High-toughness stainless steel welding rod used in ultralow-temperature environment and preparation method of high-toughness stainless steel welding rod

A high-toughness, ultra-low temperature technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of reducing and increasing the risk of weld thermal cracks, and achieve the effects of small spatter, good welding process performance, and stable arc

Active Publication Date: 2022-03-08

TIANJIN SAINTEAGLE WELDING CO LTD +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Excessively reducing the ferrite content will inev

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

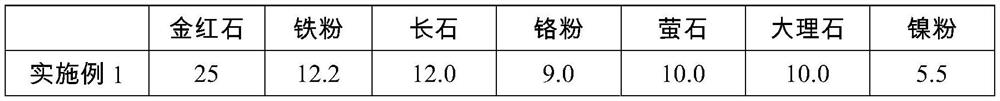

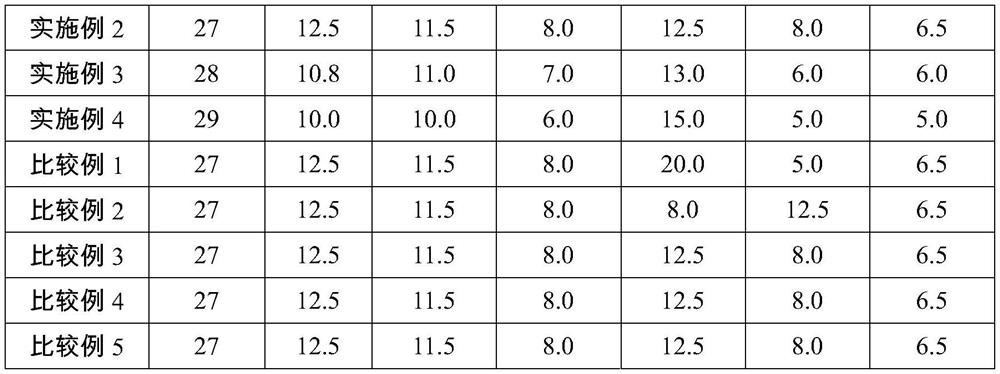

The invention belongs to the technical field of welding materials, and particularly relates to a high-toughness stainless steel welding rod used in an ultralow-temperature environment and a preparation method thereof.The high-toughness stainless steel welding rod used in the ultralow-temperature environment comprises a welding core and a coating adhering to the outer wall of the welding core; the coating is mainly prepared from, by weight, 25%-30% of rutile, 10%-15% of iron powder, 10%-15% of feldspar, 10%-15% of fluorite, 5%-10% of chromium powder, 5%-10% of nickel powder, 5%-10% of marble, 2%-5% of electrolytic manganese metal, 2%-5% of molybdenum powder, 2%-5% of mica, 2%-5% of titanium dioxide, 1%-4% of cryolite, 1%-4% of ferrotitanium and 1%-2% of sodium carbonate. The invention provides a high-toughness E316L-16 stainless steel welding rod used in an ultralow-temperature environment. The high-toughness E316L-16 stainless steel welding rod has a certain ferrite number and excellent low-temperature impact toughness.

Description

technical field [0001] The invention belongs to the technical field of welding materials, and in particular relates to a high-toughness stainless steel welding rod used in an ultra-low temperature environment and a preparation method thereof. Background technique [0002] current technology: [0003] Austenitic stainless steel with a face-centered cubic crystal structure has become one of the recognized ultra-low temperature structural materials due to its good low-temperature comprehensive performance, and is widely used in coiled tube heat exchangers, liquefied natural gas and other cryogenic storage and transportation containers and special In the working condition of low temperature service environment. However, studies have shown that due to the complex metallurgical process, the overall performance of the weld metal is far inferior to that of the base metal, especially the low-temperature impact toughness (-196°C) of the weld after manual arc welding with titanium-cal...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/02B23K35/30B23K35/36B23K35/40

CPCB23K35/0266B23K35/3601B23K35/3086B23K35/40

Inventor 寇伟祥宋美婧韩欢庆赵振博杜桂涛张明洋代颖李英魁高慧吴胜文

Owner TIANJIN SAINTEAGLE WELDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com