Bimetal compounding method

A bimetal and metal technology, applied in the field of bimetal composite casting, can solve the problems of low interface bonding strength, difficult control of solidification time, and many casting interface defects, so as to promote metallurgical bonding, promote the use value, and avoid coarse grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

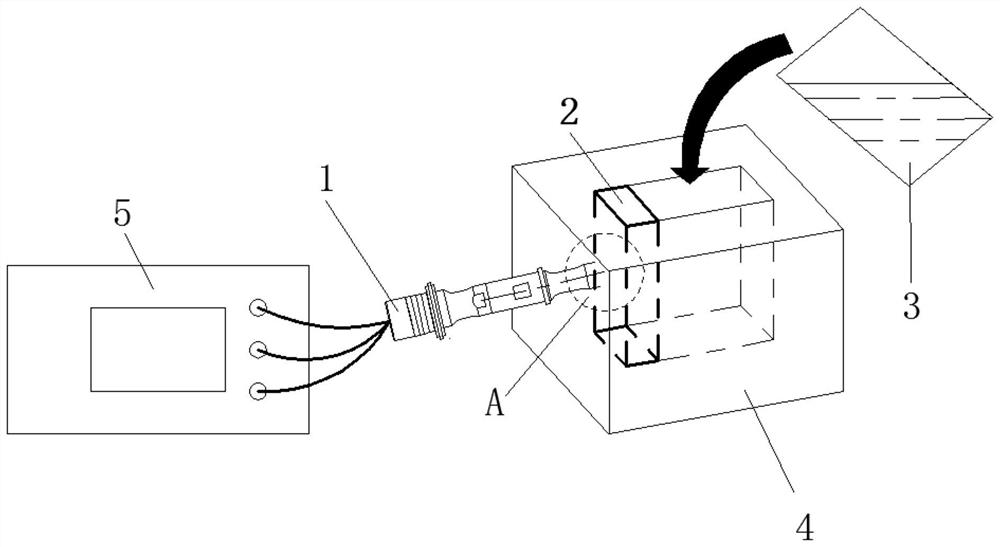

[0050] as attached figure 1 and 2 Shown, the bimetal composite method of the present invention, the concrete steps of this method are as follows:

[0051] S1. Perform surface treatment on the surface of the solid metal to be composited;

[0052] S2. Place the solid metal to be compounded in the mold, fix the solid to be compounded on the ultrasonic vibration tool head, and apply ultrasonic vibration to the solid metal to be compounded;

[0053] S3, turn on the ultrasonic vibration device, so that the ultrasonic vibration tool head and the solid metal to be composited generate ultrasonic vibration;

[0054] S4. Melting another metal to be compounded to 10-100°C above the liquidus line, and then pouring it into the mold in step S2, the molten metal solution is compounded with the fixed metal under the action of ultrasonic vibration;

[0055] S5. After the metal solution is solidified, turn off the ultrasonic vibration device, cool to room temperature, and obtain a bimetallic ...

Embodiment 2

[0076] In this embodiment, 6061 aluminum alloy is used as the solid metal matrix material, and the size is 60×50×2mm, as follows:

[0077] (1), the aluminum alloy base plate 2 is perforated, and polished on 400# sandpaper;

[0078] (2), sequentially cleaning the oxide film on the surface of the aluminum alloy substrate plate 2 with 10% hydrochloric acid solution and 10% sodium hydroxide solution, then cleaning with distilled water and drying for later use;

[0079] (3), mold 4 is heated to 200 ℃ for 30 minutes;

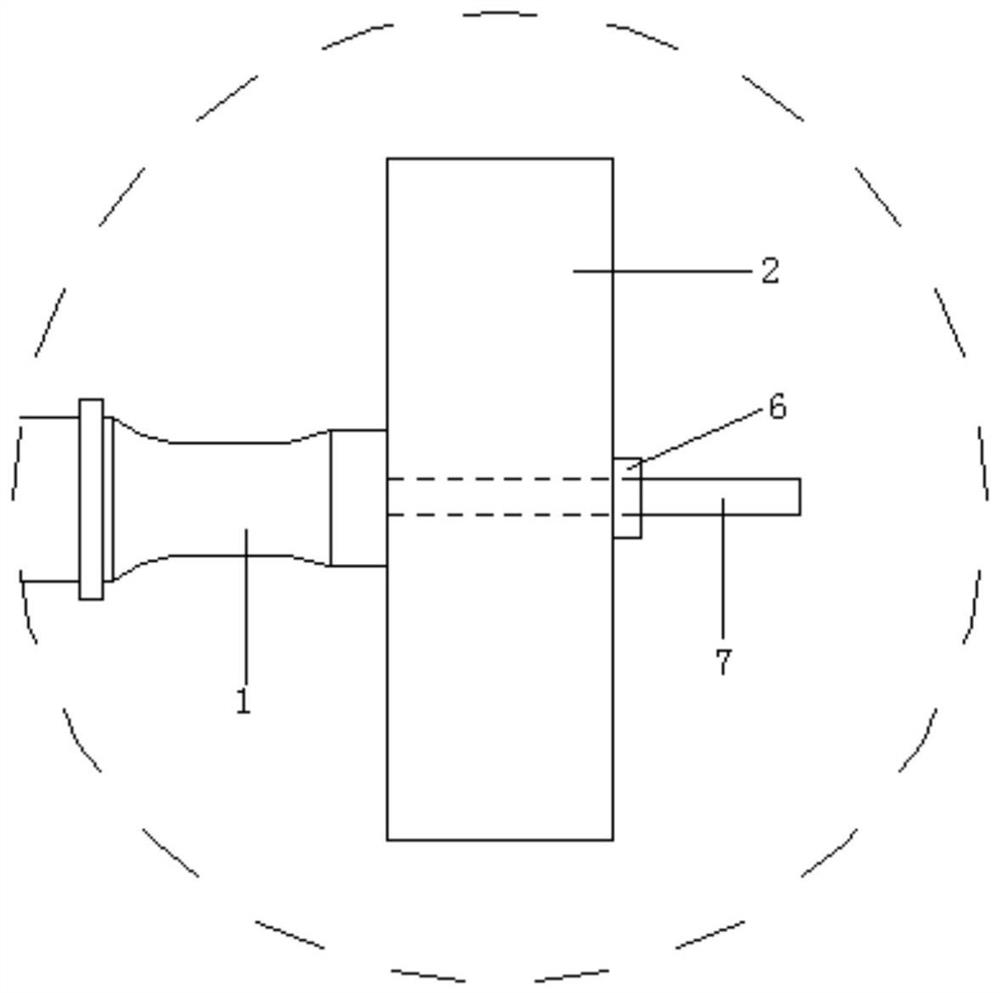

[0080] (4) Fix the cleaned aluminum alloy base plate 2 on the ultrasonic horn 1 by fastening nuts 6 and bolts 7, place it vertically in the mold 4, and select the vibration direction to be perpendicular to the joint surface to vibrate;

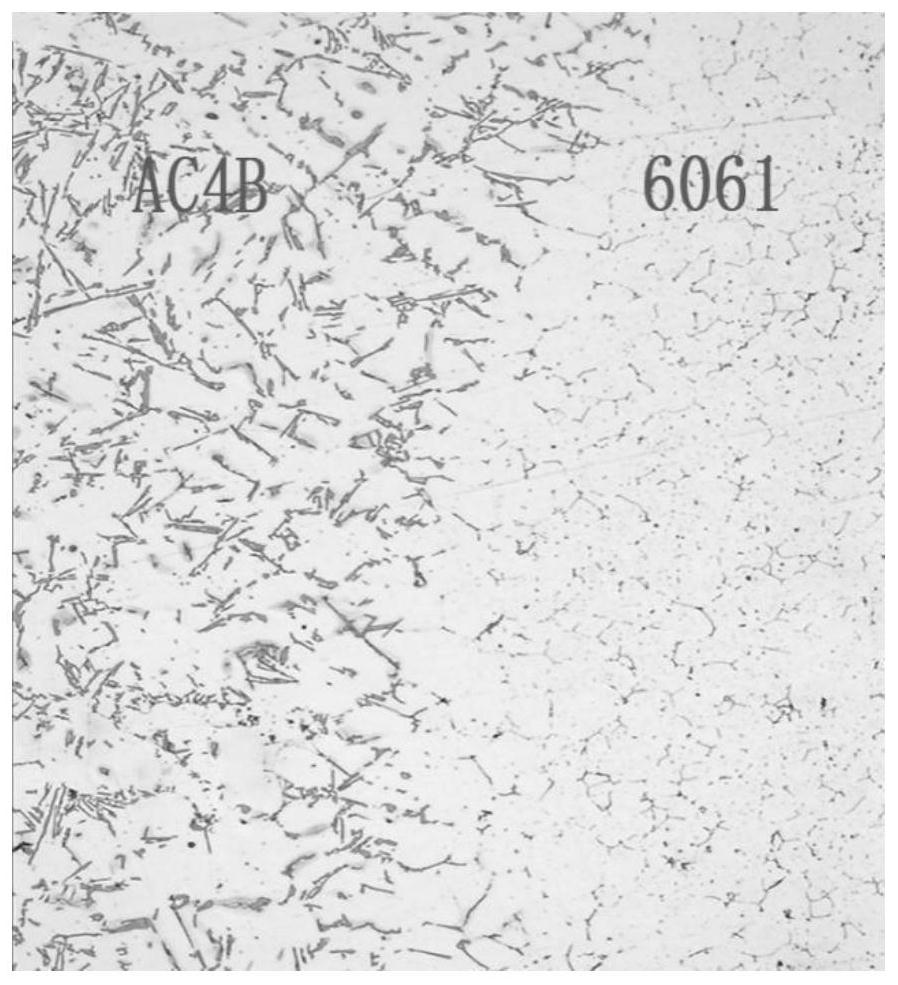

[0081] (5) Set the ultrasonic power to 960W, the vibration frequency to 24KHz, turn on the ultrasonic vibration device 5, apply ultrasonic vibration to the aluminum alloy base plate 2, and then cast the liquid AC4B aluminum alloy 3 a...

Embodiment 3

[0085] In this embodiment, 7075 aluminum alloy is used as the solid metal matrix material, and the size is 60×50×2mm, as follows:

[0086] (1), the 7075 aluminum alloy base plate 2 is perforated, and polished on 400# sandpaper;

[0087] (2), sequentially cleaning the oxide film on the surface of the aluminum alloy substrate plate 2 with 10% hydrochloric acid solution and 10% sodium hydroxide solution, then cleaning with distilled water and drying for later use;

[0088] (3), mold 4 is heated to 200 ℃ for 30 minutes;

[0089] (4) Fix the cleaned aluminum alloy base plate 2 on the ultrasonic horn 1 by fastening nuts 6 and bolts 7, place it vertically in the mold 4, and select the vibration direction to be perpendicular to the joint surface to vibrate;

[0090] (6) Set the ultrasonic power to 3000W, the vibration frequency to 20KHz, turn on the ultrasonic vibration device 5, apply ultrasonic vibration to the 7075 aluminum alloy base plate 2, and then cast the liquid A356 aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com