Construction method for lattice column of subway station

A construction method and lattice column technology, which can be used in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems affecting the construction progress of subway stations, the construction performance of lattice columns, and the easy inclination of lattice columns. The overall structural strength is high, the construction cost is reduced, and the construction efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

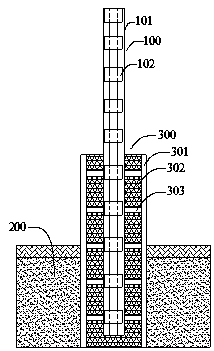

[0035] A construction method for a lattice column in a subway station, comprising the following preparation steps: preparation of a lattice column 100, construction of a column pile 200 and construction of the lattice column.

[0036] Wherein the lattice column 100 includes four angle steels 101 and a plurality of panels 102, and the preparation of the lattice column includes the following steps:

[0037] a1. Arrangement of lattice columns 100: Four angle steels 101 are symmetrically arranged in pairs to form a columnar structure with a rectangular cross section. A plurality of decorative plates 102 are arranged at intervals from the top to the bottom of the columnar structure to form the main body of the lattice column. The contact area between the panel 102 on the column and the angle steel 101 is at least half of the area of the panel.

[0038] a2. Welding patch 102: Weld the patch 102 along the bottom of the columnar structure to the top, and the distance between the las...

Embodiment 2

[0057] A construction method for a lattice column in a subway station, comprising the following preparation steps: preparation of a lattice column 100, construction of a column pile 200 and construction of the lattice column.

[0058] Wherein the lattice column 100 includes four angle steels 101 and a plurality of panels 102, and the preparation of the lattice column includes the following steps:

[0059] a1. Arrangement of lattice columns 100: Four angle steels 101 are symmetrically arranged in pairs to form a columnar structure with a rectangular cross section. A plurality of decorative plates 102 are arranged at intervals from the top to the bottom of the columnar structure to form the main body of the lattice column. The contact area between the panel 102 on the column and the angle steel 101 is at least half of the area of the panel.

[0060] a2. Welding patch 102: Weld the patch 102 along the bottom of the columnar structure to the top, and the distance between the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com