Fabricated steel-concrete composite structure culvert

A combined structure and concrete technology, applied in the field of structural culverts, can solve problems such as extended construction period, scattered construction points, and slow installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

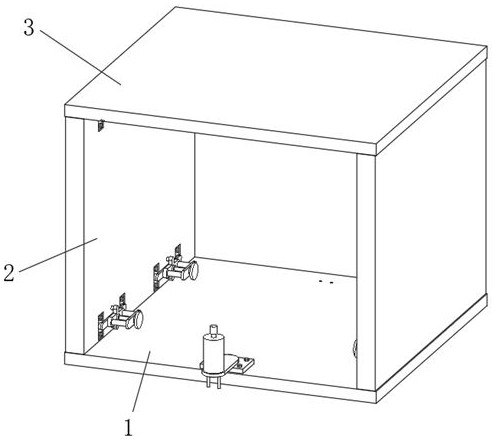

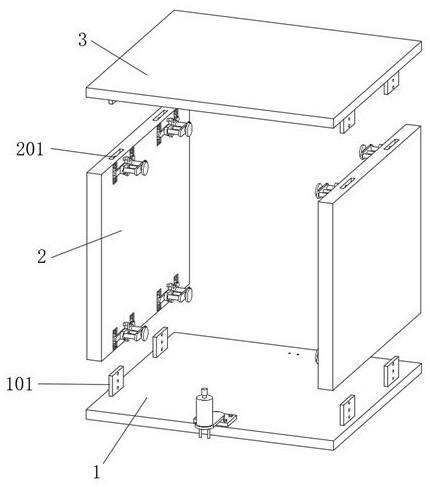

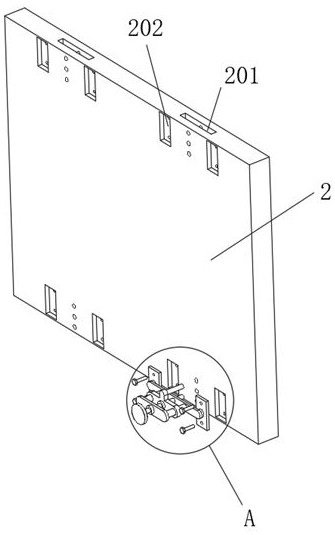

[0033] Such as Figure 1-7 The culvert of a prefabricated steel-concrete composite structure includes a base plate main body 1, a standing plate main body 2 and a top plate main body 3. The upper surface of the base plate main body 1 is fixedly connected with four sets of first inserts 101, four sets of first inserts 101 It is symmetrically distributed in pairs. The side wall of the first plug 101 is provided with a first locking hole 1011. The bottom of the top plate main body 3 is fixedly connected with a second plug 301. The position of the second plug 301 is the same as that of the first plug 101. Correspondingly, the side wall of the second plug 301 is provided with a second locking hole 3011, and the top and bottom of the stand main body 2 are provided with positioning grooves 201 corresponding to the first plug 101 and the second plug 301. A plug 101 and a second plug 301 are movably inserted in the positioning groove 201, the side wall of the main body 2 of the stand i...

Embodiment 2

[0037] Embodiment 2 is a further improvement to Embodiment 1.

[0038] Such as Figure 1-7An assembled steel-concrete composite structure culvert is shown, including a base plate main body 1, a standing plate main body 2 and a top plate main body 3. The upper surface of the base plate main body 1 is fixedly connected with four sets of first inserts 101, four sets of first inserts 101 are symmetrically distributed in pairs. The side wall of the first insert 101 is provided with a first locking hole 1011. The bottom of the top plate main body 3 is fixedly connected with a second insert 301. The position of the second insert 301 is the same as that of the first insert. Corresponding to 101, the side wall of the second plug 301 is provided with a second locking hole 3011, and the top and bottom of the stand main body 2 are provided with positioning grooves 201 corresponding to the first plug 101 and the second plug 301, The first plug 101 and the second plug 301 are movably inser...

Embodiment 3

[0043] Embodiment 3 is a further improvement to Embodiment 1.

[0044] Such as Figure 1-7 An assembled steel-concrete composite structure culvert is shown, including a base plate main body 1, a standing plate main body 2 and a top plate main body 3. The upper surface of the base plate main body 1 is fixedly connected with four sets of first inserts 101, four sets of first inserts 101 are symmetrically distributed in pairs. The side wall of the first insert 101 is provided with a first locking hole 1011. The bottom of the top plate main body 3 is fixedly connected with a second insert 301. The position of the second insert 301 is the same as that of the first insert. Corresponding to 101, the side wall of the second plug 301 is provided with a second locking hole 3011, and the top and bottom of the stand main body 2 are provided with positioning grooves 201 corresponding to the first plug 101 and the second plug 301, The first plug 101 and the second plug 301 are movably inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com