Grain control method for production of ultrawide double-zero aluminum foil blanks by electrolytic aluminum liquid cast-rolling process

A technology of electrolytic aluminum liquid and double zero aluminum foil, applied in the direction of metal rolling, etc., can solve the problems of uneven structure and performance of the plate, great difficulty, less non-spontaneous crystal nuclei, etc., to ensure the effect of grain refinement and increase the number of , Improve the effect of the utilization of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

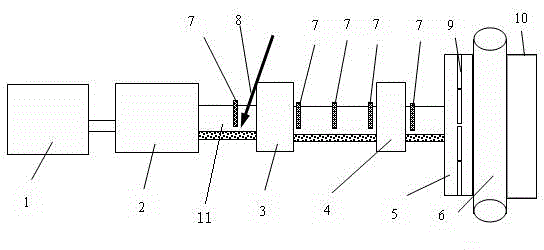

Method used

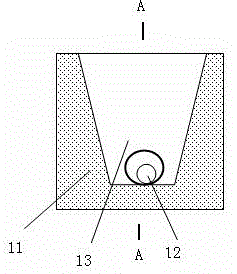

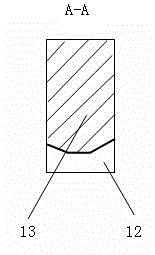

Image

Examples

Embodiment 1

[0023] [1] Horizontal aluminum casting and rolling production line, put in remelted aluminum ingots and / or casting and rolling waste according to the proportion of 40% solid material, and the solid material is evenly dispersed to the bottom of the entire smelting furnace. Melt at low temperature for 10 hours, then raise the temperature of the molten aluminum to 740°C within 30 minutes for alloy preparation, refine the molten aluminum after the alloy composition is qualified, and transfer the molten aluminum to the static furnace after the refining is completed and stand for 35 minutes;

[0024] [2] After the converter, put it in the furnace every 4 hours, use Ar+CCl 4 Stir the molten aluminum evenly for 10 minutes;

[0025] [3] The molten aluminum in the stationary furnace reaches the front box through the degassing box and the filter box, and is injected into the gap between the two casting rolls through the casting nozzle for rolling. The liquid enters the filter box throug...

Embodiment 2

[0030] [1] Horizontal aluminum casting and rolling production line, put in remelted aluminum ingots and / or casting and rolling waste according to the proportion of 45% solid material, and the solid material is evenly dispersed to the bottom of the entire smelting furnace. Melt at low temperature for 5 hours, then raise the temperature of the molten aluminum to 750°C within 20 minutes for alloy preparation, refine the molten aluminum after the alloy composition is qualified, and transfer the molten aluminum to the static furnace after refining for 45 minutes;

[0031] [2] After the converter, put it in the furnace for every 5 hours, use Ar+CCl 4 Stir the molten aluminum evenly for 10 minutes; the following is the same as in Example 1.

[0032] The cast-rolled blanks with a width of 1750mm and 1920mm produced by the above implementation method are stably rolled to 0.0065mm, and the pinholes are all at 200 / m 2 Below, the best is 70 pcs / m 2 within.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com