Roofing system fixing seat and roofing system adopting same

A roof system and fixing seat technology, which is applied in the direction of flat/curved roof, roof, roof cladding, etc., can solve the effect of wind resistance is not particularly ideal, the installation process of the top and the ridge is complicated, and it is not easy to check and install Complete and other problems, to achieve the effect of improving the effect of wind resistance, simplifying the processing and forming process, and simple shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

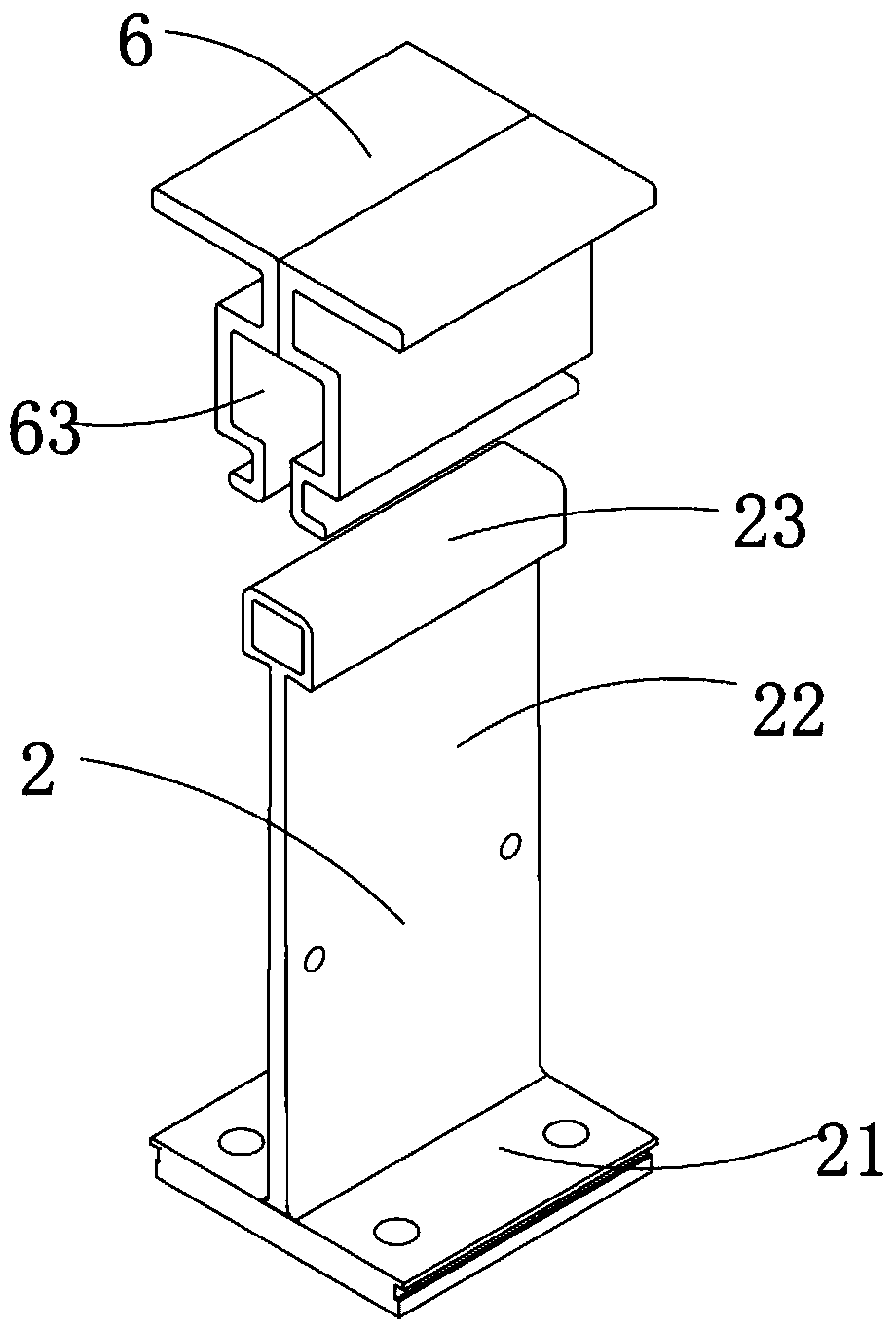

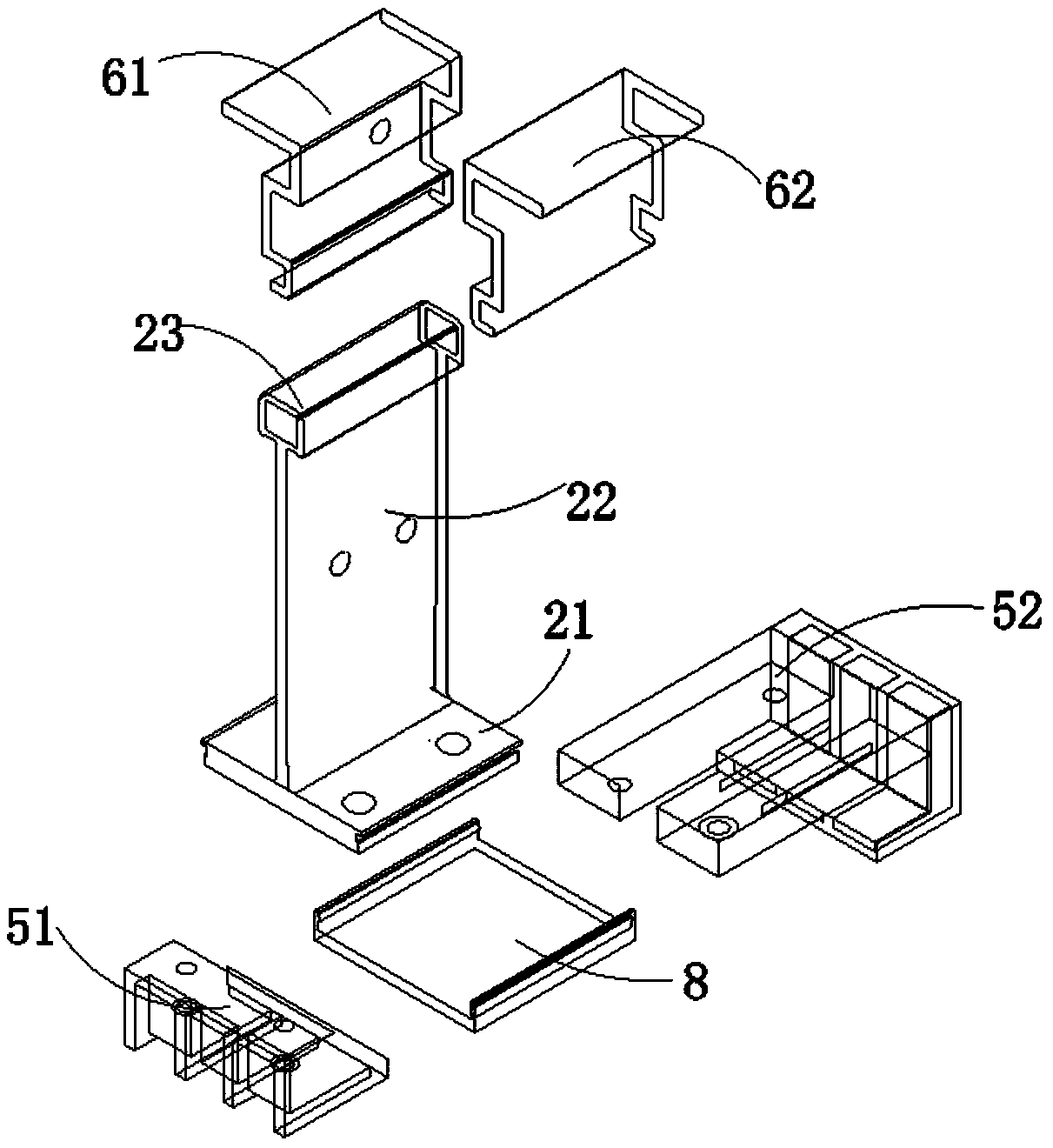

[0038] A roof system fixing seat 2 of the present invention, such as figure 1 As shown, it includes a base 21, a connecting portion 22 and a locking portion 23. The locking portion 23 is used for locking the waterproof board 3. The locking portion 23 is square, and the four folded edges of the square locking portion 23 are arc-shaped. The locking portion 23 The outer side of the joint with the connecting portion 22 is smoothed. The base 21 , the connecting portion 22 and the locking portion 23 are integrally formed.

[0039] Setting the locking part of the fixing seat in a square shape can increase the contact area between the locking part and the waterproof board, and the force-bearing area increases, thereby improving the wind resistance of the waterproof board; at the same time, the square structure is better than the plum blossom head in the prior art The structure is easier to process and shape; and it is more convenient and fast in the process of seaming the waterproof ...

Embodiment 2

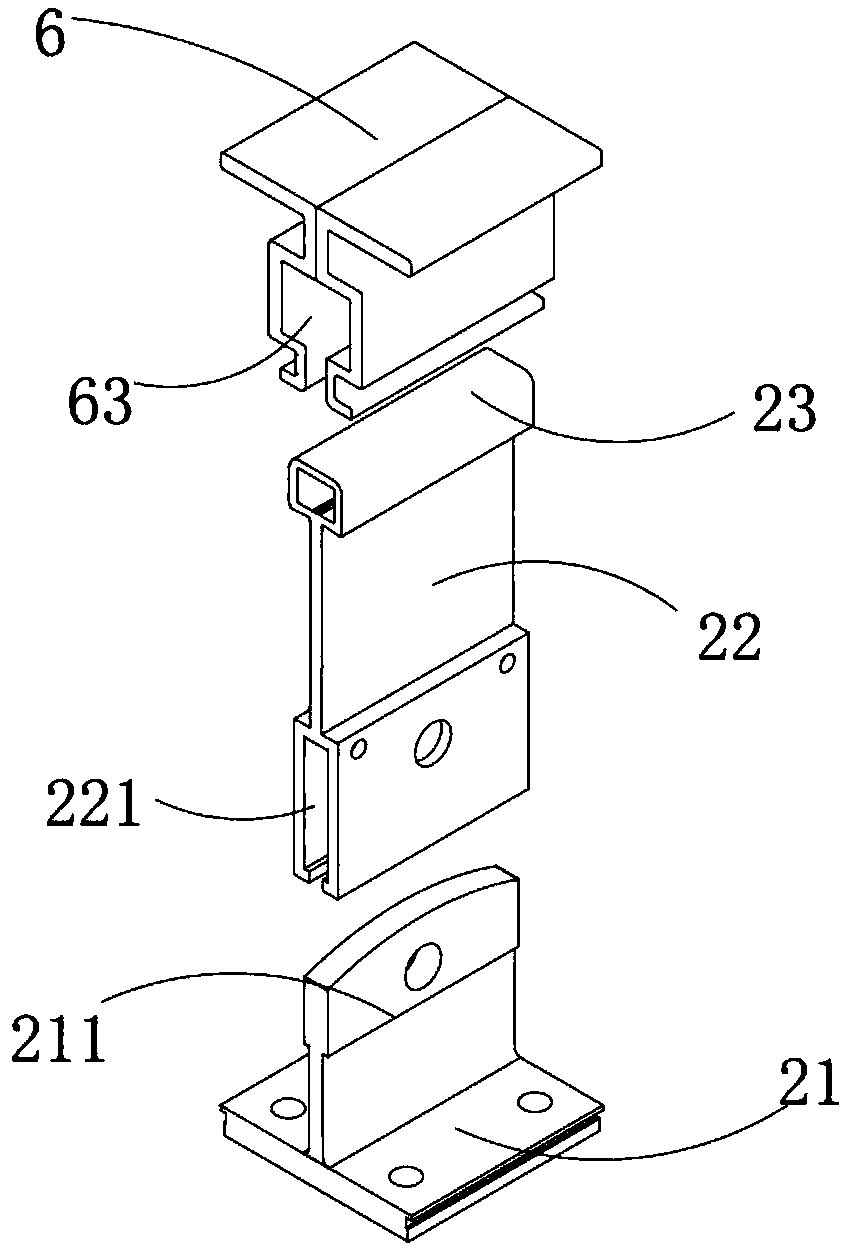

[0048] The difference between embodiment 2 and embodiment 1 is:

[0049] As shown in the figure, the locking part 23 and the connecting part 22 of the fixed seat 2 are integrally formed, the connecting part 22 extends downwards with a connecting opening 221, and the base extends upwards with a connecting block 211 that can be inserted into the opening, and the connecting opening 221 and the connecting block 211 is provided with a matching screw hole, and the connection block 211 and the connection opening 221 pass through the screw hole and are rotatably connected by a screw. Through the rotatable connection between the connecting part and the base, it is beneficial to prevent the waterproof board from being deformed due to thermal expansion and contraction, etc., causing problems such as uneven stress and other potential safety hazards.

Embodiment 3

[0051] The difference between embodiment 3 and embodiment 1 is:

[0052] As shown in the figure, the base 21 is fixed on the profiled plate 7 by bolts. According to different needs, different installation methods can be selected. It is more convenient to use bolts to fix the connection, and it can solve the problems that the self-tapping screws cantilever shake due to the thermal expansion and contraction of the roof after the self-tapping screws are installed, and the water damages the anti-board or the nailing point leaks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com