Electric spark punching machine capable of punching conical holes

A technology of electric spark and piercing machine, which is applied in the field of electric spark piercing machine, can solve the problems of uncontrollable taper hole size, difficult to control taper hole size, and low qualified rate of finished products, so as to solve the problem of low processing efficiency and improve work efficiency. Efficiency, the effect of reducing production waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

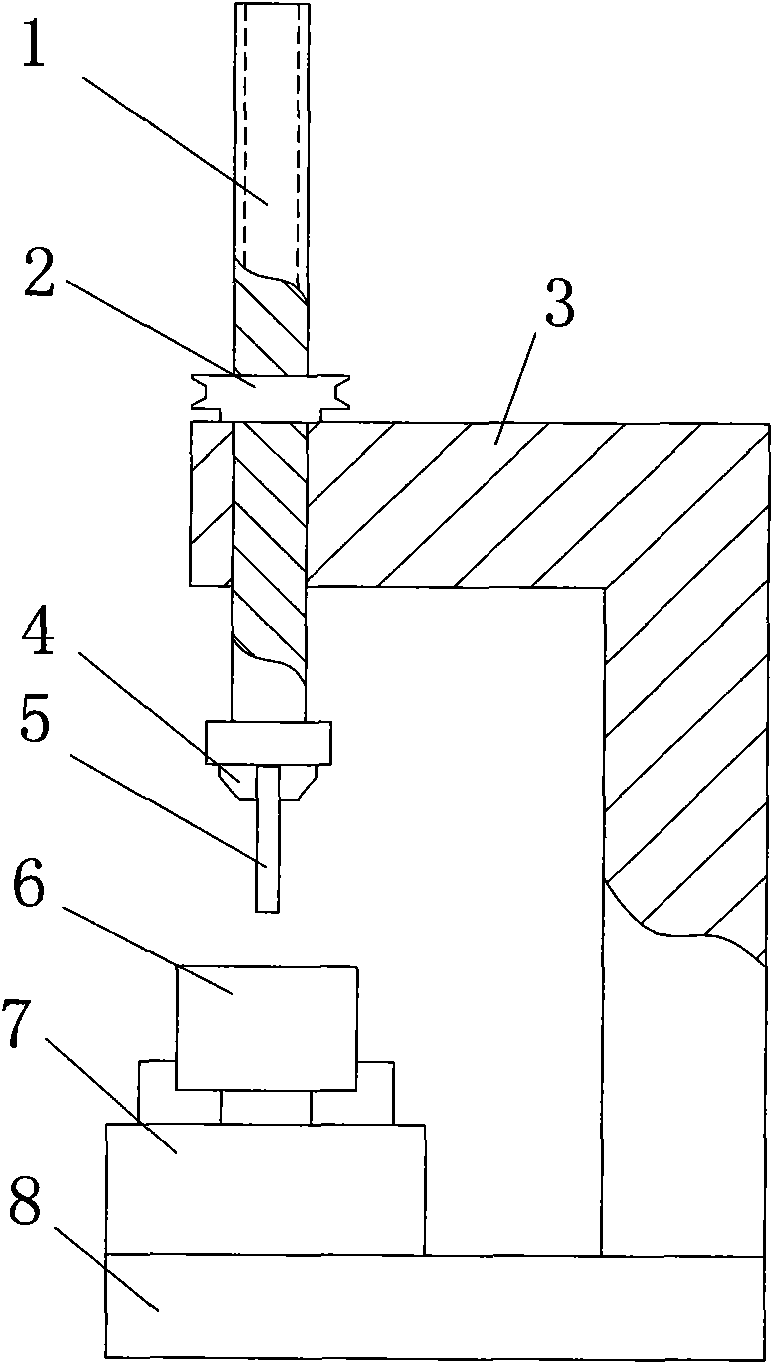

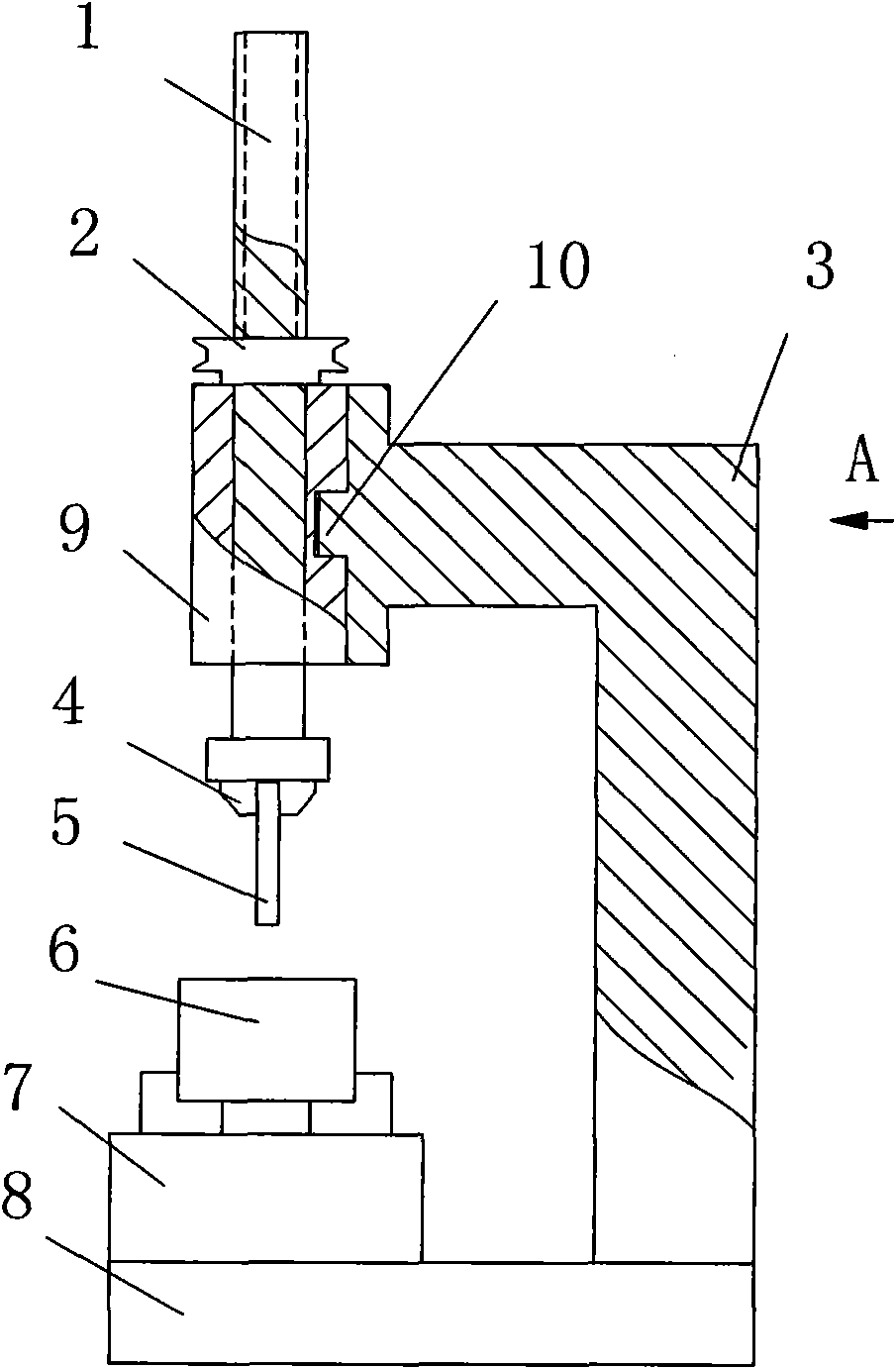

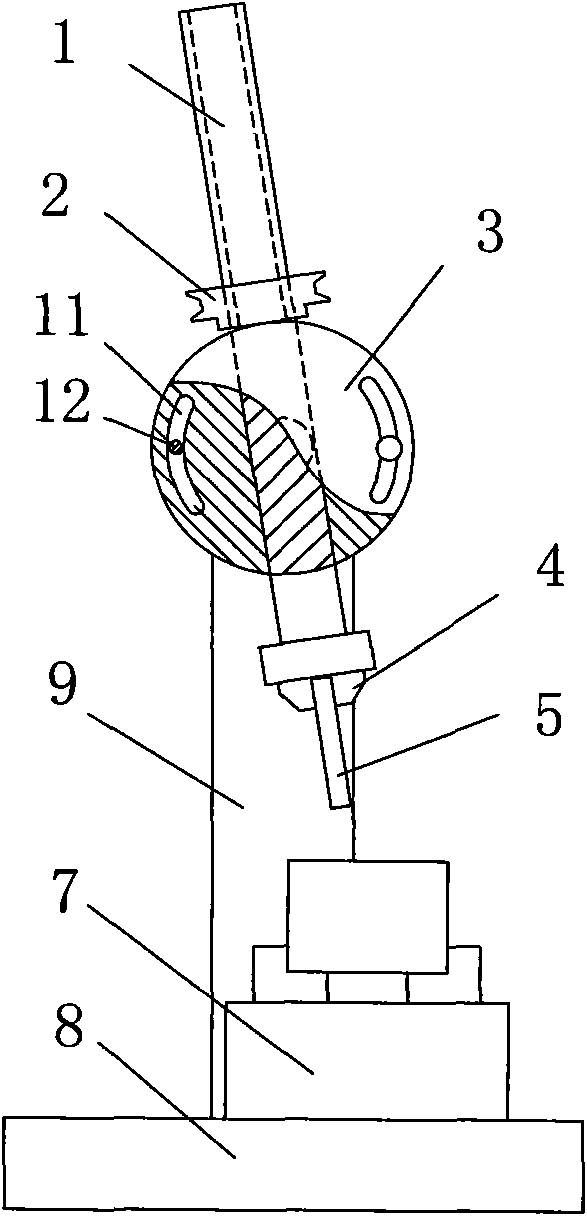

[0011] Such as Figure 2 to Figure 4 As shown, the guide sleeve 3 is a disc, and the vertical guide hole is arranged along the symmetric center of the radial direction of the disc. The lifting rod 1 is connected with the guide sleeve 3 through the vertical guide hole. The lower end of the lifting rod 1 has a chuck 4 for fixing the electrode 5. The upper end of the lifting rod 1 is a screw rod, which is connected with the pulley 2 through threaded fit. The center of the disc surface on one side of the guide sleeve 3 is provided with a shaft hole, the electrode positioning bracket 9 is provided with a pin 10 that matches the shaft hole on the guide sleeve 3, and the guide sleeve locking device is two pairs of locking bolts 12 and nuts 13. The disc surface of the guide sleeve 3 is symmetrically provided with two arc-shaped holes 11 concentric with the shaft hole. The locking bolt 12 passes through the arc-shaped hole 11 and the bolt hole of the electrode positioning bracket 9 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com