Hydraulic apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

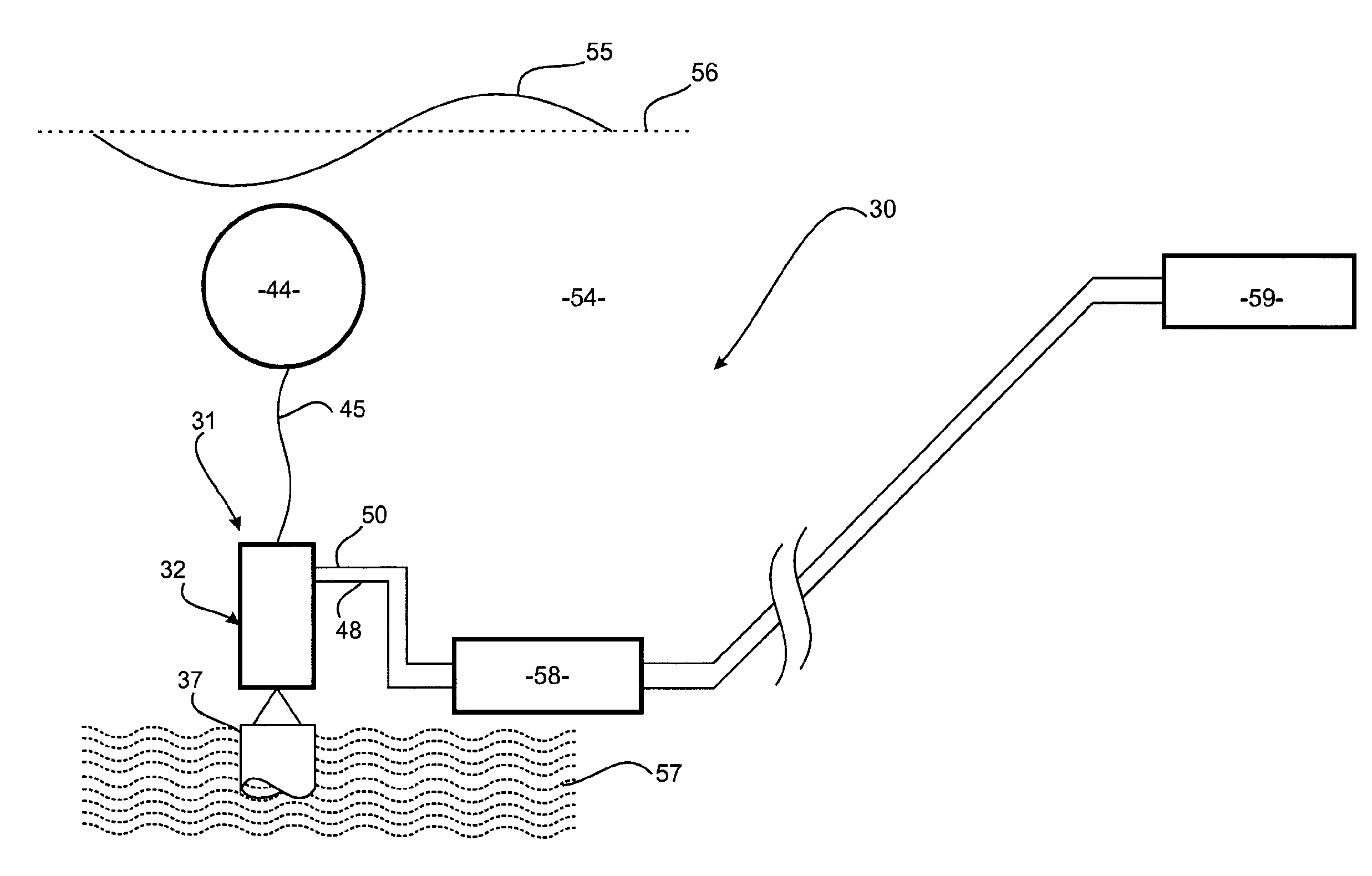

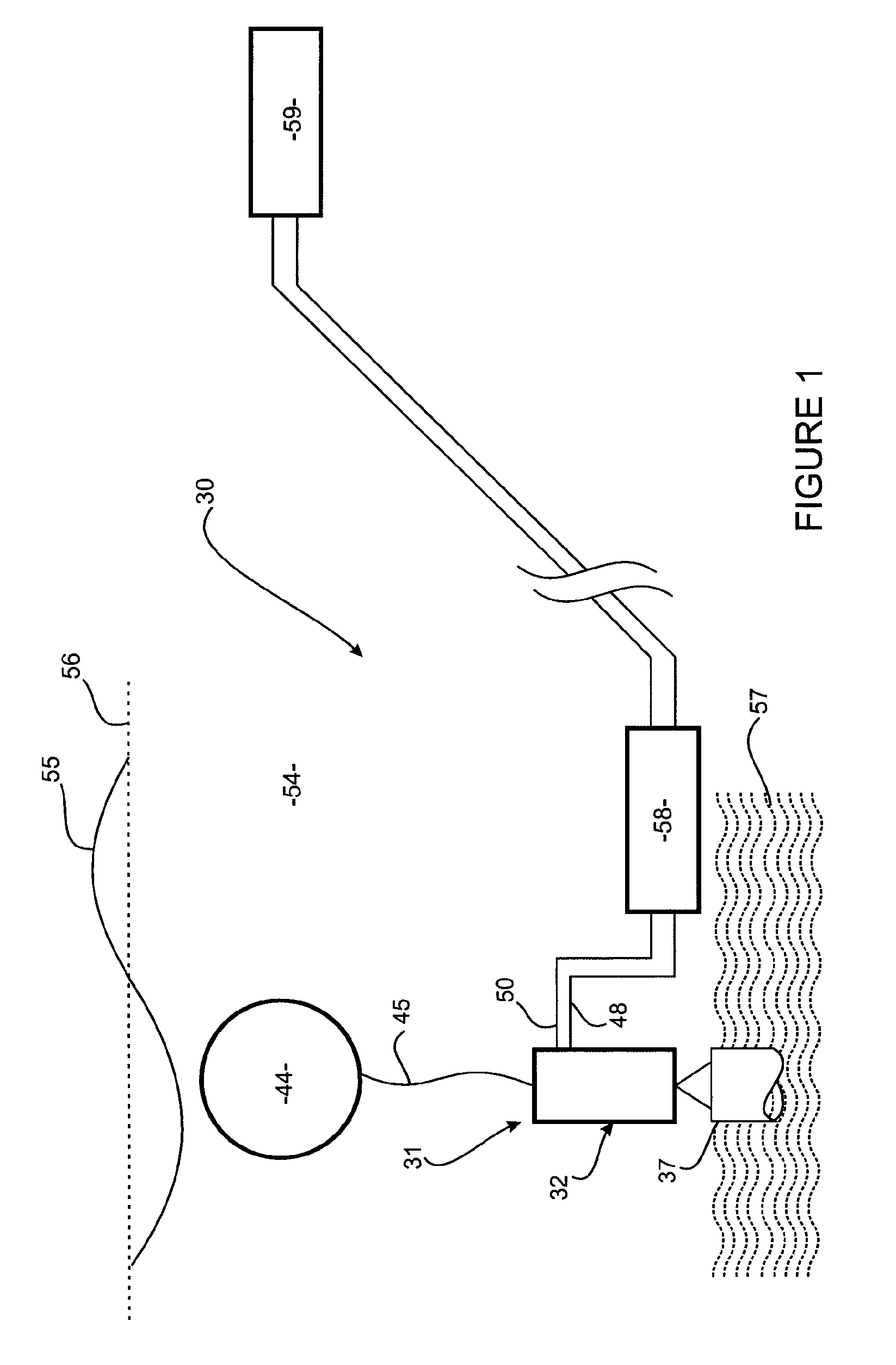

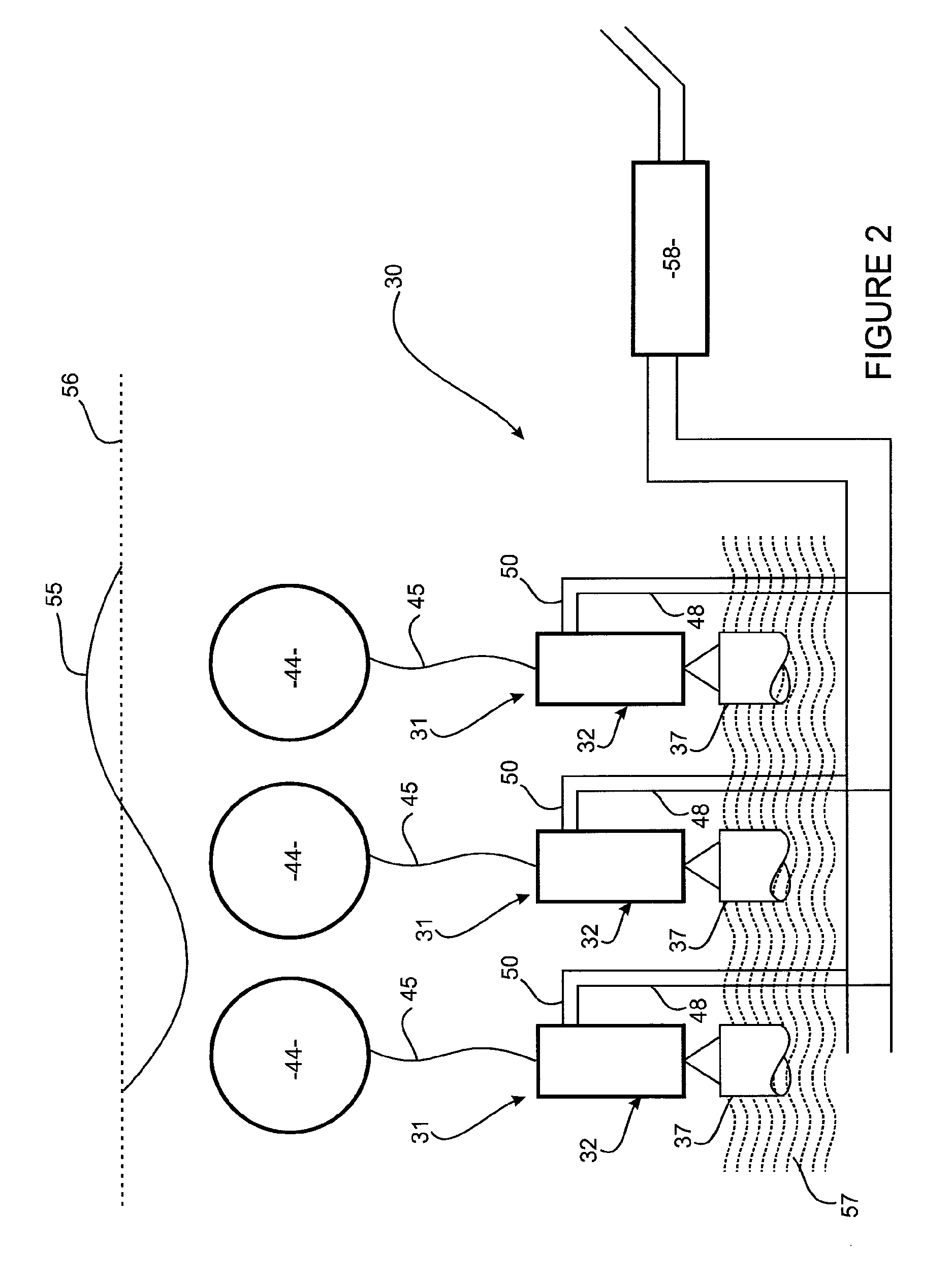

[0114]Referring to FIGS. 1 to 3, a closed loop hydraulic apparatus 30 for extracting energy from wave motion / converting wave energy includes an axial hydraulic pump 31 that includes a pump body 32 defining a chamber 33. The pump body 32 includes a side wall 34 having an upper end which is closed by a top, wall 35, and a lower end which is closed by a bottom wall 36. The bottom wall 36 is configured for attachment to a base 37.

[0115]A piston 38 is received by the chamber 33 such that the piston 38 partitions the chamber 33 into a rod or working side 39 and a blind side 40, and such that the piston 38 is able to slide back and forth within the chamber 33. A seal (not depicted) between the piston 38 and the side wall 34 inhibits fluid from flowing past the piston 38 and between the working side 39 and the blind side 40. Ideally, the working side 39 and the blind side 40 of the chamber 33 do not communicate within the pump 31 owing to the perfect sealing of the moving piston 38 with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com