Manufacturing die of unmanned aerial vehicle blade

A technology of drones and blades, which is applied to household appliances, other household appliances, household components, etc., can solve the problem that it is difficult to ensure the consistency of the installation angle between the blade body and the positioning pin, and it is difficult to ensure the balance and safety of high-speed rotating blades. , angular positioning deviation and other problems, to achieve the effect of low scrap rate, low manufacturing cost and high deflection angle accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

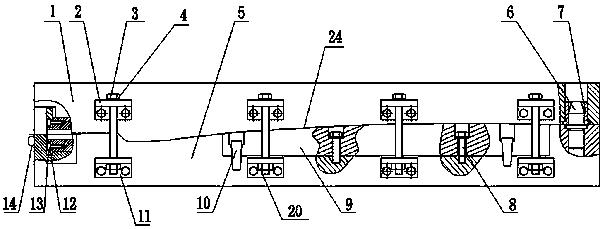

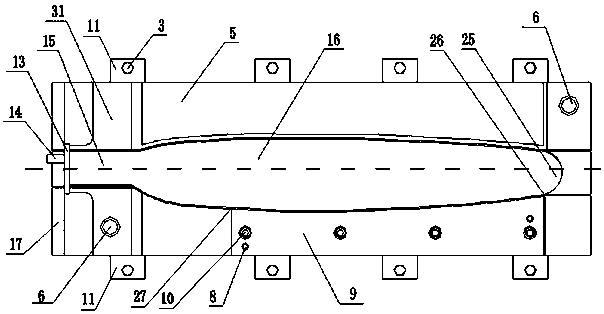

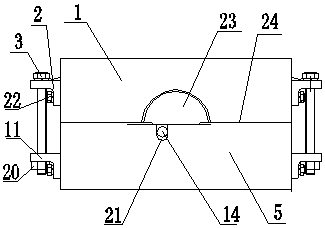

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] Such as Figure 1 to Figure 19As shown, this embodiment includes an upper mold 1, a lower mold and positioning pins I6. The mold cavity that completely matches the blade airfoil 16 is divided into an upper mold 1 and a lower mold on the curved surface formed by the line connecting the front and rear edge maximum contour lines 24 of the blade airfoil 16, and the mold cavity is divided into an upper mold cavity 28 and a lower mold cavity 30. The upper mold 1 and the lower mold are provided with semicircular receiving grooves 35 and 33 of the petiole 15 on the end wall at one end of the petiole 15, that is, on the left walls 29 and 31 of the upper and lower die cavities. The lower mold is on the lower mold cavity end wall corresponding to the blade trailing edge, that is, the lower mold cavity front wall 36, and cuts out the cutting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com