Keel-adjustable mounting structure for prefabricated wall surface

An installation structure and prefabricated technology, applied in building construction, covering/lining, construction, etc., can solve problems such as weak installation and inability to accurately adjust the keel, and achieve good wall flatness, firm installation, and guaranteed installation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

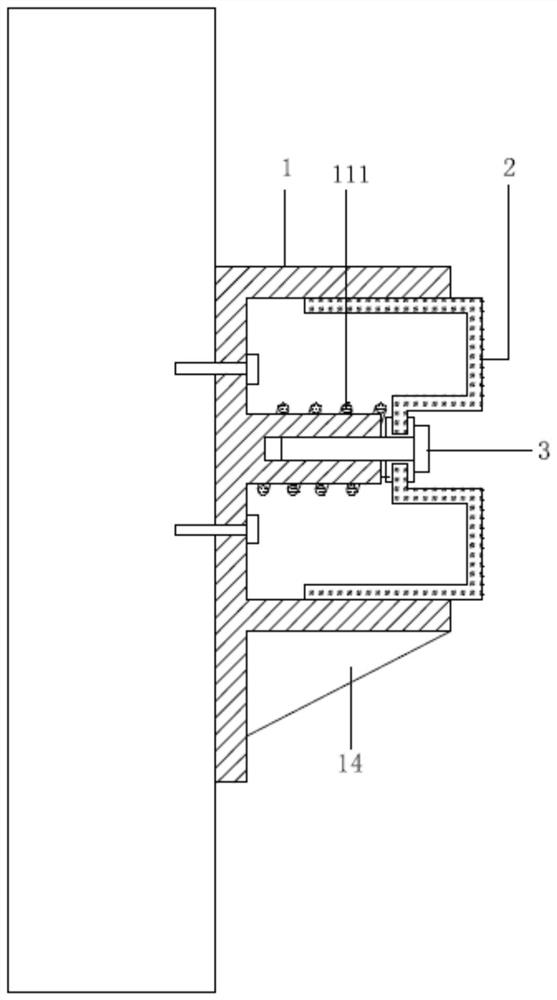

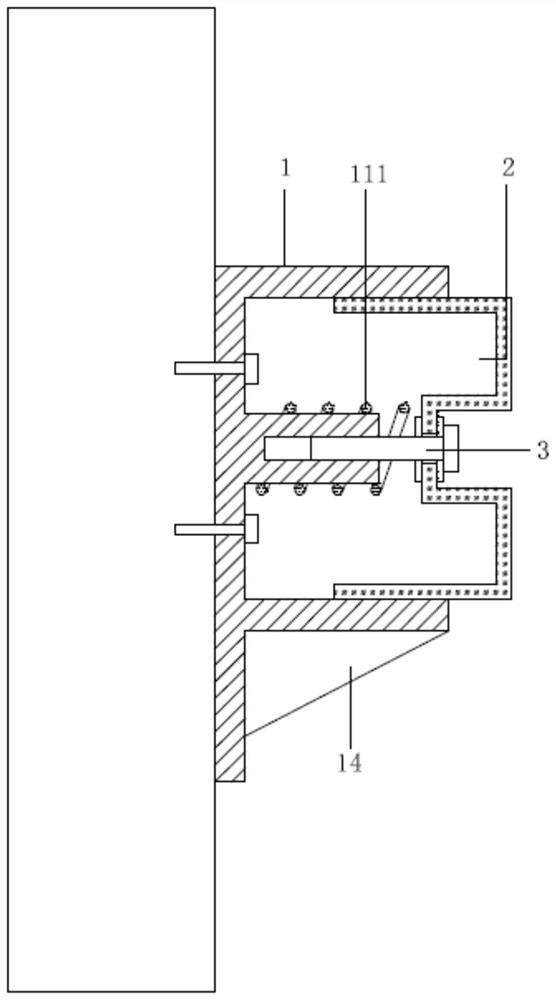

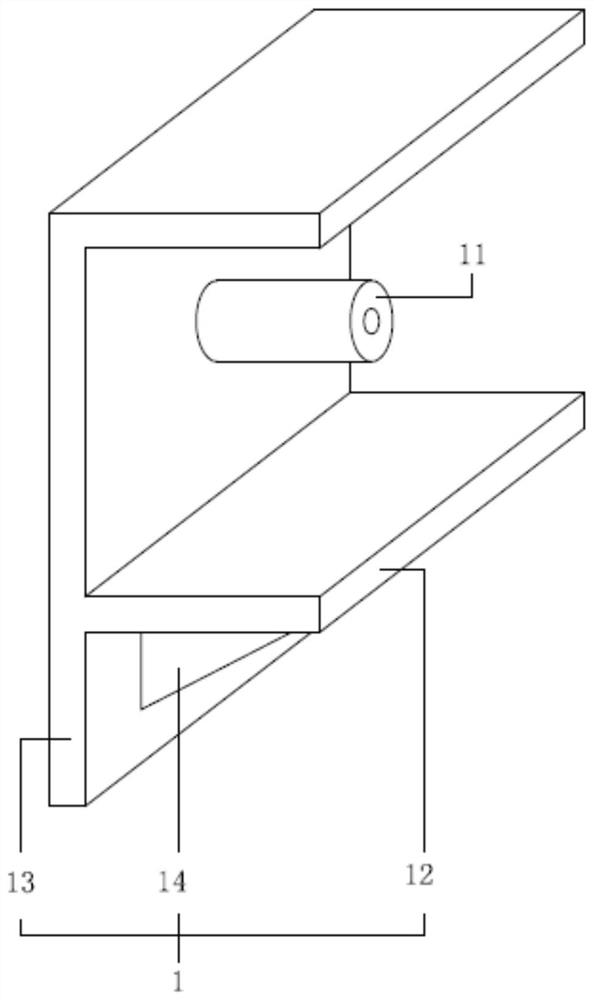

[0025] See Figure 1 to Figure 7 , The figure shows a keel adjustable installation structure for a fabricated wall provided by the first embodiment of the present invention, which includes a leveling piece 1, a keel 2 and an adjusting bolt 3. The leveling piece 1 is fixedly installed on the base of the wall, The leveling member 1 is provided with a column sleeve 11, the inner wall of the column sleeve 11 is provided with threads, the column sleeve 11 is provided with a spring 111, and the leveling member 1 is provided with two baffles 12 arranged in parallel, and the keel 2 The surface is provided with a groove 21, the bottom surface of the groove 21 is provided with a waist-shaped hole 211 arranged along the length of the groove 21, the adjusting bolt 3 passes through the waist-shaped hole 211 and is connected to the column sleeve 11, and the spring 111 abuts against the concave On the bottom surface of the groove 21, the bent edges 22 on both sides of the keel 2 abut on the b...

Embodiment 2

[0030] See Figure 1 to Figure 7 , The figure shows an adjustable installation structure of the keel of the fabricated wall provided by the second embodiment of the present invention. On the basis of the above embodiment, this embodiment further makes the following as an improved technical solution: waist A fastener 4 is arranged in the shaped hole 211. The adjusting bolt 3 is inserted through the fastener 4. The fastener 4 includes a first rib 41, a second rib 42 and a connecting post 43. The first rib 41 and the second rib 41 The two ribs 42 are symmetrically arranged at both ends of the connecting column 43, the first rib 41 and the second rib 42 are clamped on both sides of the bottom surface of the groove 21; the fastener 4 is made of rubber.

[0031] Rubber fasteners, on the one hand, can protect the keel at the waist-shaped hole from being deformed by the first rib and the second rib, and ensure that the keel is installed firmly; on the other hand, it can make the keel and...

Embodiment 3

[0033] See Figure 1 to Figure 7 , The figure shows an adjustable installation structure of the keel of the fabricated wall provided in the third embodiment of the present invention. On the basis of the above-mentioned embodiment, this embodiment further makes the following as an improved technical solution: The width of a rib 41 is greater than the width of the waist hole 211; the diameter of the connecting post 43 is equal to the width of the waist hole 211; the width of the second rib 42 is equal to the width of the waist hole 211.

[0034] With this structure, when installing the fasteners, align the second baffle plate with the waist-shaped hole and press it to pass through the waist-shaped hole. The first baffle plate at the other end of the connecting column is wider than the waist-shaped hole. Will pass through the waist-shaped hole, and then turn the fastener to prevent the fastener from falling out of the waist-shaped hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com