Solar automatic tracking system

An automatic tracking and solar energy technology, which is applied in the field of solar power generation, can solve the problems that the distance between the racks cannot be too large, it cannot be used for installation, and the solar strings are open, so as to enhance safety and adaptability, and improve the wind resistance of the hardware , Improve the effect of tracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

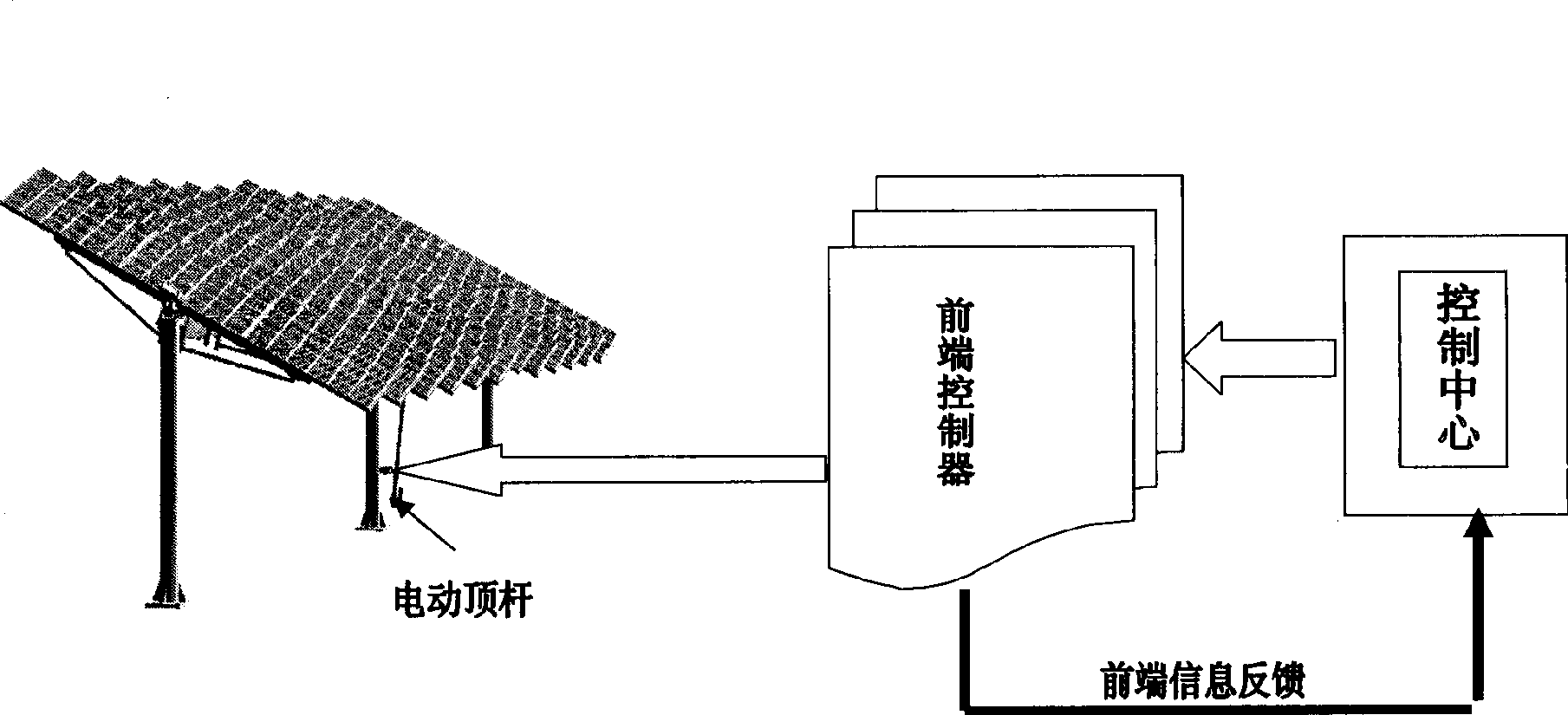

[0068] The control system is composed of control circuit, tracking control module and so on.

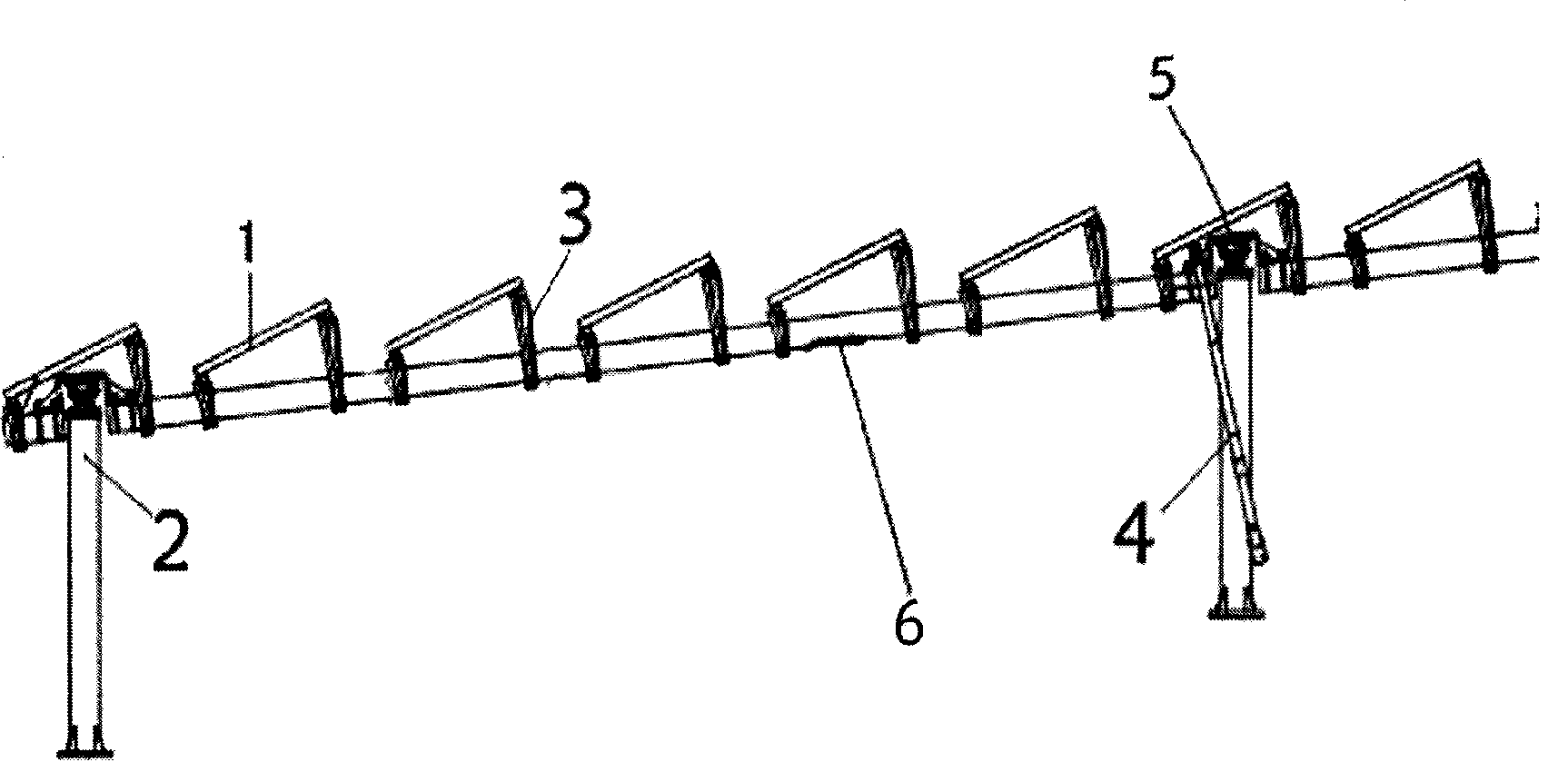

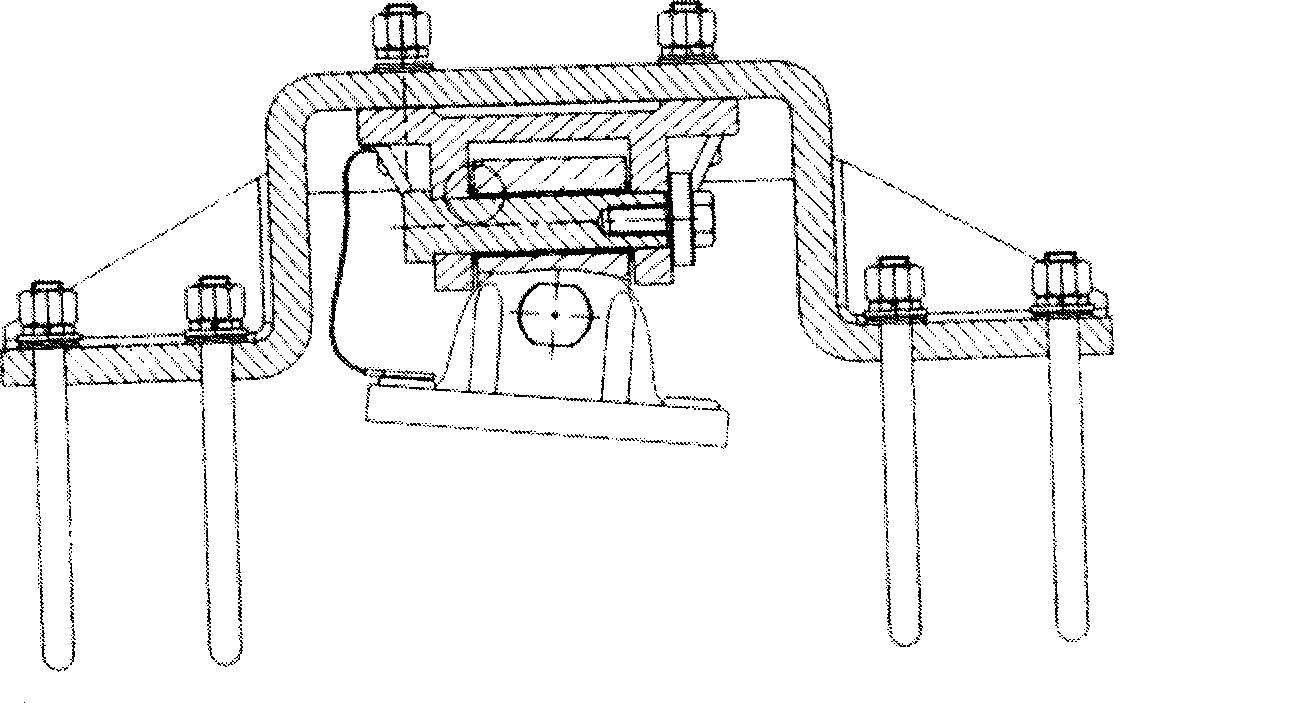

[0069] Among them, the control circuit is composed of a control center, a partition controller, a front-end controller, and an electric ejector rod. The control center is the brain of the entire solar automatic tracking system, which can display the real-time status of all solar matrix racks in the entire control area in real time. Including: running posture, real-time angle of the current battery panel, the state of the sun (illuminance), sunrise and sunset time of the day, working status of each hardware device of the control system, etc. According to the astronomical information obtained from the database, the attitude control data of solar panels in different seasons in spring, summer, autumn and winter can be formulated, and sent to each control front end to implement automatic tracking control. Its partition controller plays a linking role in the control system. The master co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com