Online forced cooling method and device for extrusion die

A technology of extrusion dies and dies, which is applied in the field of metal hot extrusion forming, can solve the problems of reducing extrusion forming resistance, unbalanced cohesive force, and increasing production costs, so as to increase extrusion speed, avoid coarse grains, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

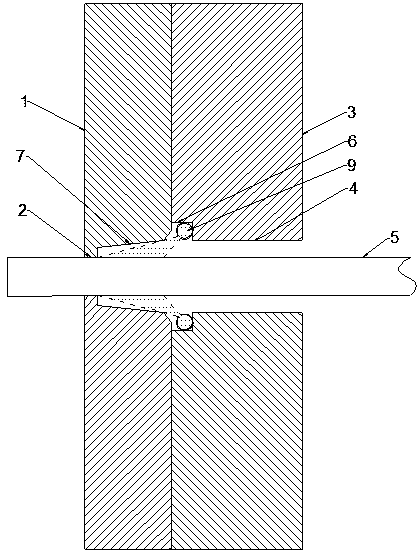

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

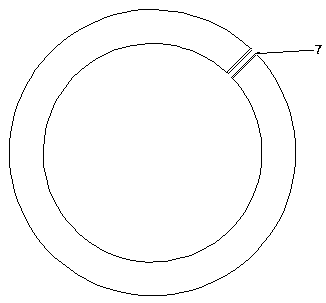

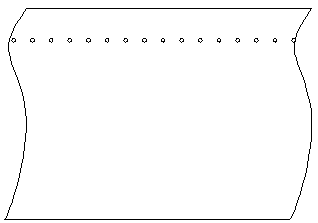

[0019] An extrusion die online forced cooling method is used for metal hot extrusion forming. The main cross-section shape of the discharge channel is surrounded between the discharge port of the extrusion die and the special pad for the die, and the annular through groove is processed on the special pad for the die. Cooling gas is sprayed to the surface of the extruded material on the discharge port by means of the small air outlet holes on the air pipe laid in the annular channel.

[0020] The cooling gas is an inert gas, which may be an inert gas such as nitrogen. The inert gas can also act as a protective atmosphere to protect the surface of the hot extruded material from being oxidized by high temperature, making the surface bright and free of defects.

[0021] Such as figure 1 , 2 , 3, a kind of extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com