Plastic-steel fire resisting window

A fire-proof window and plastic-steel technology, applied in the field of windows, can solve the problems of glass fire-proof function failure, poor high-temperature resistance of plastic-steel profiles, and easy occurrence of fire hazards, saving time and manpower, and ensuring the effect of installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

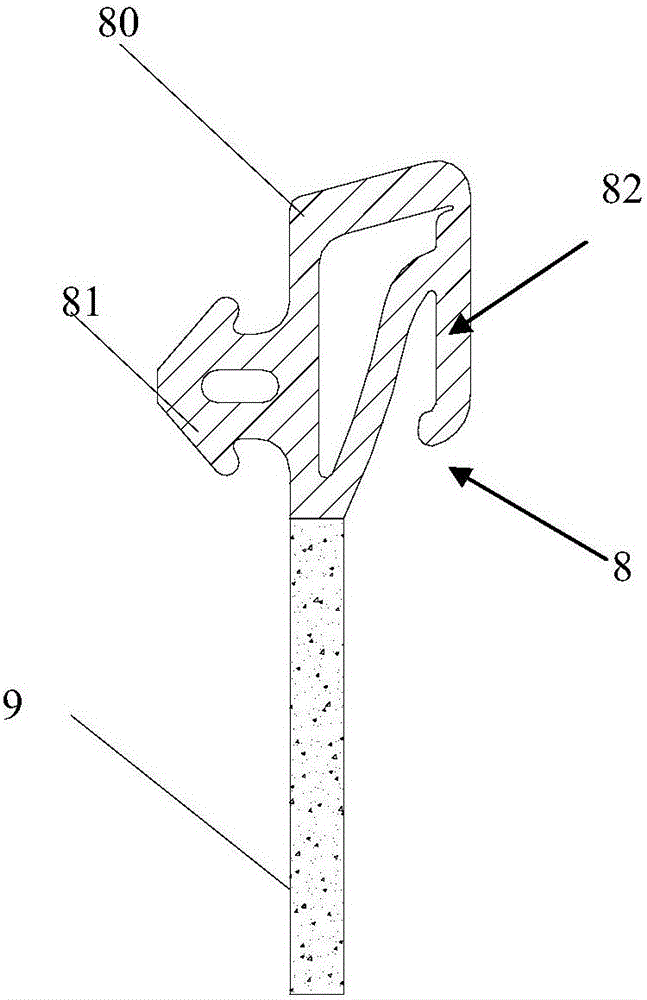

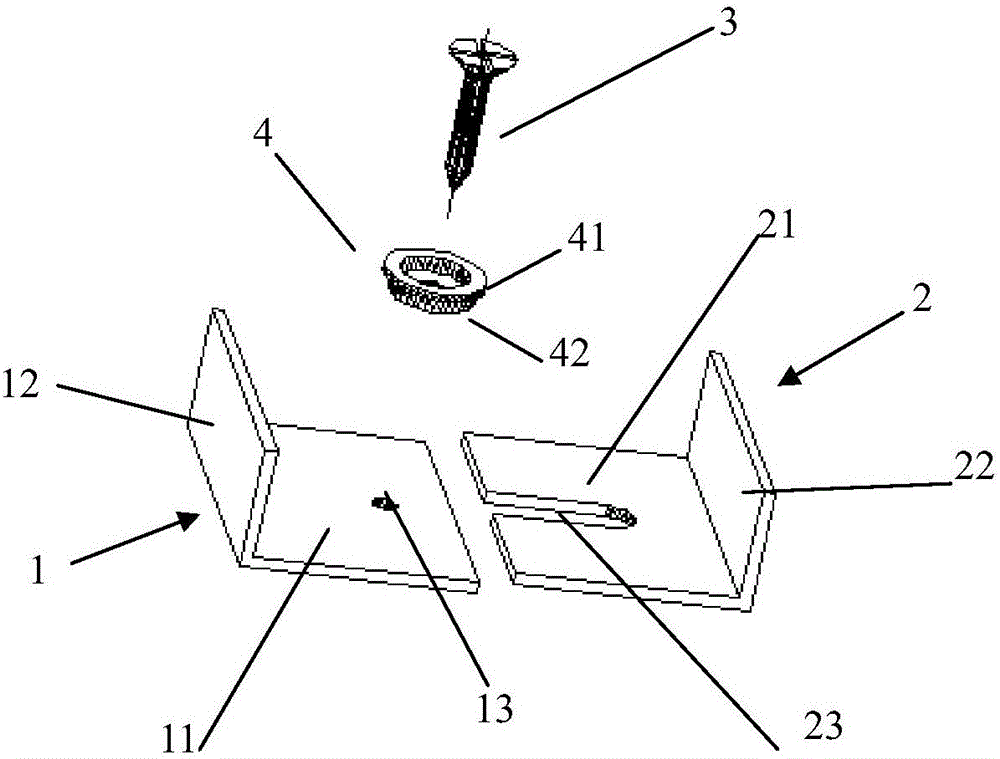

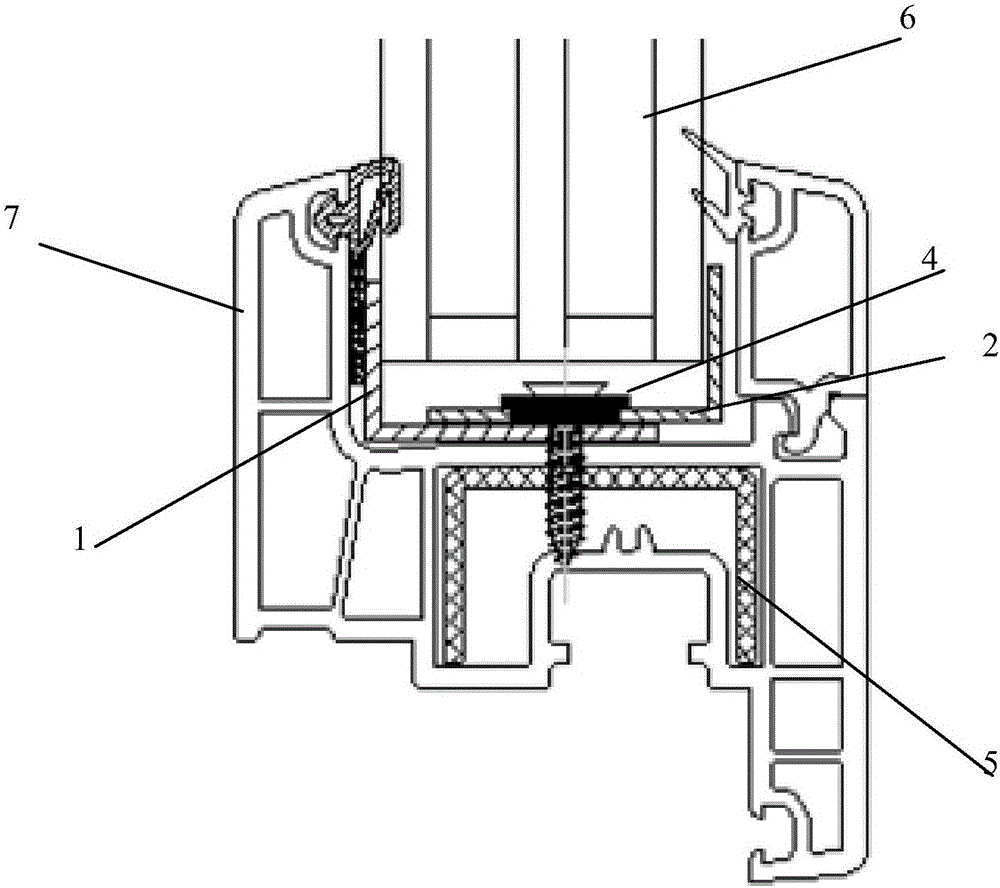

[0019] Such as Figure 1-3 As shown, the plastic-steel fireproof window of the present invention includes glass 6, a PVC profile frame 7 embedded with a steel lining 5, and at least one glass fastening device, and a sealing portion; the glass fastening device includes iron or steel L-shaped fixed plate 1, iron or steel L-shaped movable plate 2, iron or steel fixed screws 3 and iron or steel cushion cover 4, the cushion cover is a boss-shaped structure, which includes a lower cylinder body 42 and the upper positioning ring 41 that protrudes outward relative to the lower cylinder, and the fixing screw 3 passes through the perforation 13 on the horizontal part 11 of the cushion cover 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com