Ceramic enhanced type nickel-based composite coating and preparation method thereof

A composite coating and reinforced technology, applied in the direction of coating, metal material coating process, etc., can solve the problems of pores and cracks, reduce the corrosion resistance of the coating, incomplete structure, etc., and achieve complete structure and high spreadability. , the effect of improving organizational integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

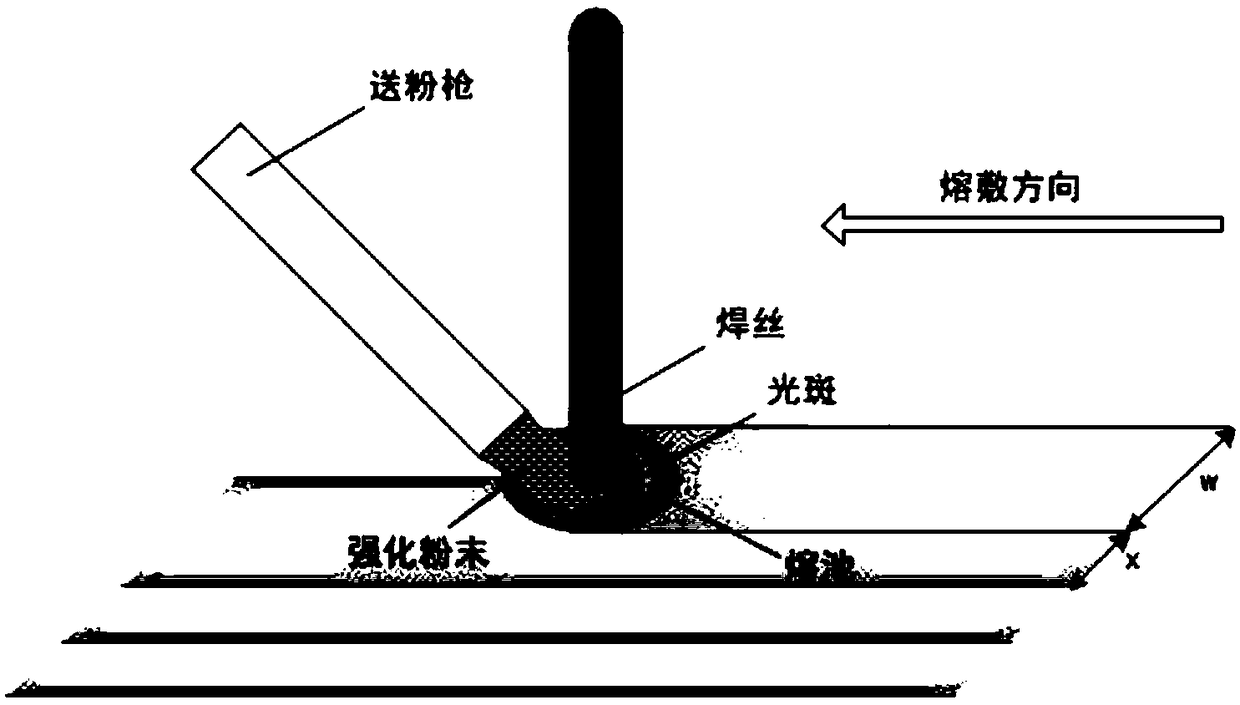

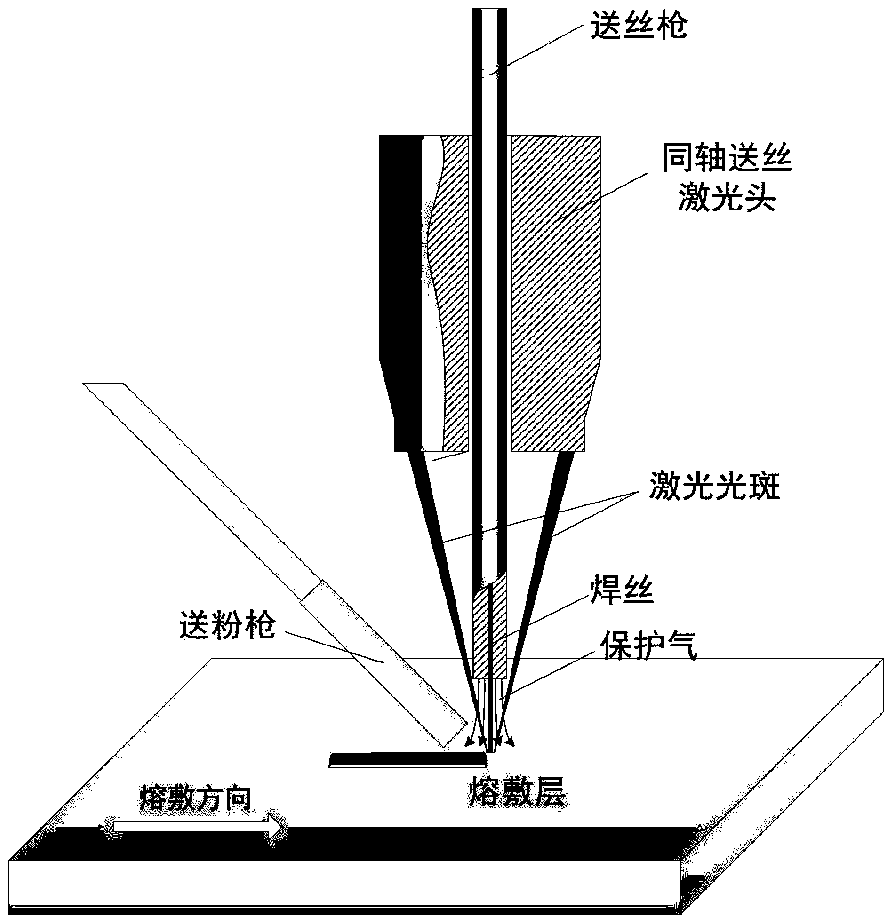

[0051] After grinding the 316L stainless steel plate with sandpaper, wash it with acetone and dry it. As the base material, fix it on the workbench. Use TiC powder and Inconel 625 alloy welding wire as the cladding material. The composition of the Inconel 625 alloy welding wire is Cr 20 %, Ni 62%, Mo 8%, Nb 4%, Mn 0.3%, Co 0.2%, Si 0.5% and Fe 5%. Pre-place the TiC powder in the powder feeder, adjust the angle of the powder feed gun to be 45° from the horizontal plane, the top of the powder feed gun is the same as the wire outlet of the wire feed gun, and the height is 3-5mm from the surface of the substrate to ensure that the powder feed position is in line with the feed The silk position is the light spot. The placement of the cladding material and the base material is as follows: figure 1 shown.

[0052] The welding process adopts argon protective atmosphere, the gas flow rate is 5L / min, the laser melting is completed by laser surface focusing, the laser and powder feeder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com