Preparation method and application of nano tungsten trioxide and nano tungsten powder

A technology of nano-tungsten trioxide and nano-tungsten powder, applied in the direction of tungsten oxide/tungsten hydroxide, nanotechnology, carbide, etc., to achieve the effect of improving nucleation rate, improving mixing uniformity and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] Step 1. Ultrasonically disperse 0.6g of carbon nanoparticles in 100mL of deionized water for 2h with the assistance of 0.4g of dispersant PVP, then add 20g of ammonium metatungstate with a mass purity of 99.5% and stir to obtain a mixed solution; The average particle size of the carbon nanoparticles is 20nm, the mass purity is 99%, and the carbon nanoparticles are an amorphous structure;

[0032]Step 2. The mixed solution obtained in step 1 is rotated to dryness at 90° C. at a speed of 600 rpm to obtain a composite powder;

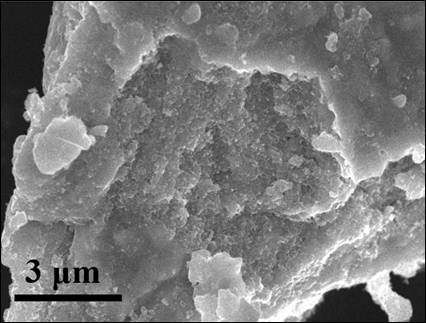

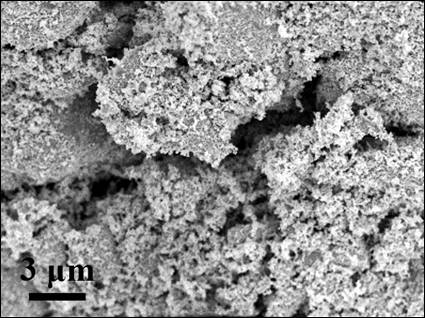

[0033] Step 3: Decompose the composite powder obtained in step 2 at a rate of 80°C / min to 550°C in an air atmosphere and keep it warm for 2 hours to obtain nano-tungsten trioxide;

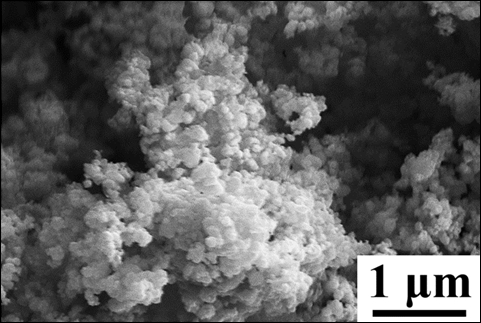

[0034] Step 4. Lay the nano-tungsten trioxide obtained in step 3 until the thickness of the material layer is 3mm. Under the hydrogen atmosphere, first raise the temperature to 600°C at a rate of 2.5°C / min and keep ...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042] Step 1: Disperse 0.8g of carbon nanoparticles in 100mL of deionized water by ultrasonication for 1.5h with the assistance of 0.2g of dispersant PVP, then add 20g of ammonium metatungstate with a mass purity of 99.5% and stir to obtain a mixed solution; The average particle size of the carbon nanoparticles is 10nm, the mass purity is 99%, and the carbon nanoparticles have an amorphous structure;

[0043] Step 2. The mixed solution obtained in Step 1 is rotated to dryness at 100° C. at a speed of 200 rpm to obtain a composite powder;

[0044] Step 3: Decompose the composite powder obtained in step 2 at a rate of 100°C / min to 500°C in an air atmosphere and keep it warm for 5 hours to obtain nano-tungsten trioxide;

[0045] Step 4. Lay the nano-tungsten trioxide obtained in step 3 until the thickness of the material layer is 2mm. Under the hydrogen atmosphere, first raise the temperature to 560°C at a rate of 5°C / min a...

Embodiment 3

[0049] This embodiment includes the following steps:

[0050] Step 1. Disperse 0.5g of carbon nanoparticles in 100mL of deionized water with the aid of dispersant 0.6g of PVP and 0.6g of PEG1000 for 1h, then add 50g of ammonium metatungstate with a mass purity of 99.5% and mix well , to obtain a mixed solution; the average particle size of the carbon nanoparticles is 20nm, the mass purity is 99%, and the carbon nanoparticles are an amorphous structure;

[0051] Step 2. The mixed solution obtained in Step 1 is rotated to dryness at 95° C. at a speed of 250 rpm to obtain a composite powder;

[0052] Step 3: Decompose the composite powder obtained in step 2 by raising the temperature to 620°C at a rate of 10°C / min in an air atmosphere and keeping it warm for 2 hours to obtain nano-tungsten trioxide;

[0053] Step 4. Lay the nano-tungsten trioxide obtained in step 3 until the thickness of the material layer is 6mm. Under the hydrogen atmosphere, first raise the temperature to 620...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com