Ceiling plate splicing structure of fabricated ceiling

A ceiling panel and assembly technology, which is applied in the direction of ceiling, building components, building structures, etc., can solve the problems of high processing difficulty of plate reinforcements, unfavorable maintenance and upgrading, etc., so as to facilitate transformation and reuse, avoid plate edge deformation, Easy to improve the effect of the upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

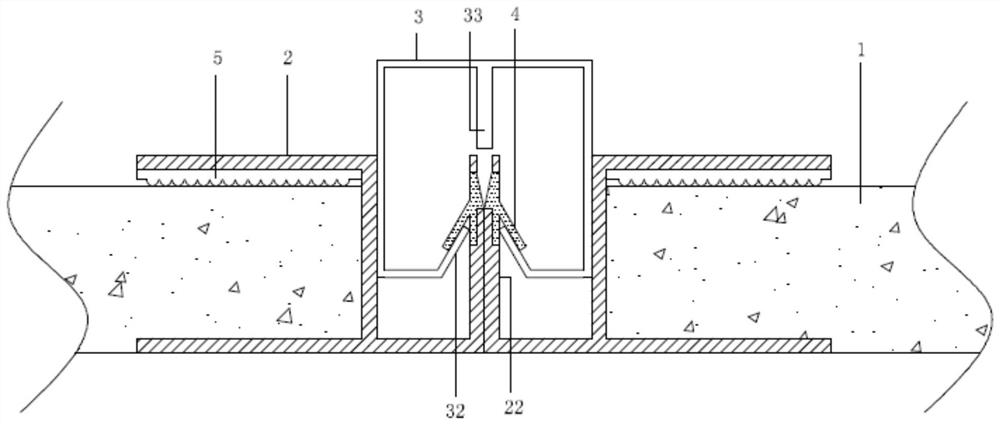

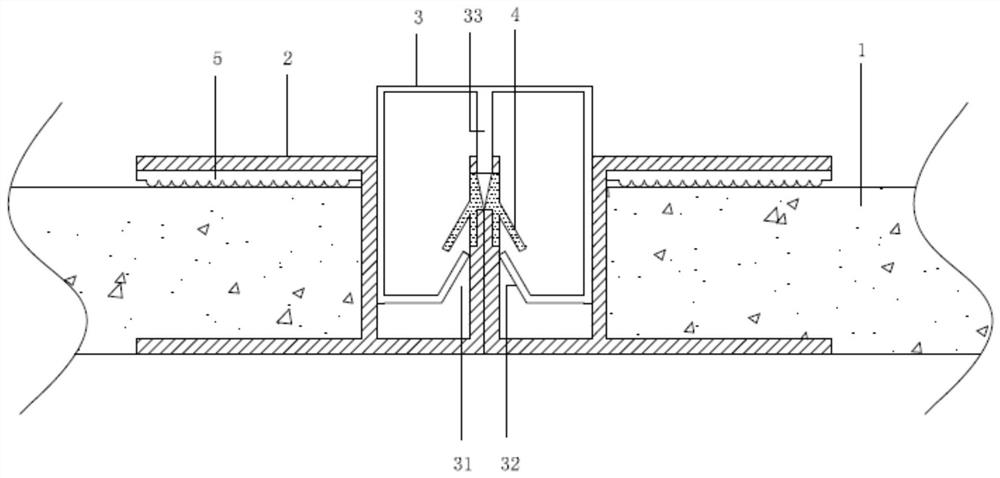

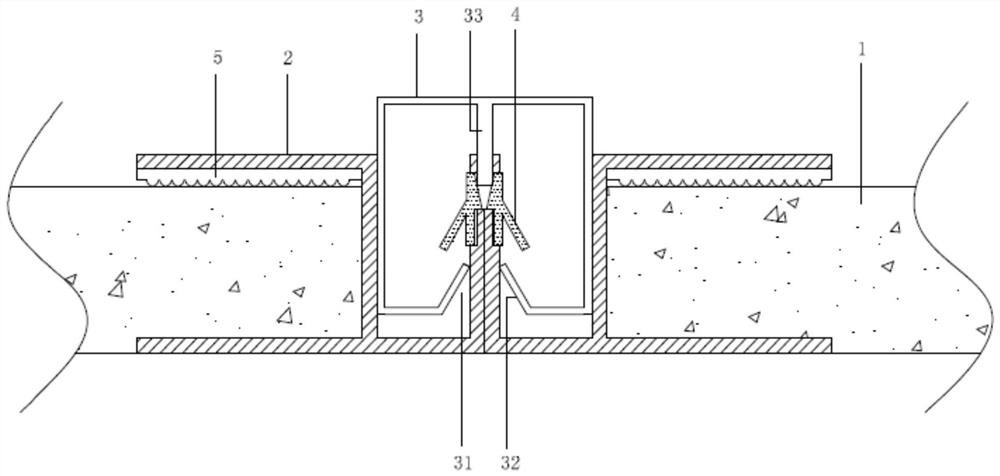

[0026] see Figure 1 to Figure 7 , the figure shows a ceiling panel splicing structure of a prefabricated suspended ceiling provided by Embodiment 1 of the present invention, including a ceiling panel 1, a panel reinforcement 2 and a articulated keel 3, and the panel reinforcement 2 includes a mounting part 21 and a articulated plate 22, the two opposite sides of the ceiling plate 1 are clamped in the installation part 21, the articulated plate 22 is fastened in the buckle groove 31 at the bottom of the articulated keel 3, and the articulated plate 22 is provided with at least one buckle Part 4, the buckle part 4 includes a mounting plate 41 and a clamping plate 42, the mounting plate 41 is clamped in the mounting hole 221 on the hitch plate 22, and the clamping plate 42 is hooked on the shrapnel 32 of the hitch keel 3.

[0027] Specifically, see Figure 1 to Figure 7 , the hooking plate 22 is provided with a plurality of buckling parts 4 arranged in parallel along its length...

Embodiment 2

[0031] see Figure 1 to Figure 7 , the figure shows the splicing structure of a prefabricated suspended ceiling provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: articulated plate 22 is provided with a first stepped surface 222 on the back, and a bump 43 is provided on the back of the mounting plate 41. The section of the bump 43 is triangular, and the width of the bump 43 gradually increases from top to bottom, and the bottom surface 431 of the bump 43 is snapped on On the first step surface 222, the ejection plate 33 corresponding to the first step surface 222 is arranged in the articulated keel 3; the width of the first step surface 222 is equal to 1 / 2 of the width of the ejection plate 33; the bottom surface 431 of the protrusion 43 The thickness is greater than the thickness of the mounting plate 41.

[0032] In order to further facilitate the reuse and...

Embodiment 3

[0034] see Figure 1 to Figure 7 , the figure shows a splicing structure of a prefabricated suspended ceiling provided by Embodiment 3 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: ceiling board 1 The bottom is provided with a second stepped surface 11 , and the second stepped surface 11 is clamped on the bottom plate of the installation part 21 .

[0035] The second stepped surface at the bottom of the ceiling board is clamped to the bottom plate of the installation part, so that the finished surface formed by the final splicing is flat and the decorative effect is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com