Vehicle door sealing strip pasting and mounting system and pasting method

An installation system and sealing strip technology, which is applied in the field of door sealing strip pasting installation system, can solve the problems of low applicability, limited application of vehicle models, and difficulty in ensuring installation accuracy, so as to improve installation effect, reduce storage space, and improve installation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

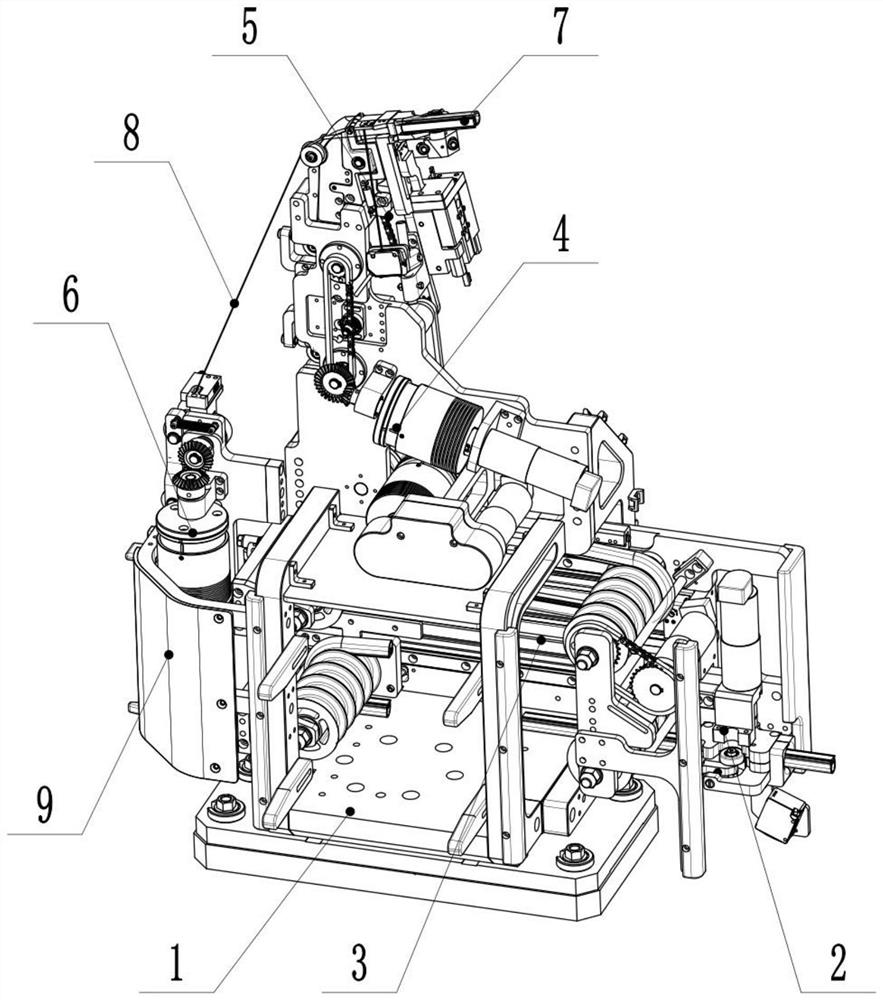

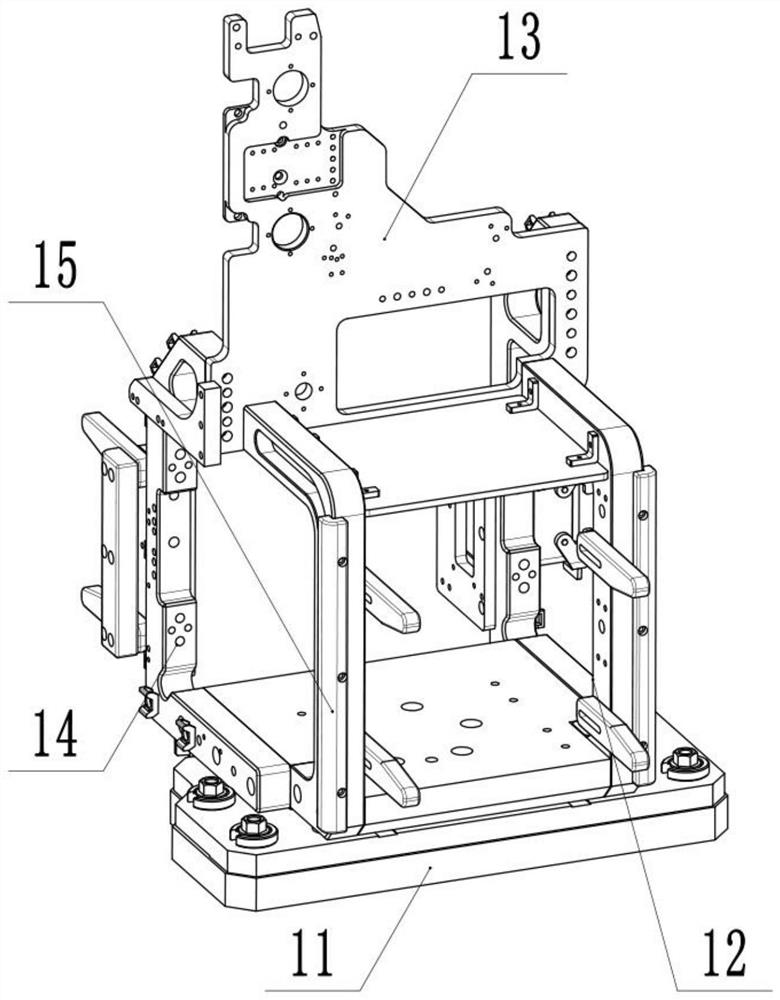

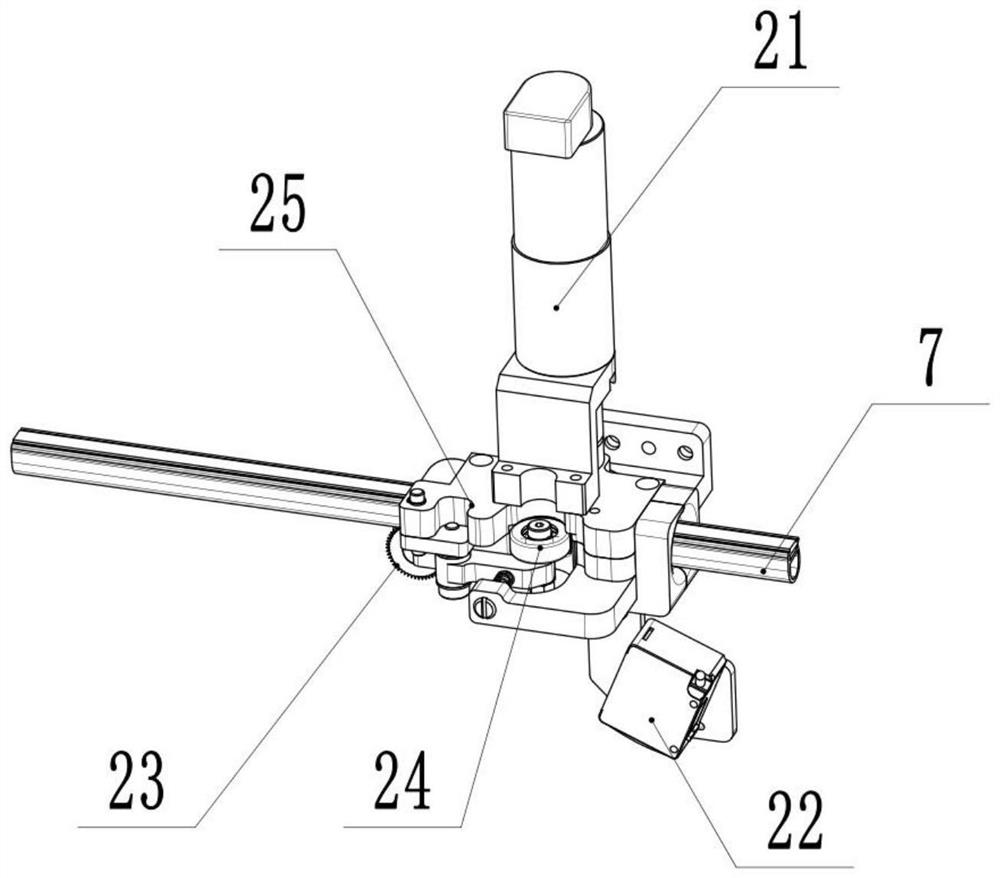

[0045] Such as Figure 1-10 A car door sealing strip sticking installation system shown is used for rolling and installing the sticky sealing strip on the car door, so as to ensure the firmness of the sticking of the weather strip and the car door and improve the installation efficiency. The discharge power device in the door sealing strip paste installation system adjusts the output distance value of the sealing profile according to the displacement value of the connecting plate unit moving relative to the car door driven by the moving device based on the car door. It is convenient to ensure that the speed at which the moving device drives the connecting plate unit to move relative to the door is equal to the speed at which the discharge unit 5 outputs the sealing profile, which is beneficial to avoid the sealing profile being stretched durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com