Load management auxiliary power system

a technology of auxiliary power system and load management, which is applied in the direction of transportation and packaging, light and heating equipment, laminated elements, etc., can solve the problems of insufficient area, increased normal maintenance costs of the truck engine and its associated system, and staggering fossil fuel waste in the trucking industry. , to achieve the effect of maximizing the load placed on the auxiliary engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

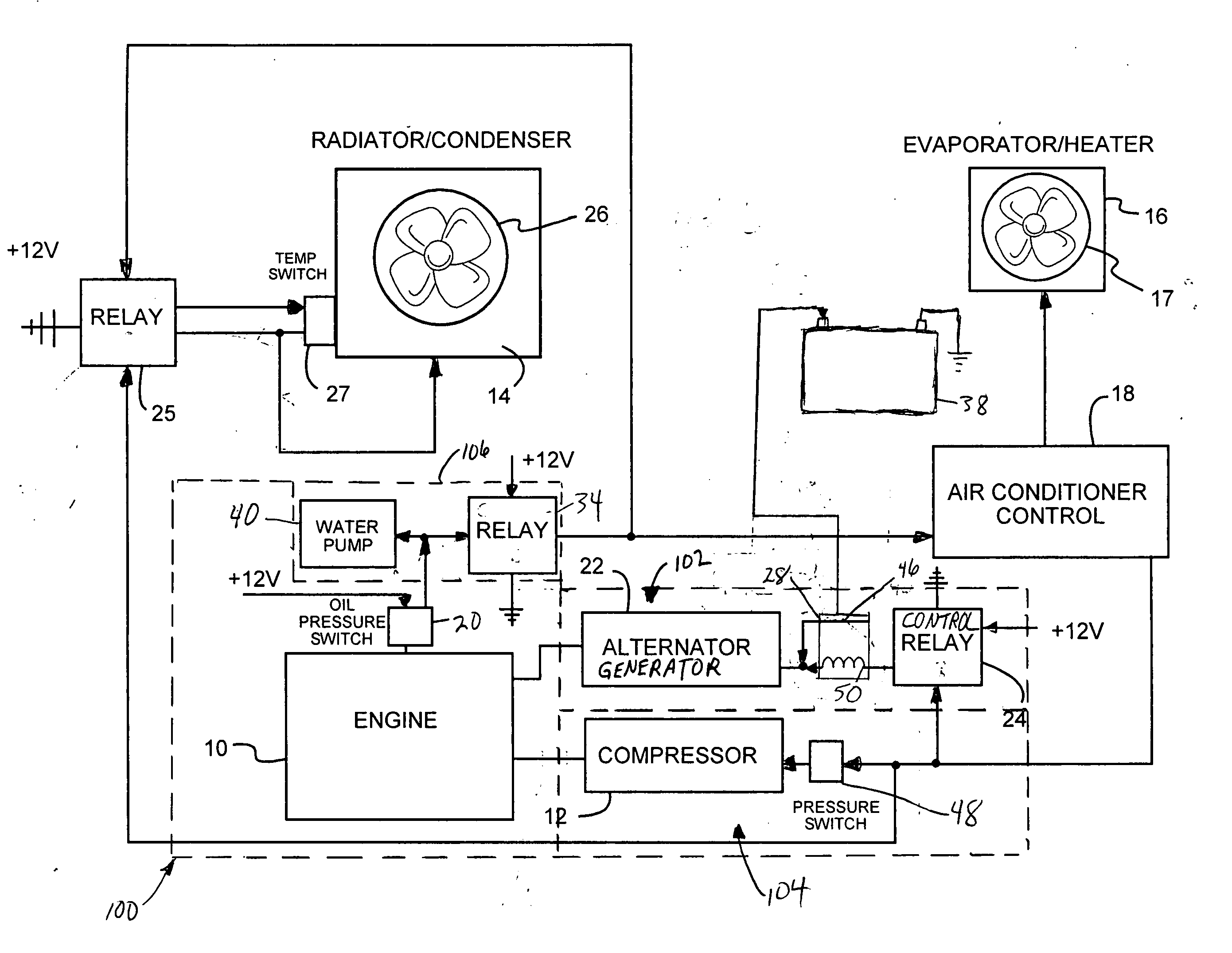

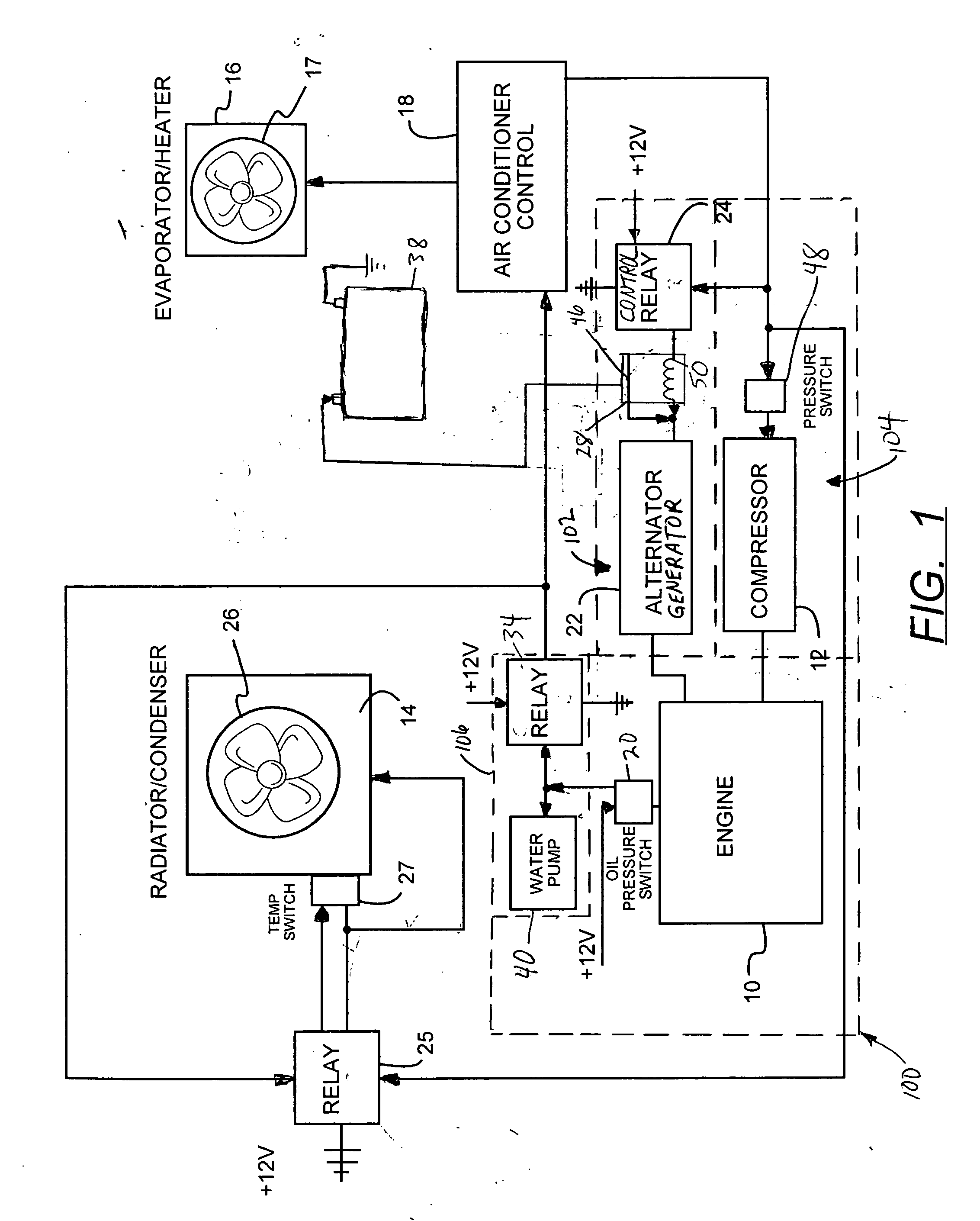

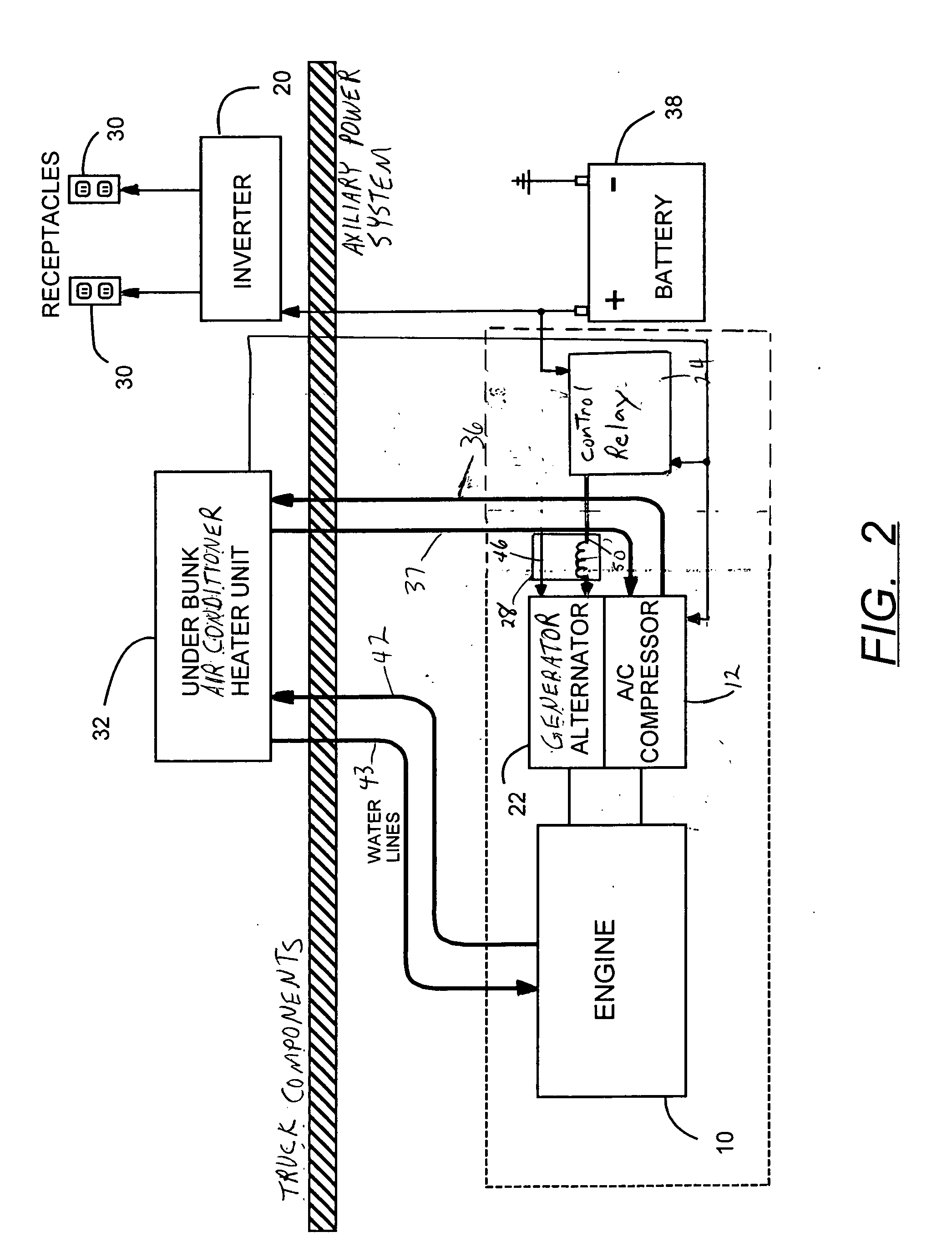

[0031] Now referring to FIG. 1, a diagrammatic representation of one embodiment of the instant invention auxiliary power system 100 is illustrated. The auxiliary power system generally includes an auxiliary engine 10 for selectively providing power to an electrical generation system 102, an air conditioning system 104, and a heating system 106. In the preferred embodiment the auxiliary engine is sized so that it is not capable of simultaneous operation of the air conditioning system and the electrical generation system to their respective full capacities. The auxiliary power system includes a unique control relay / regulator combination 24, 28 for reducing electrical power produced by the electrical generation system 102 during simultaneous operation of the air conditioning system 104. This construction and arrangement permits the size and weight of the auxiliary power system to be substantially smaller than the power systems of the prior art. The arrangement also permits the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com