Mounting and fixing device of pipe gallery deformation joint water-stop belt and construction method

A fixing device and waterstop technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the hidden danger of water seepage, the offset of the buried waterstop, and affect the waterstop effect of the waterproof structure at the deformation joint, etc. problem, to prevent deviation and ensure the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

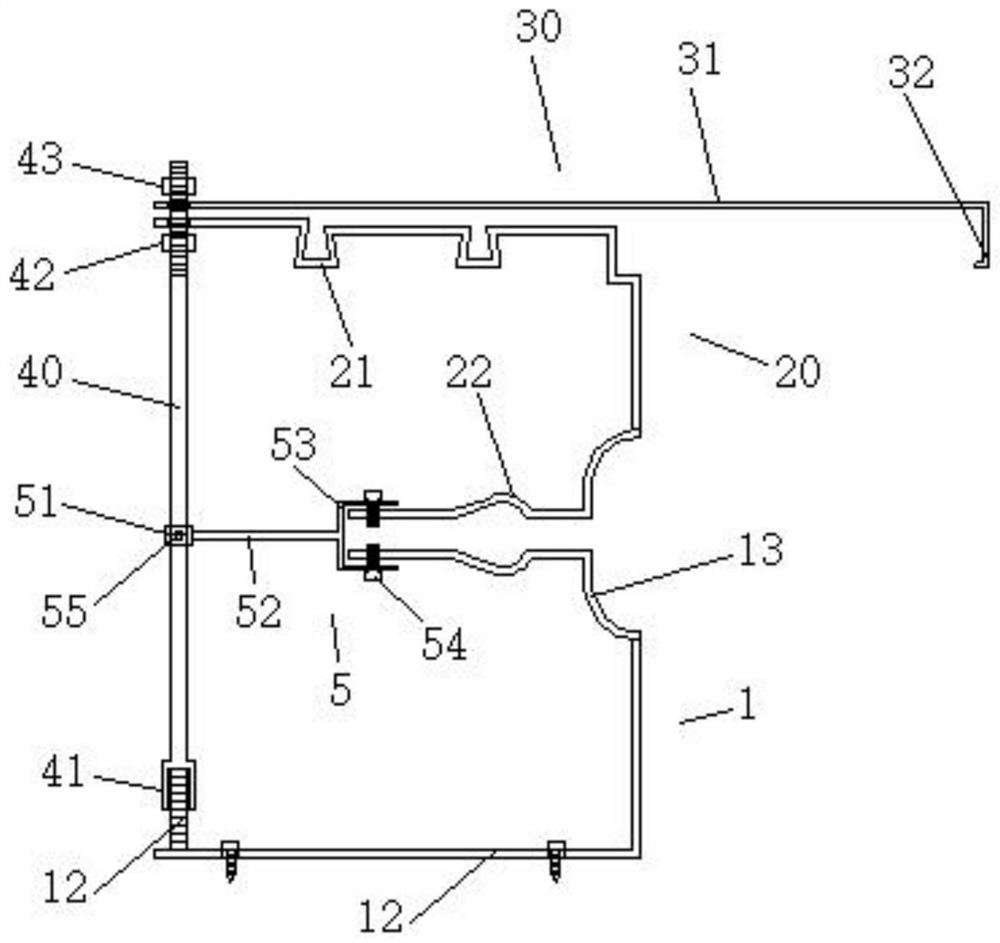

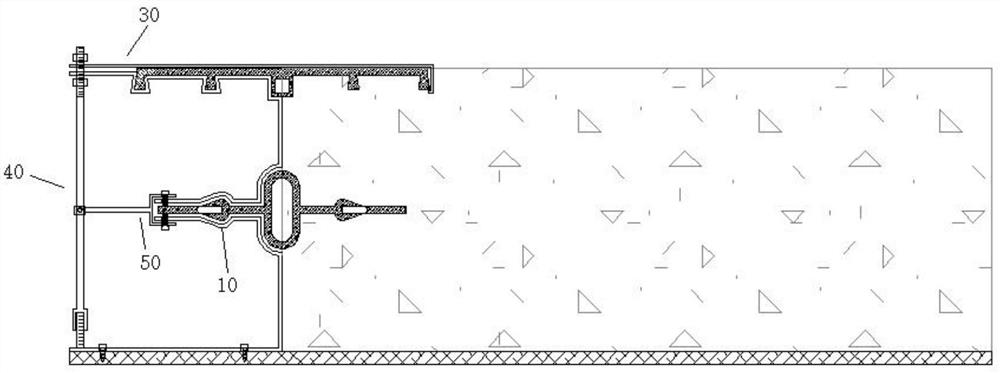

[0036] refer to figure 1 and figure 2 As shown, a pipe gallery deformation joint waterstop installation and fixing device, including the lower bearing frame 10, the upper bearing frame 20, the pressure bracket 30, the support 40 and the bearing bracket 50, the lower bearing frame 10, the upper bearing frame 20 The pressure bracket 30 is arranged sequentially from bottom to top. The lower bracket 10 and the upper bracket 20 are arranged opposite to each other to limit the position of the buried waterstop. The pressure bracket 30 is used to limit the position of the back-mounted waterstop. Floating up, one end of the support 40 is detachably connected to the lower bracket 10, and the other end is detachably connected to the upper bracket 20 and the pressure bracket 30 in turn, and the bracket 50 is located between the lower bracket 10 and the upper bracket 20, The bearing bracket 50 is installed on the supporting member 40 and is used for connecting the lower bracket 10 and th...

Embodiment 2

[0044] A construction method for installing a fixing device for a pipe gallery deformation joint waterstop, comprising the following steps:

[0045] A. Pipe gallery structure formwork installation

[0046] During the installation and construction of the concrete structure formwork of the pipe gallery, the bottom formwork picks out 400mm-500mm outside the deformation joint, and uses the ink fountain to pop out the center line and side line of the deformation joint on the Moban;

[0047] B. Installation of the lower bracket 10

[0048] Install on the outside of the corner of the L-shaped base 11 along the center line of the deformation joint, and fix the installation with screws and the bottom template;

[0049] C. Install the support 40 and the bracket 50

[0050] The bottom of the support member 40 is matched and connected with the screw rod 12 through the sleeve one 41, and the sleeve two 51 is sleeved on the outside of the support member 40, and the sleeve two 51 is locked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com