Aluminum alloy welding wire and manufacturing method thereof

A technology of aluminum alloy welding wire and aluminum alloy, applied in manufacturing tools, welding media, welding equipment, etc., can solve the problems of affecting mechanical properties, slow production speed, large equipment investment, etc., achieve bright surface without cracks, and reduce production energy consumption , The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

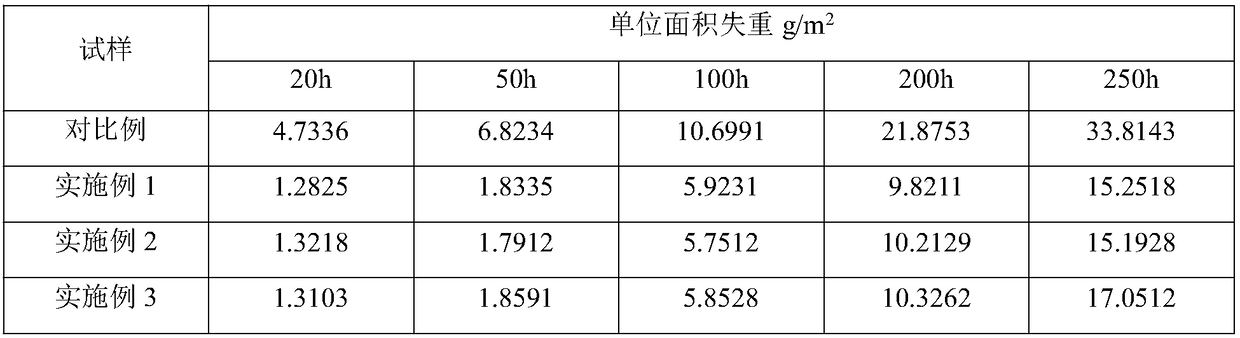

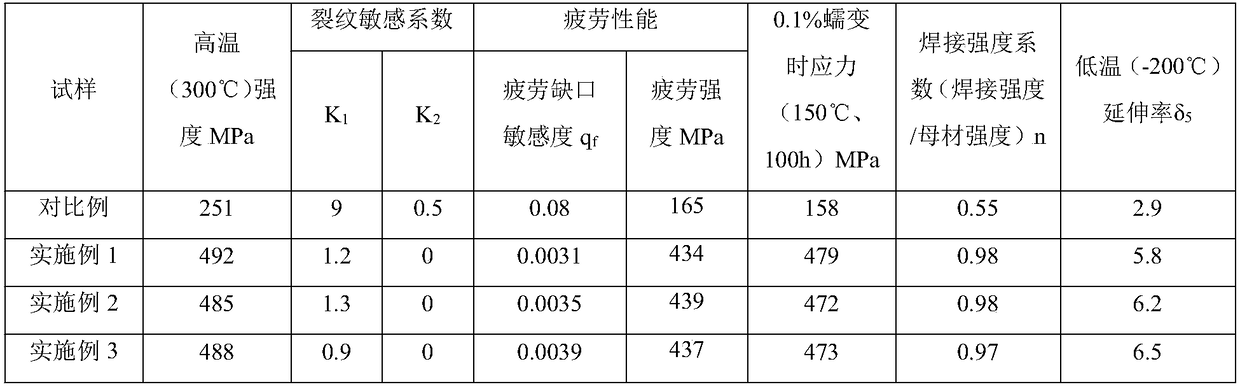

Examples

Embodiment 1

[0041] 1. Master alloy manufacturing

[0042] Manufacturing the aluminum master alloy into aluminum master alloy particles with a length of 10mm-30mm;

[0043] 2. Ingredients

[0044] The following components are dosed by weight percentage: Iron Fe 0.01%, Silicon Si 0.02%, Copper Cu 0.02%, Scandium Sc 0.002%, Manganese Mn 0.03%, Magnesium Mg 5.1%, Chromium Cr 0.005%, Zinc Zn 0.08%, Titanium Ti 0.003%, lithium Li0.005%, boron B 0.005%, vanadium V 0.003%, zirconium Zr 0.006%, cerium Ce 0.002%, yttrium Y0.001%, nickel Ni0.0001%, strontium Sr 0.0002%, ytterbium Yb 0.0003 %, neodymium Nd 0.0008%, niobium Nb 0.0005%, and the balance is aluminum Al; prepare aluminum ingots and aluminum master alloy particles in this way;

[0045] 3. Melting and alloying

[0046] rapidly melting the aluminum ingot to obtain an aluminum melt;

[0047] Flow the aluminum melt into a vacuum tilting holding furnace, heat it to 750°C-770°C, stir it electromagnetically for 10min-15min, and at the same ti...

Embodiment 2

[0056] 1. Master alloy manufacturing

[0057] Manufacturing the aluminum master alloy into aluminum master alloy particles with a length of 10mm-30mm;

[0058] 2. Ingredients

[0059] The following components are dosed by weight percentage: Iron Fe 0.05%, Silicon Si 0.05%, Copper Cu 0.08%, Scandium Sc 0.002%, Manganese Mn 0.08%, Magnesium Mg 4.5%, Chromium Cr 0.005%, Zinc Zn 0.02%, Titanium Ti 0.003%, lithium Li0.15%, boron B 0.002%, vanadium V 0.003%, zirconium Zr 0.008%, cerium Ce 0.003%, yttrium Y 0.002%, nickel Ni0.00015%, strontium Sr 0.002%, ytterbium Yb 0.0005% , neodymium Nd 0.001%, niobium Nb 0.008%, and the balance is aluminum Al; wherein, aluminum ingots and aluminum master alloy particles are prepared in this way;

[0060] 3. Melting and alloying

[0061] rapidly melting the aluminum ingot to obtain an aluminum melt;

[0062] Flow the aluminum melt into a vacuum tilting holding furnace, heat it to 750°C-770°C, stir it electromagnetically for 10min-15min, and at...

Embodiment 3

[0071] 1. Master alloy manufacturing

[0072] Manufacturing the aluminum master alloy into aluminum master alloy particles with a length of 10mm-30mm;

[0073] 2. Ingredients

[0074] The following ingredients are dosed by weight percentage: Iron Fe 0.15%, Silicon Si 0.08%, Copper Cu 0.09%, Scandium Sc 0.009%, Manganese Mn 0.18%, Magnesium Mg 5.2%, Chromium Cr 0.002%, Zinc Zn 0.15%, Titanium Ti 0.003%, lithium Li0.03%, boron B 0.008%, vanadium V 0.008%, zirconium Zr 0.009%, cerium Ce 0.005%, yttrium Y 0.001%, nickel Ni0.002%, strontium Sr 0.003%, ytterbium Yb 0.005% , neodymium Nd 0.001%, niobium Nb 0.01%, and the balance is aluminum Al; wherein, aluminum ingots and aluminum master alloy particles are prepared in this way;

[0075] 3. Melting and alloying

[0076] rapidly melting the aluminum ingot to obtain an aluminum melt;

[0077] Flow the aluminum melt into a vacuum tilting holding furnace, heat it to 750°C-770°C, stir it electromagnetically for 10min-15min, and at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com