Cabinet used for converter, converter and rail vehicle

A converter and cabinet technology, applied in the field of machinery, can solve the problems of easy damage, high temperature of the skin plate, thick welding seam, etc., so as to ensure the service life and improve the structural rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

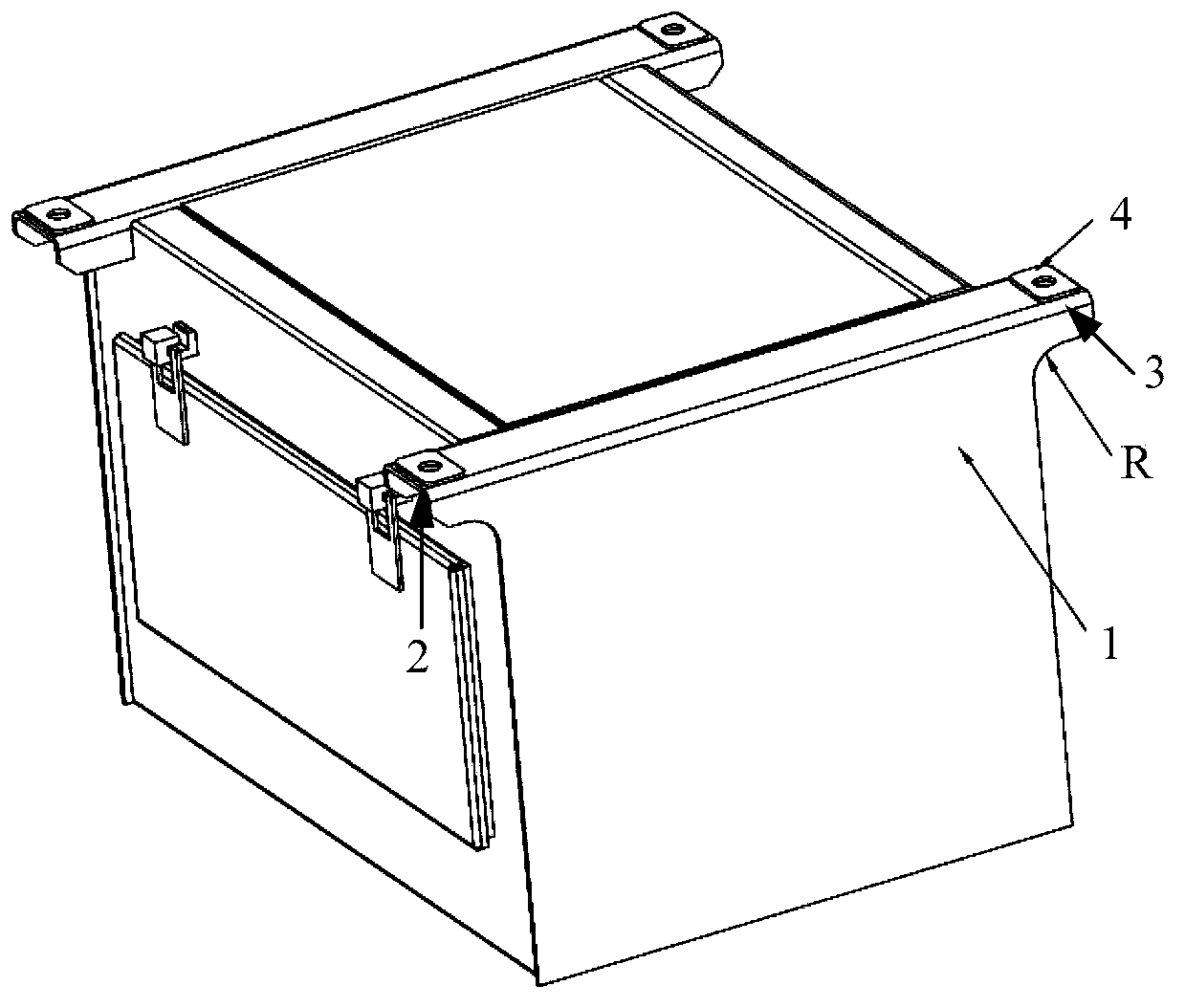

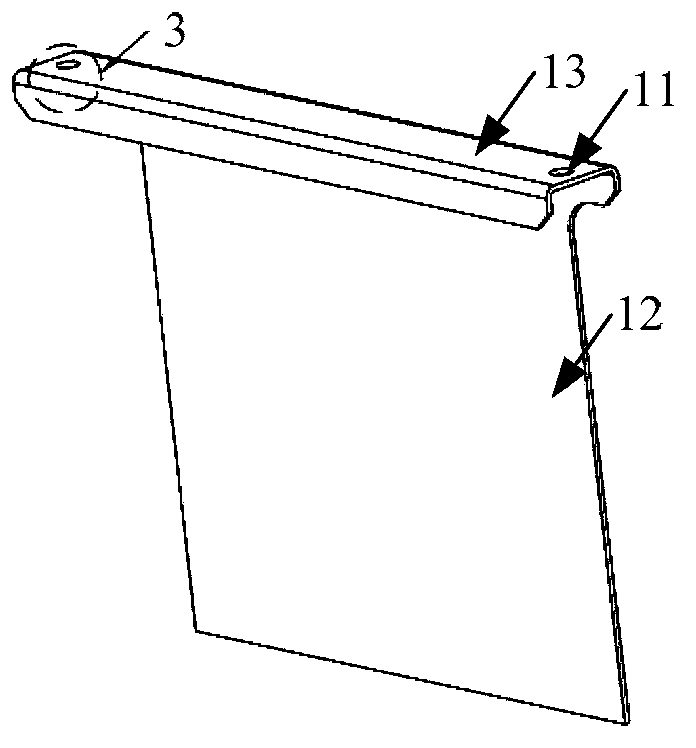

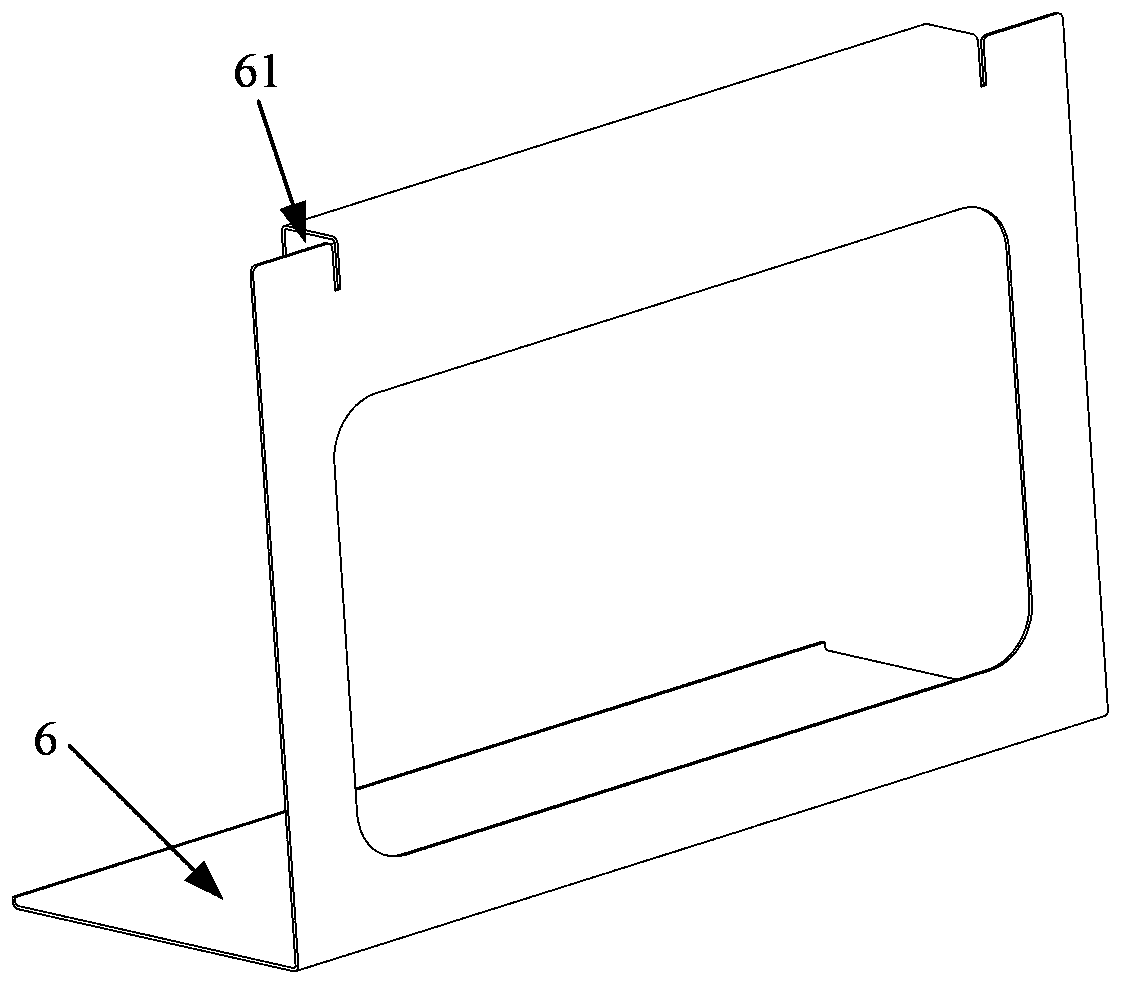

[0025] figure 1 The schematic diagram of the cabinet structure provided by the embodiment of the present invention, figure 2 for figure 1 Schematic diagram of the structure of the first wall plate, image 3 for figure 1 Schematic diagram of the structure of the second wall panel.

[0026] An embodiment of the present invention provides a cabinet for a converter, which includes a wall plate assembly 1 and a skin 2 . The wall plate assembly 1 includes a first wall plate 5 and a second wall plate 6, the number of the first wall plate 5 and the second wall plate 6 is several pieces, each of the first wall plate 5 and the second wall plate 6 surrounds into a cavity; the skin 2 covers the outside of each of the first wall plate 5 and the second wall plate assembly 6; wherein, the two ends of the first wall plate 5 are integrally formed with outwardly protruding lugs 3. The skin 2 covers the outside of the lifting lug 3, the lifting lug 3 is provided with a first installation h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com