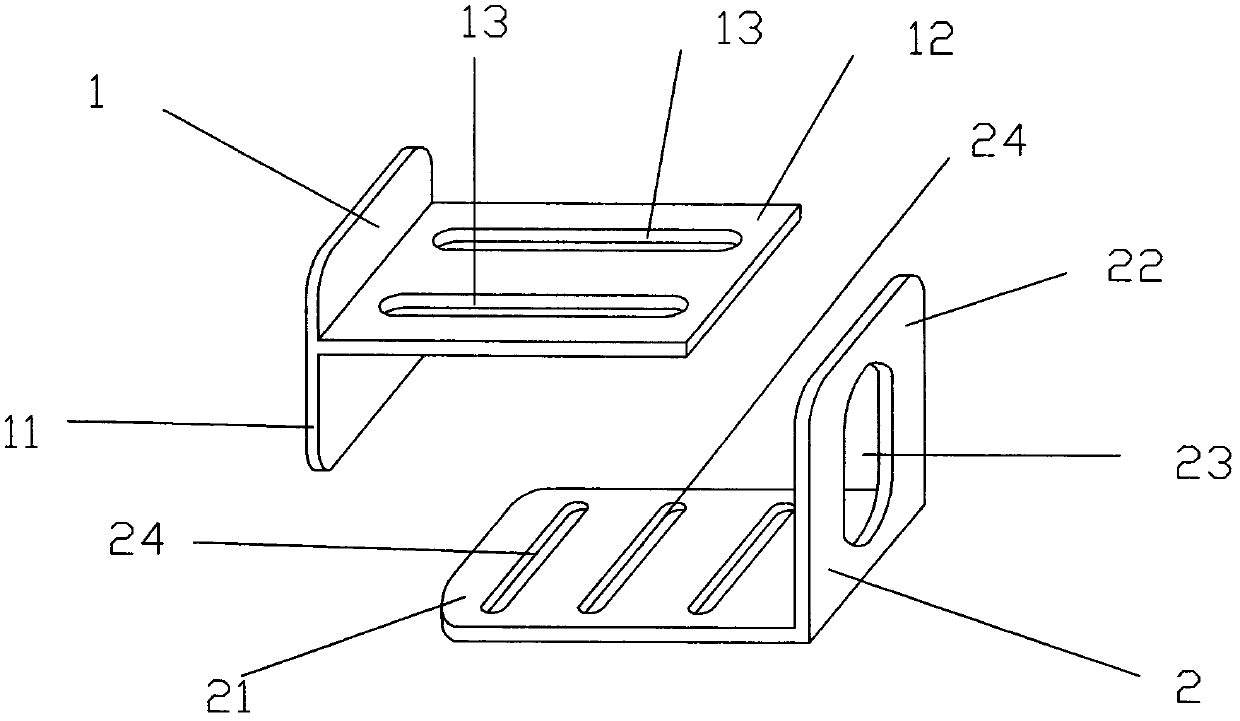

Assembling type decoration plate installation device

InactiveCN110905155ARealize initial limit tightnessRealize preliminary limit installationCovering/liningsStructural engineeringMechanical engineering

Owner:NANNING COLLEGE FOR VOCATIONAL TECH

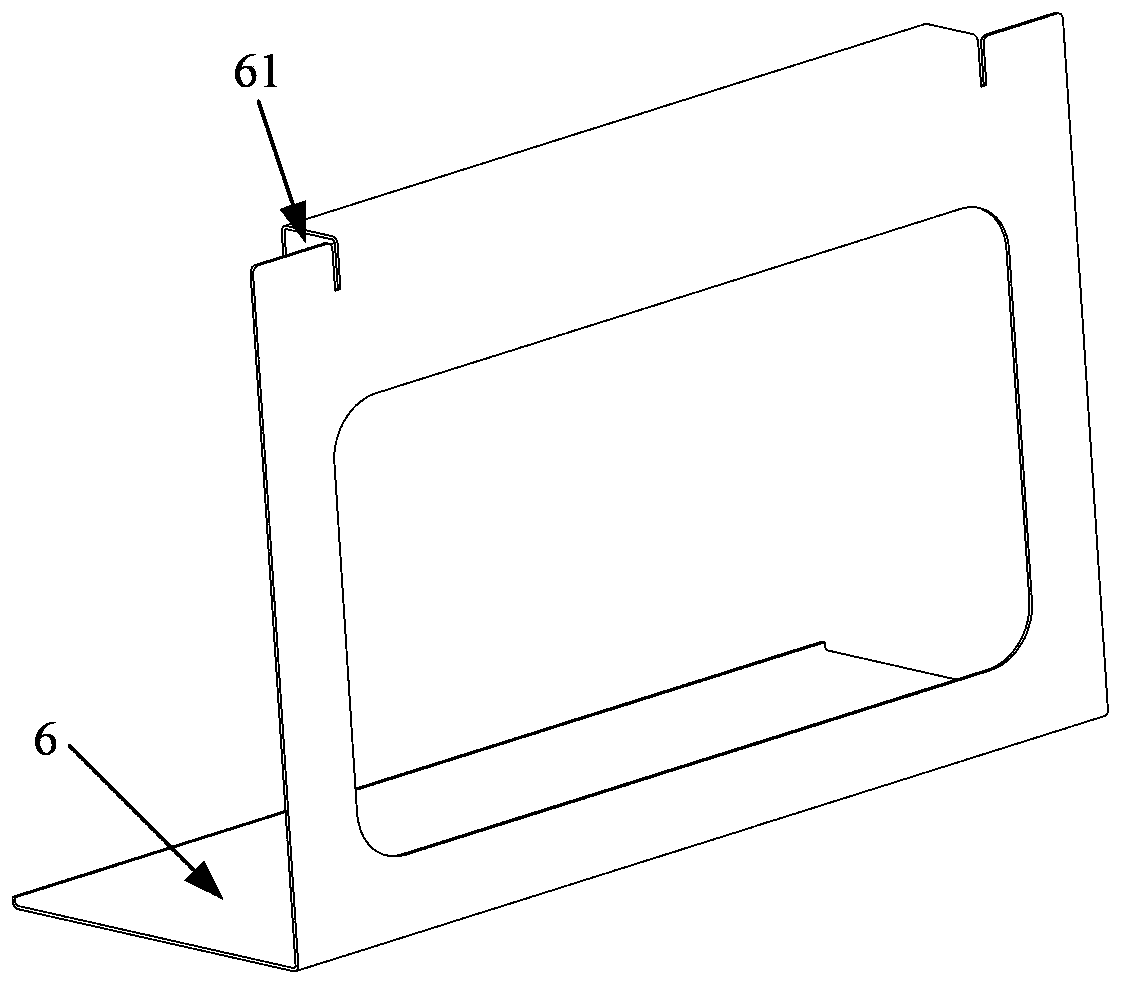

Ceiling plate splicing structure of fabricated ceiling

PendingCN111945954AGuaranteed installation effectEasy to useCeilingsStructural engineeringMechanical engineering

The invention provides a ceiling plate splicing structure of a fabricated ceiling. The ceiling plate splicing structure comprises a ceiling plate, a plate reinforcing member and a hanging keel, wherein the plate reinforcing member comprises a mounting part and a hanging plate, two opposite side edges of the ceiling plate are clamped in the mounting part, the hanging plate is buckled in a bucklinggroove in the bottom of the hanging keel, at least one buckling member is arranged on the hanging plate, the buckling member comprises a mounting plate and a clamping plate, the mounting plate is clamped in a mounting hole in the hanging plate, and the clamping plate is hung on an elastic piece of the hanging keel. According to the ceiling plate splicing structure of the fabricated ceiling, the plate reinforcing member of a combined structure is convenient to transform and reuse, and the ceiling cost is reduced.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

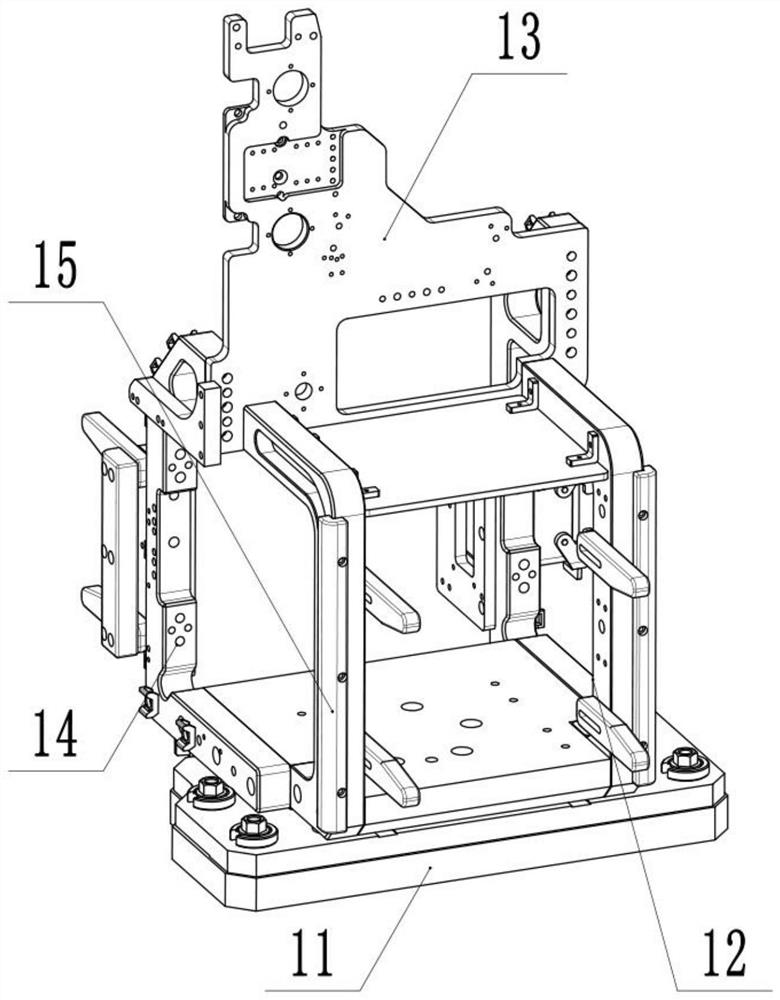

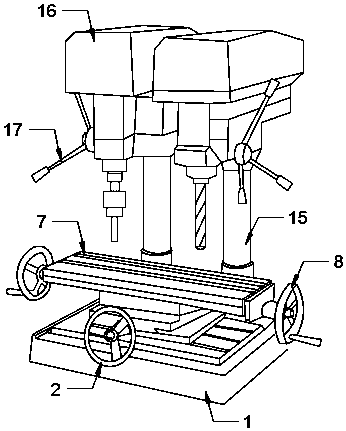

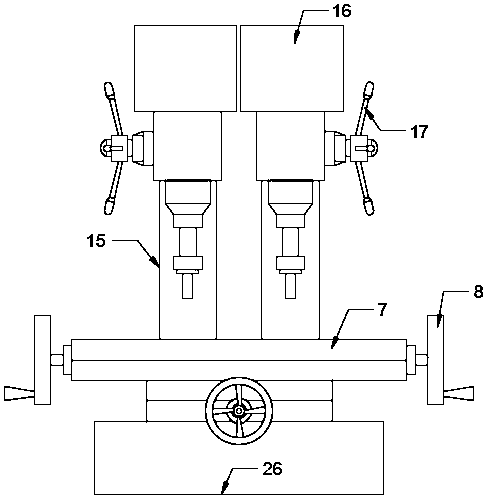

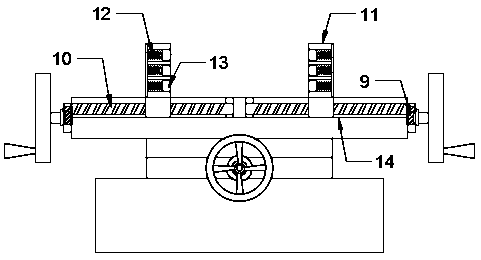

Double-end drilling and milling fixture for machining end surface of disk hub

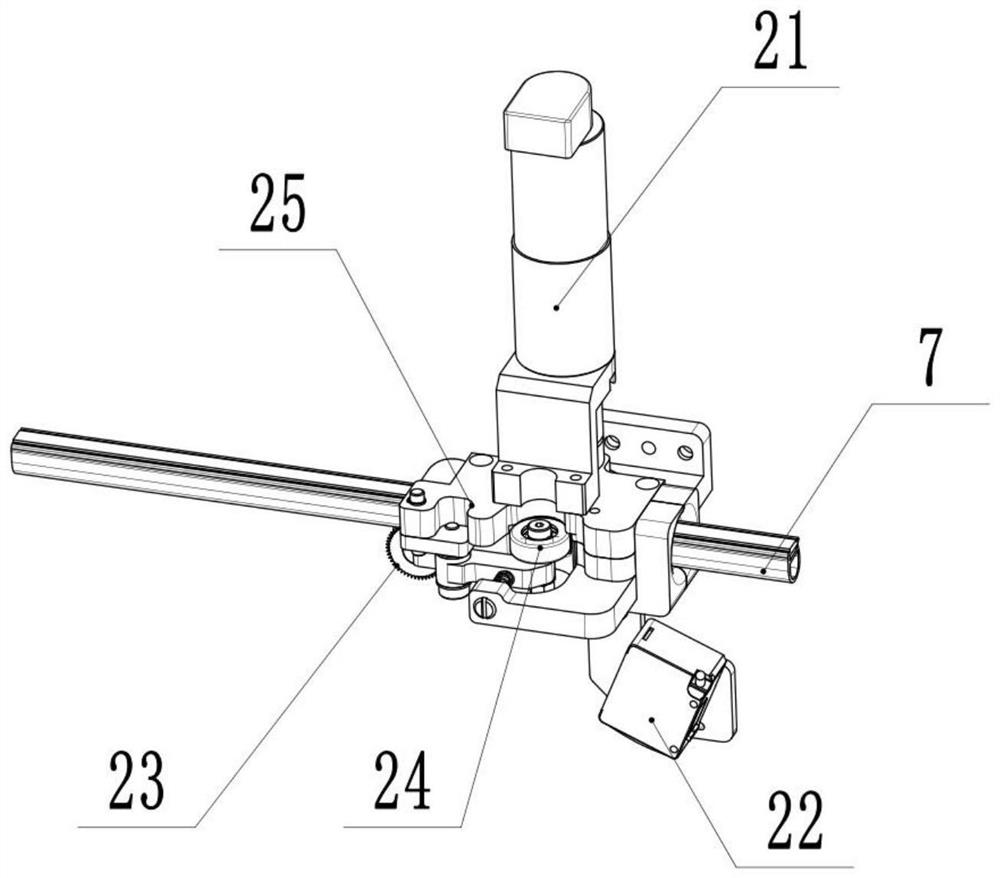

InactiveCN109128920AEasy to placeStable supportLarge fixed membersPositioning apparatusFixed frameGear wheel

The invention discloses a double-end drilling and milling fixture for machining an end surface of a disk hub. The double-end drilling and milling fixture for machining the end surface of the disk hubcomprises a base; a lifting mechanism is fixedly arranged at the upper end of the base; the lifting mechanism comprises a first hand wheel, first gears, rack plates, fixing frames and lifting platforms; the plurality of fixing frames are arranged at the upper end of the base; a plurality of first gears are movably mounted at the middle parts of the plurality of fixing frames through bearings; theplurality of first gears are connected with each other through rotating shafts; the first hand wheel is fixedly mounted on one side, close to the rotating shaft, outside the fixing frame; the plurality of rack plates are movably mounted on one sides, close to the first gears, in the plurality of fixing frames; the plurality of rack plates are engaged with the first gears; lifting platforms are fixedly arranged at the upper ends of the plurality of rack plates; and clamping mechanisms are fixedly arranged at the upper end of the lifting platforms. According to the double-end drilling and milling fixture for machining the end surface of the disk hub, the accurate positioning of the end surface of the disk hub can be limited, and double-end rapid machining can be realized.

Owner:南京新尼亚文汽车零部件有限公司

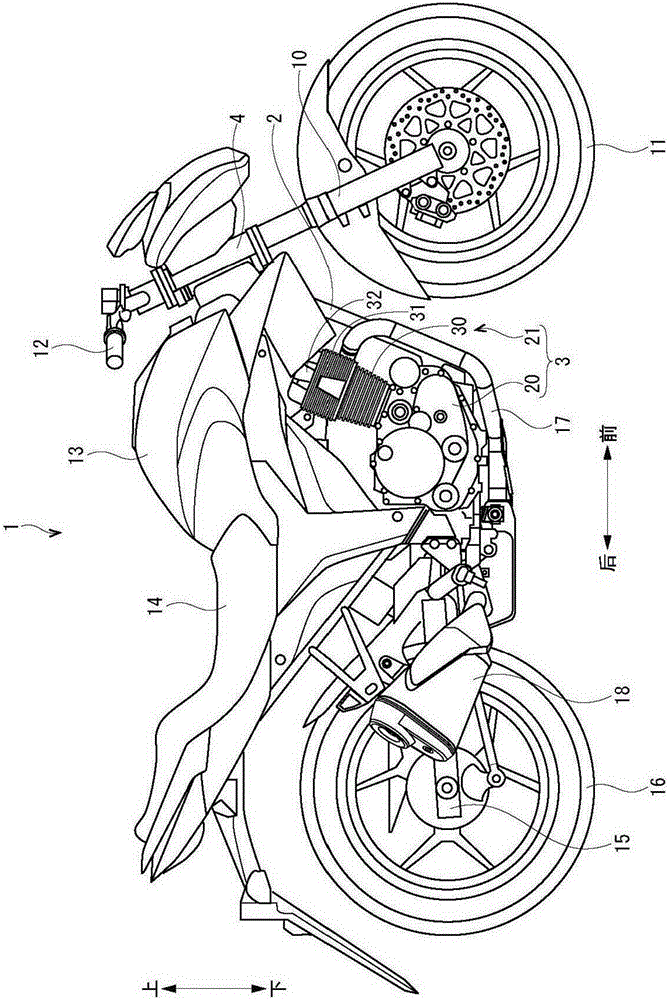

Motorcycle seat mat locking mechanism

The invention relates to a motorcycle cushion lock device, which comprises a lock element with bolt hole at the first cushion bottom plate, the first lock on the motorcycle, wherein the first lock as a sliding or rotating bolt, and a return spring for extending the bolt into the bolt hole of lock element; the contract distance of bolt can move outside the bolt hole; the bolt is connected to the flexible cable through in the flexible tube to contract the bolt; the flexible cable and the free end of flexible tube are outside the lock. The invention has simple structure.

Owner:LONGXIN IND GROUP

Roofing system fixing seat and roofing system adopting same

PendingCN109356333AImprove wind resistanceGuaranteed safe bearingRoof covering using slabs/sheetsRoof covering insulationsEngineeringMechanical engineering

The invention provides a roofing system fixing seat and a roofing system adopting the same. The roofing system fixing seat comprises a base, a connecting part and a locking part, wherein the base is fixed to a secondary purline or a pressure plate of the roofing system, the locking part is used for locking edges of a waterproof plate, and the locking part is in square shape. According to the roofing system fixing seat, the contact area between the locking part and the waterproof plate is increased, and the stress area between the locking part and the waterproof plate is increased, so that thewind-lifting resistance effect of the waterproof plate is improved, and the installation process can be simplified and the installation effect can be better ensured due to the fact that the square structure of the locking part is relatively simple.

Owner:四川佳科幕墙工程有限公司

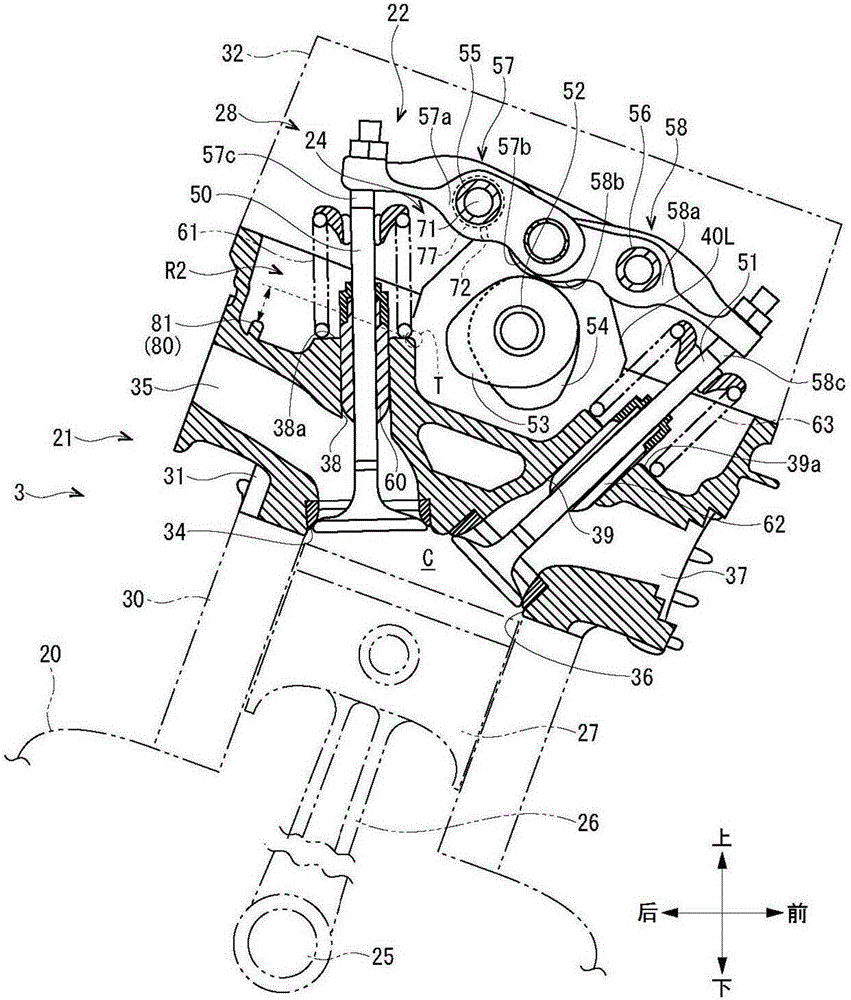

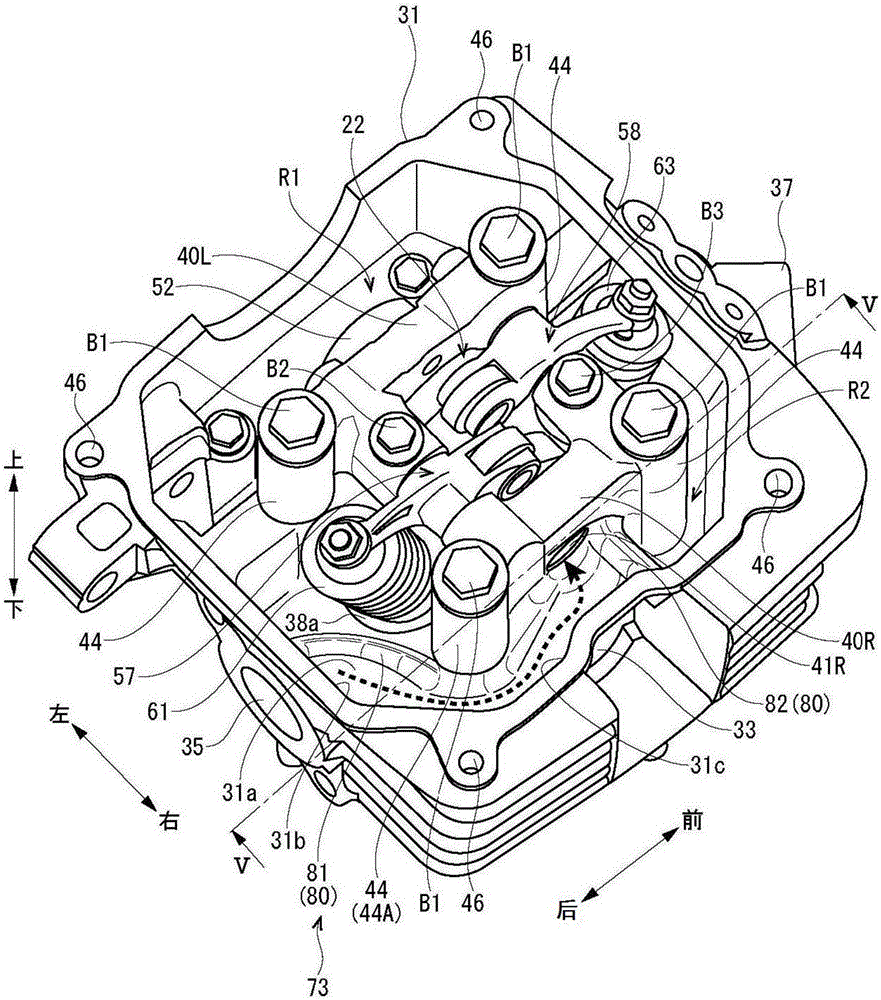

Internal combustion engine valve transmission lubricating device

ActiveCN106150588ASuppress snoringGuaranteed installation effectValve arrangementsLubrication of auxillariesBall bearingCylinder head

The present invention provides an internal combustion engine valve transmission lubricating device which inhibits the sound in the bearing portion separated from a transmission device. The device comprises: a cylinder stator vertically stand at a crankcase in an inclined posture; a valve transmission device driving a drain tap through a cam shaft extending along the width direction; a transmission device configured in a transmission chamber at one side of the width direction and connected with the and the cam shaft; and a lubrication mechanism jetting lubricating oil to lubricate the valve transmission device. The valve transmission device includes a pair of rolling bead bearing arranged at the other side of the width direction, supported at two sides of the width direction of the cam shaft and embedded at the cylinder cover for fixture. The lubrication mechanism has a guidance passage formed at the cylinder cover which is used for guide the lubricating oil of the lubricating valve transmission device to the rolling bead bearing.

Owner:SUZUKI MOTOR CORP

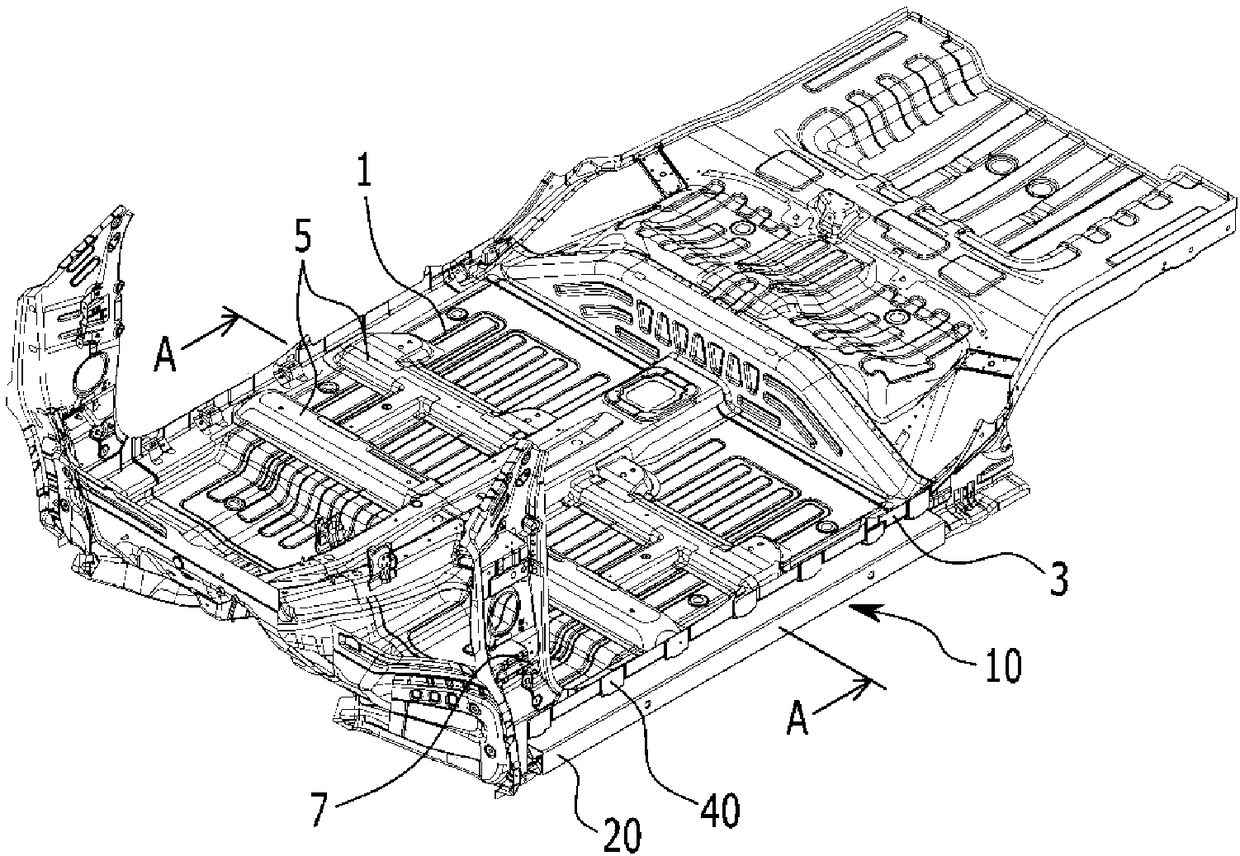

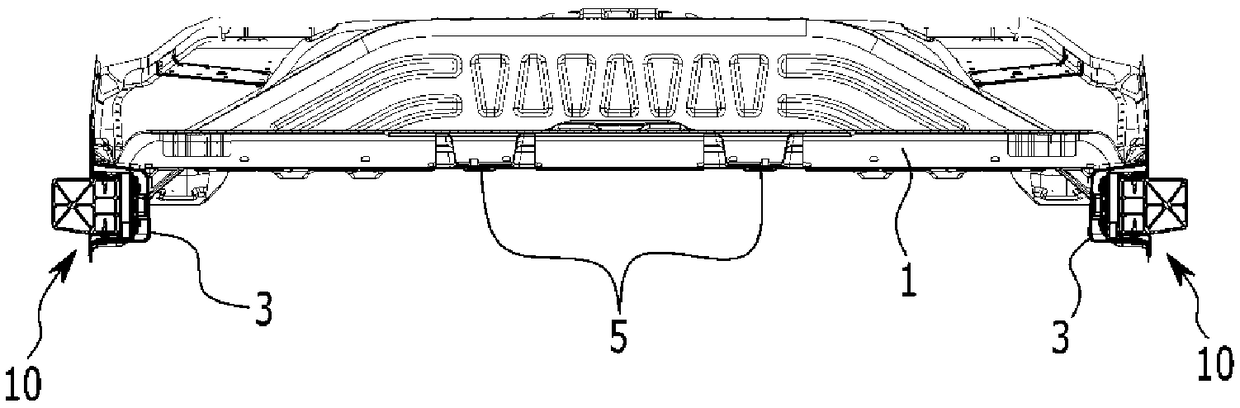

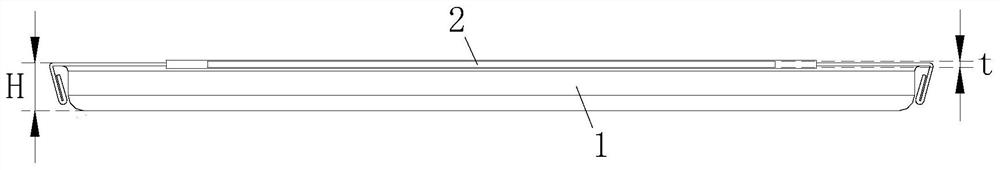

Reinforcement Unit of Side Sill for Electric Vehicles

ActiveCN108068885AEnsure shock safetyGuaranteed installation effectPedestrian/occupant safety arrangementUnderstructuresElectric vehicleEngineering

The invention relates to a reinforcement unit of a side sill for an electric vehicle. The side sill includes side sill inner panels and side sill outer panels that are respectively provided under opposite ends of a center floor panel. The reinforcement unit includes a reinforcement pipe member provided between the side sill inner panel and the side sill outer panel along a length direction of a vehicle body, and a connection apparatus comprising a plurality of fixing brackets and a plurality of pipe nuts. The connection apparatus fixes the reinforcement pipe member to the side sill inner panel.

Owner:HYUNDAI MOTOR CO LTD +1

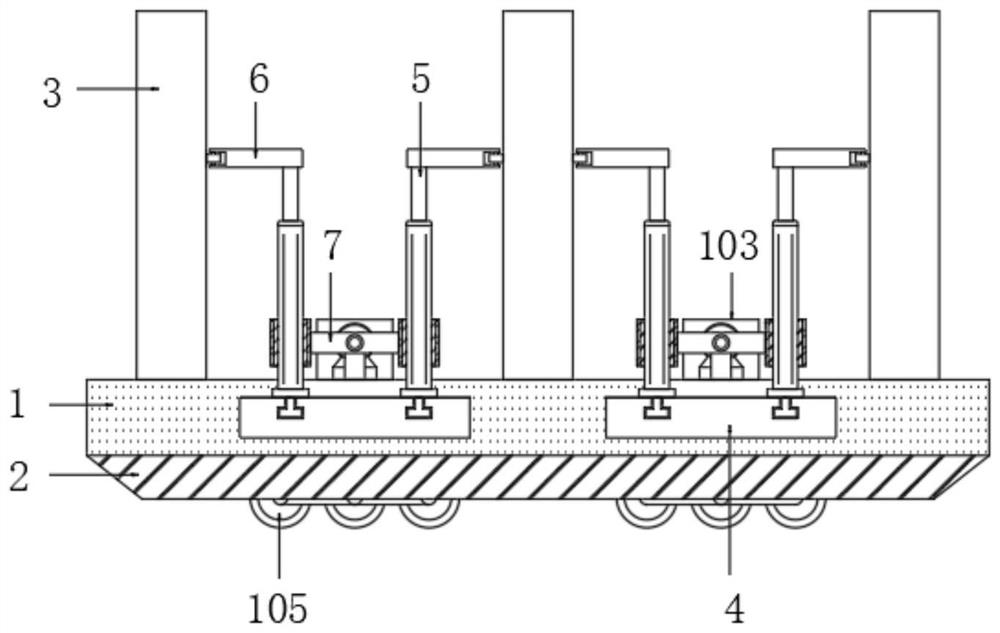

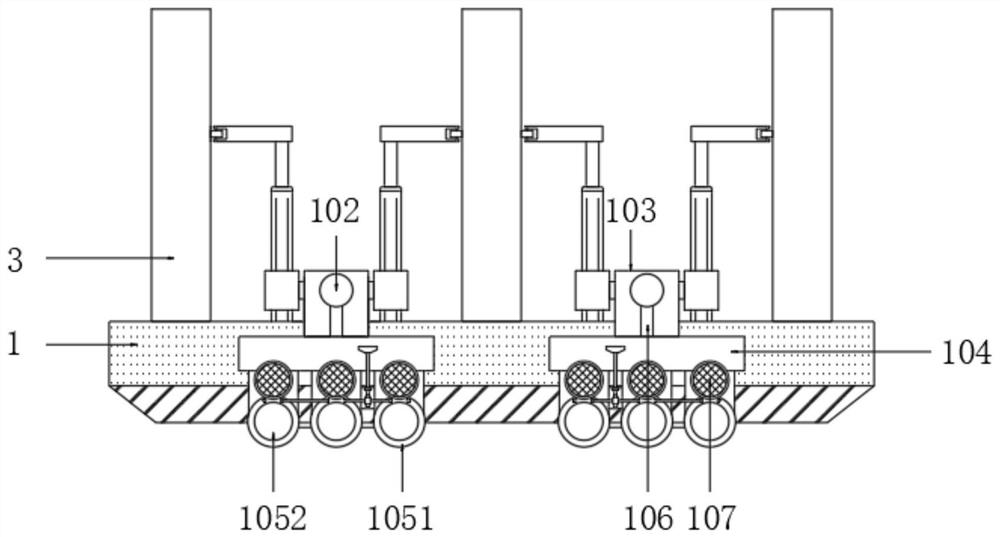

Photovoltaic installation equipment suitable for water and installation method

ActiveCN112636674AGuaranteed installation effectIncrease gravityPhotovoltaic supportsPhotovoltaic energy generationStructural engineeringMechanical engineering

Owner:山东润马光能科技有限公司

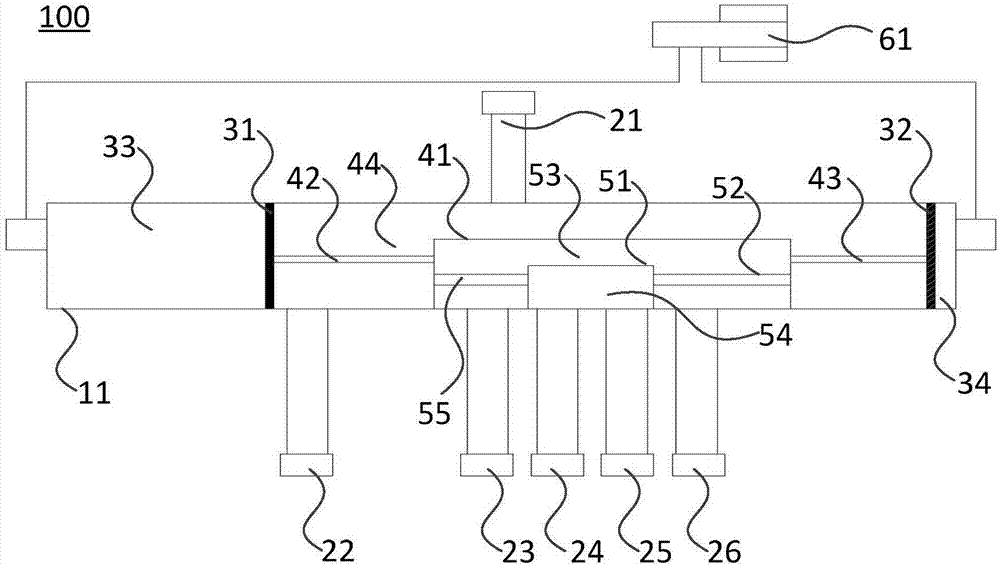

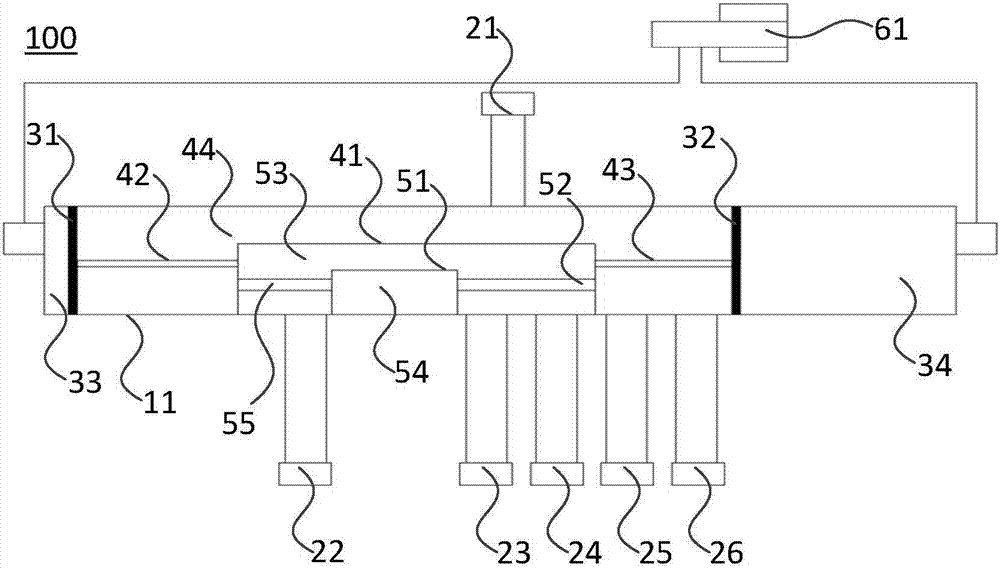

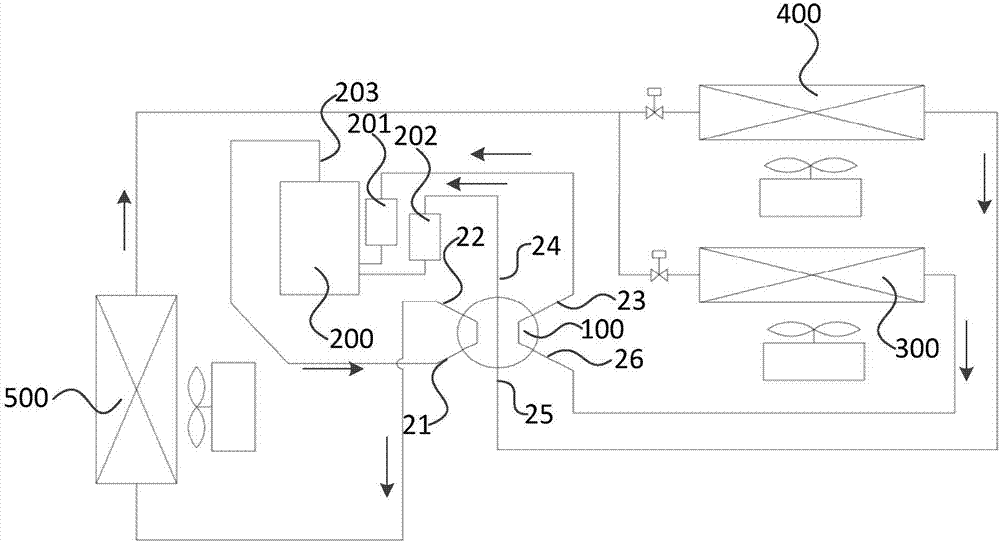

Air conditioning system

ActiveCN107166819ASimple pipingSimplify piping designMechanical apparatusFluid circulation arrangementFour-way valveRefrigeration

The invention provides an air conditioning system capable of switching between refrigeration and heating. The air conditioning system comprises a reversing valve, a compressor, a first indoor unit, a second indoor unit and an outdoor unit. The reversing valve in the air conditioning system can conveniently enable six connecting pipes to switch between a 2-2-2 communicating mode and a 3-3 communicating mode; compared with a technical scheme of synchronously using two four-way valves in the prior art, the same effect can be achieved; but for the air conditioning system, after one reversing valve is used for replacing the two four-way valves, pipelines are simplified, the pipeline design is convenient, the space is released, the installation of the compressor can be guaranteed, the further design optimization is convenient, and the valve and pipeline costs are reduced; and in particular, the invention is suitable for an air conditioning system containing double air sucking compressors.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

Fabricated steel-concrete composite structure culvert

InactiveCN112726437AGuaranteed accuracyGuaranteed installation effectGround-workMechanical engineeringCulvert

The invention relates to the technical field of structural culverts, in particular to a fabricated steel-concrete composite structure culvert which comprises a bottom plate body, a standing plate body and a top plate body, first inserting blocks are fixedly connected to the upper surface of the bottom plate body, the four sets of first inserting blocks are symmetrically distributed in pairs, and first locking holes are formed in the side walls of the first inserting blocks. A second inserting block is fixedly connected to the bottom of the top plate body, a second locking hole is formed in the side wall of the second inserting block, positioning grooves are formed in the top and the bottom of the standing plate body, fixing mechanisms corresponding to the first inserting block and the second inserting block are arranged on the side wall of the standing plate body, and a positioning hole is formed in one side of the upper surface of the bottom plate body; a locking mechanism is arranged on the other side of the upper surface of the bottom plate main body, when the bottom plate main body, the standing plate main body and the top plate main body are mounted, positioning and mounting of the bottom plate main body, the standing plate main body and the top plate main body are facilitated, the splicing time is saved, the accuracy of the mounting position is guaranteed, and the bottom plate main body, the standing plate main body and the top plate main body can be temporarily fixed.

Owner:闫志伟

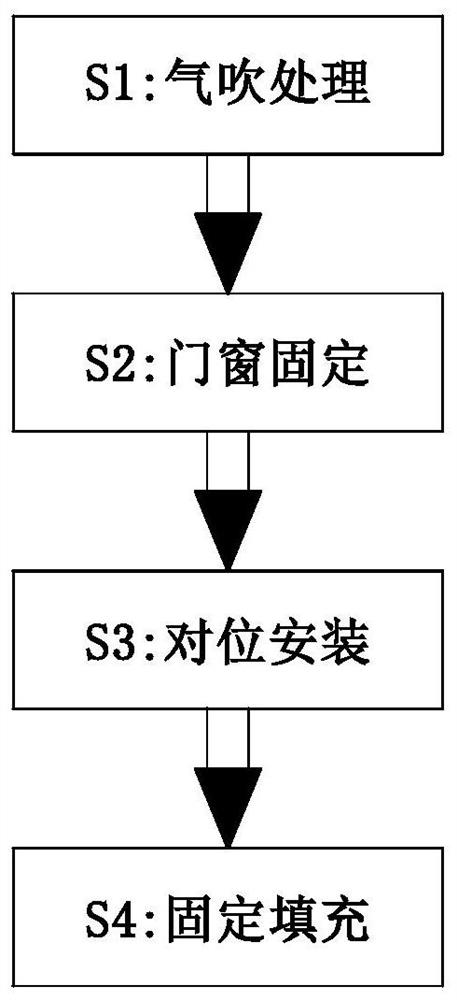

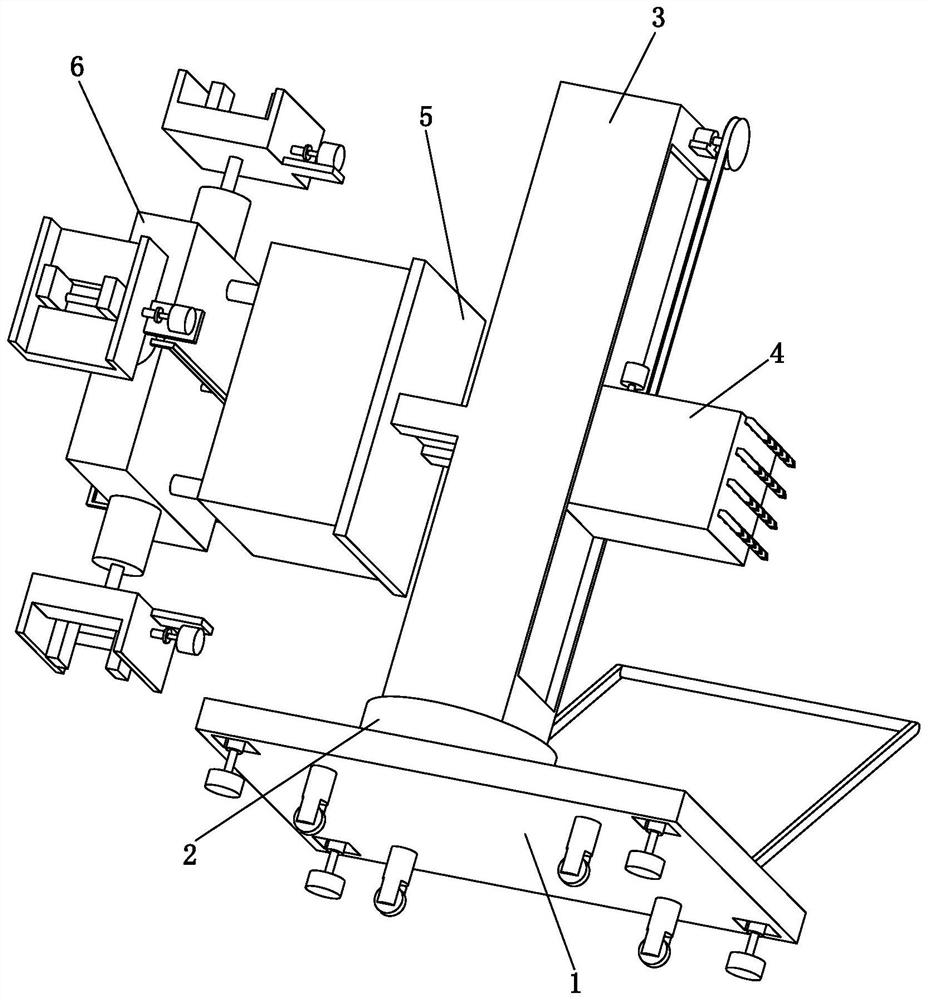

Installation construction method for bridge-cut-off aluminum alloy door and window

InactiveCN112943043ASave human effortImprove installation efficiencyWork holdersSpecial door/window arrangementsEngineeringStructural engineering

The invention relates to an installation construction method for a bridge-cut-off aluminum alloy door and window. A base, a rotating device, a square column, a cleaning device, a lifting device and an installation device are included. The installation construction method can solve the following problems possibly encountered in the installation process of an existing bridge-cut-off aluminum alloy door and window that a, the bridge-cut-off aluminum alloy door and window is supported and aligned manually, thus the bridge-cut-off aluminum alloy door and window is installed in a rectangular notch, the mode needs more manpower, the installation process is time-consuming, and thus the installation efficiency is low; and b, in the manual installation process, deviation between the bridge-cut-off aluminum alloy door and window and the rectangular notch is caused possibly due to personal errors, thus the installation quality of the bridge-cut-off aluminum alloy door and window is reduced, and the using effect of the bridge-cut-off aluminum alloy door and window is affected.

Owner:武汉市绍阳科技有限公司

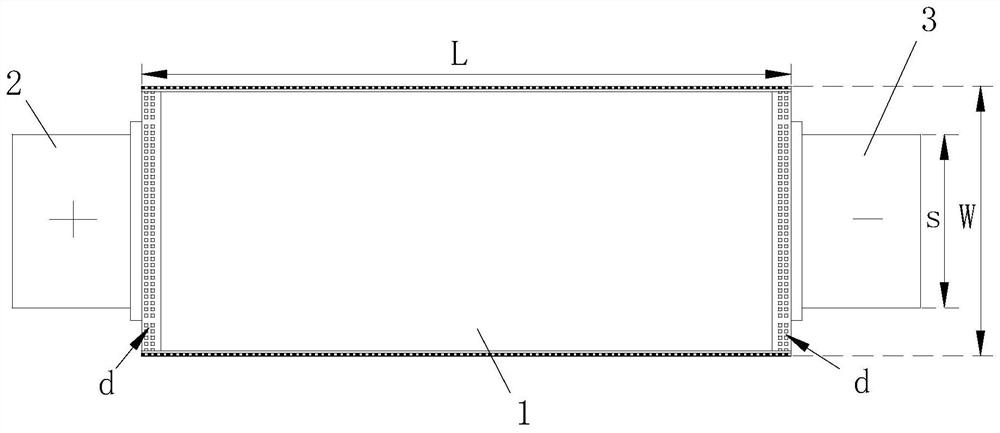

HEV soft package battery cell and battery pack

InactiveCN112349950AGuaranteed high rate charge and discharge capabilityGuaranteed powerFinal product manufactureLi-accumulatorsPlastic filmBattery cell

The invention provides an HEV soft package battery cell and a battery pack, the HEV soft package battery cell comprises a battery cell main body and a battery cell tab, the battery cell main body is provided with an aluminum-plastic film shell, and a pole group and an electrolyte which are sealed in the aluminum-plastic film shell, the battery cell tab is provided with a positive pole tab and a negative pole tab, one ends of the positive pole tab and the negative pole tab are positioned in the aluminum-plastic film shell and are connected with pole group, and other ends of the positive pole tab and the negative pole tab extend out of the aluminum-plastic film shell. The battery cell is characterized in that the battery cell main body is of a cuboid structure, the length L of the battery cell main body is smaller than or equal to 250 mm, the width W and the thickness H of the battery cell main body meet the conditions that 20%L <= W <= 60%, and 1%L <= H <= 5%L. According to the HEV softpackage battery cell, the high-rate charging and discharging capacity of the battery cell can be guaranteed, the power performance of the battery cell is guaranteed, the safety performance of the battery cell can also be improved, and the HEV soft package battery cell has good practicability.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

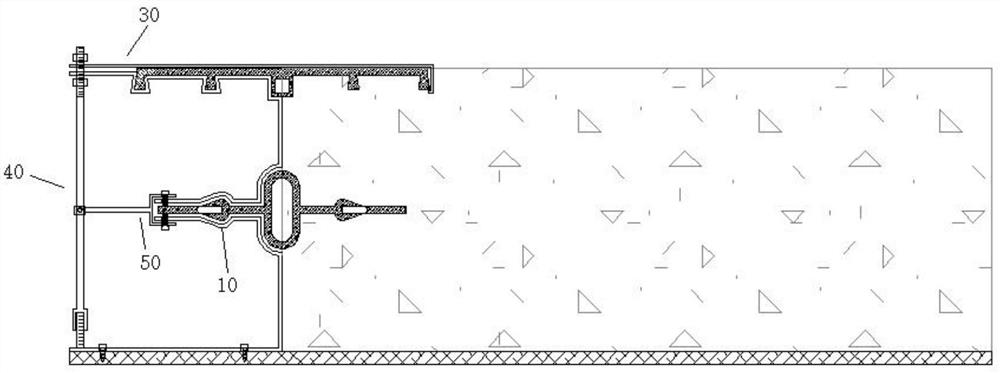

Keel-adjustable mounting structure for prefabricated wall surface

PendingCN111980344AGuaranteed installation effectStable installationCovering/liningsWall plateEngineering

The invention provides a keel-adjustable mounting structure for a prefabricated wall surface. The keel-adjustable mounting structure comprises a leveling piece, a keel and an adjusting bolt, wherein the leveling piece is fixedly arranged on a wall base layer; a column sleeve is arranged on the leveling piece, threads are arranged on the inner wall of the column sleeve, a spring is arranged on thecolumn sleeve in a sleeving mode, and two baffles arranged in parallel are arranged on the leveling piece; a groove is formed in the surface of the keel, and a kidney-shaped hole formed in the lengthdirection of the groove is formed in the bottom face of the groove; and the adjusting bolt penetrates through the kidney-shaped hole to be connected to the column sleeve, the spring abuts against thebottom face of the groove, and the bent edges on the two sides of the keel abut against baffles of the leveling piece. According to the keel-adjustable mounting structure for the prefabricated wall face, the keel for the prefabricated wall face can be accurately adjusted, so that mounting is firm, and the flatness of the wall face formed by fixing wallboards to the keel is good.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

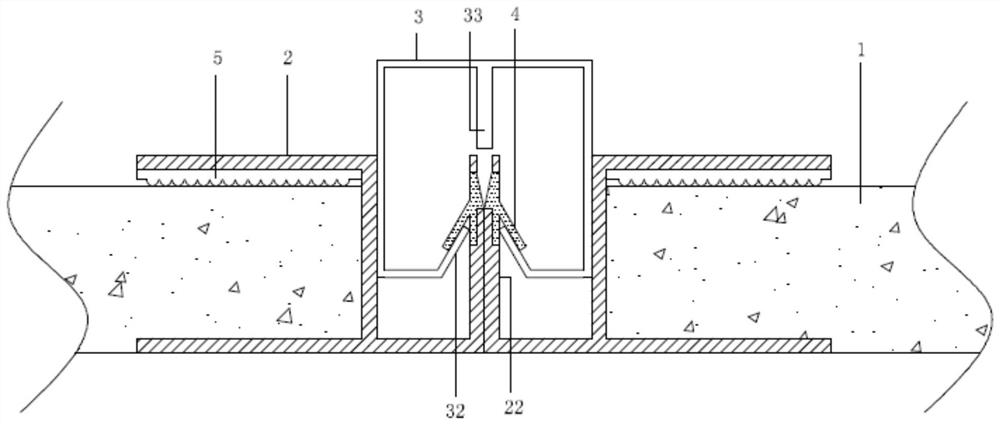

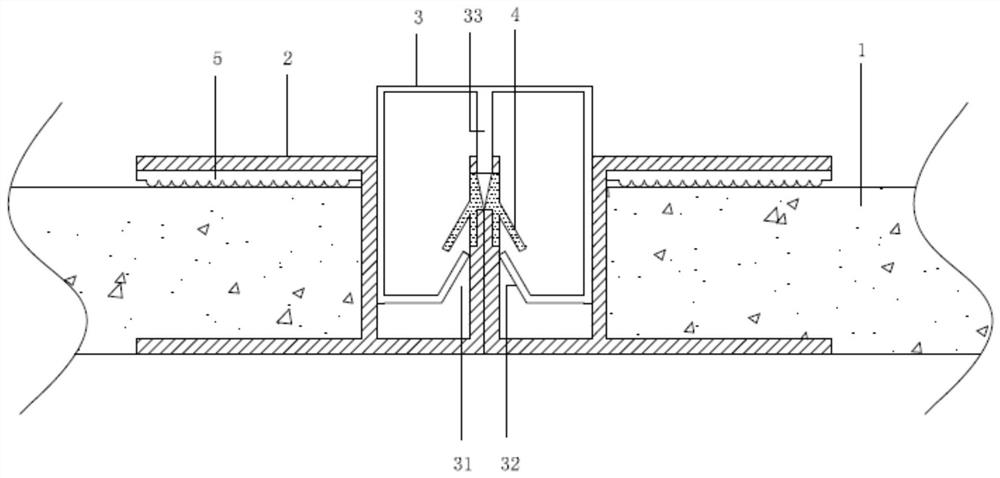

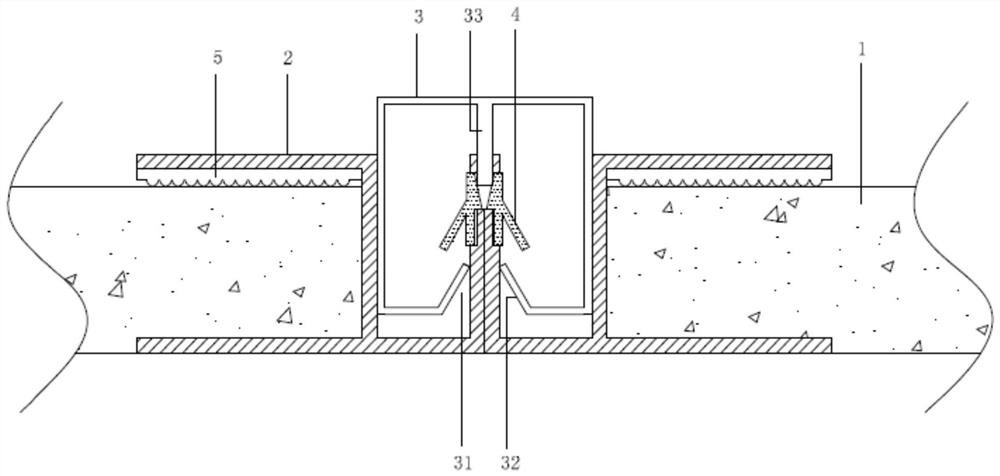

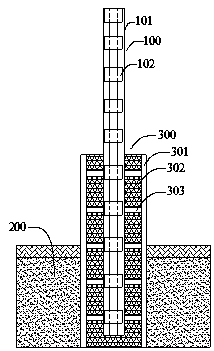

Modularization same-layer drainage device for high-rises and mounting method thereof

ActiveCN107237395AEffectively cover installation gapsSolve the problem of stagnant water leakageSewerage structuresSewer pipelinesVertical tubeWater discharge

The invention provides a modularization same-layer drainage device for high-rises and a mounting method thereof. The device comprises a water accumulating box, a vertical tube connecting pipe, a lower air pipe which penetrate the bottom wall of the water accumulating box, an upper air pipe which is installed on the top cover of the water accumulating box and is communicated with the inner part of the water accumulating box; and a waste water discharge inlet which is installed in the top cover of the water accumulating box; a vertical tube connecting pipe is provided with a water outlet which is positioned inside the water accumulating box; the waste water drainage inlet and a water outlet are communicated; the vertical tube connecting pipe is provided with a side discharge connecting member which is communicated with a water closet discharge port, wherein the side discharge member comprises a flat sewage box; an end, communicated with the vertical tube connecting pipe, of the sewage box is provided with a sewage outlet; a side wall of the sewage box is provided with a water closet connecting port whose opening direction is vertical to the axis of the vertical tube connecting pipe. The modularization same-layer drainage device for high-rises of the invention has a simple structure, scientific design and reliable performance and is convenient to use; the device has excellent seepage-proofing performance; stink proofing is realized by concentrated water sealing; the water closet discharge port is convenient to mount and is not liable to block.

Owner:河南锐诚节能环保科技有限公司

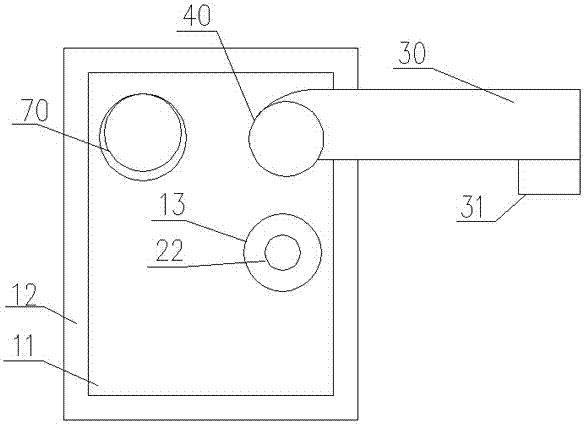

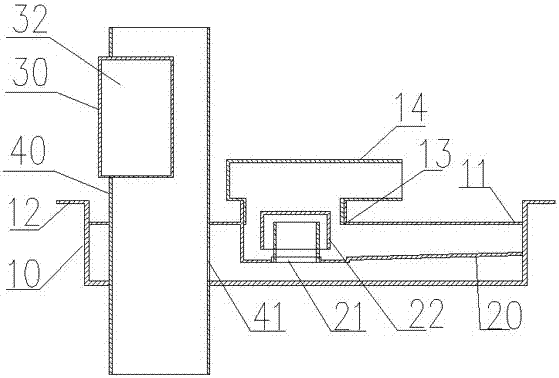

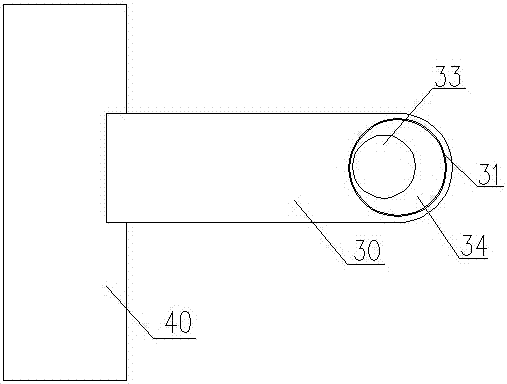

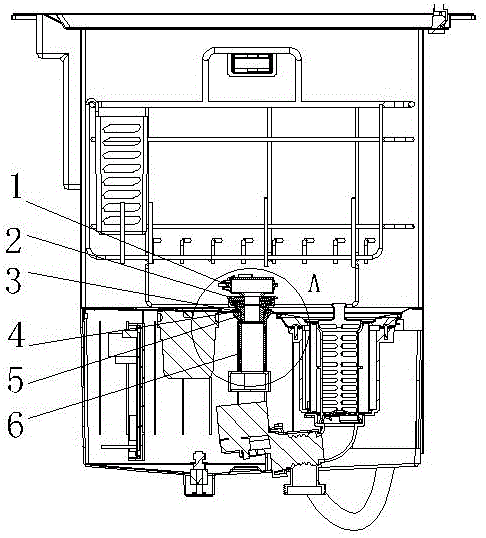

Rotary spray arm installing structure for water tank type cleaning machine

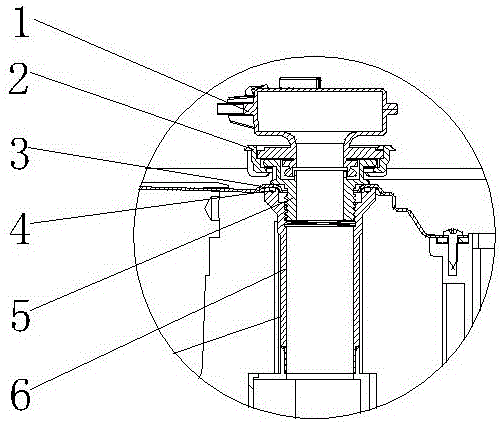

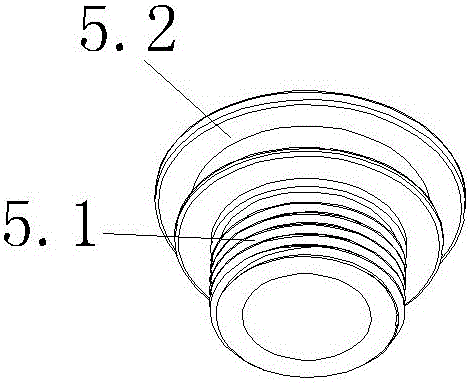

PendingCN106618425AImprove reliabilityImprove stabilityTableware washing/rinsing machine detailsCleaning equipmentAgricultural engineeringWater tanks

The invention provides a rotary spray arm installing structure for a water tank cleaning machine. The rotary spray arm installing structure comprises a rotary spray arm mounted at the bottom of a water tank inner cavity, and a vertical rotating shaft part is disposed at the lower end of the rotary spray arm. The rotary spray arm installing structure further comprises a spray arm fixing column vertically fixed in the upper portion of the water tank bottom plate for the spray arm to install, and a spray arm installing base connected with the spray arm fixing column, the rotary shaft part is rotatably installed on the spray arm installing base though mounting nuts; the rotary shaft part is relatively fixed with the mounting nuts by a limiting component arranged along the circumferential direction. The rotary spray arm installing is more reliable and more stable.

Owner:NINGBO ZHONGWU DONGFANG OPTOELECTRONICS TECH CO LTD

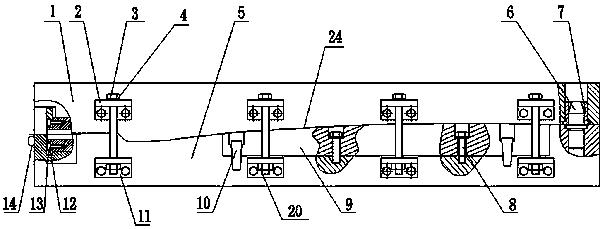

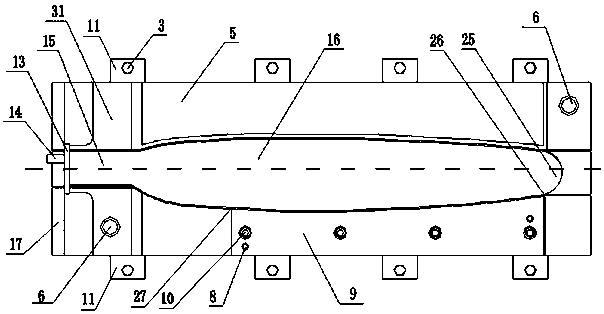

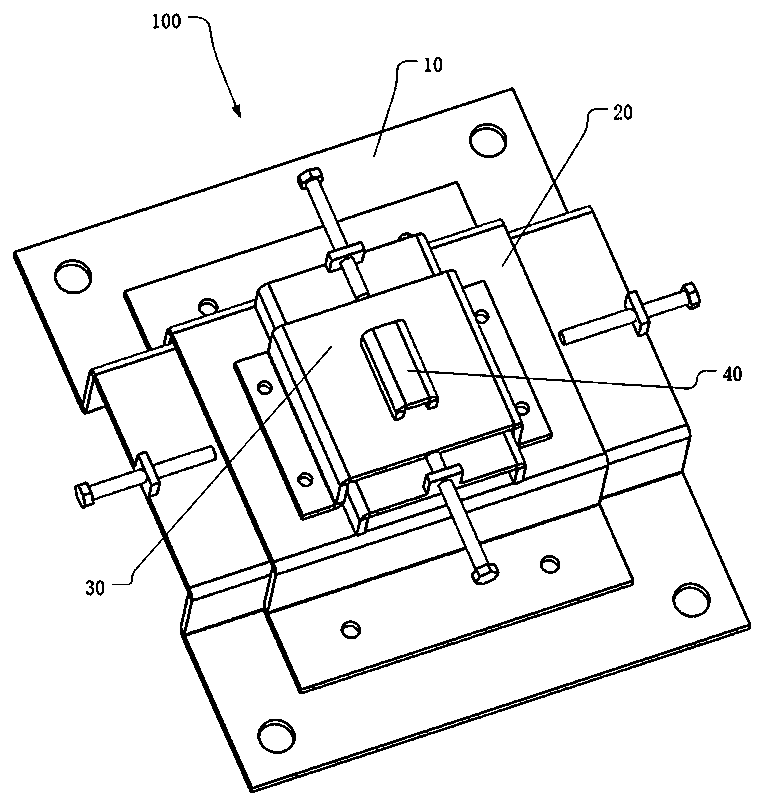

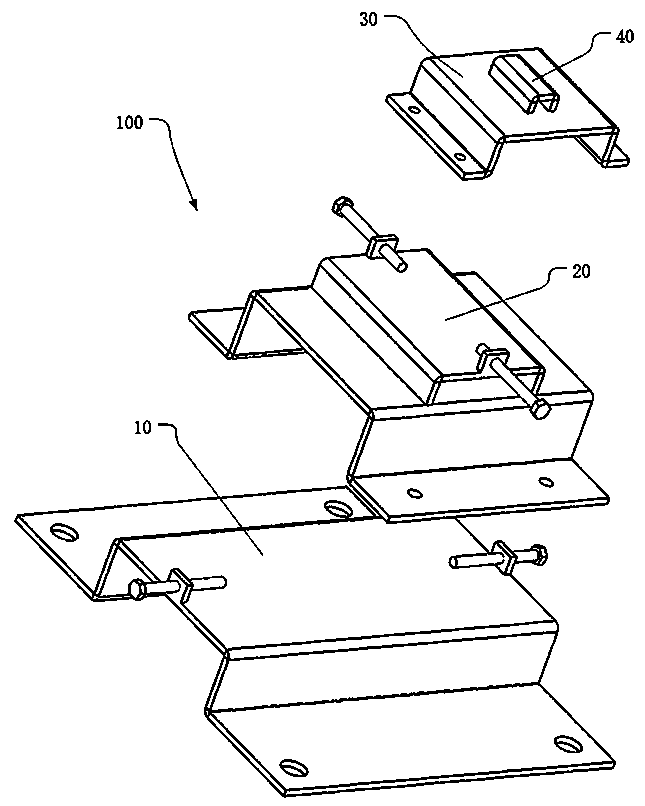

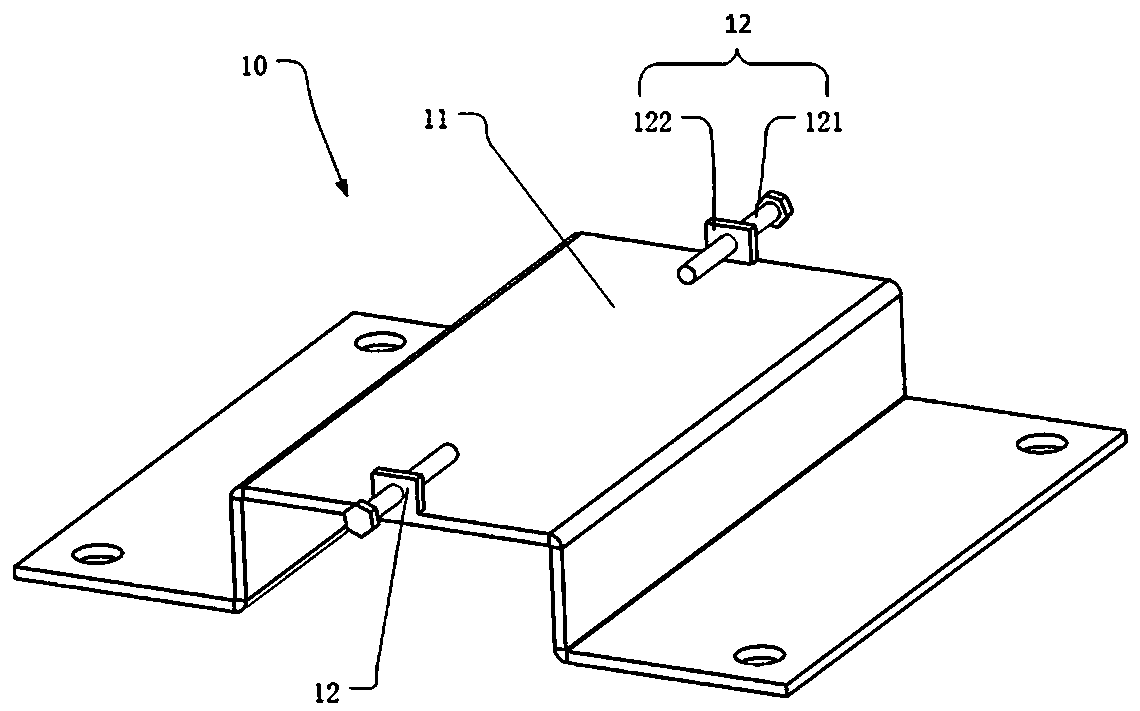

Manufacturing die of unmanned aerial vehicle blade

PendingCN111231183ASimple processingHigh precisionDomestic articlesUncrewed vehicleMechanical engineering

The invention discloses a manufacturing die of an unmanned aerial vehicle blade. The manufacturing die comprises an upper die, a lower die and positioning pins I; the lower die cuts cutting blocks rightwards from the left reflex angle zero-degree line position on the front wall of a lower die cavity corresponding to the trailing edge of the blade, the right end face of each cutting block corresponds to the starting position of the arc transition of the tail end of a blade body and the tail end of a blade tip, the lower end face of each cutting block is lower than the lowest point of the intersection line of the front wall of the lower die cavity and the bottom face of the lower die cavity, the rear end face of each cutting block are the inner end face of the front wall of the lower die cavity, and the front end face of each cutting block is not larger than the outer end face of the front wall of the lower die cavity; the symmetrical positioning pins I are arranged at the left end and the right end of the upper end face of a lower die block, positioning holes I are formed in the lower end face of the upper die, and after die is closed, the positioning pins I are located in the positioning holes I correspondingly; fixing mechanisms are evenly arranged on the front walls and the rear walls of the upper die block and the lower die block, and after die is closed, the upper die blockand the lower die block are fixed together through the fixing mechanisms. The manufacturing die is easy to manufacture, low in manufacturing cost, high in manufacturing precision and low in rejectionrate; and the unmanned aerial vehicle blade manufactured by the manufactured die is easy to demold, low in manufacturing cost and high in blade quality.

Owner:AVIC HUIYANG AVIATION PROPELLER

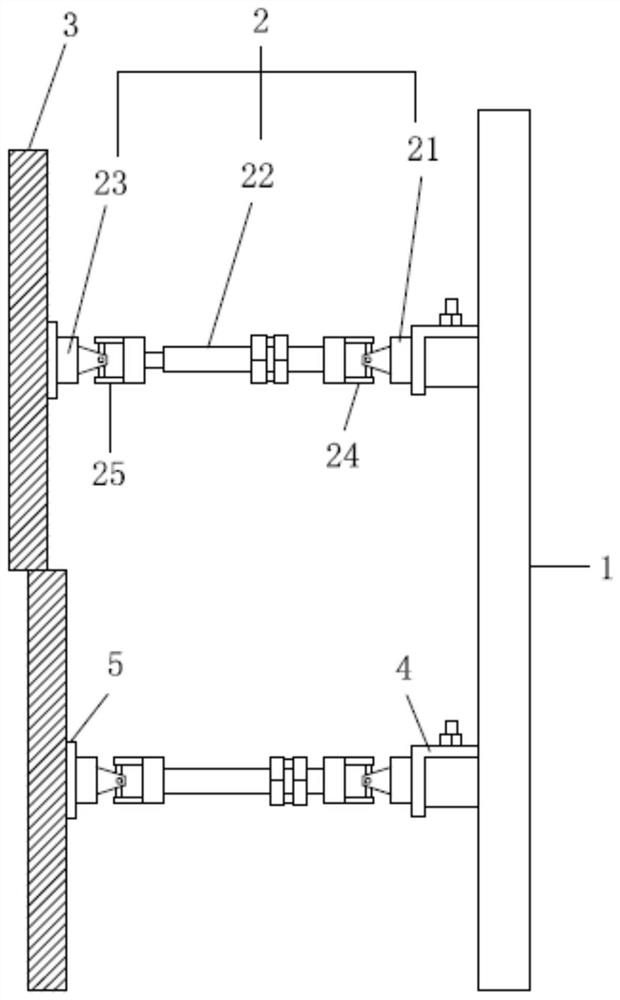

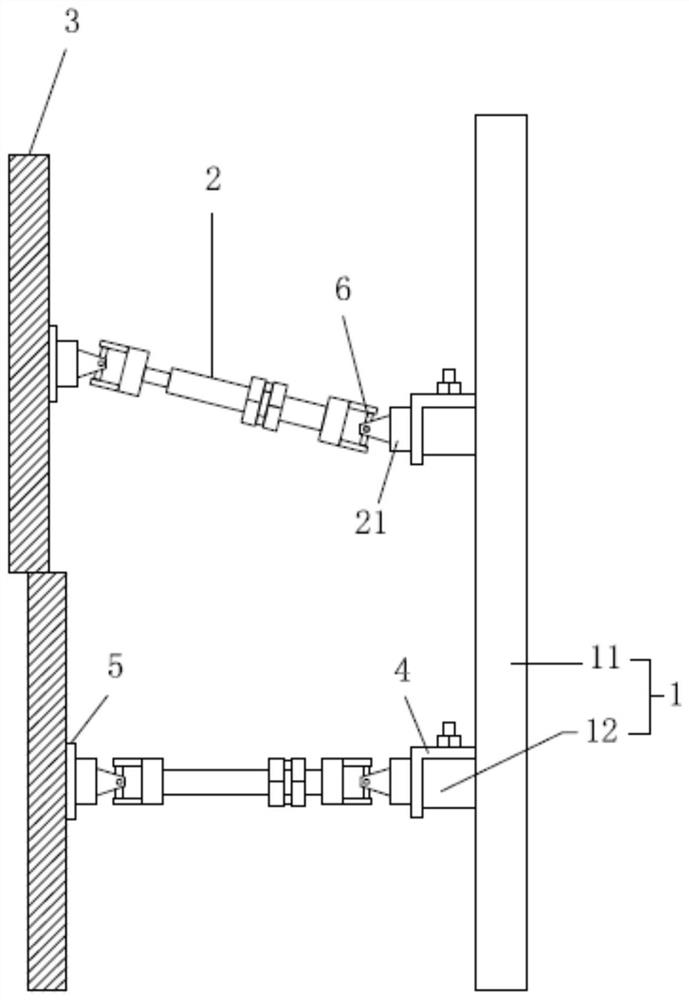

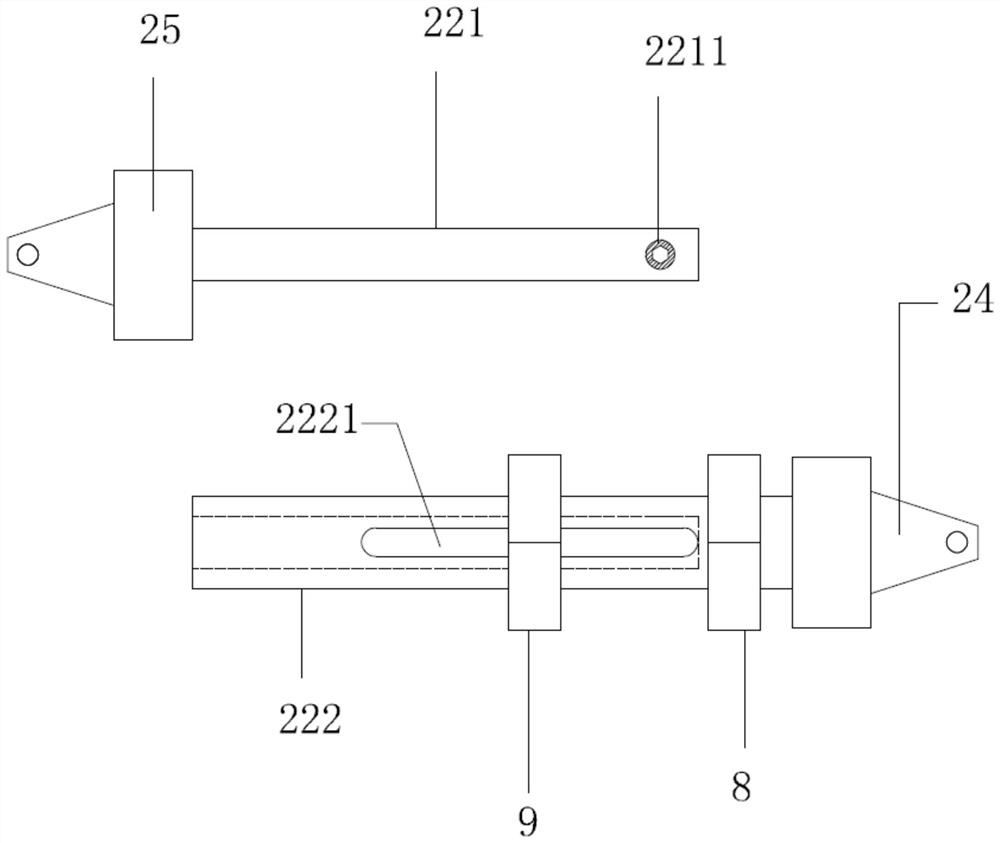

Adjustable concave-convex modeling stone curtain wall unit type design structure

PendingCN113969635AImprove installation efficiencyFlexible adjustmentCovering/liningsWallsEngineeringMechanical engineering

The invention discloses an adjustable concave-convex modeling stone curtain wall unit type design structure. The adjustable concave-convex modeling stone curtain wall unit type design structure comprises a steel framework base layer, a universal connecting piece and a stone curtain wall unit, wherein the universal connecting piece comprises a first universal fork, a telescopic rod and a second universal fork, the first universal fork is fixedly installed on the steel framework base layer through a first connecting seat, and the second universal fork is fixedly installed on the back surface of the stone curtain wall unit through a second connecting seat; a first connecting fork is arranged at one end of a telescopic rod, a second connecting fork is arranged at the other opposite end of the telescopic rod, the first connecting fork is rotationally connected with a first cross-shaped rotating shaft, and the first universal fork is rotationally connected with the first cross-shaped rotating shaft; the second connecting fork is rotationally connected with a second cross-shaped rotating shaft, and the second universal fork is rotationally connected with the second cross-shaped rotating shaft. According to the adjustable concave-convex modeling stone curtain wall unit type design structure, compared with the prior art, the installation distance between the stone curtain wall unit and the steel framework base layer during installation is flexibly adjusted, and the concave-convex modeling presentation effect of a stone curtain wall is guaranteed.

Owner:GOLD MANTIS CONSTR DECORATION

Construction method for lattice column of subway station

InactiveCN109723081AImprove structural strengthAvoid force deformationArtificial islandsUnderwater structuresButt weldingSubway station

The invention discloses a construction method for a lattice column of a subway station. The method comprises the following steps of: a, preparing the lattice column, wherein a1, arranging the latticecolumn, a2, welding a batten plate, a3, performing in-situ butt welding; b, constructing an upright column pile, wherein b1, drilling and positioning, b2, excavating to form a hole, b3, cleaning the hole and placing a steel reinforcement cage; C, constructing the lattice column, wherein c1, determining a positioning point, c2, placing the lattice column, c3, welding the lattice column and the steel reinforcement cage, c4, pouring concrete. By means of the method, the strength of the lattice column main body is guaranteed, force deformation of the lattice column main body is avoided, the installation effect of the lattice column main body is ensured, enough space for placing the lattice column and the steel reinforcement cage is provided, and the regular and horizontal arrangement of the lattice column and the reinforcement cage is ensured, the construction process of the upright column pile and the lattice column is promoted to be stable and continuous, the construction cost is reduced, and the construction efficiency is improved.

Owner:无锡快鹿地铁钢结构制造有限公司

Wall surface assembly and wall surface installing method

ActiveCN110965728AGuaranteed installation effectReasonable structureCovering/liningsWall plateEngineering

The invention discloses a wall surface assembly and a wall surface installing method. The wall surface assembly comprises a fixed base, a first movable base and a second movable base. The first movable base is arranged at the upper portion of the fixed base and can move in the horizontal direction. The second movable base is arranged at the upper portion of the first movable base and can move in the vertical direction. The second movable base is provided with a protrusion which can move in the horizontal direction and the vertical direction. The installation position of a wall plate clamped onthe protrusion can be adjusted in the horizontal direction and the vertical direction. By means of the wall surface assembly and the wall surface installing method, the structure is reasonable, construction is convenient, the transverse position and vertical position of the wall plate can be conveniently adjusted, the adjustment of the installation position of the wall plate is realized, the installing effect of the wall plate is ensured, and good promotion value is obtained.

Owner:福建省顺安建筑工程有限公司

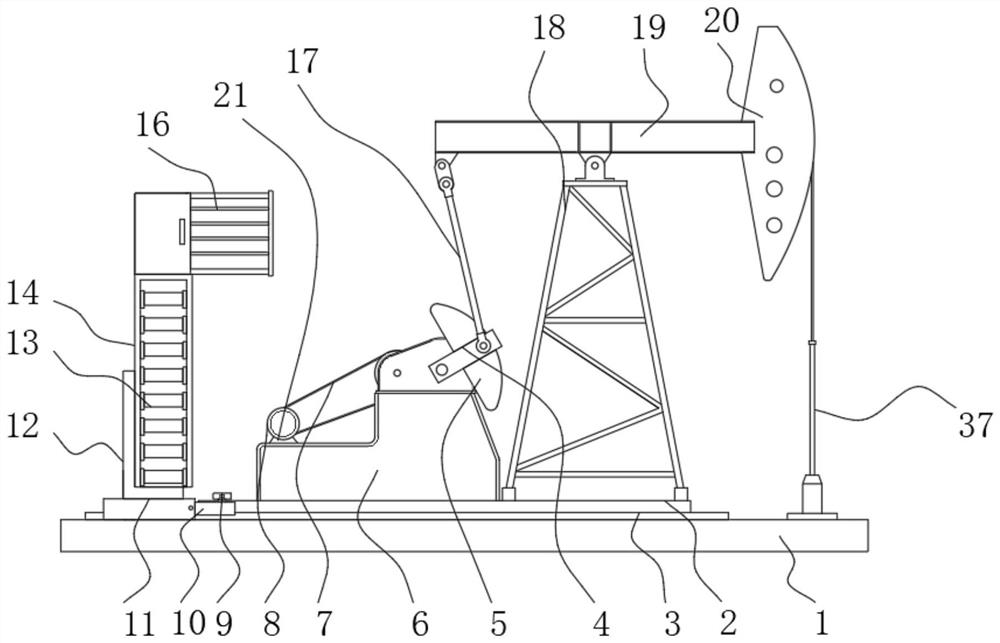

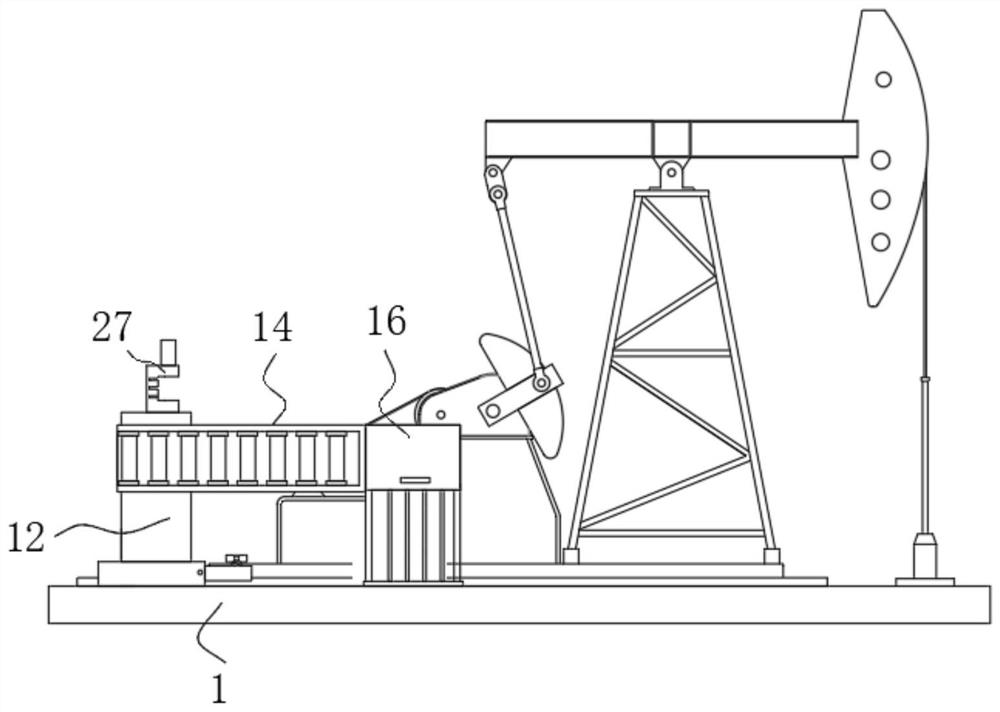

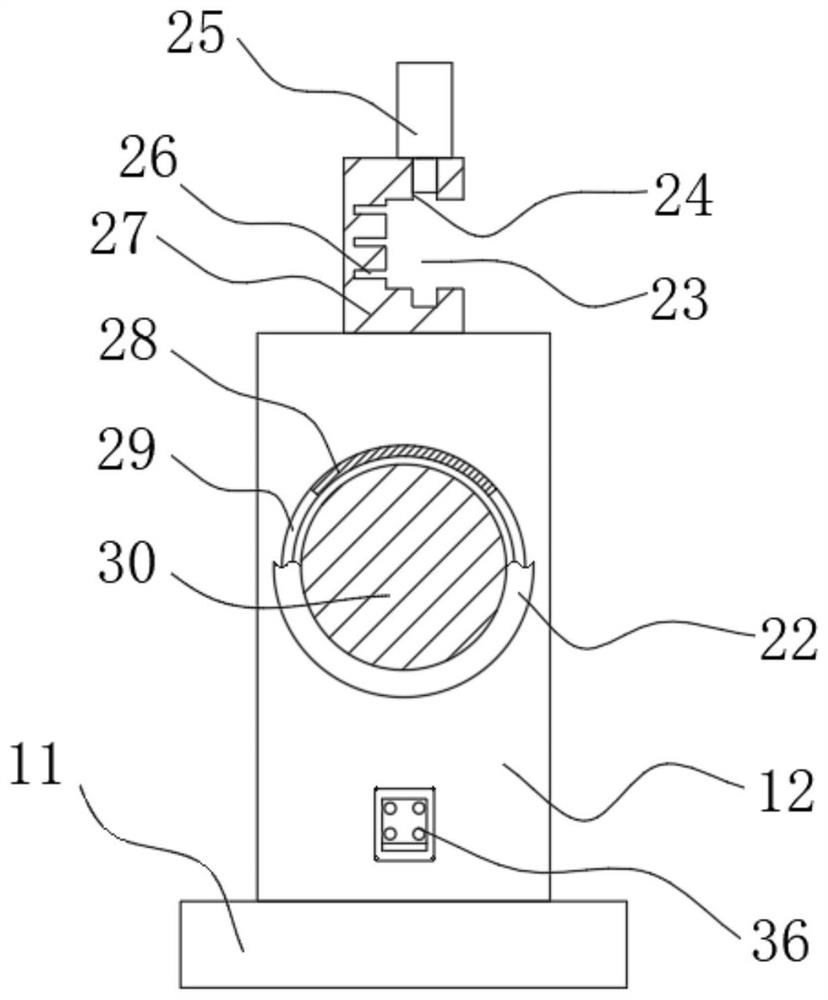

Oil exploitation device

InactiveCN111963110AGuaranteed installation effectAvoid injuryConstructionsFluid removalCrankMechanical engineering

The invention discloses an oil exploitation device. The oil exploitation device is characterized in that a fixing plate is welded to the top of a base, a support is fixedly connected with one side ofthe fixing plate, a walking beam is hinged to the top of the support, a horsehead is fixedly connected with one side of the walking beam, a sucker rod is arranged inside the horsehead, and a connecting rod is hinged to the side, away from the horsehead, of the walking beam; a crank is hinged to one end of the connecting rod, so that one side of an overhaul platform is attached to the top of the base, a support is formed between the overhaul platform and the first shell, and the two sides of the oil extraction device are effectively protected among a frame body, stair steps and the overhaul platform in the transverse direction; and the frame body is moved towards the crank, the accident that people are hurt by the rotating part of the crank is avoided, and the oil extraction safety is ensured. Through cooperation of first sliding blocks, U-shaped sliding rails, the frame body, the stair steps and the overhaul platform, the overhaul platform is moved to the position needing to be overhauled or repaired, and through the overhaul platform, potential safety hazards existing in workers during maintenance are avoided.

Owner:魏洪

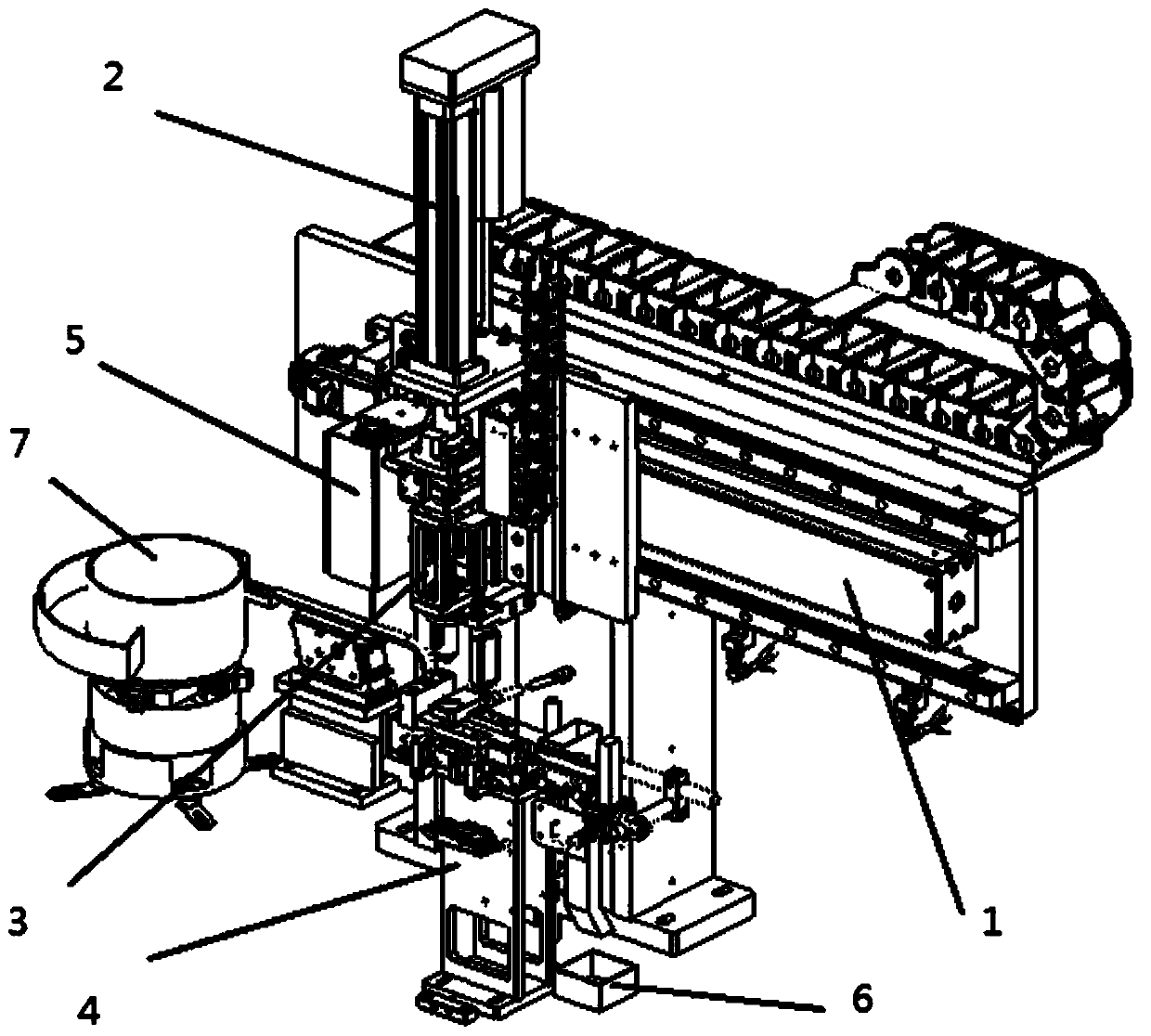

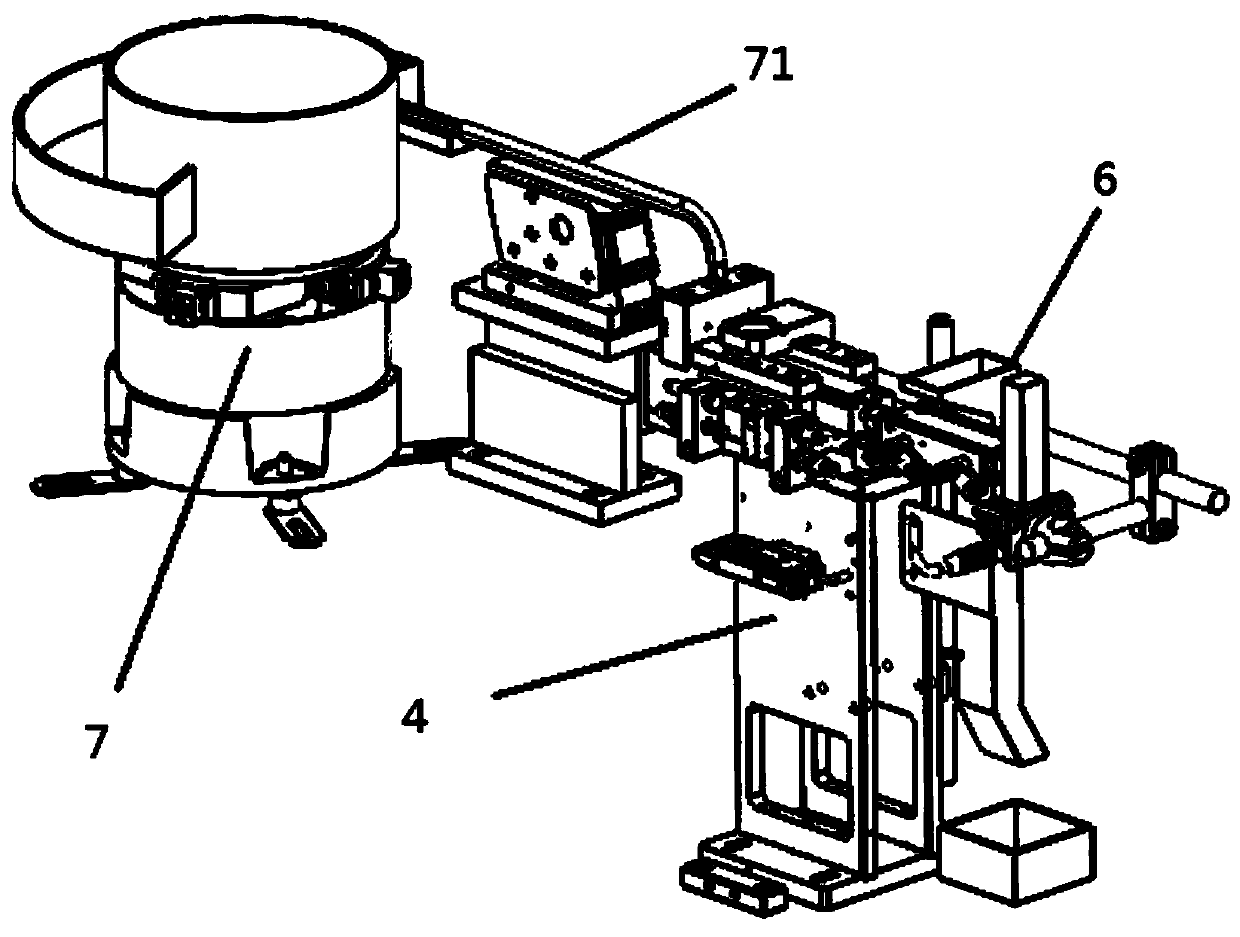

Automatic assembly device for clamping spring

ActiveCN110640418AGuaranteed installation effectQuick RetrievalMetal working apparatusControl engineeringControl theory

The invention discloses an automatic assembly device for a clamping spring. The automatic assembly device for the clamping spring comprises an X-axis moving module, a Z-axis moving module and a material taking module, the Z-axis moving module is connected to the X-axis moving module, and the material taking module is connected to the Z-axis moving module; the material taking module includes a power unit, a material taking shaft and a guide sleeve, the material taking shaft is connected to the output end of the power unit, the guide sleeve is connected with the power unit, and the power unit works to drive the material taking shaft to extend and retract in the guide sleeve; and the X-axis moving module and the Z-axis moving module move to drive the material taking module to move to a material taking position, the material taking shaft is extended to take the clamping spring, and the X-axis moving module and the Z-axis moving module move, so that the material taking module moves to a mounting position, the material taking shaft retracts, and the Z-axis moving module is descended to mount the clamping spring. According to the automatic assembly device for the clamping spring, materialtaking can be quickly performed, during mounting, the clamping spring is mounted by the combined action of the retracting of the material taking shaft and the descending of the Z-axis moving module,the mounting effect of the clamping spring is ensured, and the efficiency is improved.

Owner:卓越(昆山)自动化技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com