Preparation method of brass wire

A brass and wire technology, applied in the field of brass wire preparation, can solve the problems of poor corrosion resistance, poor bending performance, uneven hardness, etc., achieve excellent bending performance and corrosion resistance, and improve strength and plasticity , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

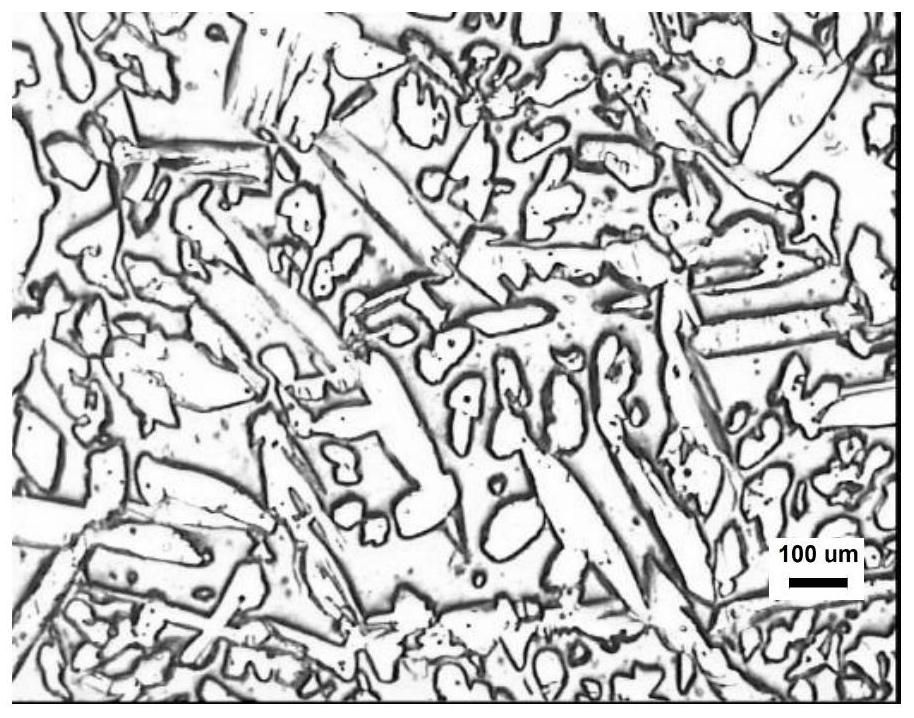

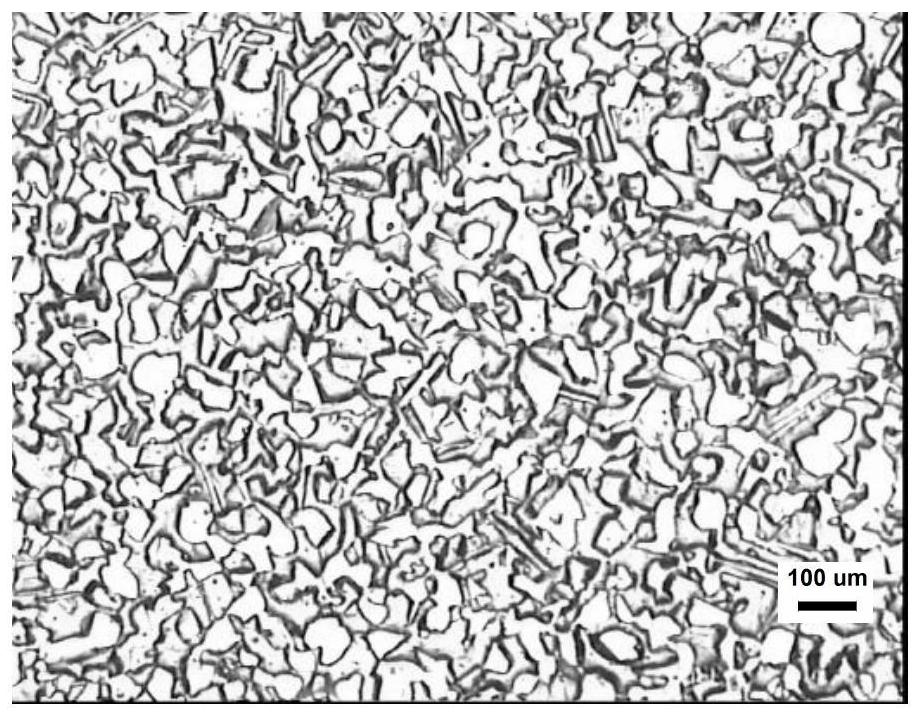

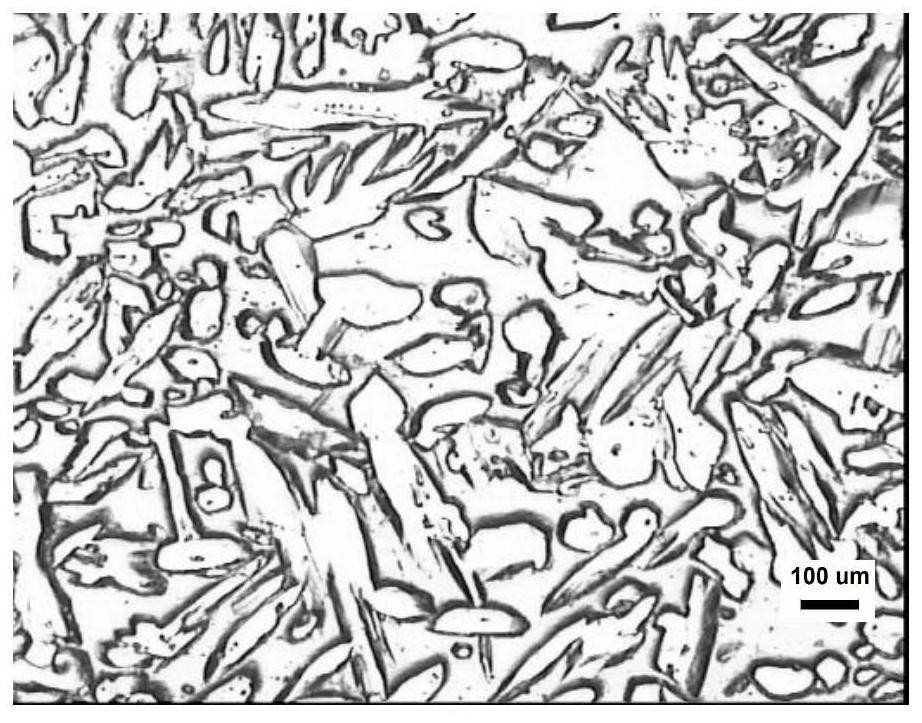

Image

Examples

Embodiment 1

[0033] Brass composition: Cu 58.6%, Mn 1.25%, Fe 0.5%, Al 0.5%, Pb 0.45%, Zn balance.

[0034] The specific production process of φ6.0mm brass wire is as follows:

[0035] A. Ingredients: including bright wire, zinc ingot, electrolytic manganese, iron-copper alloy, aluminum wire;

[0036] B, smelting, specifically comprises the following preparation steps:

[0037] 1) Gradually increase the voltage to 400V to heat up the furnace body, add bright wire and iron-copper alloy, cover with calcined charcoal, and heat up until it is completely melted;

[0038] 2) The voltage is lowered to 200V, the melt temperature is controlled at 1100°C to 1120°C, electrolytic manganese is added in batches, and then aluminum wire is added;

[0039] 3) Lower the temperature to 1060°C-1080°C, add zinc ingots to complete the dissolution, stir evenly and remove the slag;

[0040] 4) Sampling, spectroscopic testing of ingredients to pass;

[0041] 5) Add refining agent and deslagging agent, and cont...

Embodiment 2

[0049] Brass composition: Cu 58.6%, Mn 1.15%, Fe 0.45%, Al 0.5%, Pb 0.41%, Zn balance.

[0050]The specific production process of the specification φ10.5mm brass wire is as follows:

[0051] A. Ingredients: including bright wire, zinc ingot, electrolytic manganese, iron-copper alloy, aluminum wire;

[0052] B, smelting, specifically comprise the following preparation steps:

[0053] 1) Gradually increase the voltage to 400V to heat up the furnace body, add bright wire and iron-copper alloy, cover with calcined charcoal, and heat up until it is completely melted;

[0054] 2) The voltage is lowered to 200V, the melt temperature is controlled at 1100°C to 1120°C, electrolytic manganese is added in batches, and then aluminum wire is added;

[0055] 3) Lower the temperature to 1060°C-1080°C, add zinc ingots to complete the dissolution, stir evenly and remove the slag;

[0056] 4) Sampling, spectroscopic testing of components to pass;

[0057] 5) Add refining agent and deslaggin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com