Patents

Literature

33results about How to "Avoid Coarse Grains" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

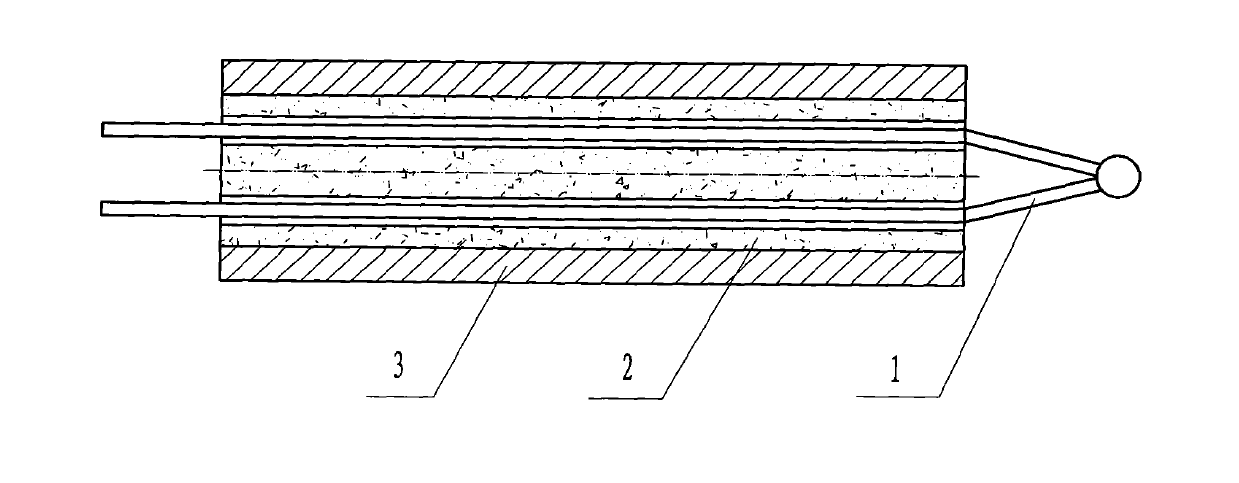

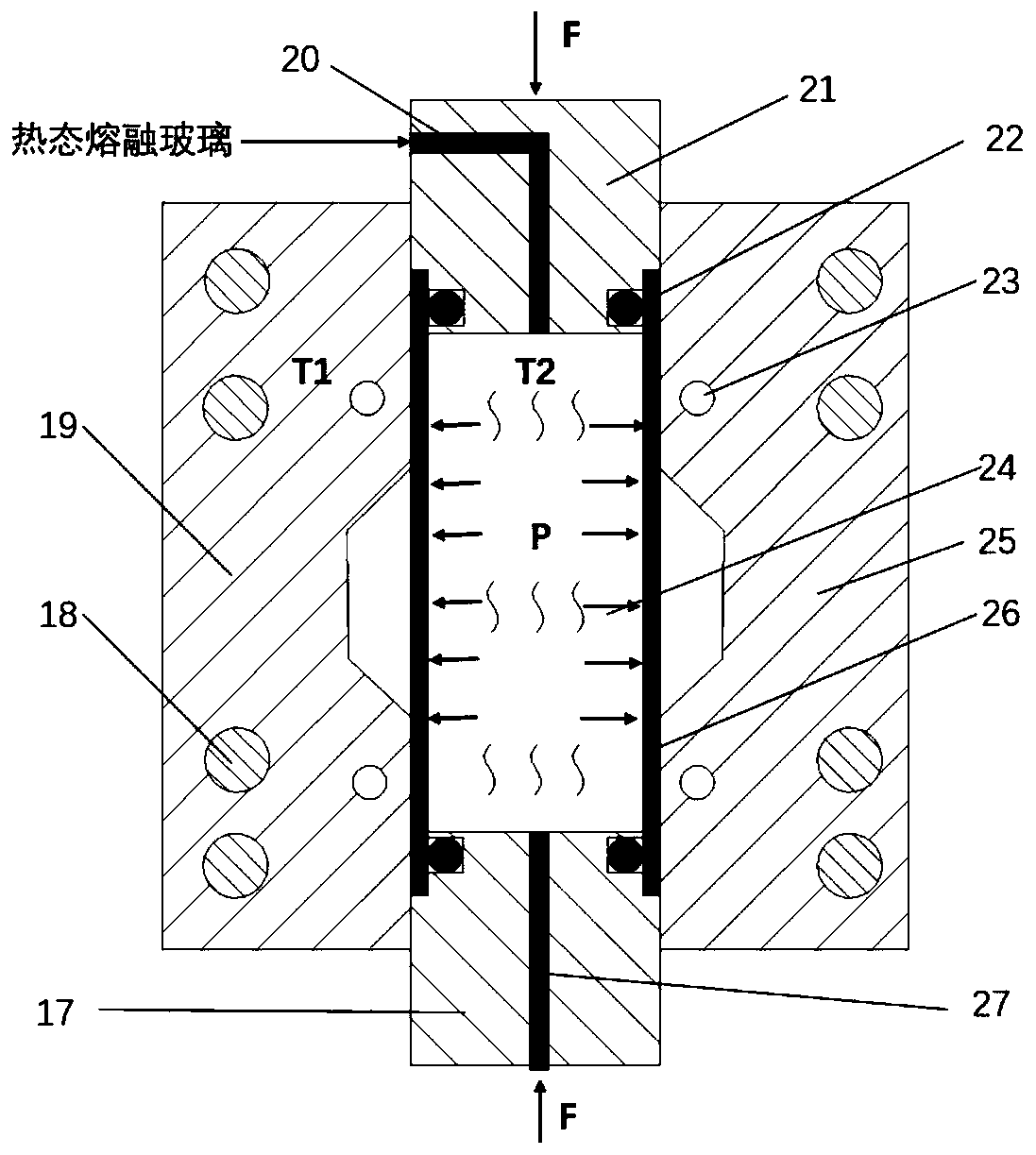

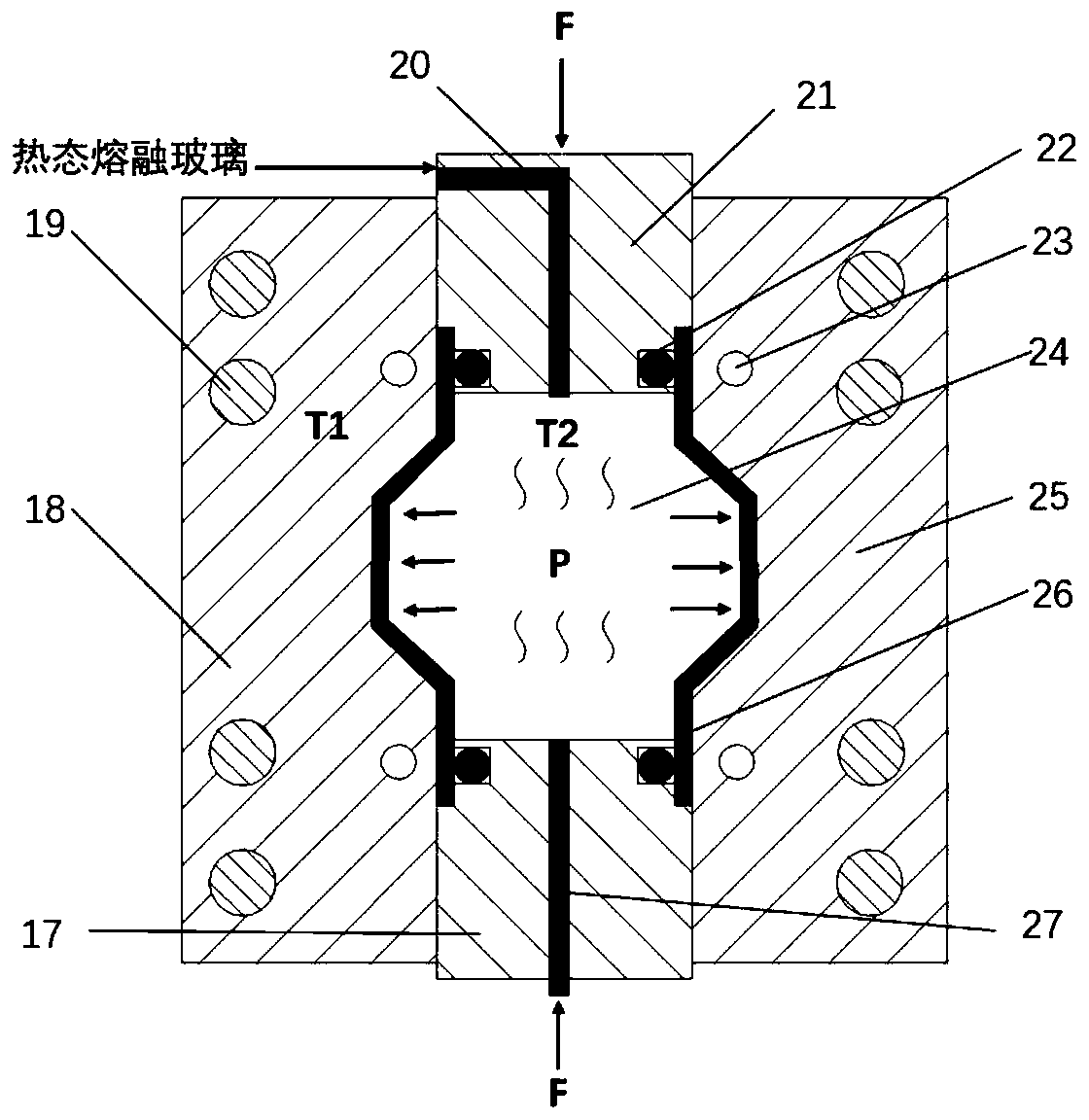

Pipe hot medium internal pressure forming method based on molten glass

ActiveCN108856441AMeet the forming temperature process requirementsReduce compressionInternal pressureHeat conducting

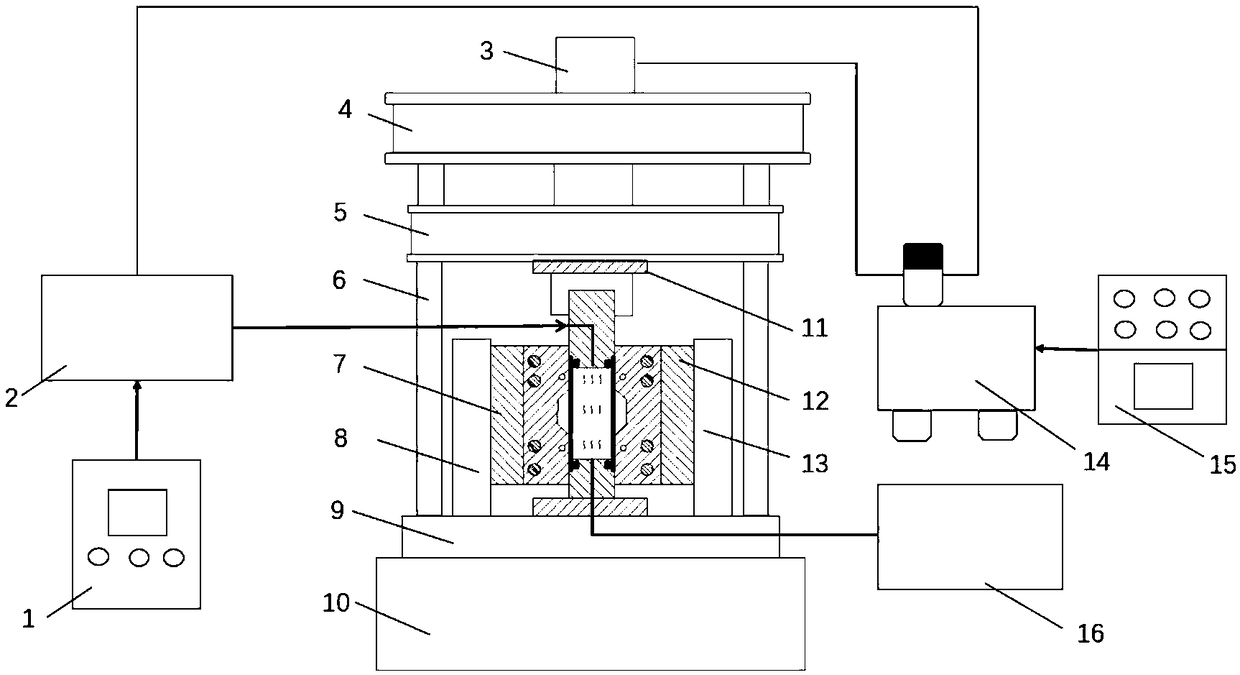

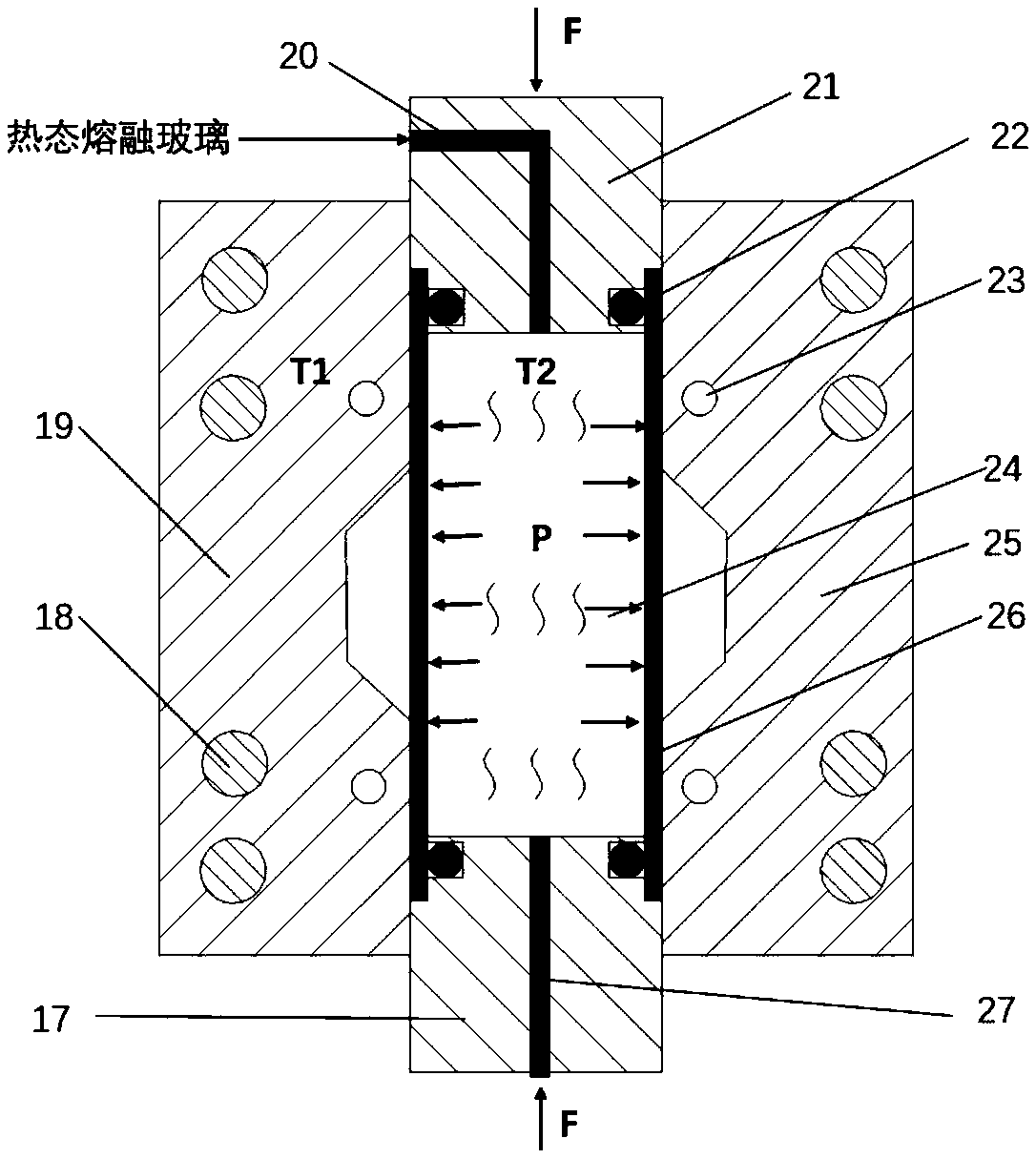

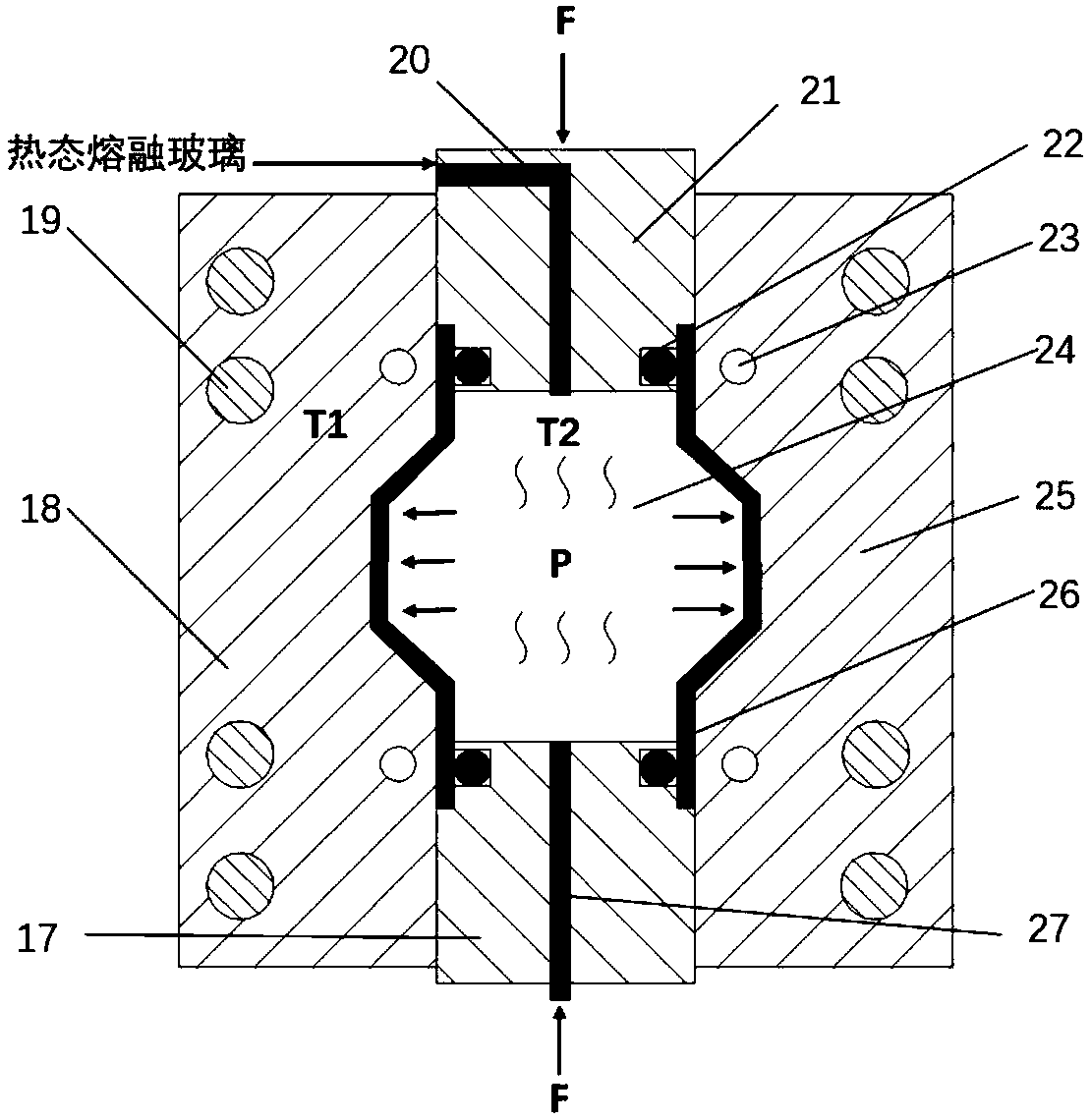

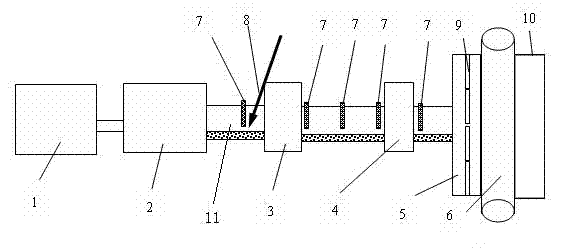

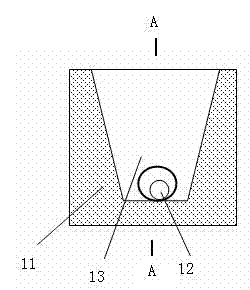

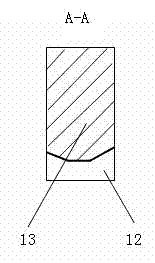

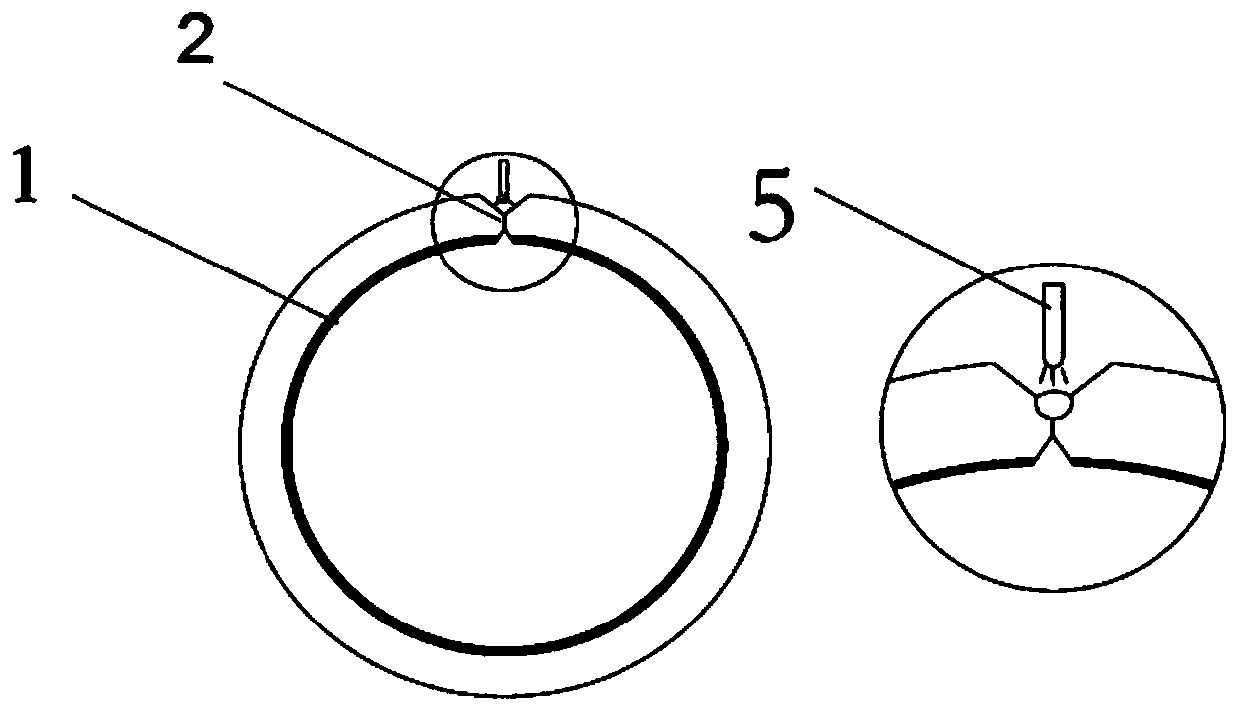

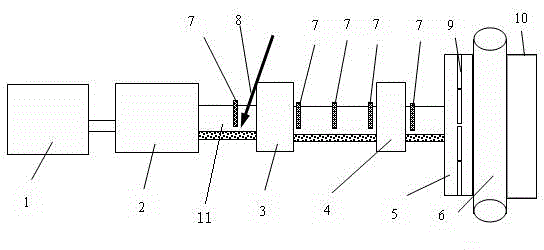

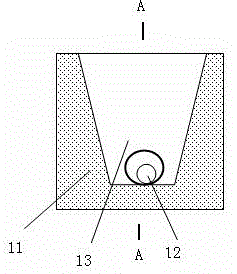

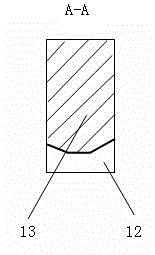

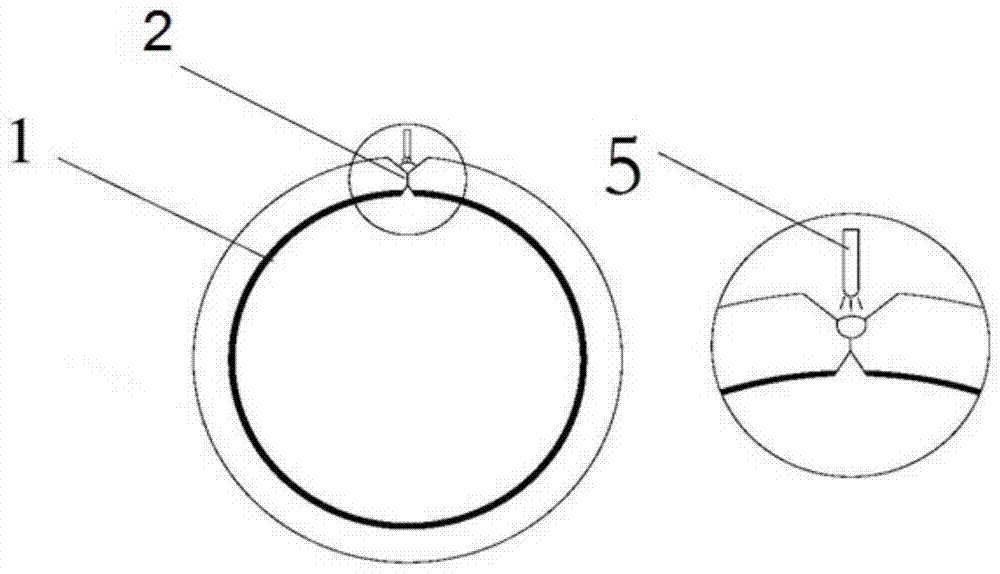

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

Manufacturing process for bolt with high strength of more than phi 30

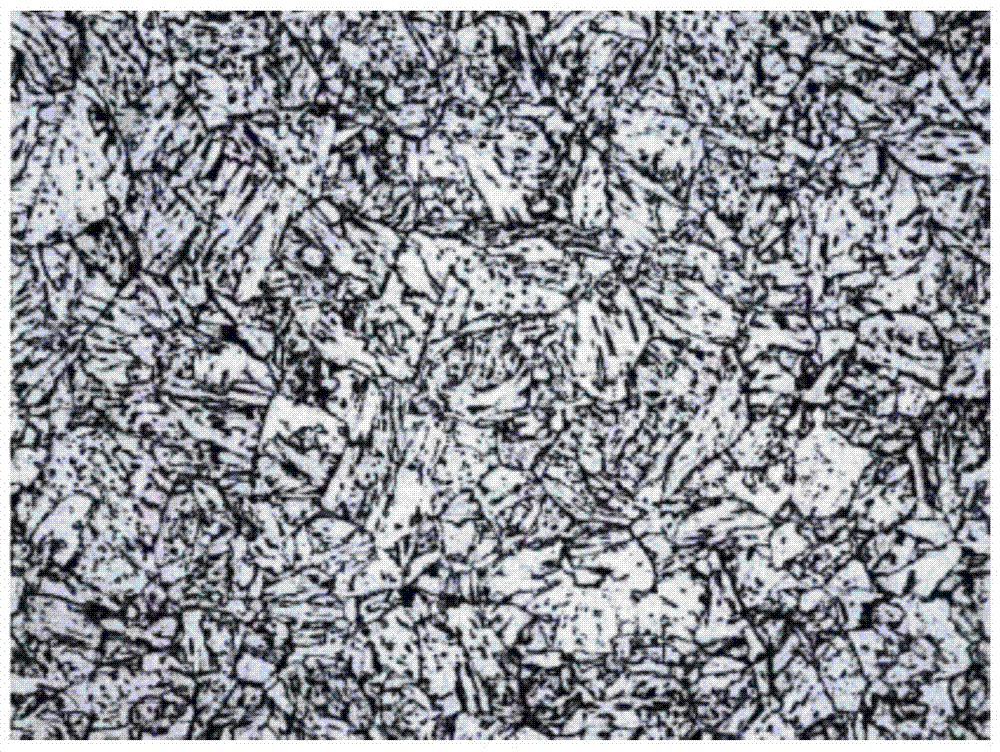

InactiveCN102248116AGrain refinementAvoid Coarse GrainsMetal-working apparatusBoltsHeat conservationExcess heat

The invention discloses a manufacturing process for a bolt with high strength of more than phi 30. The manufacturing process comprises the following steps of: forging; performing heat treatment and after treatment, wherein the heating forging temperature is between 1,100 and 1,300 DEG C, and the heating forging time is between 2 and 5 minutes; directly feeding workpieces into a mesh belt furnace quickly after forging for high temperature tempering, wherein the mesh belt furnace comprises a preheating area, a first heating area, a second heating area and a heat preservation area; preheating the workpieces through the preheating area after the workpieces are fed into the mesh belt furnace, and heating the workpieces through the first heating area and the second heating area; preserving the heat through the heat preservation area; cooling the workpieces which are subjected to the high temperature tempering; and trimming the cooled workpieces. By the manufacturing process, the workpieces are directly fed into the mesh belt furnace for high temperature tempering after being heated and forged, the excess heat of the forged workpieces is fully used, and time and energy are saved. The workpieces have a tempered sorbite structure after the high temperature tempering, grains are refined, and the phenomena that the grains are coarse and a martensite structure and a raw material structure are blended are prevented.

Owner:浙江迪特高强度螺栓有限公司

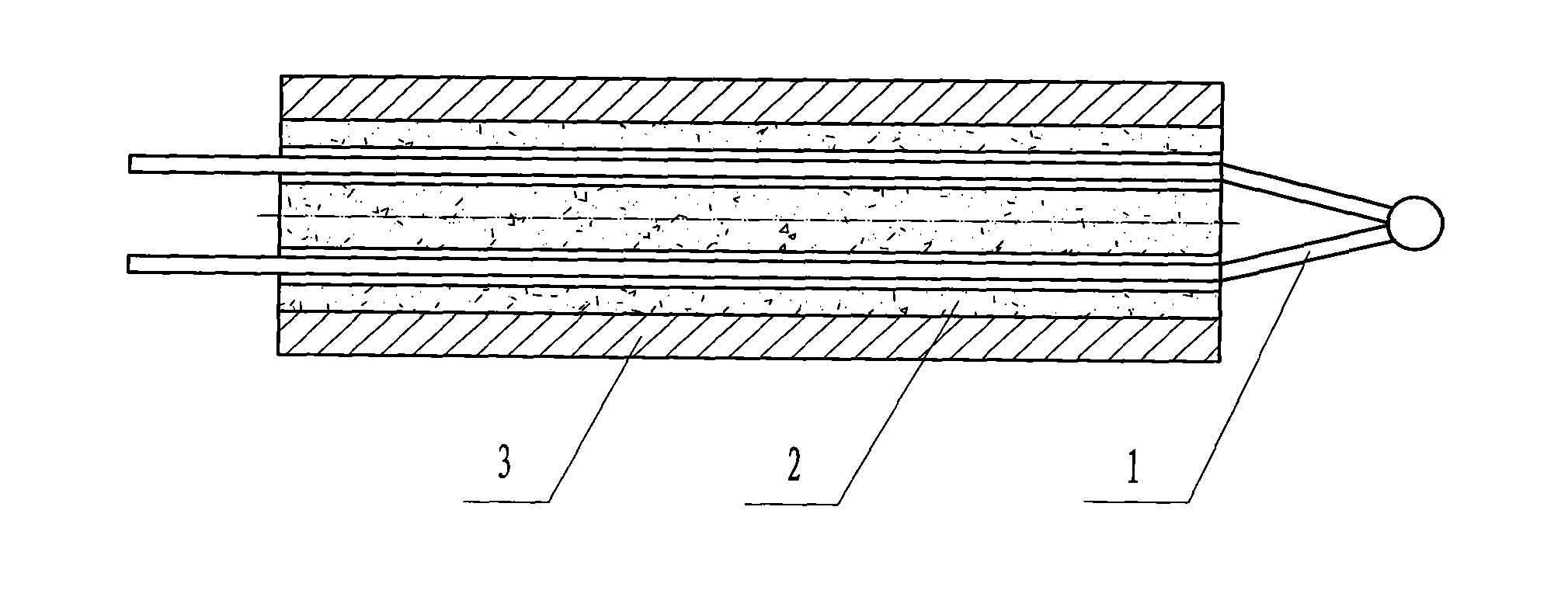

Toughening-type high-temperature iridium rhodium thermocouple

ActiveCN102937486AAvoid coarse grainsSolve the brittleThermometers using electric/magnetic elementsUsing electrical meansIridiumStress relief

The invention relates to a thermocouple for high-temperature measurement, in particular relates to a toughening-type high-temperature iridium rhodium thermocouple for temperature measurement below 2400K, and belongs to the field of temperature testing. The toughening-type high-temperature iridium rhodium thermocouple comprises a thermocouple wire, an insulation procelain tube and a protective outer shell; the thermocouple wire is arranged in the insulation procelain tube; the protective outer shell is wrapped on the outer part of the insulation procelain tube; and high-temperature binders are filled between the thermocouple and the insulation procelain tube and between the insulation procelain tube and the protective outer shell, and are used for fixing and sealing. The toughening-type high-temperature iridium rhodium thermocouple is characterized in that the positive electrode of the thermocouple is made of an IrRh alloy, and the weight percentages of Ir and Rh are respectively 40%-60% and 60%-40%; and the negative electrode of the thermocouple is made of an IrRh alloy, the weight percentages of Ir and Rh are respectively 80%-90% and 20%-10%; the positive electrode and the negative electrode are welded into thermal joint points, and stress relief annealing is required to be carried out after the welding of the thermal joint points and before the assembling of the thermocouple. The problems that traditional thermocouple is high in brittlenss and has a catalytic effect are solved; the negative electrode is prevented from cracking; and the measurement accuracy is improved.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

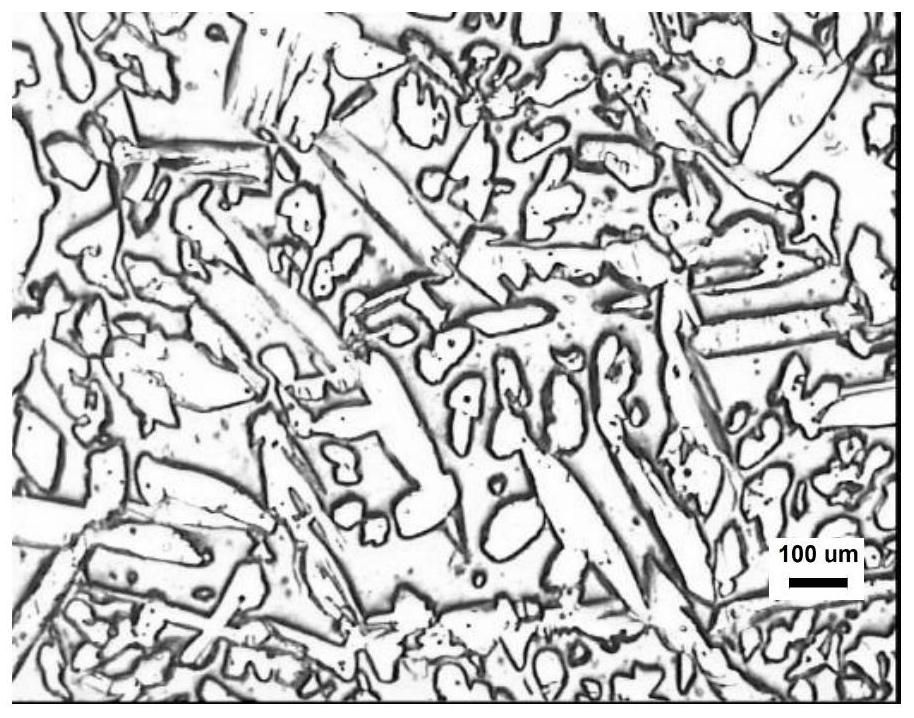

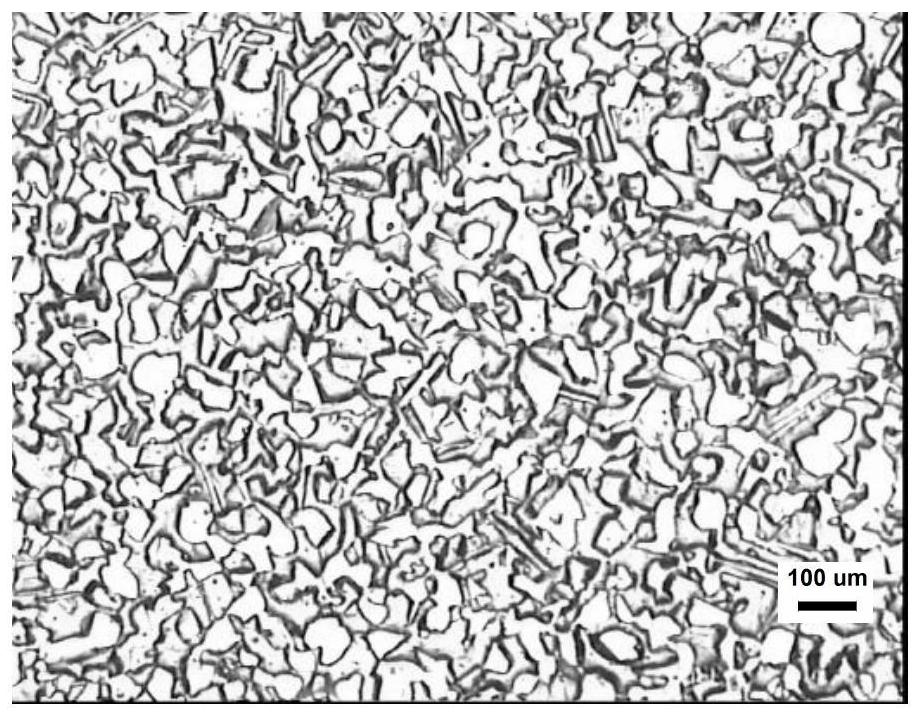

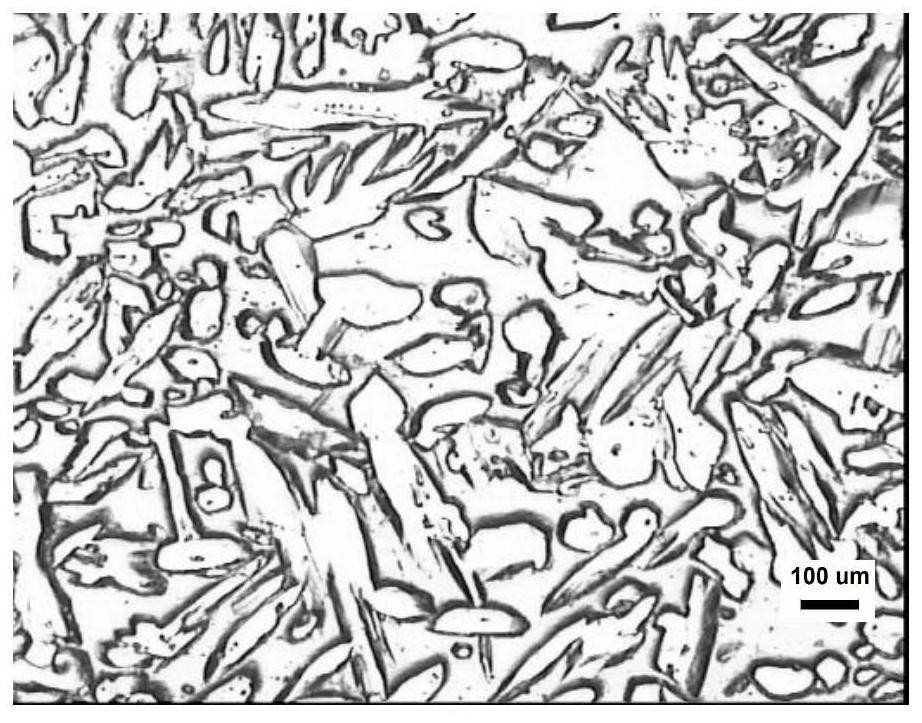

Grain control method for production of ultrawide double-zero aluminum foil blanks by electrolytic aluminum liquid cast-rolling process

ActiveCN103042030AIncrease the number of non-spontaneous crystal nucleiImprove the utilization of active ingredientsMetal rolling arrangementsProduction lineGrain structure

The invention relates to a grain control method for production of ultrawide double-zero aluminum foil blanks by electrolytic aluminum liquid cast-rolling process. A smelting furnace holding solid aluminum and electrolytic aluminum liquid in a horizontal aluminum cast-rolling line is used for smelting for 4-10 hours at the low temperature of 720-735 DEG C, the aluminum liquid is heated to 740-750 DEG C in 20-30 minutes, the aluminum liquid is refined after alloy preparation, the aluminum liquid is allowed to stand for 30-50 minutes after refining and is transferred to a standing furnace, the aluminum liquid in the standing furnace is evenly mixed for 10 minutes every 4-6 hours by Ar and CCl4, the aluminum liquid in the standing furnace flows into a filter tank through a degassing tank and a channel and flows to a front tank through the filter tank and the channel, and the aluminum liquid is injected into gaps of casting rollers by a casting spile. With the process coordinating with equipment, adjustable temperature and speed of the aluminum liquid in the casting spile are achieved, and even transverse and longitudinal grain structures of a casting slab can be obtained.

Owner:YUNNAN ALUMINUM

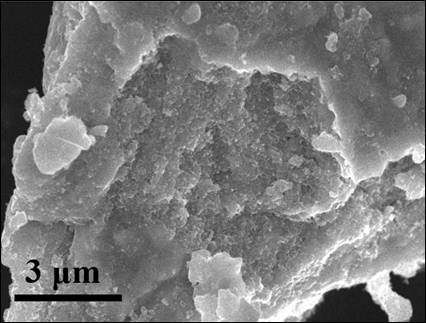

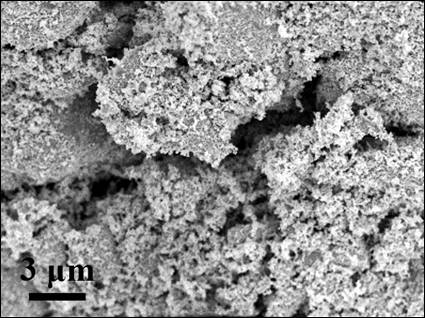

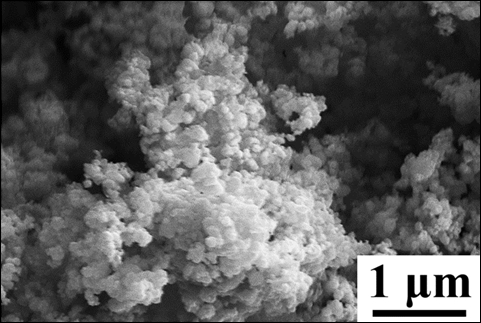

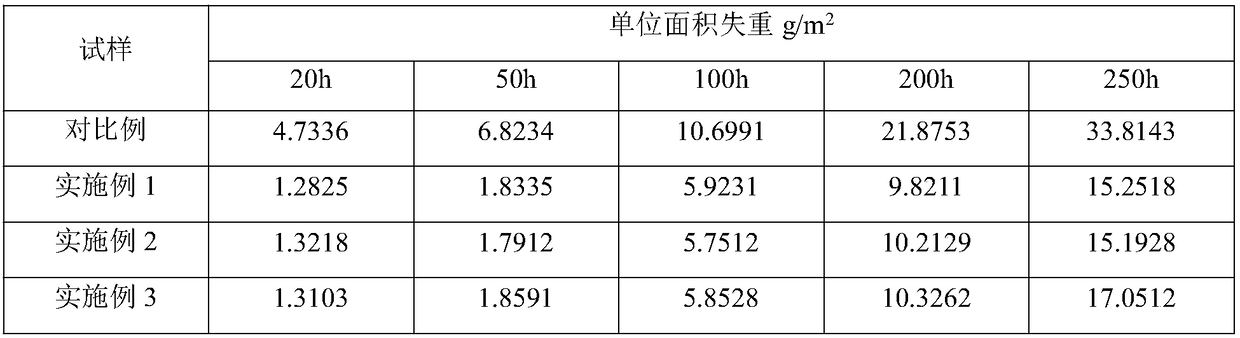

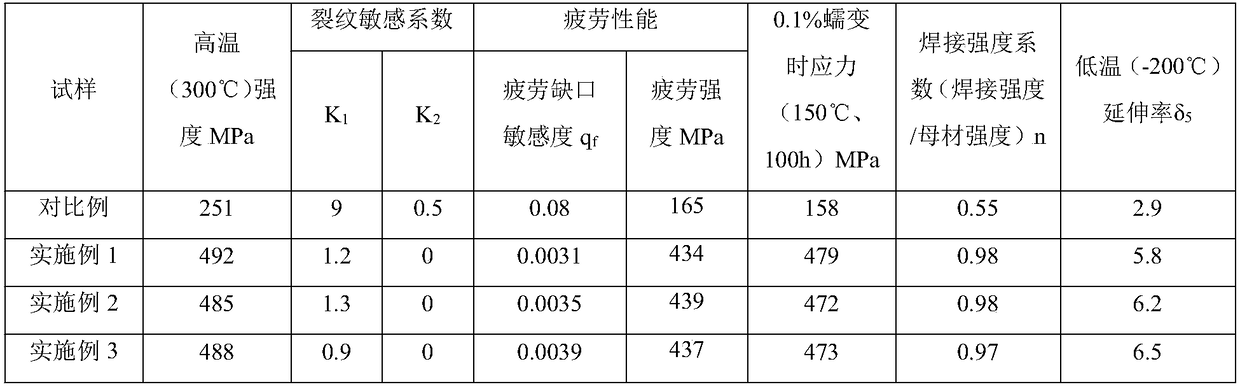

Preparation method and application of nano tungsten trioxide and nano tungsten powder

ActiveCN112222421AEasy to controlIncrease nucleation rateTungsten oxides/hydroxidesNanotechnologyAmmonium metatungstateMaterials science

The invention discloses a preparation method of nano tungsten trioxide and nano tungsten powder. The preparation method comprises the steps of firstly, dispersing carbon nanoparticles, then adding ammonium metatungstate, and uniformly stirring the materials to obtain a mixed solution; secondly, drying the mixed solution to obtain combined powder; thirdly, heating and decomposing the combined powder to obtain the nano tungsten trioxide; and fourthly, carrying out segmented hydrogen reduction on the nano tungsten trioxide to obtain the nano tungsten powder. In addition, the invention discloses application of the nano tungsten powder to preparation of superfine nano tungsten carbide and fine-grain tungsten alloy. According to the preparation method, the carbon nanoparticles are used as a nucleating agent and a pore-forming agent for decomposition of the ammonium metatungstate, and therefore the nucleation and growth processes of the tungsten trioxide are effectively controlled, the nucleation rate of the tungsten trioxide is increased, the granularity of the tungsten trioxide is reduced, the nano tungsten powder is obtained through hydrogen reduction, and the problems of regulation and control over the nucleation, the granularity and the dispersity in the ammonium metatungstate decomposition process are solved; and an application method of the nano tungsten powder is simple, crystal grains of a tungsten material are prevented from being coarse, and the high-performance tungsten material can be obtained advantageously.

Owner:西安稀有金属材料研究院有限公司

Aluminum alloy welding wire and manufacturing method thereof

ActiveCN108262576AReasonable alloy compositionEasy to organizeWelding/cutting media/materialsSoldering mediaNiobiumCerium

The invention relates to an aluminum alloy welding wire and a manufacturing method thereof. The aluminum alloy welding wire is prepared from the following elements in percentage by weight: 0.01 percent to 0.15 percent of iron, 0.01 percent to 0.12 percent of silicon, 0.01 percent to 0.1 percent of copper, 0 percent to 0.009 percent of scandium, 0.02 percent to 0.22 percent of manganese, 4.5 percent to 5.5 percent of magnesium, 0 percent to 0.009 percent of chromium, 0.01 percent to 0.18 percent of zinc, 0 percent to 0.003 percent of titanium, 0.001 percent to 0.03 percent of lithium, 0.001 percent to 0.01 percent of boron, 0 percent to 0.02 percent of vanadium, 0.005 percent to 0.009 percent of zirconium, 0.002 percent to 0.009 percent of cerium, 0.001 percent to 0.008 percent of yttrium,0.0001 percent to 0.002 percent of nickel, 0.0001 percent to 0.008 percent of strontium, 0.0001 percent to 0.009 percent of ytterbium, 0.0003 percent to 0.002 percent of neodymium, 0.0001 percent to 0.03 percent of niobium, and the balance aluminum. Compared with the prior art, according to the aluminum alloy welding wire and the manufacturing method thereof provided by the embodiment of the invention, the performance and the quality of the aluminum alloy welding wire can be remarkably improved, and the manufacturing cost of the aluminum alloy welding wire is comprehensively reduced.

Owner:江苏豪然新材料有限公司

Simple method for chromizing small-axis parts and special chromizing agent thereof

The invention refers to a simple method for small shaft part chromizing, the method includes: (1) the small shaft part and chromizing agent are mixed even and put into the chromizing bottle; (2) seals the bottle and puts the bottle into electrical furnace and seals the furnace door tightly; (3) carries on segmented heating and thermal retardation; (4) chromizing process; (5) cooling; (6) opens the chromizing bottle, pours out the mixer, and takes out the small shaft piece, filters it and eliminates the chromizing agent; (7) hardening and tempering; the special chromizing agent is made up of aluminium oxide, chrome iron powder, ammonium chloride according to the proportion of 55%: 42%: 3%. The device in the invention is simple, low investment; small harm to device. It enhances the wearing resisting and corrosion resisting property of small shaft.

Owner:许长荣

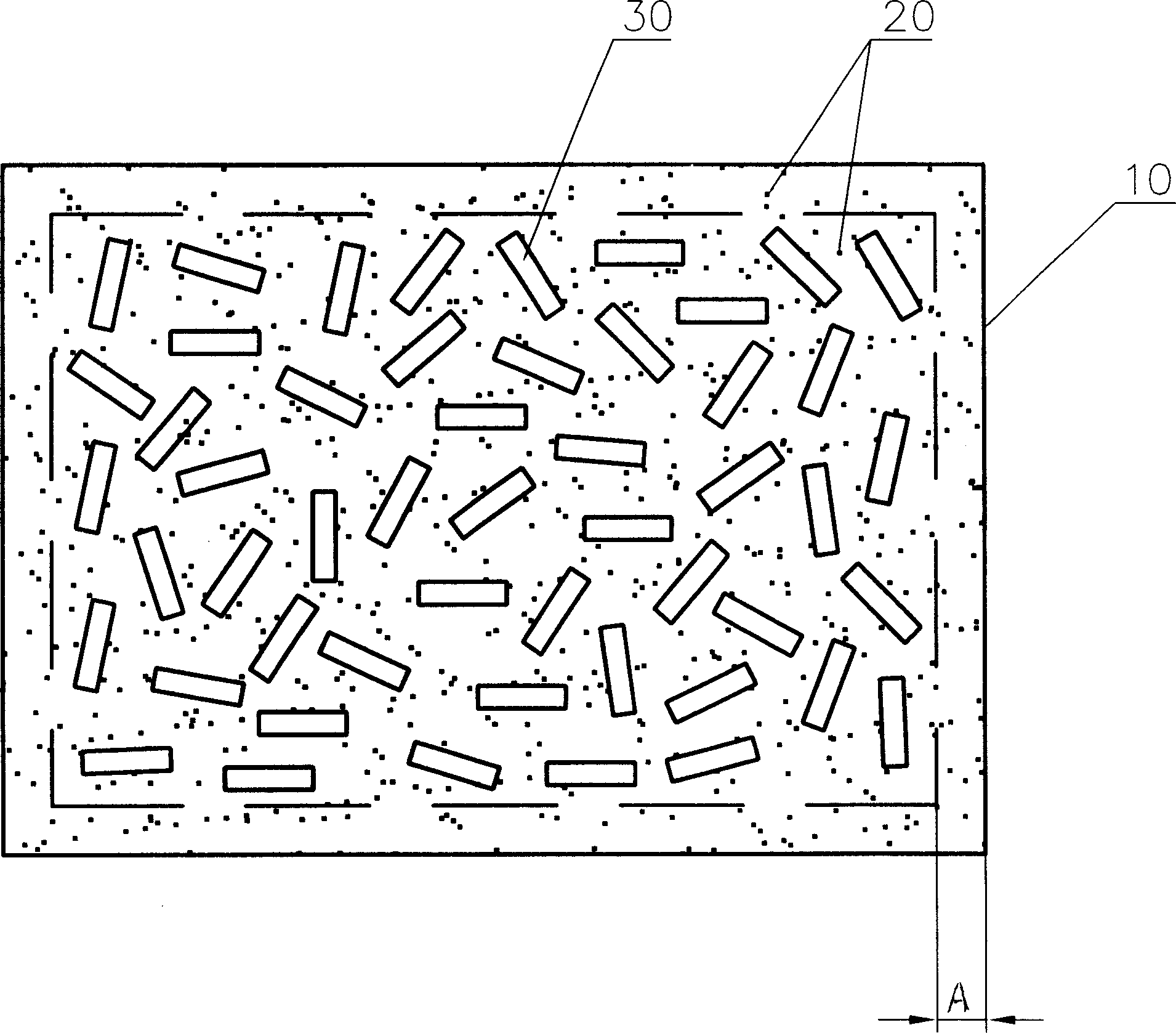

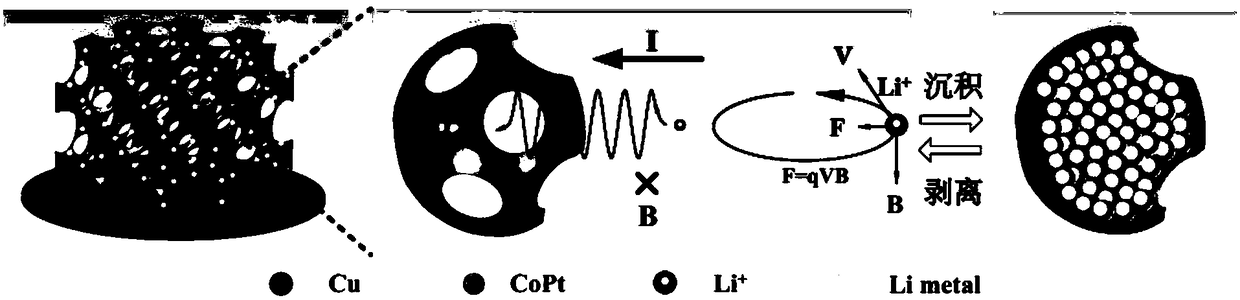

Magnetic lithium metal battery copper magnetic composite electrode material and preparation method and application thereof

ActiveCN108923024AExtended service lifeEasy to useCell electrodesSecondary cellsMicro nanoLithium metal

The invention relates to a magnetic lithium metal battery copper magnetic composite electrode material and a preparation method and application thereof and belongs to the technical field of magnetic batteries. The preparation method comprises 1), removing oxides on the surface of a copper substrate and carrying out cleaning and drying, and 2), preparing a magnetic layer structure containing a magnetic metal on the surface of the copper substrate treated by the step 1), wherein the magnetic metal includes iron, cobalt, nickel and platinum and the magnetic layer structure includes a magnetic plating layer structure, non-magnetic micro-nano-structure doped magnetic particles, magnetic micro-nano-structure doped magnetic particles and a magnetic micro-nano-structure.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of brass wire

The invention discloses a preparation method of a brass wire. The preparation method is characterized in that brass comprises the following components in percentage by mass: 55%-62% of Cu, 0.5%-1.5% of Mn, 0.2%-0.5% of Fe, 0.3%-0.8% of Al, 0.2%-0.5% of Pb and the balance being Zn and inevitable impurities; and a technological process comprises ingredients, smelting, semi-continuous casting, extrusion and combined drawing, wherein the ingredients comprise a bright line, a zinc ingot, electrolytic manganese, an iron-copper alloy and an aluminum wire which are required according to component proportions. According to the invention, by controlling a smelting technology, melt with uniform components is obtained, and preparation work is made for the subsequent semi-continuous casting to obtain a cast ingot with a uniform structure, so that the combined drawing can be directly performed after the extrusion, intermediate annealing in a traditional technology is omitted, the problems of coarse material grains, non-uniform phase structure distribution and anisotropy of physical and mechanical properties are avoided, and excellent mechanical properties, free cutting, bending performance and corrosion resistance are further obtained.

Owner:JINTIAN COPPER GROUP CORP NINGBO

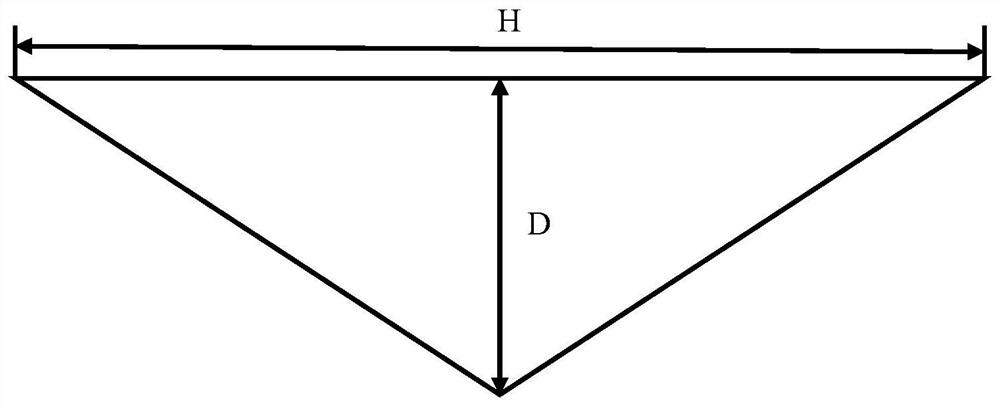

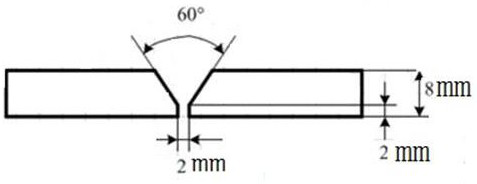

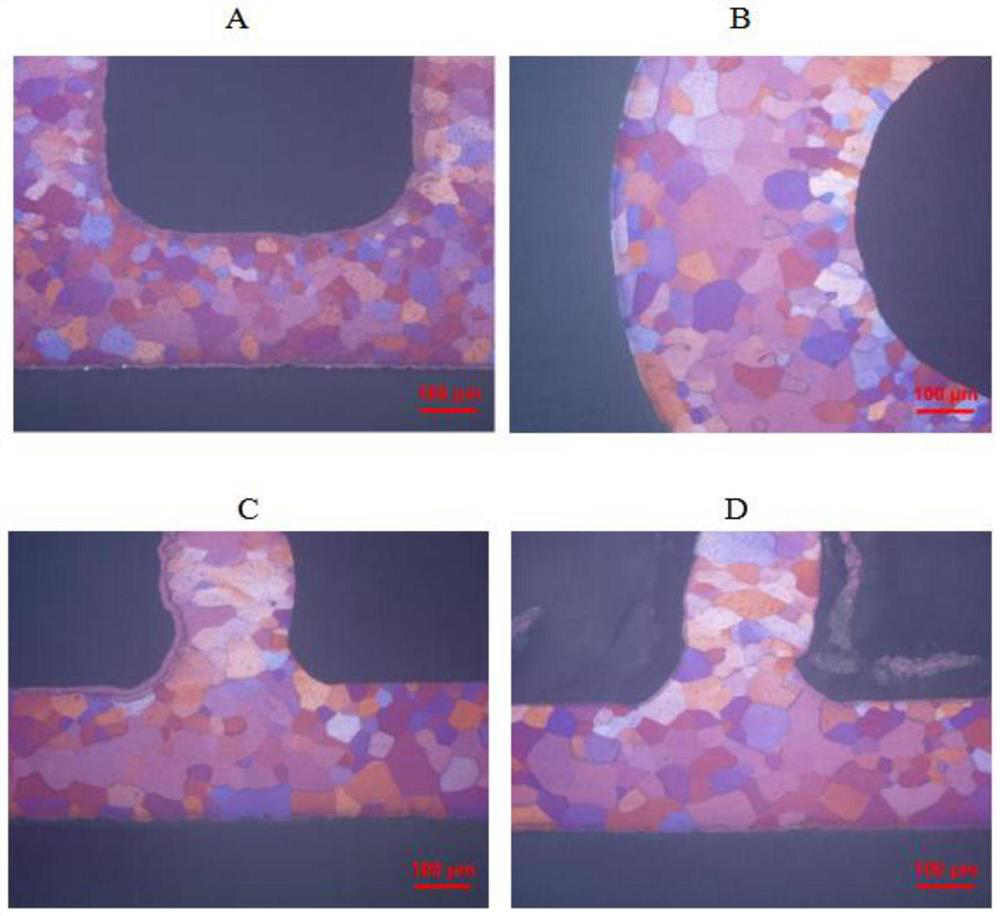

Method for repairing damage of blade leading edge of TC4 titanium alloy integral bladed-disk structure

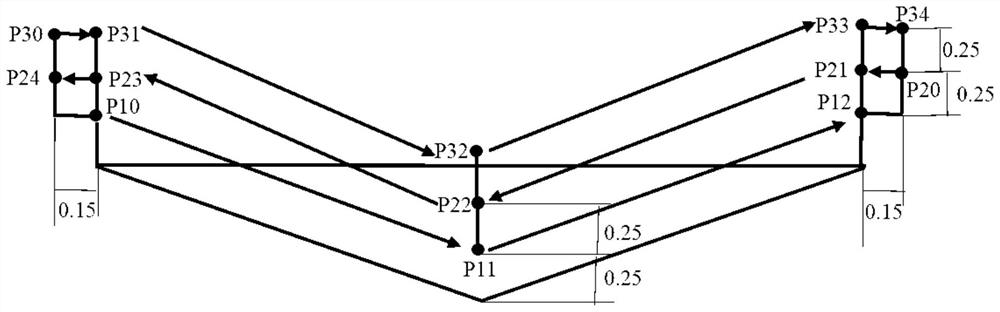

ActiveCN111975282APrevent collapseAvoid Coarse GrainsEfficient propulsion technologiesMetallic material coating processesLeading edgeStructural engineering

The invention discloses a laser additive repairing method, relates to the field of maintenance of aero-engines, and aims to provide a method for repairing the damage of a blade leading edge of a TC4 titanium alloy integral bladed-disk structure. According to the technical scheme, the method for repairing the damage of the blade leading edge of the TC4 titanium alloy integral bladed-disk structurecomprises the steps that firstly, the blade leading edge is detected, and a damage area is marked; a V-shaped groove is formed in the damage area, and the damage area is covered with the groove; the groove is subjected to laser additive repair by using TC4 powder along the repair path from one side of the groove to the bottom of the groove to the other side of the groove; the groove is subjected to next-layer repair by adopting the TC4 powder, and the repair laser power is lower than the laser power of the first-layer repair; next-layer repair is repeated until to fill the whole groove; and finally, the profile of the repair area is polished until to meet the size requirements. The method is used for repairing the damage, such as local deformation, scratching, tearing and chipping, of theblade leading edge.

Owner:PLA NO 5719 FACTORY

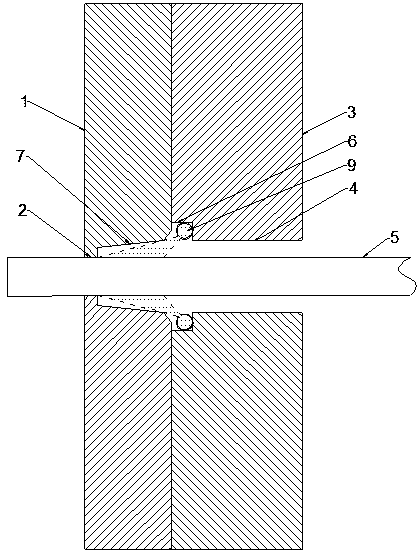

Profiled roll heat treatment method with large requirement drop for roll body and roll neck

InactiveCN108060296ANarrow down the differential temperatureGuaranteed temperatureFurnace typesHeat treatment furnacesHardnessPerformance index

The invention discloses a profiled roll heat treatment method with the large requirement drop for a roll body and a roll neck, and belongs to the field of metal heat treatment. The method comprises the steps that thermal refining is carried out according to hardness requirements of the roller neck at first, and the roll body is subjected to differential temperature treatment, wherein a ledge is wrapped by a protection sleeve before the roll body is subjected to differential temperature treatment. Product performance indexes are ensured, and product quality stability is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

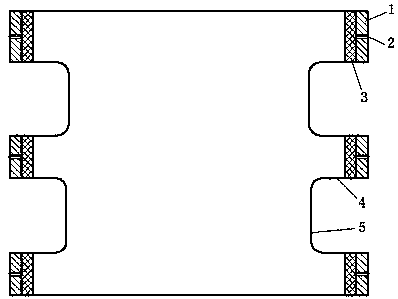

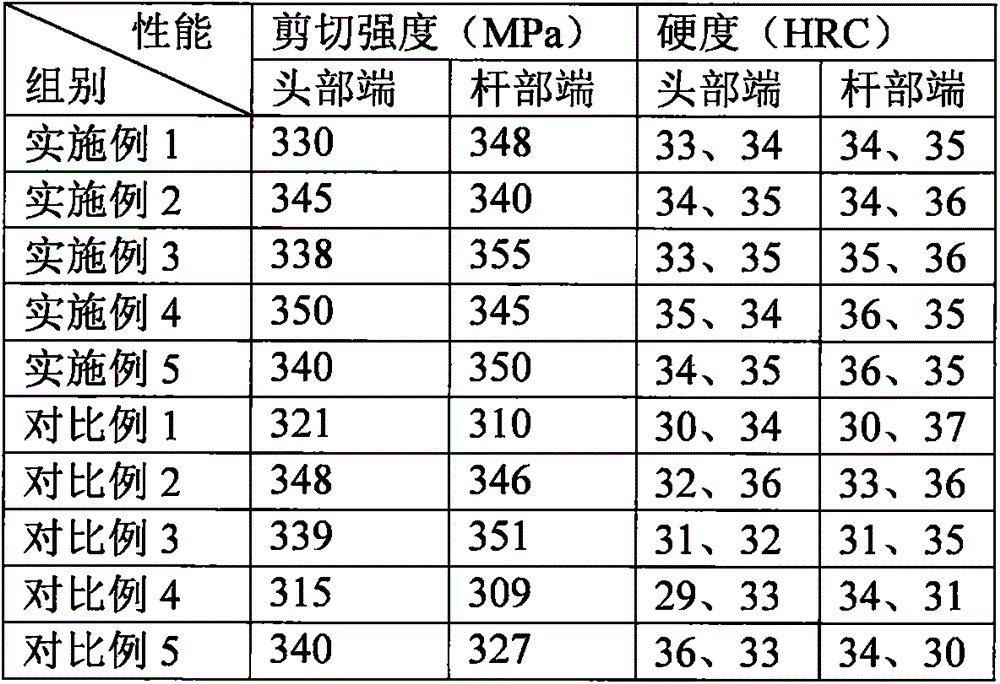

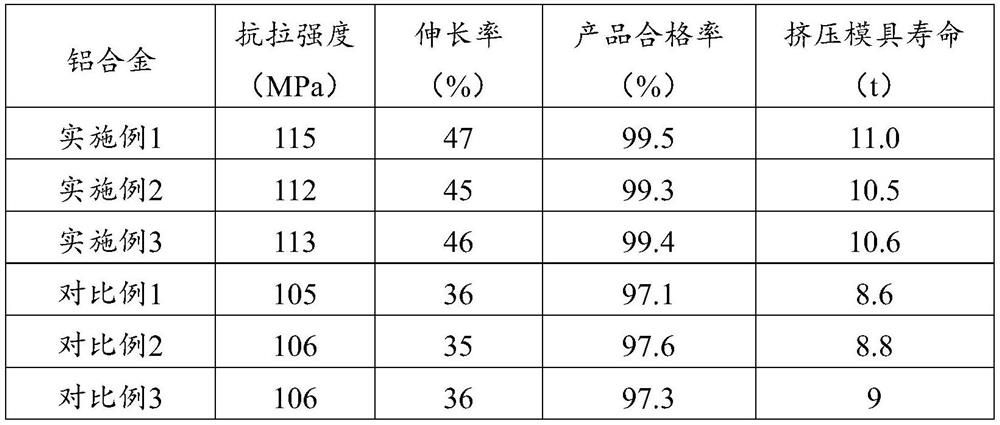

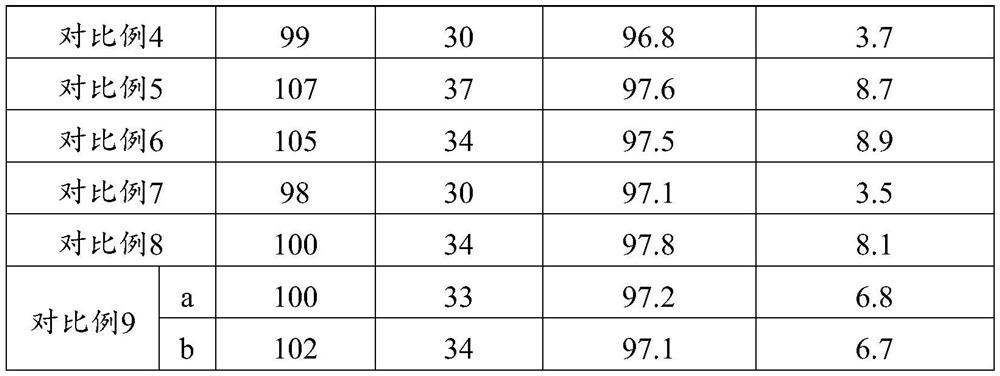

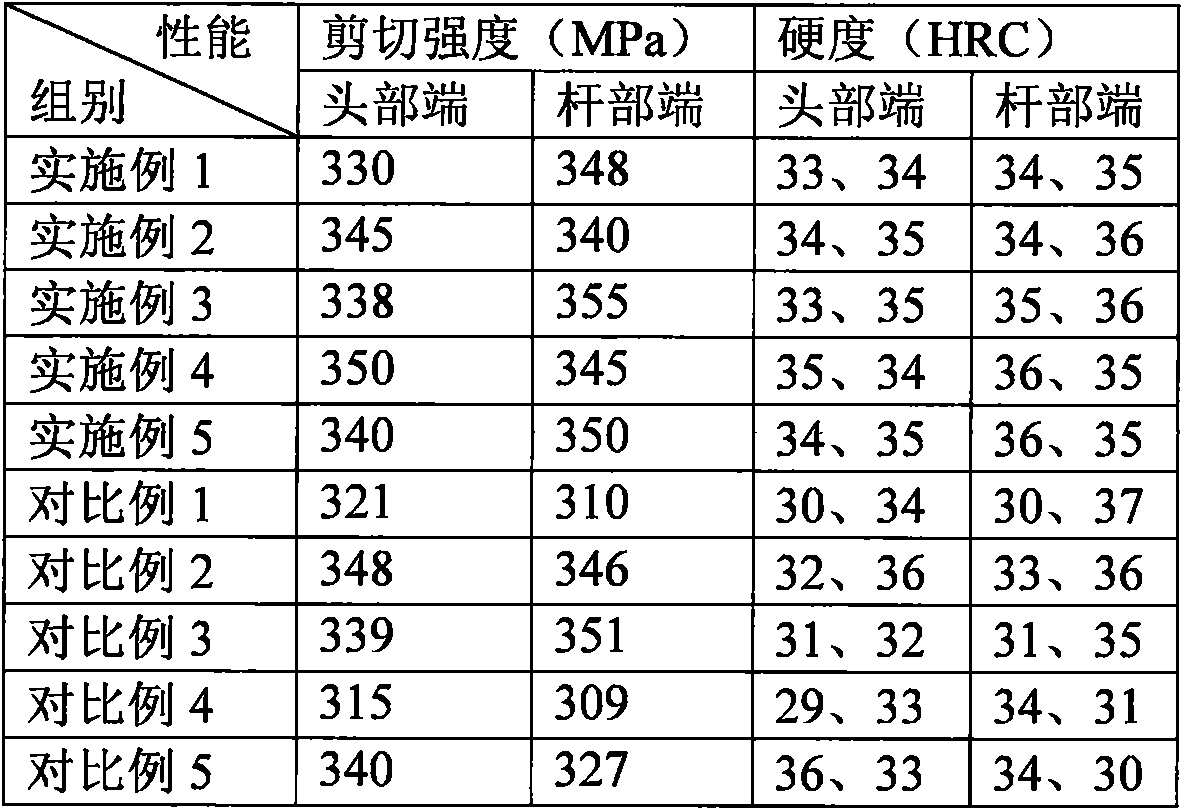

Molding technology for hub supports

The invention provides a molding technology for hub supports. The technology comprises three steps including a blanking step, a forging step and a quenching and tempering treatment step. With the technology, preliminary forging, intermediate forging and final forging are performed in the forging process, coarse grains are prevented through stage-by-stage treatment, and compared with hub supports molded with the prior art, the hub supports have the advantages that the shear strength and the hardness are greatly improved and the comprehensive mechanical performance is improved.

Owner:宁波可挺汽车零部件有限公司

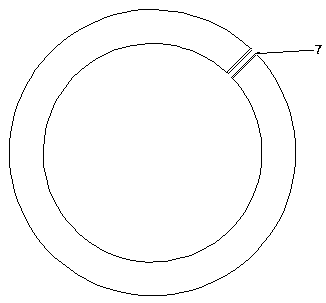

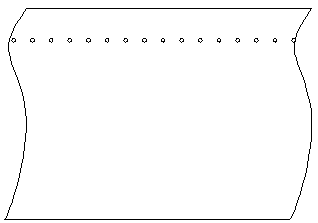

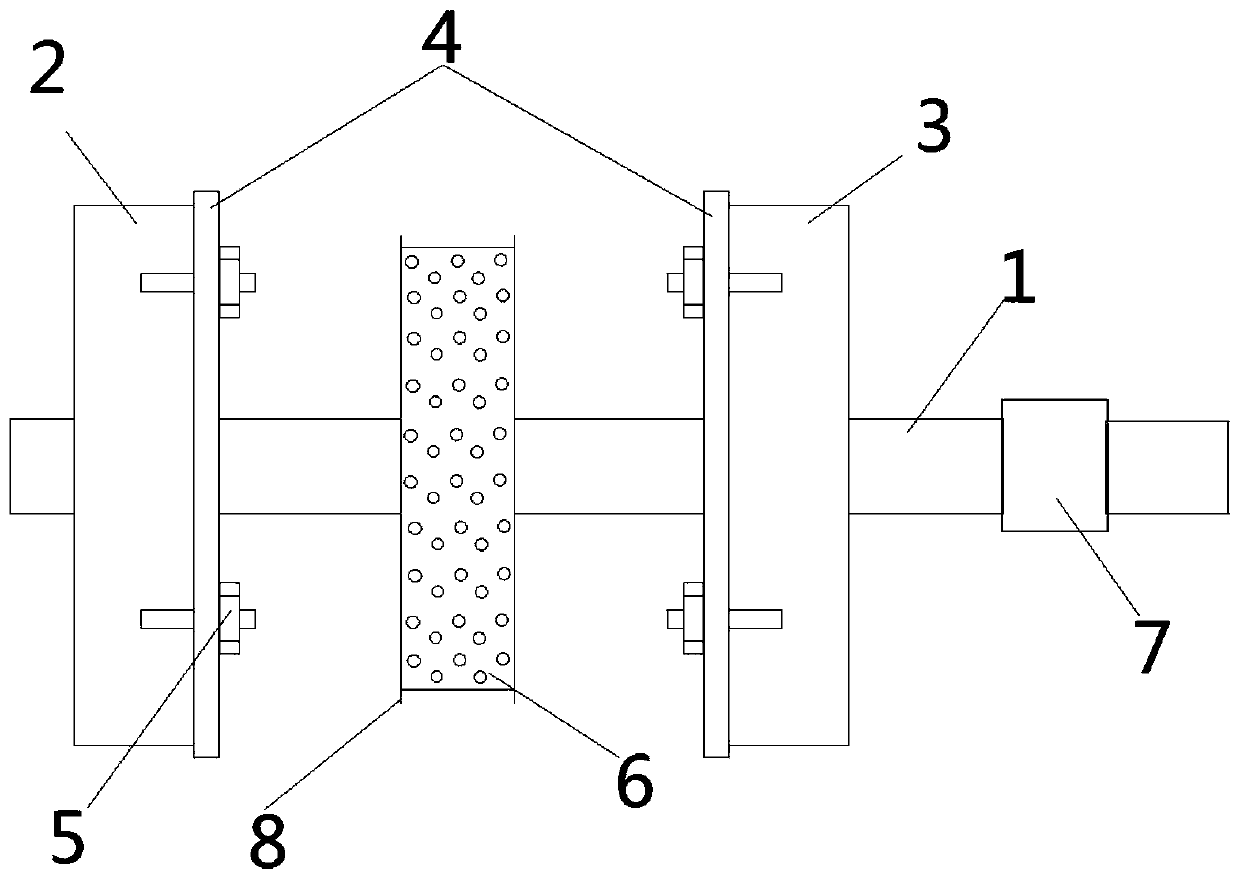

Online forced cooling method and device for extrusion die

The invention discloses an online forced cooling method and device for an extrusion die, used for metal hot extrusion forming. An annular straight slot is machined between a discharging hole of the extrusion die and a pad special for the die around the contour of a main reaction shape of the discharging hole of the extrusion die; a gas pipe is laid in the annular straight slot; cooling inert gasesare introduced into the gas pipe; the cooling gases are ejected onto a die working length and the surface of an extrusion material via tiny outlet holes in the gas pipe. According to extrusion forming production of aluminum and magnesium alloys and other products having low quenching temperature sensitivity, high-pressure forced cooling can be conveniently performed at the extrusion outlet, the extrusion material is subjected to online quenching heat treatment, and the corresponding mechanical property requirements can be met; grain coarsening caused by secondary crystallization is avoided, so that the surface quality meets the requirements, and the surface is bright; the defects in the size, shape, structure and the like of the extrusion material due to extremely high metal temperature fluctuation in the hot extrusion process can be overcome; the extrusion speed is effectively improved, and the production efficiency is improved by 10% or higher.

Owner:FUJIAN UNIV OF TECH

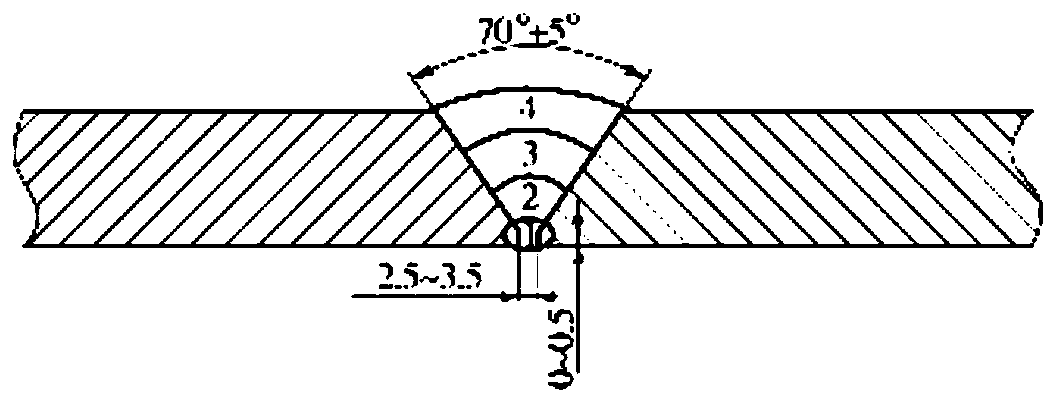

Welding method of nickel-base alloy steel pipeline

The invention discloses a welding method of a nickel-base alloy steel pipeline. A groove of a pipeline to be welded is treated, the angle of the groove of the pipeline to be welded is 70-75 degrees, the poor mobility of material liquid metal is avoided, the groove of the pipeline to be welded and the outer surface of the pipeline to be welded are polished and cleared, the situation that an oxidization layer exists on a weld opening is prevented, then after the pipeline is located and fixed, argon is adopted for protecting the groove of the pipeline to be welded, layering welding is adopted, and the situation that due to the improper welding temperature, as a result, metal grain of weld seams is thick and large, and the mechanical performance and corrosion resisting performance of the weldseams are lowered. According to the method, the scheme is reasonable, the data is reliable and explicit, the problem of 800 H welding quality can be effectively solved, the welding quality is improved, a left gas blocking baffle, a right gas blocking baffle and the inner wall of the pipeline to be welded are utilized for forming a sealing structure, then multiple gas output holes in a gas conveying pipe are utilized for inflating argon into the weld opening, the stable argon environment atmosphere is provided for welding, the device is simple in structure, and stability of the welding environment is ensured.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

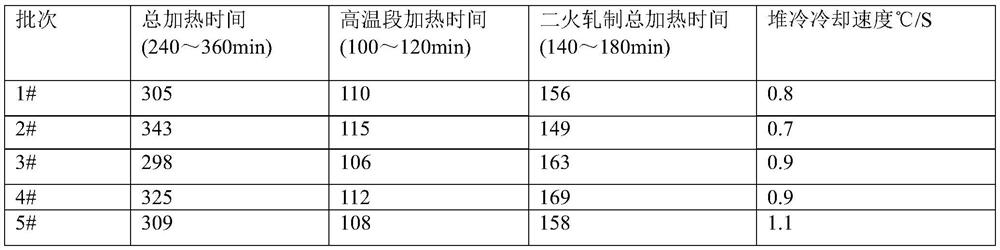

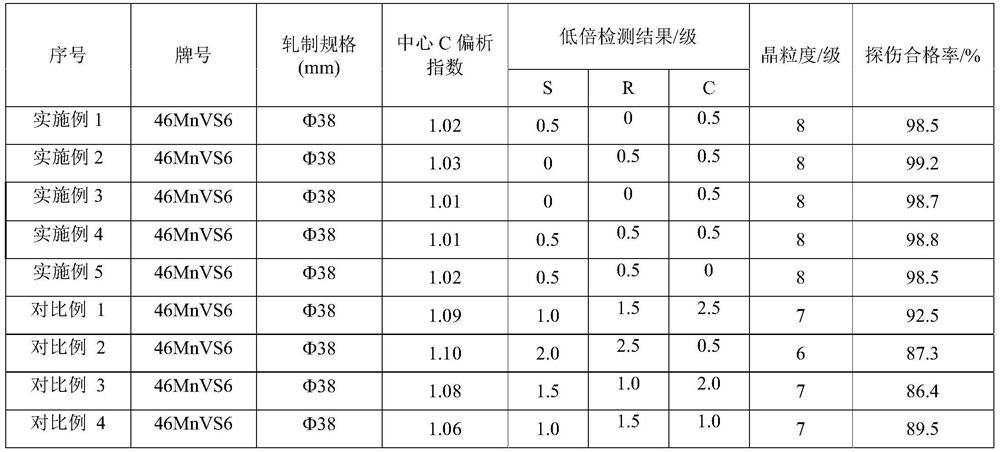

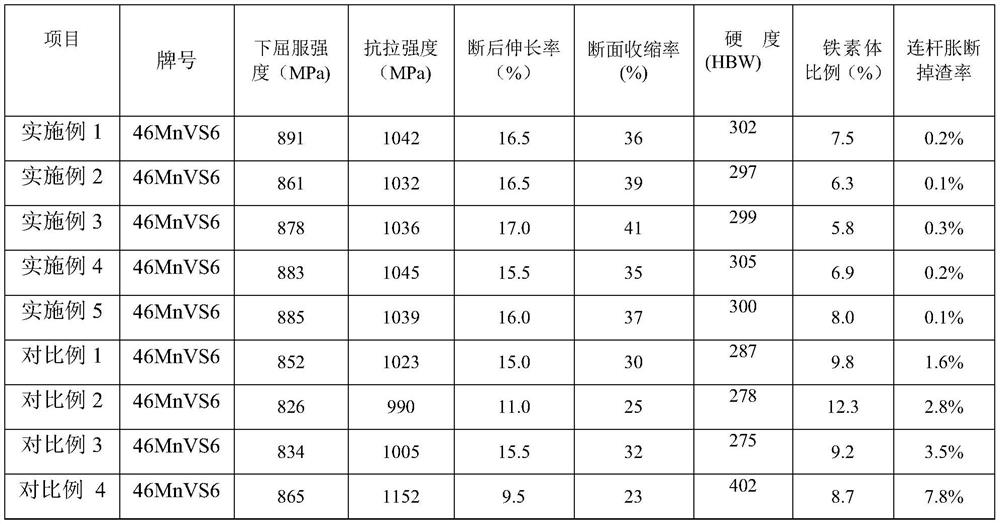

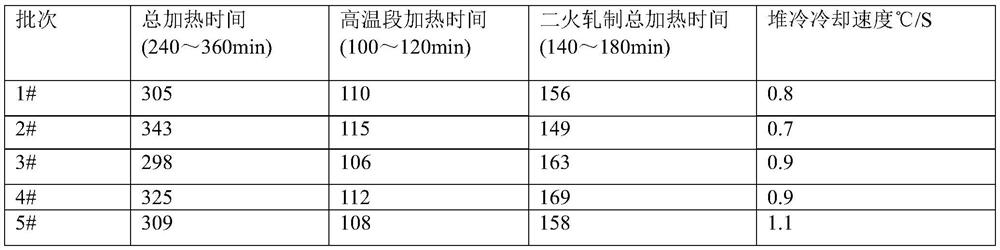

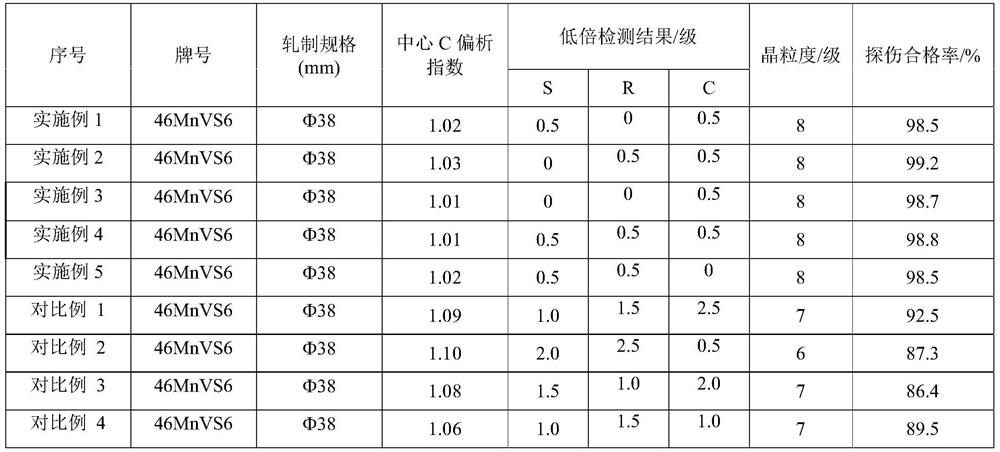

Rolling method for steel for non-quenched-and-tempered connecting rod of engine and manufacturing method of forge pieces

ActiveCN112222204AImprove uniformityHigh strengthTemperature control deviceWork treatment devicesHeating timeEconomic benefits

The invention discloses a rolling method for steel for a non-quenched-and-tempered connecting rod of an engine and a manufacturing method of forge pieces. A continuous casting billet is formed throughtwice heating, a high-temperature diffusion heating process is adopted in first heating, the total heating time is controlled to be 240-360 min, segregation elements in the material are fully diffused in the heating mode that the heating time of a high-temperature section is not shorter than 100 min, a rolling-controlled and cooling-controlled process is adopted in the second heating rolling process, and the manufacturing method of the forge pieces comprises the steps of blanking, induction heating and controlled cooling, wherein by limiting the conditions that the induction heating temperature is 1200-1230 DEG C, the cooling speed on an air cooling line is controlled to be 3-4.5 DEG C / S, the temperature of an air cooling line under a forging blank is controlled to be 580-620 DEG C, the grain size of the connecting rod is effectively refined, the strength, toughness and plasticity of the material are improved, abnormal texture is prevented, surface scratches and other defects are prevented, the ferrite proportion is reduced, and good economic benefits and environmental benefits are obtained.

Owner:ZENITH STEEL GROUP CORP +1

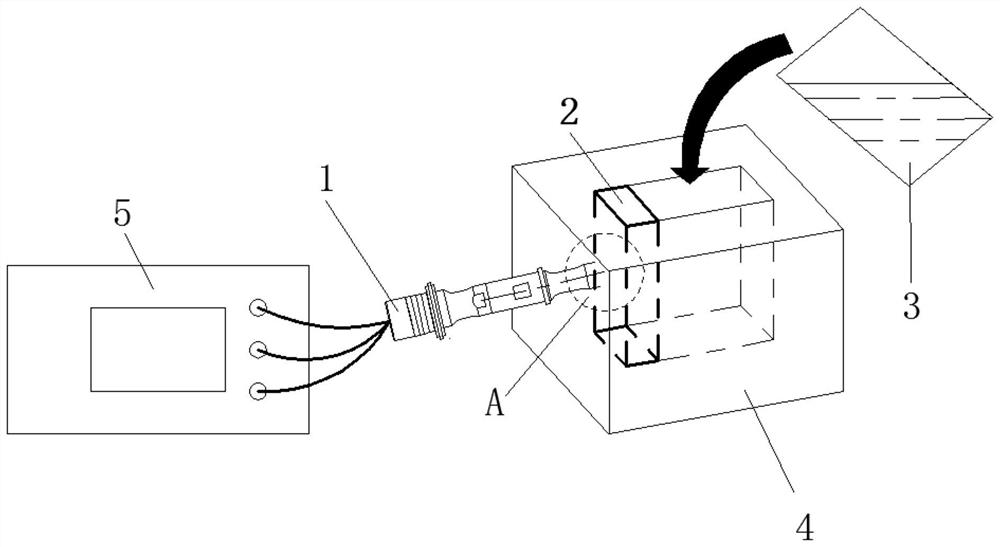

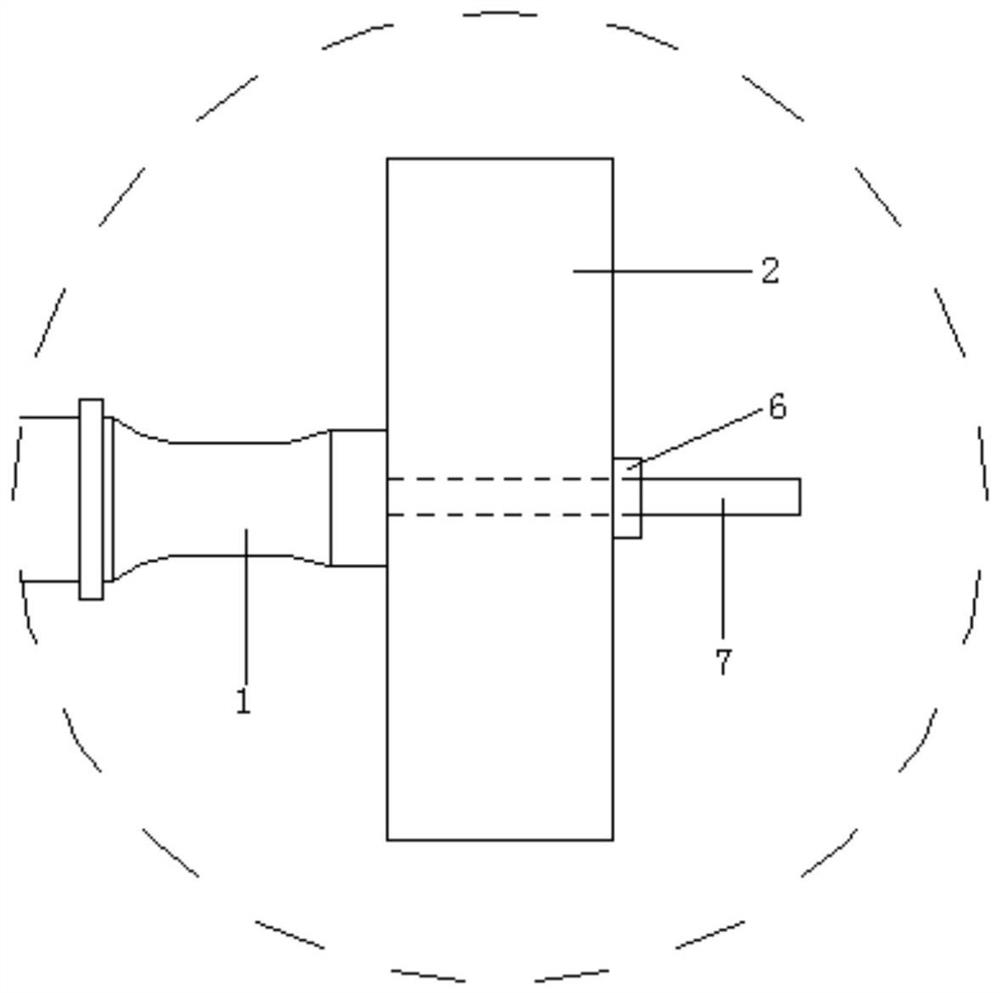

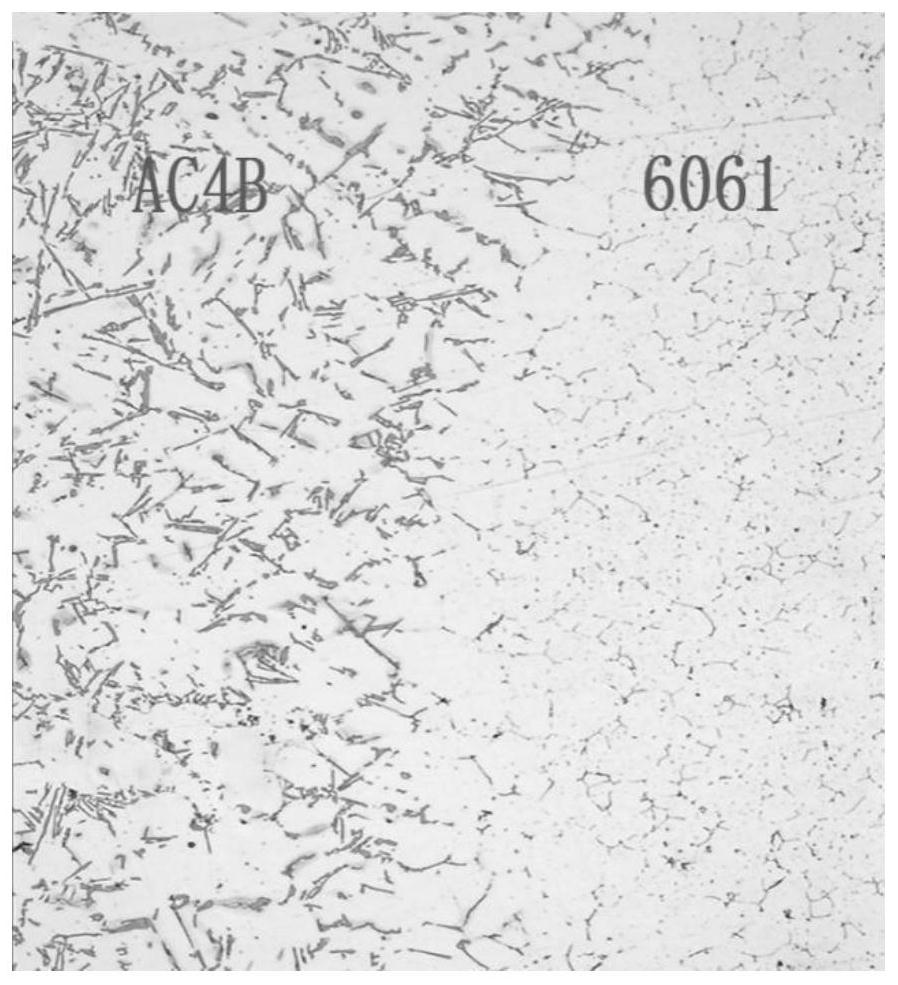

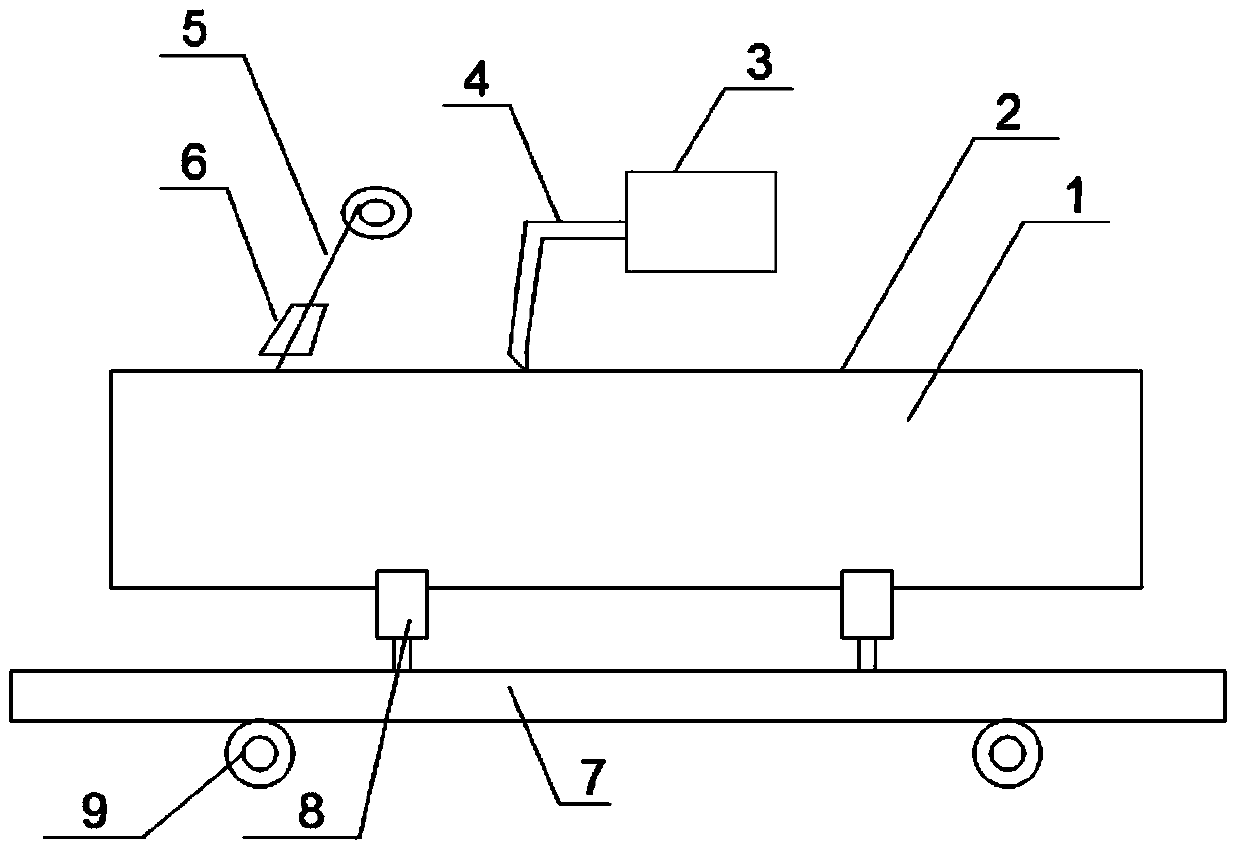

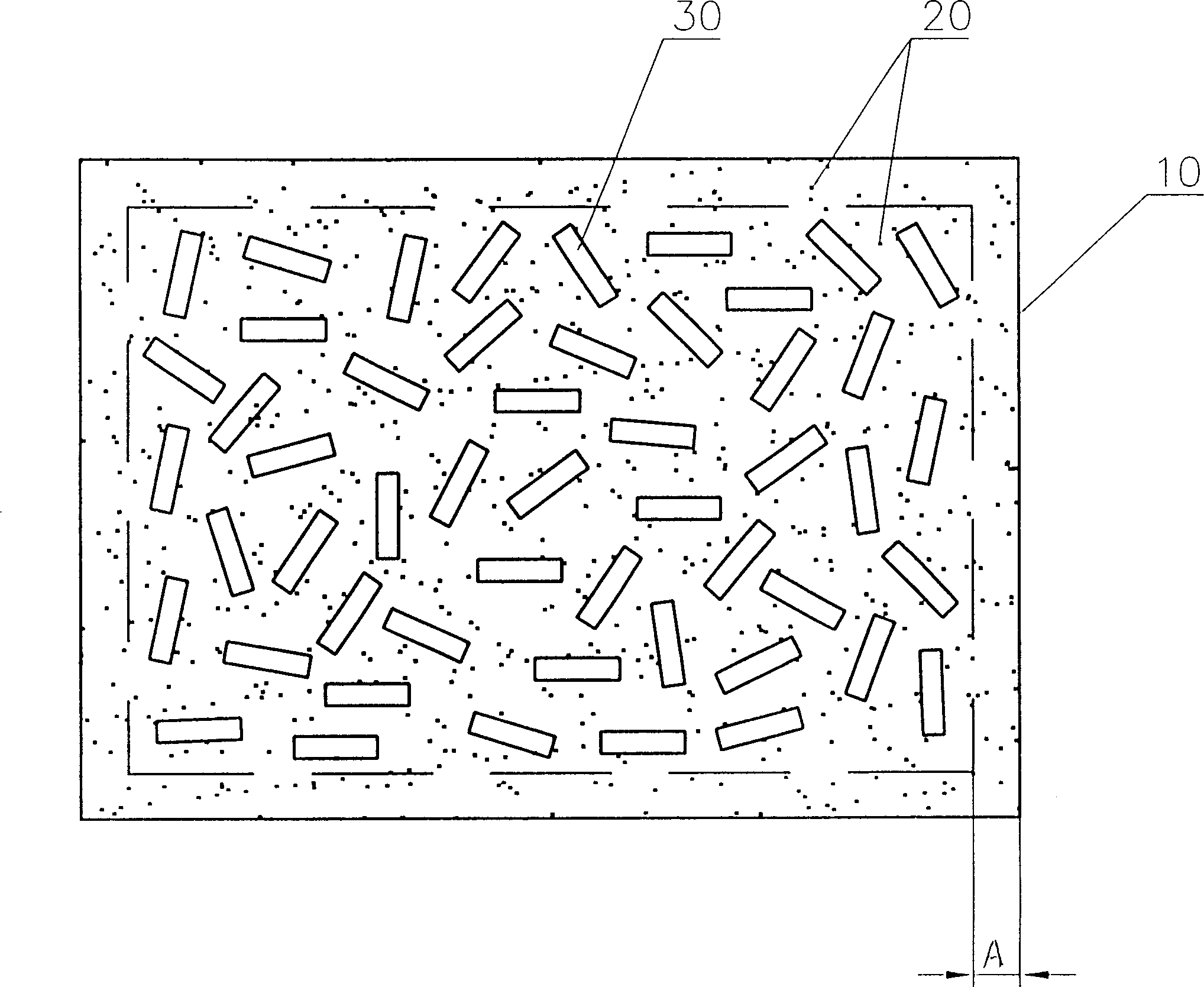

Bimetal compounding method

The invention discloses a bimetal compounding method, and belongs to the technical field of bimetal composite casting. The method aims to solve the technical problems of low interface bonding strength, difficulty in control of solidification time and many casting interface defects in the bimetal casting compounding process. According to the technical scheme, the method comprises the following specific steps that S1, the surface of solid metal to be compounded is subjected to surface treatment; S2, the solid metal to be compounded is placed in a mold, a solid to be compounded is fixed to an ultrasonic vibration tool head, and ultrasonic vibration is applied to the solid metal to be compounded; S3, an ultrasonic vibration device is started, and the ultrasonic vibration tool head and the solid metal to be compounded generate ultrasonic vibration; S4, another kind of metal to be compounded is molten to 10-100 DEG C above the liquidus and then poured into the mold in the step S2, and the molten metal solution is compounded with the solid metal under the action of ultrasonic vibration; and S5, after the metal solution is solidified, the ultrasonic vibration device is stopped, and the product is cooled to room temperature to obtain a bimetallic composite material.

Owner:QILU UNIV OF TECH

Welding seam cooling liquid for use in longitudinal submerged arc welding of steel pipes and use method thereof

ActiveCN104263325ASpeed up coolingHigh strengthWelding/cutting auxillary devicesArc welding apparatusPolyvinyl alcoholRetention time

The invention discloses welding seam cooling liquid for use in longitudinal submerged arc welding of steel pipes and a use method thereof. The welding seam cooling liquid for use in longitudinal submerged arc welding of the steel pipes comprises the following specific components in percentage by mass: 5-10 percent of polyvinyl alcohol, 10-15 percent of ethylene glycol, 10-15 percent of propylene glycol, 2-5 percent of glycerol, 1-3 percent of sodium nitrate, 0.5-1 percent of potassium hydroxide, 0.5-1.5 percent of an antifoaming agent, 0.1-1.5 percent of an anticorrosive agent and the balance of deionized water. Through adoption of the welding seam cooling liquid, the cooling speed of a welding seam is increased, and the deformation and cracking of the welding seam are avoided. Meanwhile, the high-temperature retention time of the welding seam is shortened, coarse grains in a weld microstructure are prevented, and the strength and toughness of the welding seam are enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Carrier roller heat treatment technology

InactiveCN104152641ALow degree of surface oxidation decarburizationUniform cooling rateFurnace typesHeat treatment furnacesSkin coolingHeat carrier

The invention discloses a carrier roller heat treatment technology. The carrier roller heat treatment technology comprises a quenching treatment step and a tempering step. According to the quenching treatment step, preheating, heat preservation and shock cooling working procedures are sequentially carried out on a forming carrier roller with billet materials of 40 Cr, and the water cooling and air cooling interphase circulating cooling mode is adopted by shock cooling; according to the preheating step, the carrier roller is heated to 630 DEG C to 650 DEG C, and heat preservation is carried out on the carrier roller for five or more hours; according to the heat preservation step, the heat carrier roller obtained in the preheating step is moved into a heating furnace with the temperature higher than 870 DEG C to be heated to 840 DEG C to 870 DEG C, and heat preservation is carried out on the heat carrier roller for two or more hours. The process route is simple, the shock cooling mode that water cooling and air cooling are alternatively carried out is adopted, and under the condition that the heat treatment quality target is achieved, an existing adopted oil quenching shock cooling mode is replaced. Due to changes of the process, the quenching cost is saved, meanwhile, the dependency on oil quenching agents is reduced, and due to implementation of the process, environmental protection is benefited.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

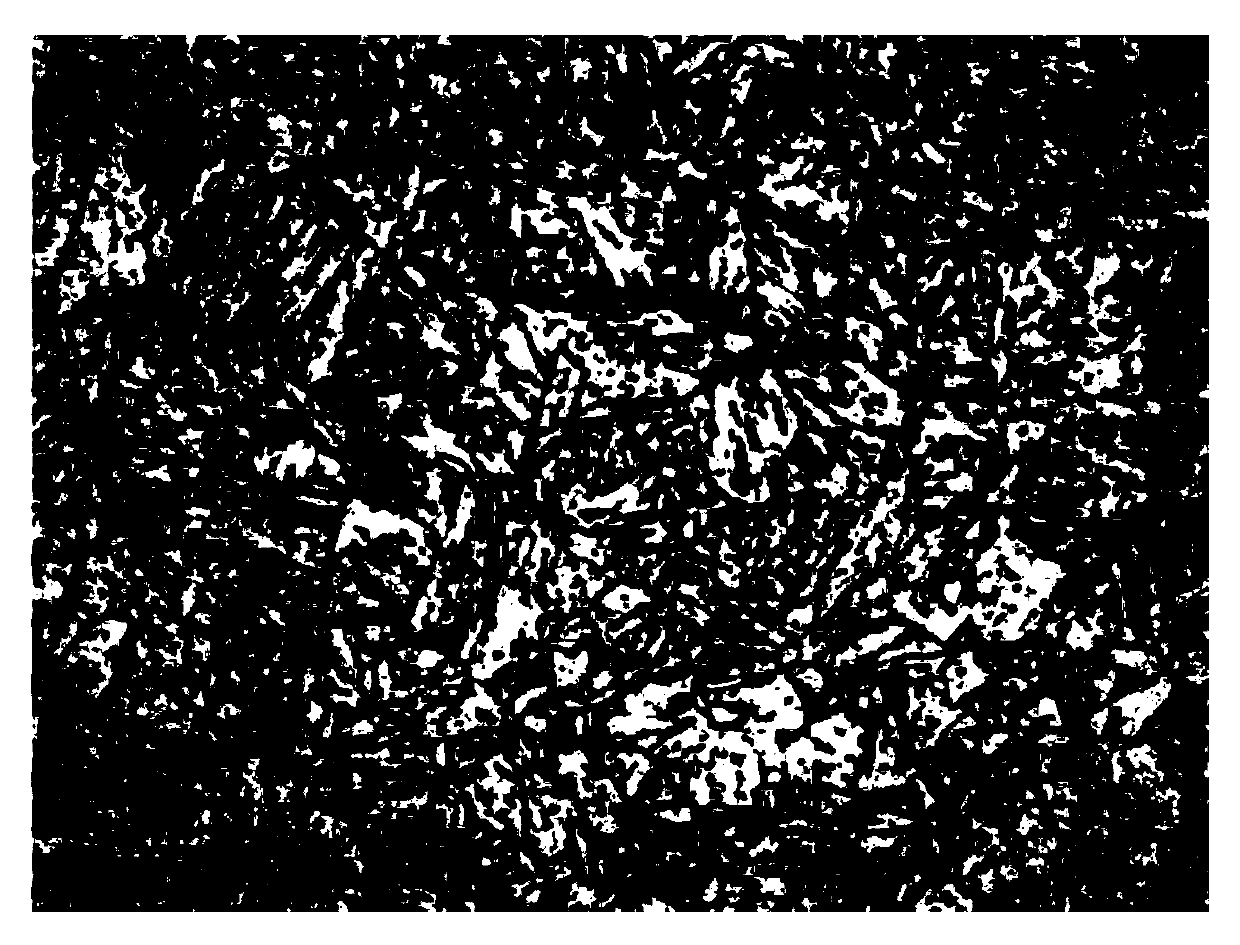

Welding method of novel high alloy austenitic heat-resistant stainless steel

InactiveCN111715982ALow heat inputAvoid Coarse GrainsElectrode holder supportersWelding/soldering/cutting articlesShielding gasSS - Stainless steel

The invention provides a welding method of novel high alloy austenitic heat-resistant stainless steel, and belongs to the field of stainless steel welding. The welding method comprises the following steps of preheating a workpiece to 100 DEG C, welding the workpiece in two passes, keeping the interlayer temperature not higher than 100 DEG C, selecting the current to be 180A, the voltage to be 18.0V, and a protective gas to be a mixed gas with a volume ratio of Ar of 97.5% and CO2 of 2.5%; the flow rate of the protective gas is 12 to 18L / min; for the first pass, the current is 180A, the voltageis 18.0V, and the welding speed is 0.3m / min; the heat input is 0.518KJ / mm; for the second pass, the current is 180A, the voltage is 18.0V, and the welding speed is 0.2 to 0.4m / min; the heat input is0.30 to 0.71KJ / mm; and the coefficient of thermal efficiency is 0.8. According to the welding method of the novel high alloy austenitic heat-resistant stainless steel provided by the invention, a weldis excellent in shaping, the overall weld appearance is uniform, and there are no weld defects such as cracks, pores, undercuts and the like.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aluminum alloy for extrusion and preparation method thereof

ActiveCN113846249AIncrease contentImprove corrosion resistanceFurnace typesHeat treatment furnacesUltimate tensile strengthContinuous rolling

The invention relates to an aluminum alloy for extrusion. The aluminum alloy comprises the following components of, in percentage by mass, 0.1%-0.2% of Si, 0.15%-0.25% of Fe, 1.8%-2.4% of Mn, 0.05%-0.18% of Zn, 0.03%-0.06% of Er, 0.008%-0.04% of Ti, 0.04%-0.08% of Be, 0.01%-0.02% of V and the balance of Al and inevitable impurities, and the total amount of the impurities is not more than 0.015%. The aluminum alloy is prepared through the technological steps of smelting, alloying, refining, molten aluminum online treatment, continuous casting, continuous rolling, cooling and take-up, annealing treatment and the like. The aluminum alloy is remarkably improved in the aspects of corrosion resistance, material strength, fluidity and structure continuity, the pressure bearing capacity of a prepared extrusion material is remarkably improved, and the service life is prolonged.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD

30-silver indium-containing brazing filler metal and preparation process thereof

InactiveCN110170766AEliminate brittlenessLow costWelding/cutting media/materialsSoldering mediaIndiumElectrolysis

The invention discloses a preparation process of 30-silver indium-containing brazing filler metal. The preparation process comprises the following steps that (1) electrolytic copper, silver and No. 1zinc are proportioned according to the proportion and then are melted, and stirring and slag removal are carried out; (2) a mixture of indium, strontium and cerium in a certain proportion is added into a solution in the step (1), and when the melting temperature is 950-980 DEG C, stirring and slag removal are carried out; (3) the discharged solution from the furnace is cast into a rod material with the diameter of 50 mm and the length of 660 mm, the outer oxide skins of the cast rod material is removed, then the cast rod material is cut into small rod materials, and the cut small rod materialsare preheated and then are extruded into wires with the wire diameter of 0.13-0.20 mm in a heating environment; and (4) the wires obtained in the step (3) are drawn into coiled wires by adopting an outer mold under the normal temperature condition. The preparation process has the beneficial effects that the tensile strength of a product is enhanced, the material cost is reduced at the same time,and the welding temperature is reduced.

Owner:新乡市七星钎焊科技有限公司

Wheel bracket forming process

ActiveCN106391984BAvoid Coarse GrainsIncreased shear strengthFurnace typesWheelsHardnessUltimate tensile strength

The invention provides a molding technology for hub supports. The technology comprises three steps including a blanking step, a forging step and a quenching and tempering treatment step. With the technology, preliminary forging, intermediate forging and final forging are performed in the forging process, coarse grains are prevented through stage-by-stage treatment, and compared with hub supports molded with the prior art, the hub supports have the advantages that the shear strength and the hardness are greatly improved and the comprehensive mechanical performance is improved.

Owner:宁波可挺汽车零部件有限公司

Toughening-type high-temperature iridium rhodium thermocouple

ActiveCN102937486BAvoid coarse grainsSolve the brittleThermometers using electric/magnetic elementsUsing electrical meansIridiumAdhesive

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Grain control method for production of ultrawide double-zero aluminum foil blanks by electrolytic aluminum liquid cast-rolling process

ActiveCN103042030BIncrease the number of non-spontaneous crystal nucleiAvoid Coarse GrainsMetal rolling arrangementsProduction lineGrain structure

The invention relates to a grain control method for production of ultrawide double-zero aluminum foil blanks by electrolytic aluminum liquid cast-rolling process. A smelting furnace holding solid aluminum and electrolytic aluminum liquid in a horizontal aluminum cast-rolling line is used for smelting for 4-10 hours at the low temperature of 720-735 DEG C, the aluminum liquid is heated to 740-750 DEG C in 20-30 minutes, the aluminum liquid is refined after alloy preparation, the aluminum liquid is allowed to stand for 30-50 minutes after refining and is transferred to a standing furnace, the aluminum liquid in the standing furnace is evenly mixed for 10 minutes every 4-6 hours by Ar and CCl4, the aluminum liquid in the standing furnace flows into a filter tank through a degassing tank and a channel and flows to a front tank through the filter tank and the channel, and the aluminum liquid is injected into gaps of casting rollers by a casting spile. With the process coordinating with equipment, adjustable temperature and speed of the aluminum liquid in the casting spile are achieved, and even transverse and longitudinal grain structures of a casting slab can be obtained.

Owner:YUNNAN ALUMINUM

A method for internal pressure forming of pipes with hot medium based on molten glass

ActiveCN108856441BMeet the forming temperature process requirementsReduce compressionMolten stateInternal pressure

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

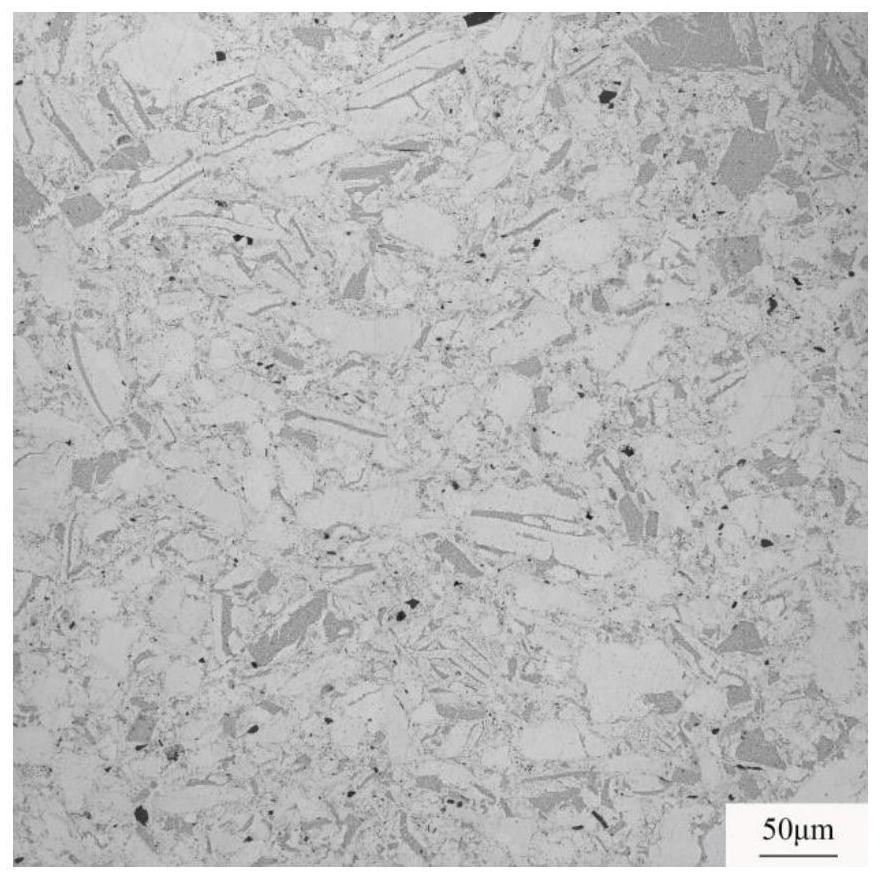

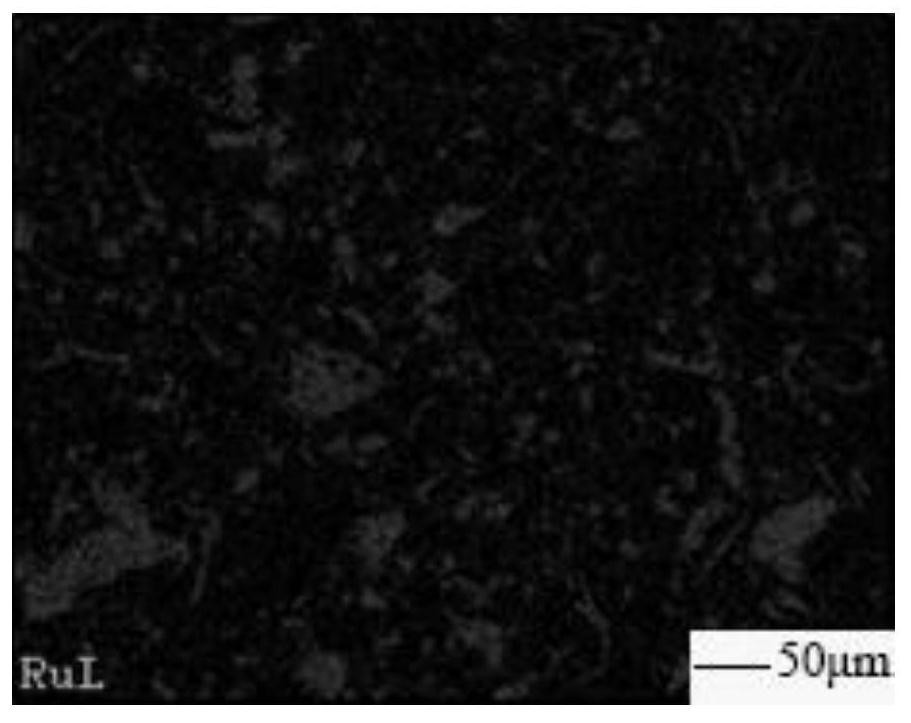

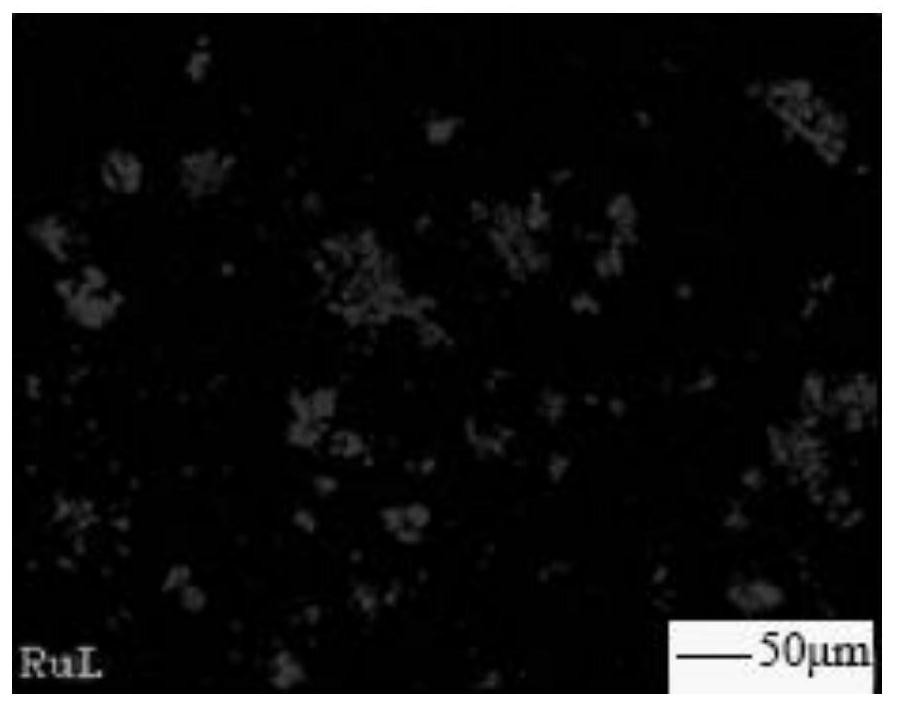

Ru-Sb-Te alloy sputtering target material suitable for being used as long-storage phase change storage medium and preparation method of Ru-Sb-Te alloy sputtering target material

PendingCN114717524AImprove uniformityImprove compactnessElectrical apparatusVacuum evaporation coatingHeat stabilityRu element

The invention discloses a high-performance Ru-Sb-Te alloy sputtering target material suitable for being used as a long-storage phase change storage medium. The Ru-Sb-Te alloy sputtering target material is an alloy target material composed of raw materials including ruthenium Ru, antimony Sb and tellurium Te according to the chemical formula Rux (Sb2Te) 100-x, x is the atomic percent of the Ru element, and x is larger than or equal to 1 and smaller than or equal to 10; in particular x is 5 or 8; the raw material is a compound of three elementary metals of Ru, Sb and Te or any two elements. The preparation method comprises the following steps: taking ruthenium, antimony, tellurium or compounds of any two elements as raw materials, and preparing Ru-Sb-Te alloy powder through a casting method; a target blank is obtained through mechanical crushing and pressure sintering, and finally the target is obtained through machining and forming. By adding ruthenium, the defects of low phase change temperature, poor thermal stability and the like of the Sb2Te compound are overcome; through powder preparation and pressure sintering after smelting, a sputtering target material with good uniformity and high density is obtained, and the defects that a target material prepared through direct fusion casting is multiple in smelting defect, coarse in grain, poor in machinability and the like are overcome; and the high requirement of the phase change storage field on the RST target material is fully met.

Owner:昆明贵研新材料科技有限公司

A rolling method of steel for non-quenched and tempered connecting rod of an engine and a manufacturing method of a forging

ActiveCN112222204BImprove uniformityHigh strengthTemperature control deviceWork treatment devicesHeating timeEconomic benefits

The invention discloses a rolling method of steel for non-quenched and tempered connecting rods of engines and a manufacturing method of forgings. The continuous casting slab is made into material through two fires, one of which adopts high-temperature diffusion heating process, and the total heating time is controlled from 240 to 360 minutes, and the heating time of the high-temperature section is not less than 100 minutes to fully diffuse the segregated elements in the material. The controlled rolling and controlled cooling process is adopted during fire rolling. The forging method includes blanking, induction heating, and controlled cooling. The induction heating temperature is 1200-1230°C, and the cooling rate on the air-cooled line is controlled to be 3-4.5°C / S. Controlling the temperature of the lower air-cooling line of the forging blank at 580-620°C effectively refines the grain size of the connecting rod, improves the strength, toughness and plasticity of the material, prevents abnormal structures, and prevents defects such as surface scratches produce, reduce the proportion of ferrite, and obtain good economic and environmental benefits.

Owner:ZENITH STEEL GROUP CORP +1

A kind of aluminum alloy for extrusion and preparation method thereof

ActiveCN113846249BIncrease contentImprove corrosion resistanceFurnace typesHeat treatment furnacesUltimate tensile strengthContinuous rolling

The invention relates to an aluminum alloy for extrusion. The components and the mass percentages of the components are: Si 0.1-0.2%, Fe 0.15-0.25%, Mn 1.8-2.4%, Zn 0.05-0.18%, Er 0.03-% 0.06%, Ti 0.008‑0.04%, Be 0.04‑0.08%, V 0.01‑0.02%, the rest are Al and unavoidable impurities, the total amount of impurities does not exceed 0.015%, after smelting, alloying, refining, aluminum liquid online It is prepared by process steps such as treatment, continuous casting, continuous rolling, cooling and rewinding, and annealing treatment. The aluminum alloy of the present invention is significantly improved in corrosion resistance, material strength, fluidity and organizational continuity, the pressure bearing capacity of the produced extruded material is significantly improved, and the service life is prolonged.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD

Weld seam coolant for straight seam submerged arc welding of steel pipe and its application method

ActiveCN104263325BSpeed up coolingHigh strengthWelding/cutting auxillary devicesArc welding apparatusPolyvinyl alcoholRetention time

The invention discloses welding seam cooling liquid for use in longitudinal submerged arc welding of steel pipes and a use method thereof. The welding seam cooling liquid for use in longitudinal submerged arc welding of the steel pipes comprises the following specific components in percentage by mass: 5-10 percent of polyvinyl alcohol, 10-15 percent of ethylene glycol, 10-15 percent of propylene glycol, 2-5 percent of glycerol, 1-3 percent of sodium nitrate, 0.5-1 percent of potassium hydroxide, 0.5-1.5 percent of an antifoaming agent, 0.1-1.5 percent of an anticorrosive agent and the balance of deionized water. Through adoption of the welding seam cooling liquid, the cooling speed of a welding seam is increased, and the deformation and cracking of the welding seam are avoided. Meanwhile, the high-temperature retention time of the welding seam is shortened, coarse grains in a weld microstructure are prevented, and the strength and toughness of the welding seam are enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com