Weld seam coolant for straight seam submerged arc welding of steel pipe and its application method

A technology of straight seam submerged arc and coolant, which is applied to arc welding equipment, other household appliances, chemical instruments and methods, etc., to achieve the effects of avoiding deformation and cracking, increasing electrical conductivity, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

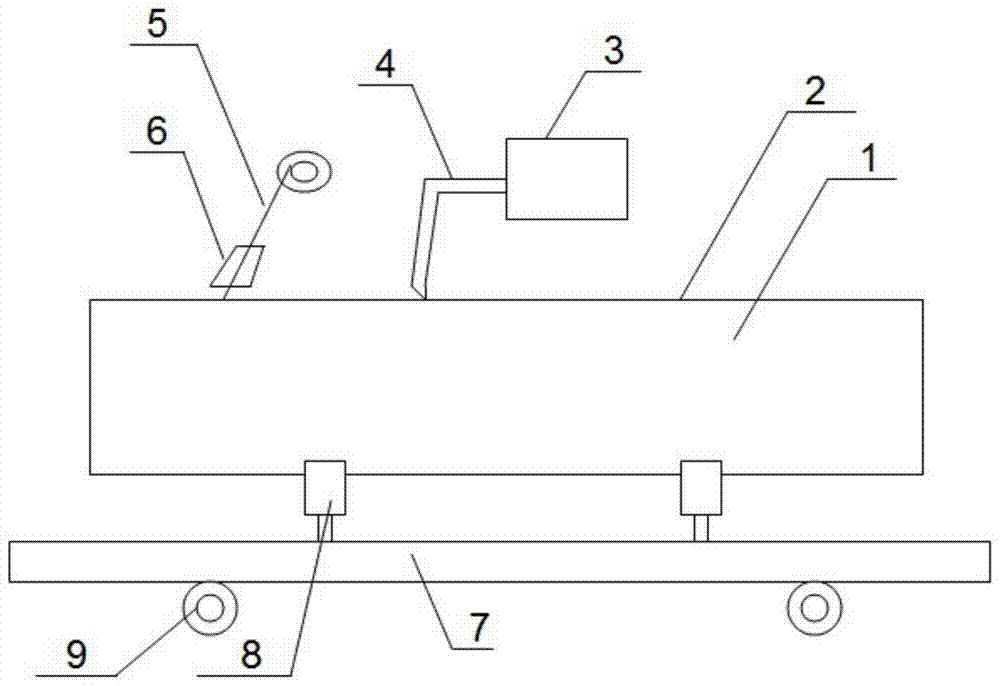

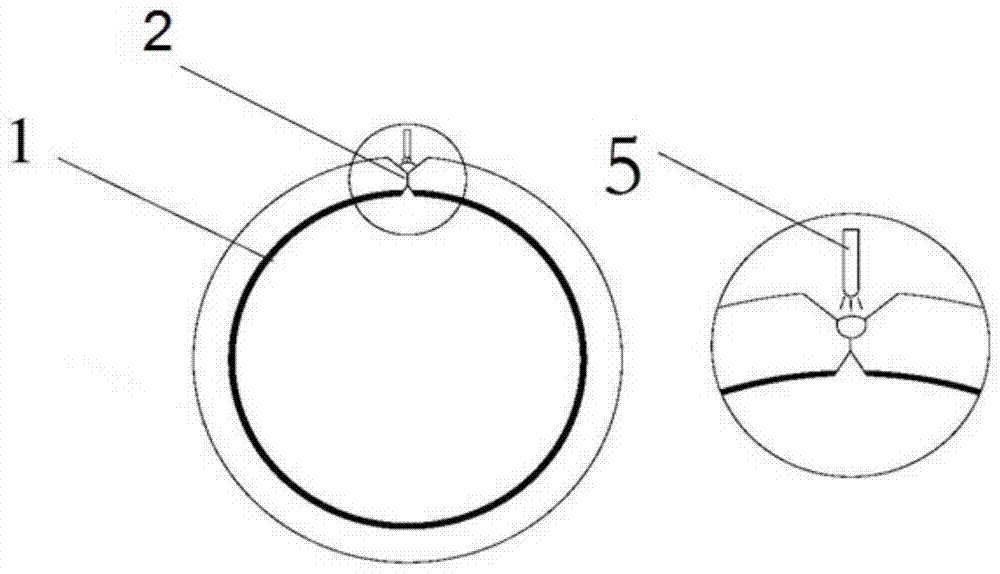

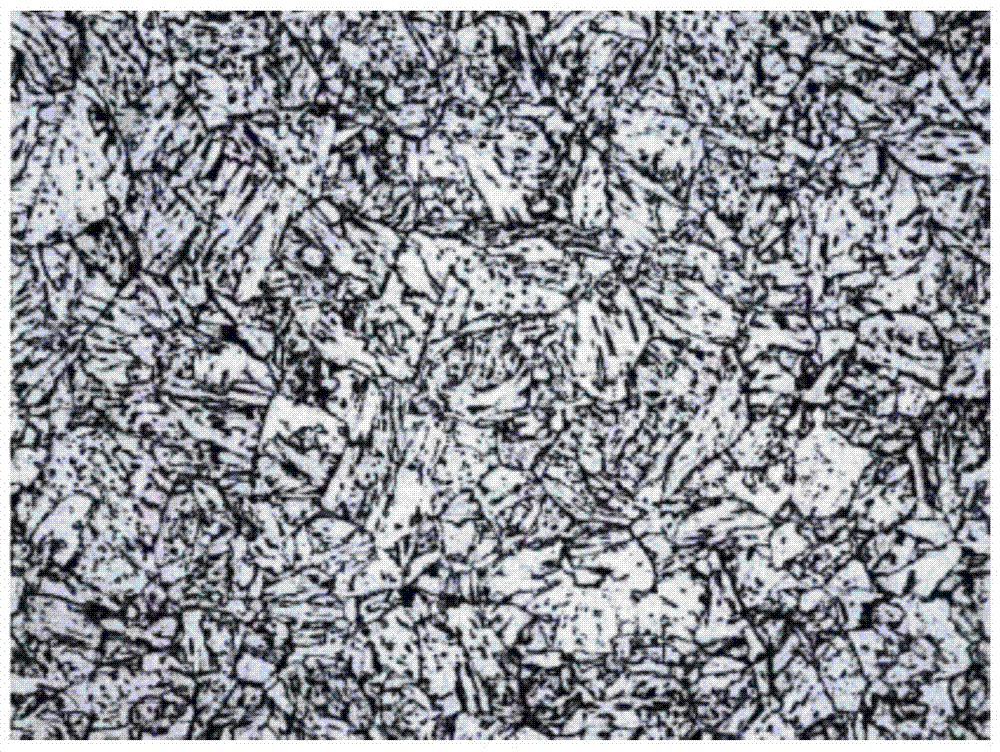

[0025] Such as Figure 1 to Figure 3 as shown, image 3 It is the metallographic appearance of the X80 steel pipe weld seam in Example 1. The finer the crystal grains in the metallographic appearance, the higher the strength of the weld seam structure and the better the toughness.

[0026] A kind of steel pipe straight seam submerged arc welding weld seam coolant of the present invention, concrete composition mass percentage is as follows:

[0027]

[0028] Prepare each component according to the above ratio, add it into a reaction kettle with a stirring device and a heating function, adjust the temperature at 30° C. and stir until completely dissolved to obtain the cooling liquid of the present invention.

[0029] The corrosion inhibitors are polyphosphate and chromate. The defoamer is a low-foaming nonionic surfactant.

[0030] The method for using the weld seam coolant of straight seam submerged arc welding of steel pipes according to the present invention comprises t...

Embodiment 2

[0036] The difference between embodiment 2 and embodiment 1 is: a steel pipe straight seam submerged arc welding seam coolant of the present invention, the specific composition mass percentage is as follows:

[0037]

[0038] Prepare each component according to the above ratio, add it into a reaction kettle with a stirring device and a heating function, adjust the temperature at 35° C. and stir until completely dissolved to obtain the cooling liquid of the present invention.

[0039] The corrosion inhibitor is chromate. The defoamer is a polyether type nonionic surfactant.

[0040] The method for using the weld seam coolant of straight seam submerged arc welding of steel pipes according to the present invention comprises the following steps:

[0041] (1) Place the steel pipe 1 made of X70 on the rotating roller 8 of the welding trolley 7. During welding, the welding trolley can move at a constant speed from left to right through the wheel 9; before welding, adjust the posi...

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is: a kind of steel pipe straight seam submerged arc welding seam coolant of the present invention, the specific composition mass percentage is as follows:

[0045]

[0046] Prepare each component according to the above ratio, add it into a reaction kettle with a stirring device and a heating function, adjust the temperature at 40° C. and stir until completely dissolved to obtain the cooling liquid of the present invention.

[0047] The anti-corrosion agent is polyphosphate. The defoamer is a low-foaming nonionic surfactant and a polyether nonionic surfactant.

[0048] The method for using the weld seam coolant of straight seam submerged arc welding of steel pipes according to the present invention comprises the following steps:

[0049] (1) Place the steel pipe 1 made of X60 on the rotating roller 8 of the welding trolley 7. During welding, the welding trolley can move at a constant speed from left to right throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com