Rotary spray arm installing structure for water tank type cleaning machine

A sink-type washing machine and rotating spray arm technology, which is applied in the field of washing machines, can solve problems such as poor reliability and stability, falling off of the rotating spray arm, and unstable rotation speed, so as to achieve good reliability and stability and ensure the installation effect , Good maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

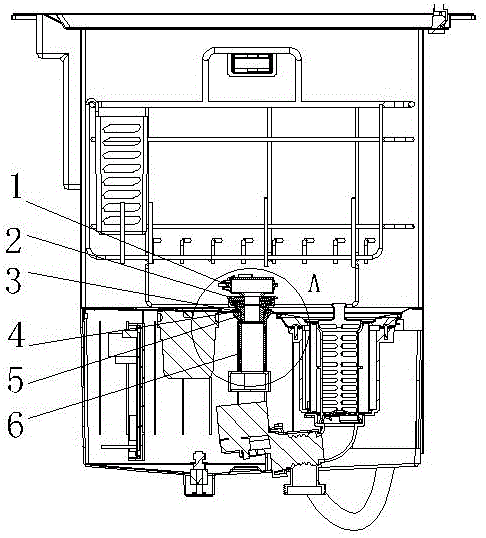

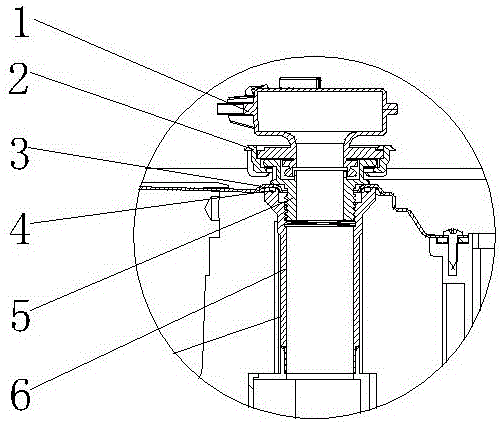

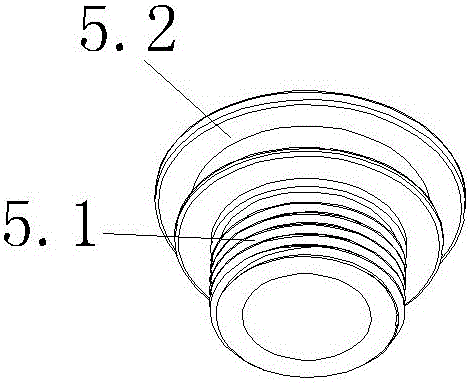

[0018] Such as Figure 1-10 As shown, a rotating spray arm installation structure for a sink type washing machine includes a rotating spray arm 1 arranged at the bottom of the inner cavity of the tank. The lower end of the rotating spray arm 1 is provided with a vertical shaft part 1.1, which also includes a vertical The spray arm fixing column 6 fixed on the lower part of the water tank bottom plate 3 for the spray arm installation and the spray arm mounting seat 5 for connecting with the spray arm fixing column 6, the rotating shaft part 1.1 is rotatably installed on the spray arm through the mounting nut 2 On the mounting base 5 ; the rotating shaft part 1.1 and the mounting nut 2 are relatively fixed by a limiting assembly along the circumferential direction.

[0019] A snap ring 1.1.1 is provided on the rotating shaft portion 1.1, and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com