Special-shaped GRG block partition limiting installation structure and splicing method thereof

A technology of installation structure and splicing method, which is applied in building structure, covering/lining, construction, etc., can solve the problems such as difficult to control the installation quality of special-shaped GRG, and achieve the effect of ensuring the overall installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

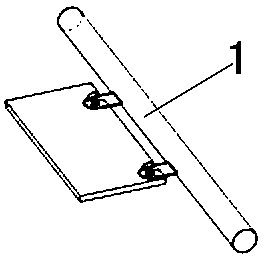

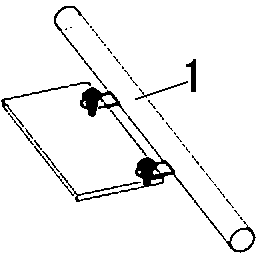

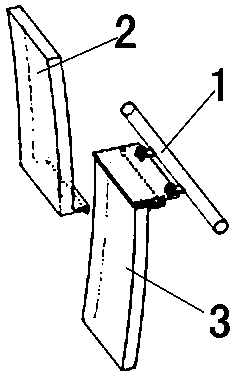

[0035] Embodiment one: if Figure 8 Shown: a special-shaped plate GRG block partition limit installation structure, which includes a fixed steel frame 1, an upper GRG plate 2, and a lower GRG plate 3. The upper GRG plate 2 is provided with an "L" shaped flange at the junction of the lower GRG plate 3 . The lower GRG plate 3 is provided with an "L"-shaped flange at the junction of the upper GRG plate 2, and the upper GRG plate 2 reserves an L-shaped flange on the GRG plate 3.

[0036] Such as Figure 1 to Figure 4 As shown, the fixed steel frame 1 is fixed to the GRG inner steel frame structure, and the upper GRG plate 2 and the lower GRG plate 3 are joined together to form a structural unit; the L-shaped flange of the lower GRG plate 3 and the L-shaped flange of the upper GRG plate 2 Form a "U" shaped groove.

[0037] Such as Figure 6 As shown, the back of the lower GRG plate 3 where the upper GRG plate 2 meets is reinforced with a GRG “U”-shaped plate 5 .

[0038] Such ...

Embodiment 2

[0040] Embodiment two: if Figure 1 to Figure 5 As shown, the splicing method of the special-shaped plate GRG block partition limit installation structure includes the following steps,

[0041] A. According to the division of the GRG typesetting area, do the overall laying-out of the site, and set the zero-time fixed steel structure; install the limit woodworking board, fix it with bolts, and fix it on the fixed steel frame 1 through the U-shaped opening on the limit woodworking board and the bolts Limiting woodworking board: the limiting woodworking board is left to fix the U-shaped opening and fixed on the fixed steel frame 1 by bolts.

[0042] B. Put the upper thread on the limiting woodworking board, and install the GRG plates on both sides according to the completed upper thread: the upper GRG plate 2 and the GRG plate 3 are installed and fixed by splicing the L-shaped flange and the limiting woodworking board to support the limit: The limit woodworking board is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com