Integrated cast steel supporting roller

A back-up roll and cast steel technology, applied in the direction of rolls, furnace types, furnaces, etc., can solve problems such as poor metallurgical bonding, peeling of the working layer, and easy-to-break rolls, so as to improve the nucleation rate, reduce the radial hardness drop, and cut small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

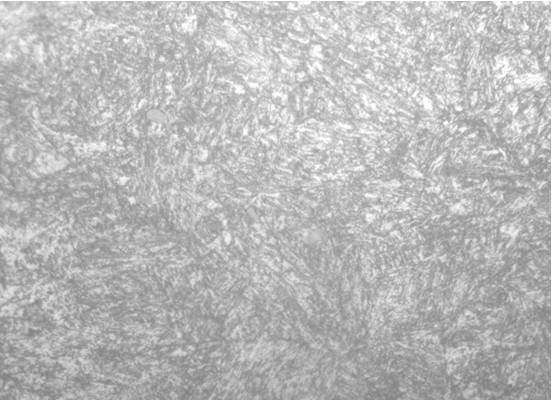

[0018] Example 1: Add scrap steel and corresponding ferroalloy materials except Ca, B, V and Ti elements in the intermediate frequency electric furnace, and carry out pre-furnace analysis on the composition of molten steel after melting, so that the composition obtained by smelting is (wt%): C : 0.43, Si: 0.38, P: 0.021, S: 0.013, Ni: 0.25, Cr: 4.83, Mo: 0.55, Mn: 0.69, and the rest are iron and impurities. 2 minutes before tapping, raise the furnace temperature to 1620°C and add 0.18wt% V-Fe (V is measured as a pure substance) and 0.2wt% Ti-Fe (Ti is measured as a pure substance), and add 0.010 wt% during tapping %B-Fe (B is measured as a pure substance), and 0.025 wt% calcium-silicon cored wire (Ca is measured as a pure substance) is inserted into the ladle after tapping. When the molten steel temperature is 1470°C, static casting of integral cast steel back-up roll slabs is started, and the composition of the obtained final sample is (wt%): C: 0.42, Si: 0.45, P: 0.022, S: 0...

Embodiment 2

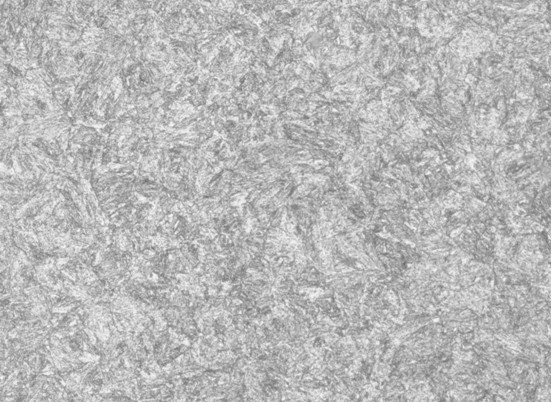

[0019] Embodiment 2: As in Example 1, the smelting composition obtained is (wt%): C: 0.52, Si: 0.37, P: 0.022, S: 0.015, Ni: 0.21, Cr: 5.1, Mo: 0.60, Mn: 0.72, The rest is iron and impurities. 3 minutes before tapping, the furnace temperature was raised to 1615°C, and 0.19 wt % V-Fe (V was measured as a pure substance) and 0.18 wt % Ti-Fe (Ti was measured as a pure substance) were added, and 0.024 wt % was added during tapping. wt% B-Fe (B is measured as a pure substance), and 0.023 wt% calcium-silicon cored wire (Ca is measured as a pure substance) is inserted into the ladle after tapping. When the temperature of the molten steel is 1475°C, static casting of the integral cast steel back-up roll slab is started, and the composition of the obtained final sample is (wt%): C: 0.51, Si: 0.51, P: 0.023, S: 0.013, Ni: 0.23, Cr: 5.05 , Mo: 0.59, V: 0.16, Ti: 0.17, B: 0.019, Ca: 0.02, Mn: 0.70, and the rest are iron and impurities. The grain size of the slab core is grade 6. Put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com