Patents

Literature

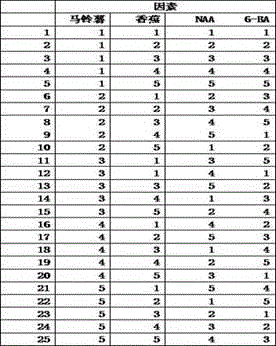

80results about How to "Reduce production waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead free solder alloy and its preparation method

InactiveCN1570166ARight melting pointLow costWelding/cutting media/materialsSoldering mediaMaterials scienceTin

The invention relates to a lead-free solder alloy for welding the electronic elements and its manufacturing method. The lead-free solder alloy is characterized in that the main components are Sn, Ag, Cu, and Ni, and In, Bi, Pd, P, Ge, Ga, Se, Te, La, Ce, Pr, Nd, Pm, Sm, Eu, Tm are added selectively. The preparation method is characterized by taking Sn, Ag, Cu, Ni and the additional elements in proportion and smelting them at the temperature of 1300 C. to 1500 C. to obtain the intermediate alloy by using water glass covering process; melting the residual Sn and the intermediate alloy at the temperature of 300 C. to 350 C. by using water glass covering process, and casting the molten materials into alloy pig and soldering tin rod at the temperature of between 250 C. and 350 C.. The lead-free solder alloy provided by the invention can be used for welding the Ag and Pd noble metal electronic element.

Owner:邓和升

Glue solution for copper-clad plate, composite based CEM-1 copper-clad plate, and preparation methods of glue solution and composite based CEM-1 copper-clad plate

ActiveCN106398110AImprove performanceWide range of usesSynthetic resin layered productsPaper/cardboard layered productsEpoxyOrganic solvent

The invention provides a glue solution for a copper-clad plate, a composite based CEM-1 copper-clad plate, and preparation methods of the glue solution and the composite based CEM-1 copper-clad plate. The glue solution for the copper-clad plate comprises the raw materials in parts by weight: 1200-2000 parts of epoxy soybean oil modified phenolic resin, 1200-2000 parts of epoxy resin, 150-250 parts of phenolic resin, 300-700 parts of a flame retardant, 250-350 parts of a curing agent, 1-5 parts of a curing accelerant, 50-150 parts of an inorganic filler and 100-300 parts of an organic solvent. On one hand, the epoxy soybean oil modified phenolic resin provided by the invention has the advantages of simple preparation process, good product performance and wide application; on the other hand, the glue solution for the copper-clad plate has the advantages of simple preparation process, good product performance, wide application and good permeability to wood pulp paper; what is noteworthy is that the composite based CEM-1 copper-clad plate provided by the invention has the advantages of simple preparation process, relatively good punching property, relatively good soldering resistance and good processing performance.

Owner:抚州市龙兴电子材料有限公司

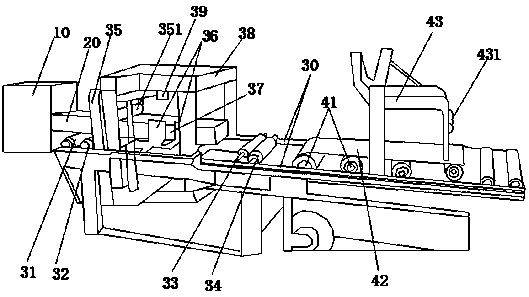

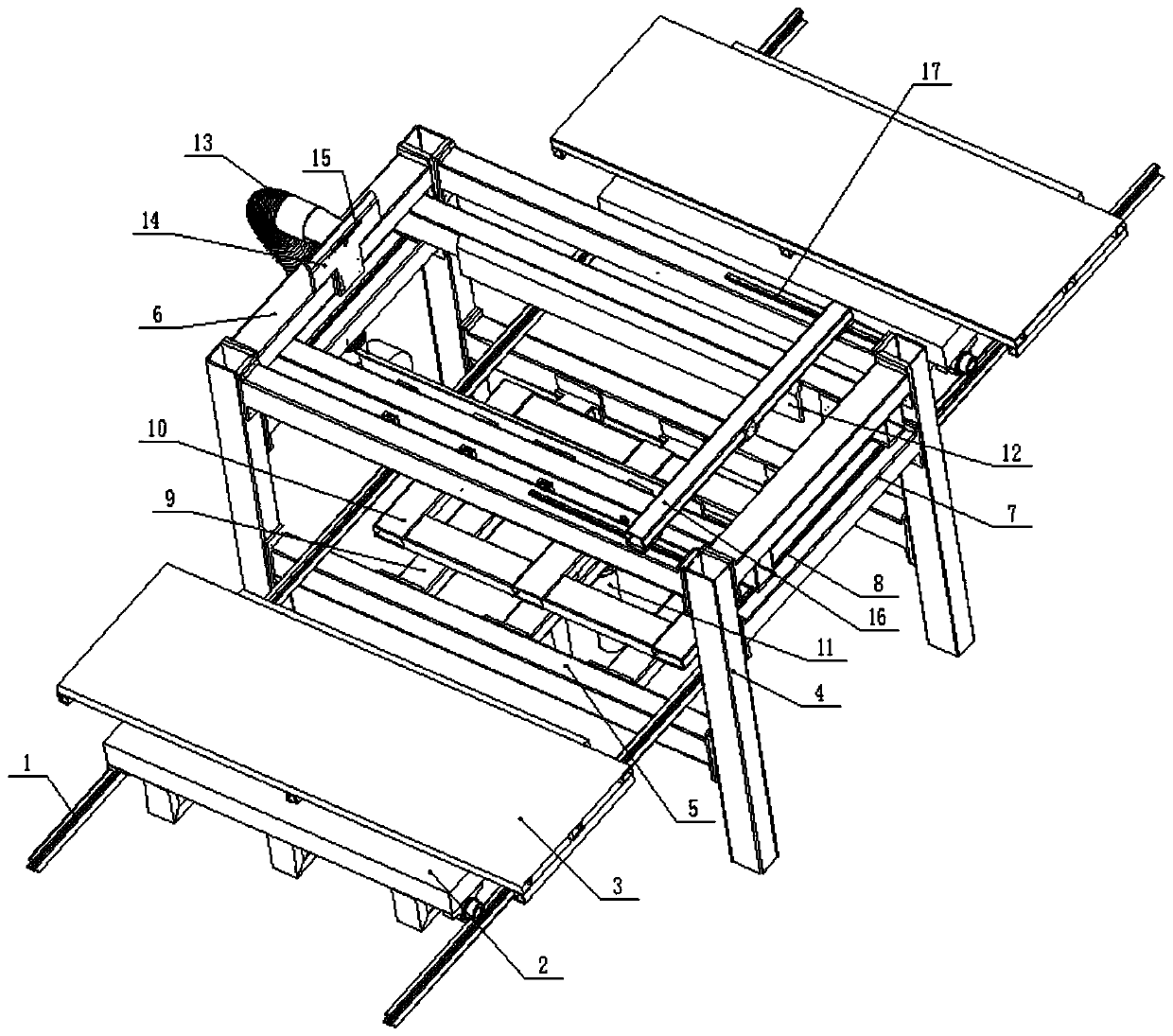

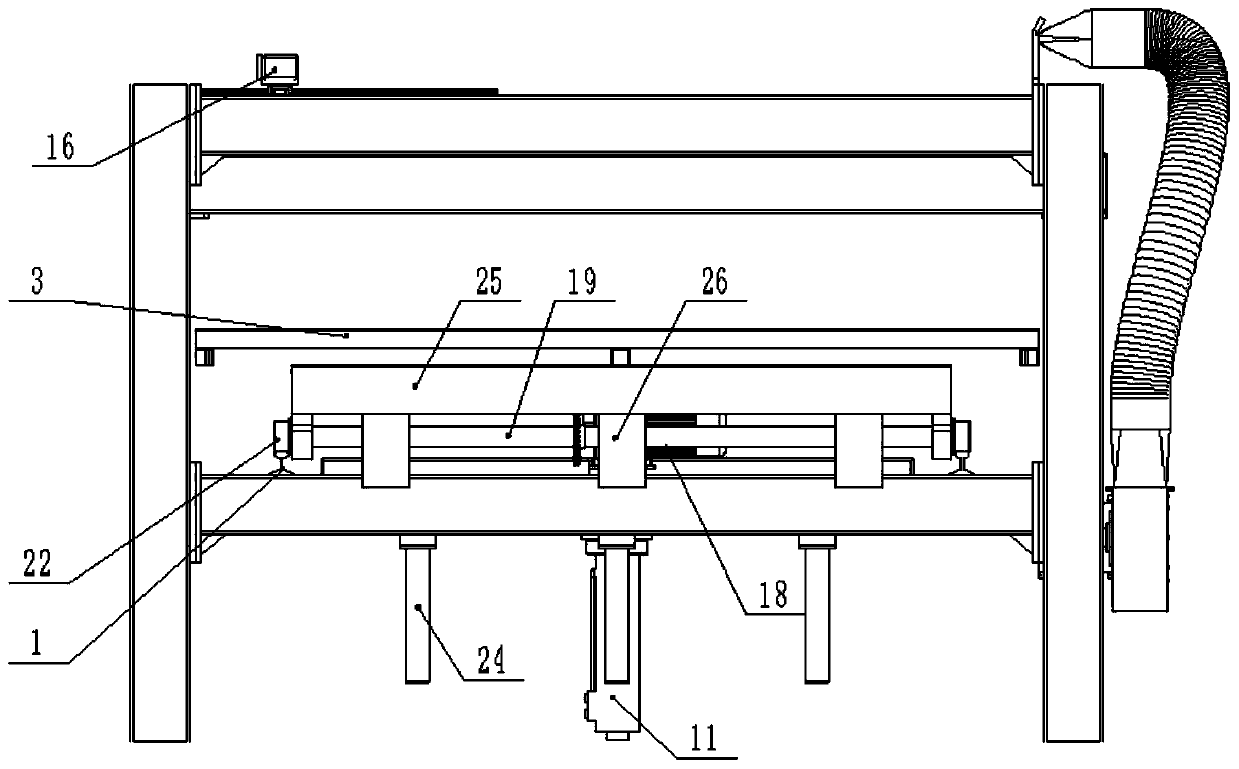

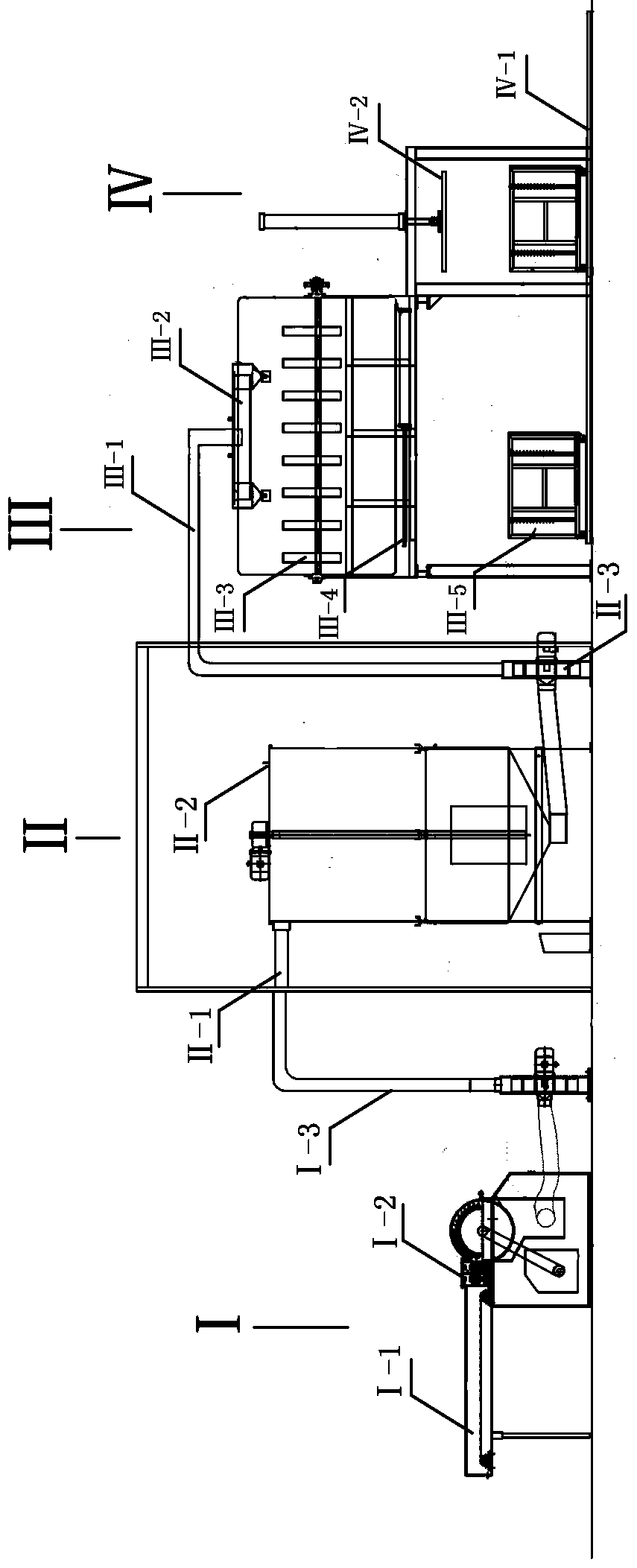

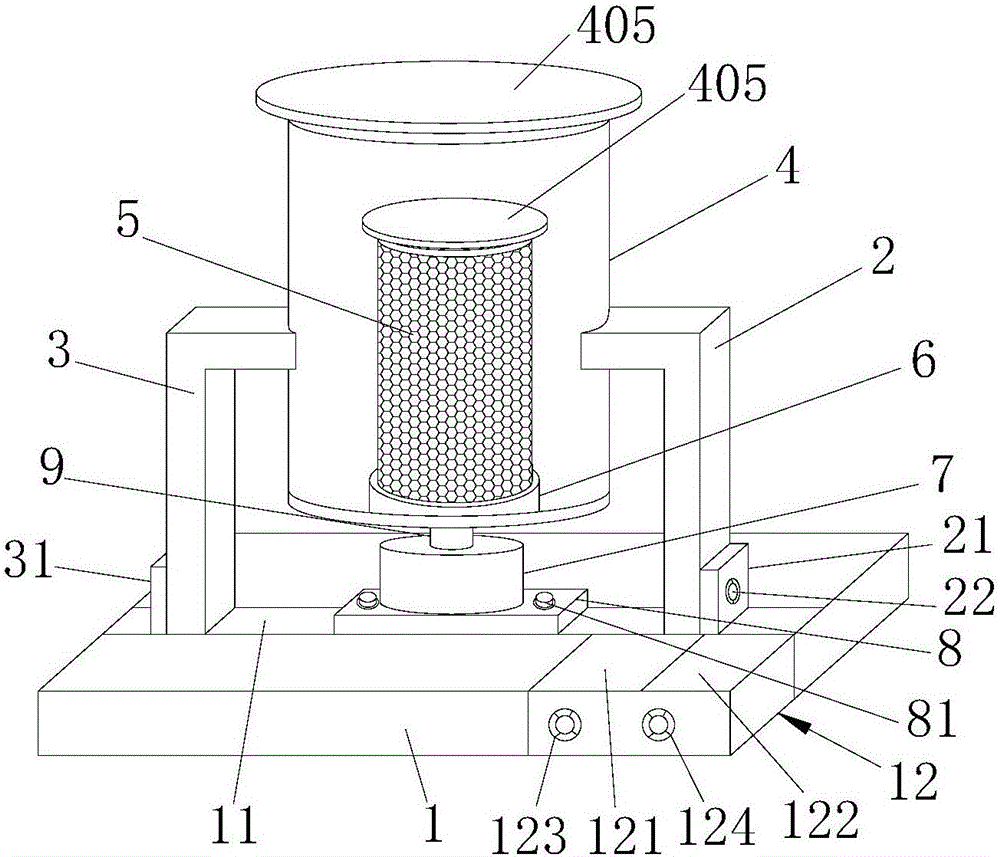

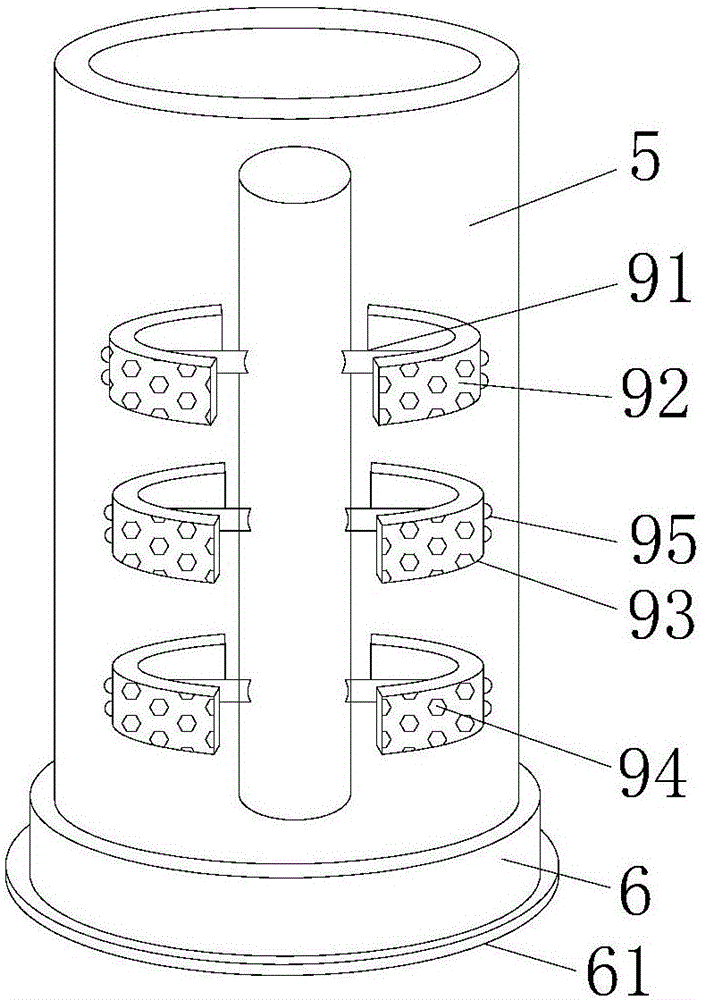

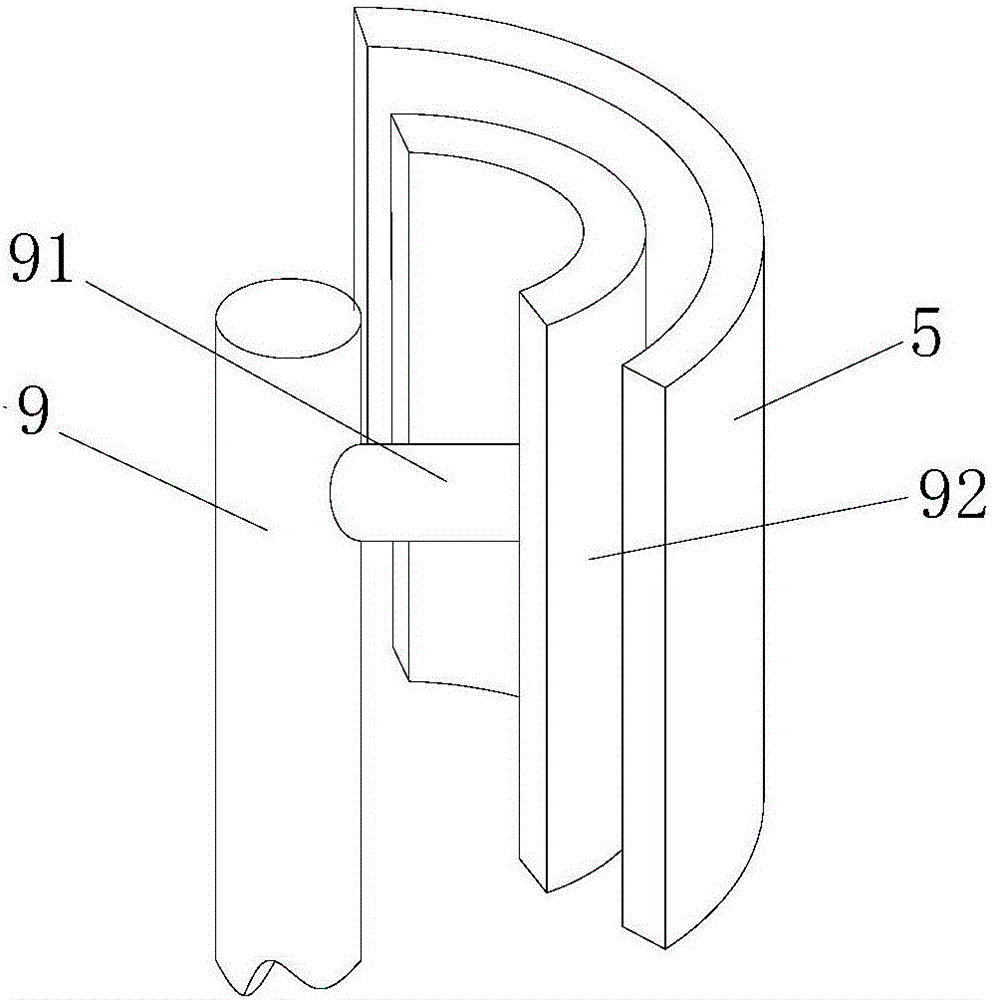

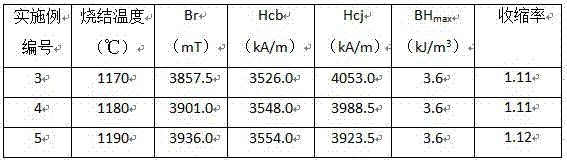

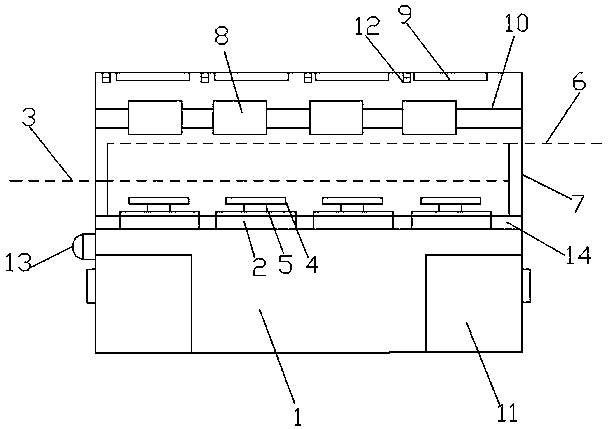

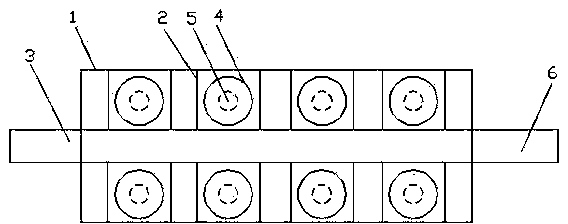

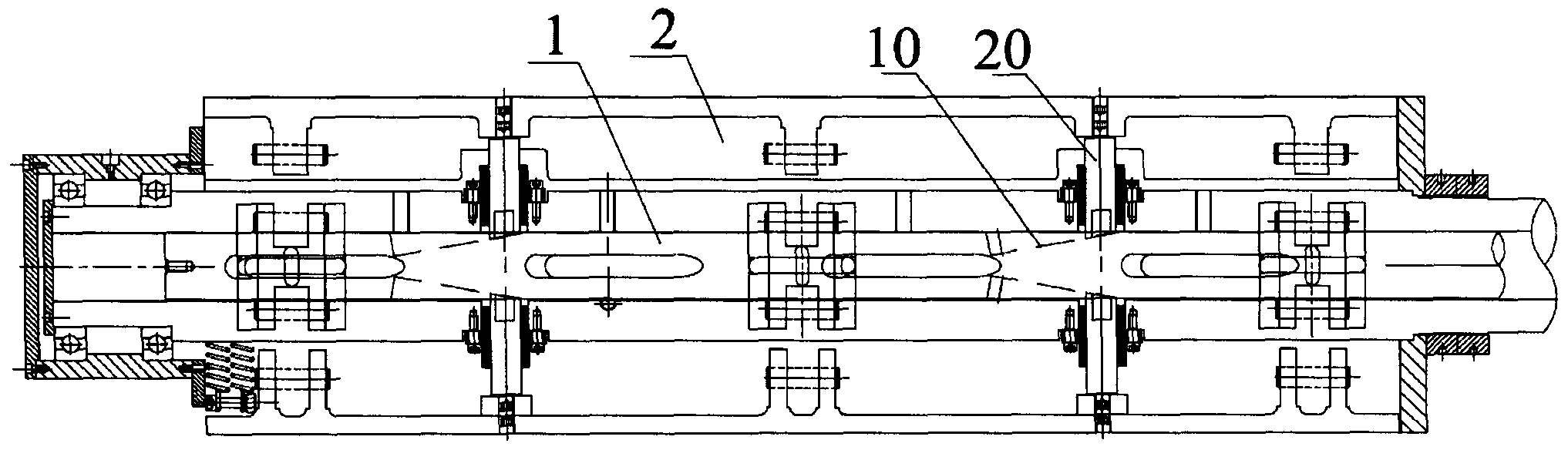

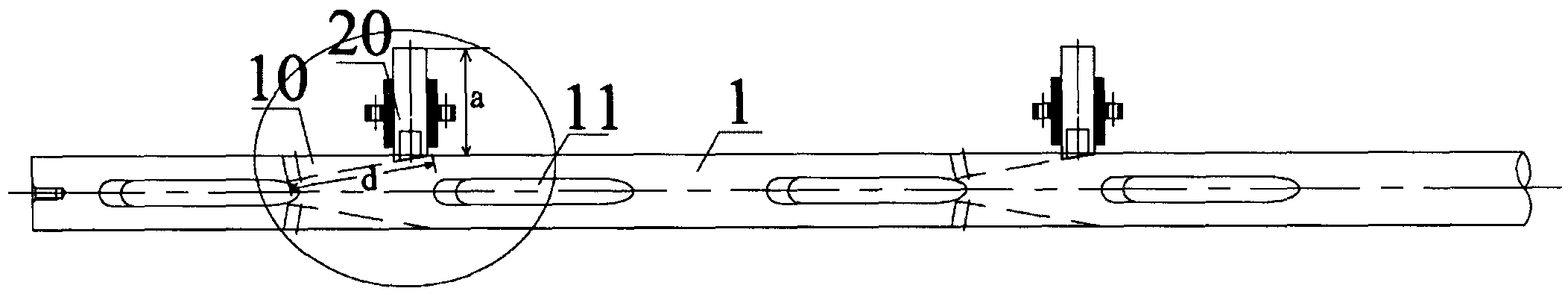

Shale sintered brick blank slitting device

InactiveCN105500506AReduce production wasteReduce manufacturing costCeramic shaping apparatusScrapWaste recycling

The invention relates to a shale sintered brick blank slitting device used for horizontally and longitudinally cutting long-strip-shaped brick blank from a vacuum brick making machine. The shale sintered brick blank slitting device comprises a blank movement type cutting device for horizontally cutting the long-strip-shaped brick blank from the vacuum brick making machine, a blank slitting device for longitudinally cutting the horizontally cut long-strip-shaped brick blank from the blank movement type cutting device, and a mud blank waste recycling device for recycling mud blank waste by being matched with a sintered perforated brick blank slitting device. According to the shale sintered brick blank slitting device, a condition of conveying while cutting can be realized, so that the relatively high efficiency and fastness can be realized, production waste is effectively reduced, the production cost is reduced, and the production efficiency is improved; at the same time, the waste recycling device is arranged, so that the waste formed at two ends of the cut long-strip-shaped brick blank directly falls into a waste recycling belt and then is conveyed into a waste recycling slot, and further the manual cost is saved.

Owner:阎五一

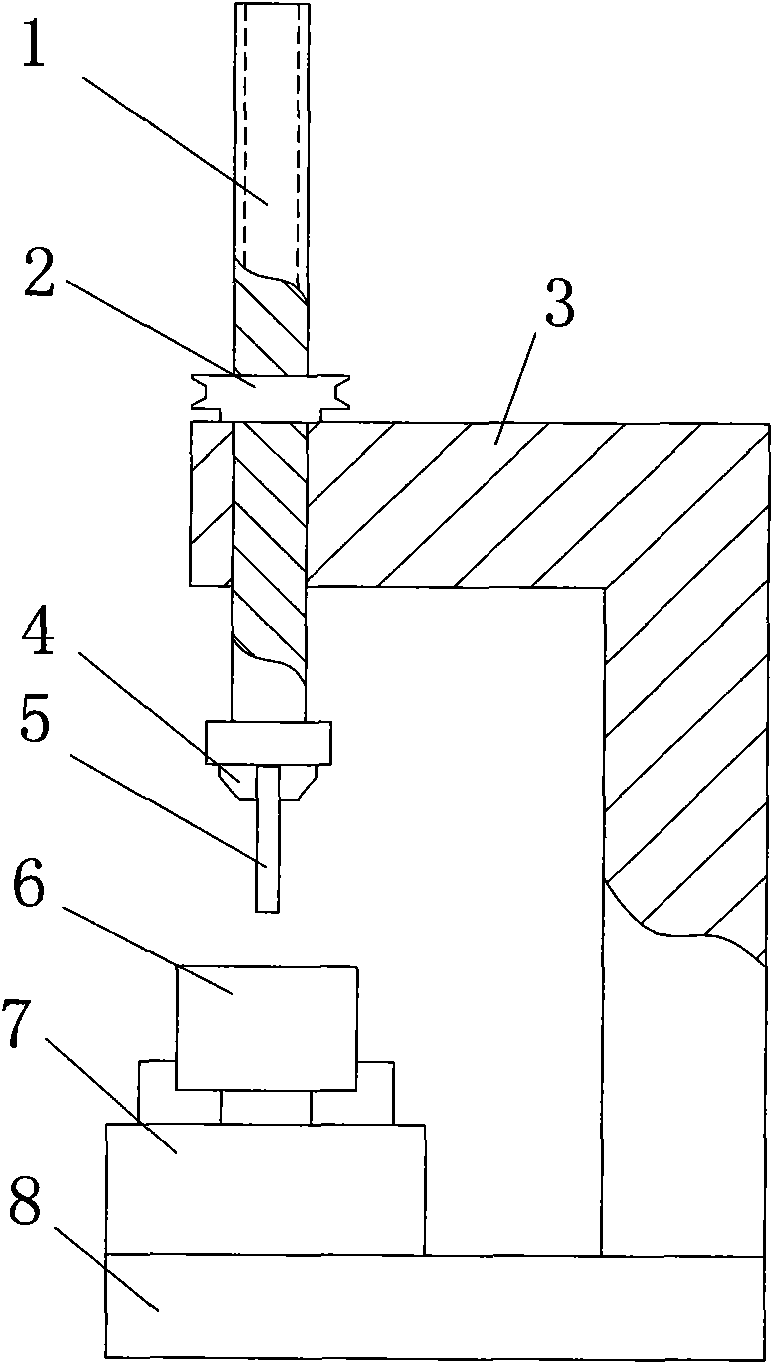

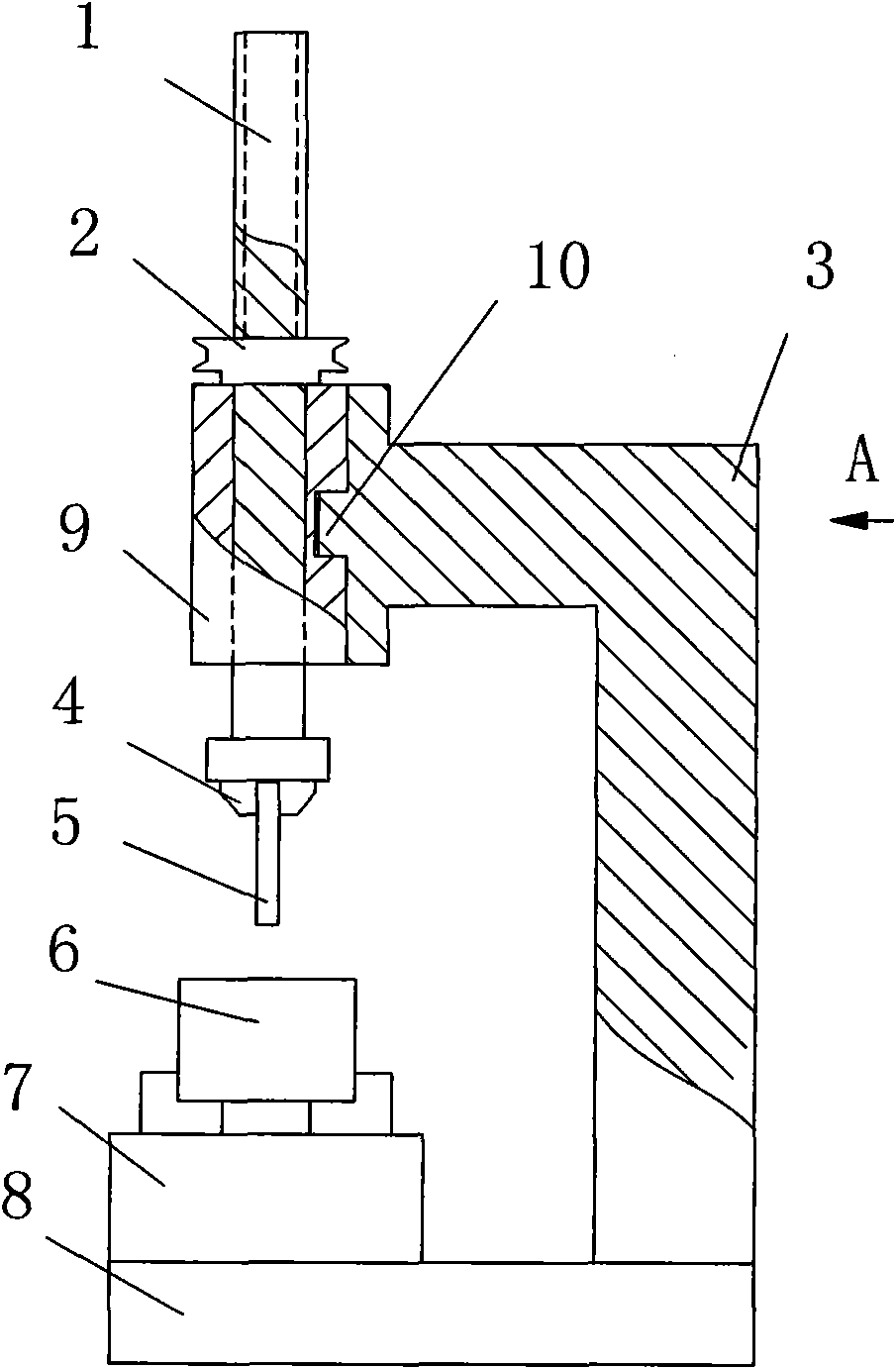

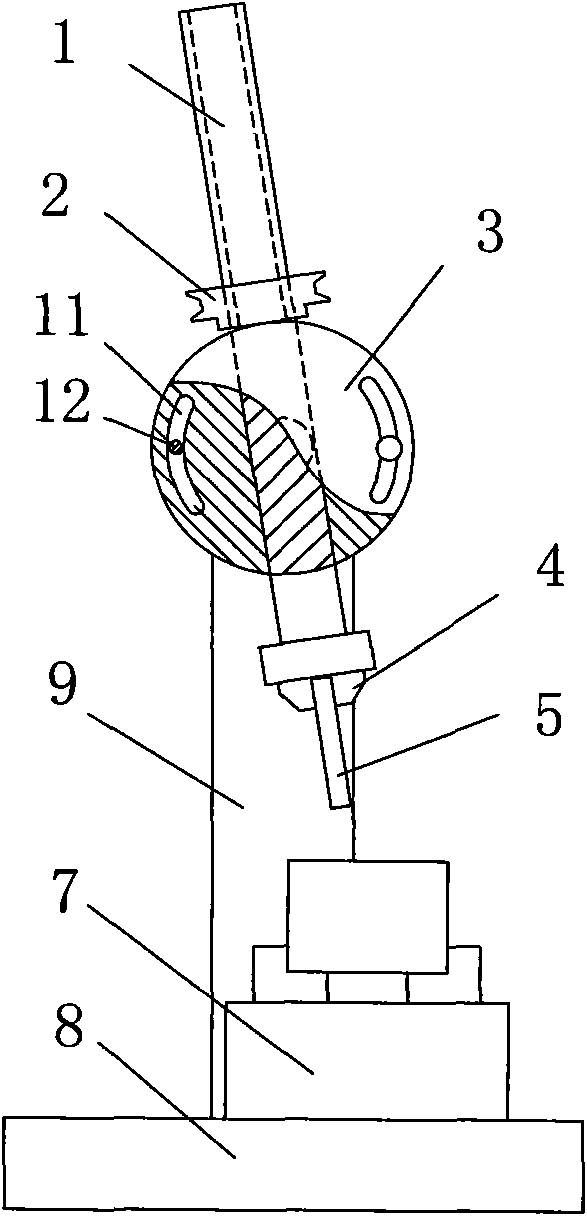

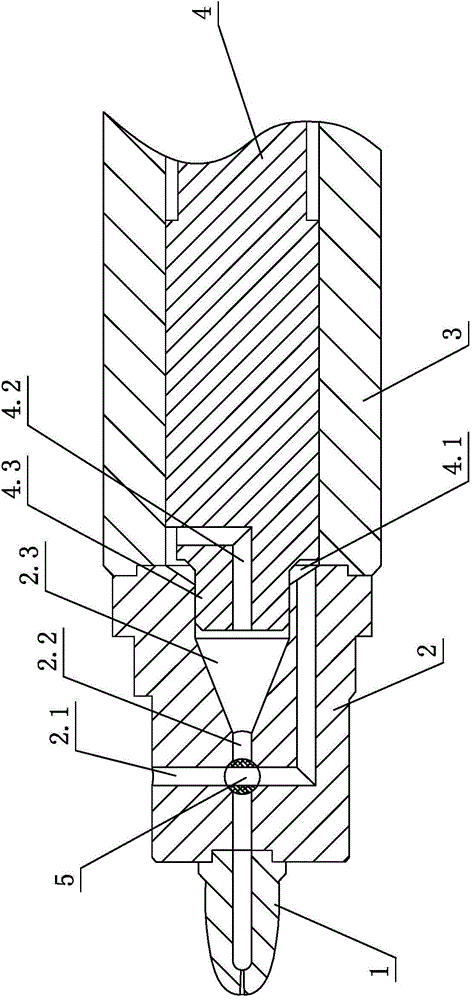

Electric spark punching machine capable of punching conical holes

The invention relates to an electric spark punching machine capable of punching conical holes, which comprises a lifting rod, an electrode positioning support and a base, wherein a guide sleeve is arranged above the electrode positioning support, a vertical guide hole which is matched with the lifting rod is arranged on the guide sleeve, a clamping head for fixing an electrode is arranged at the lower end of the lifting rod, and the guide sleeve is linked with the electrode positioning support by revolute joints. The electric spark punching machine adopts the electrode deflection way and can process the conical holes without replacing the electrode, thereby effectively solving the shortcomings of low processing efficiency and difficult control of size of through holes of the conical holes, greatly improving the working efficiency, saving the production cost and simultaneously reducing the production of waste products.

Owner:安徽聚芯智造科技股份有限公司

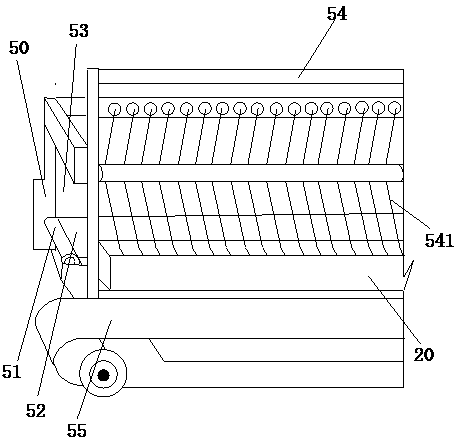

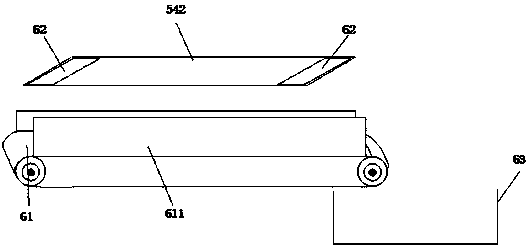

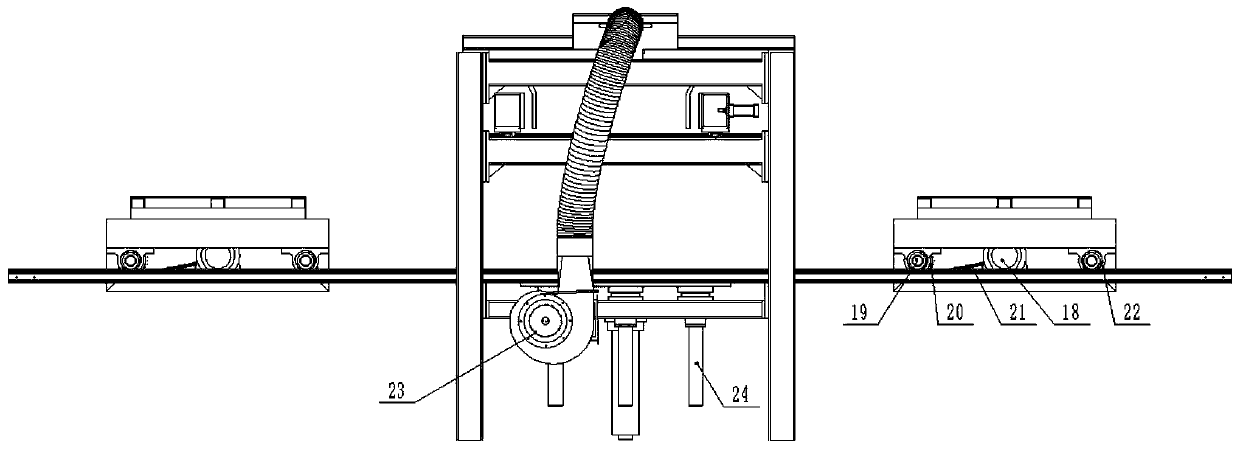

Panel receiving equipment

PendingCN110921338AReduce production wasteReduce labor costsStacking articlesMechanical conveyorsPower apparatusIndustrial engineering

The invention discloses panel receiving equipment and belongs to the technical field of forming and discharging of door leaves of steel doors. The panel receiving equipment comprises a receiving rack,a moving track, a receiving trolley, a receiving tray, a supporting rack and a power device. The moving track is mounted on the lower side in the receiving rack, the receiving trolley is slidably mounted on the moving track, the receiving tray is mounted on the receiving trolley, a lifting rack is mounted right below the receiving rack, the power device which controls the lifting rack to lift orland is mounted below the lifting rack, a receiving cavity penetrating from top to bottom is arranged in the receiving rack, the receiving trolley and the receiving tray together are driven by the supporting rack to move up and down in the receiving cavity, and a panel is placed on the receiving tray through a top opening of the receiving cavity. The panel receiving equipment solves the problems that the panels are deformed and it is time-wasting and labor-wasting to pile up the panels as a result of non-standard transfer, stacking and piling of existing formed door leaf panels after forming,and has the advantages of improving the production efficiency, saving the labor cost and guaranteeing the product quality.

Owner:CHENGDU HELE DOORS

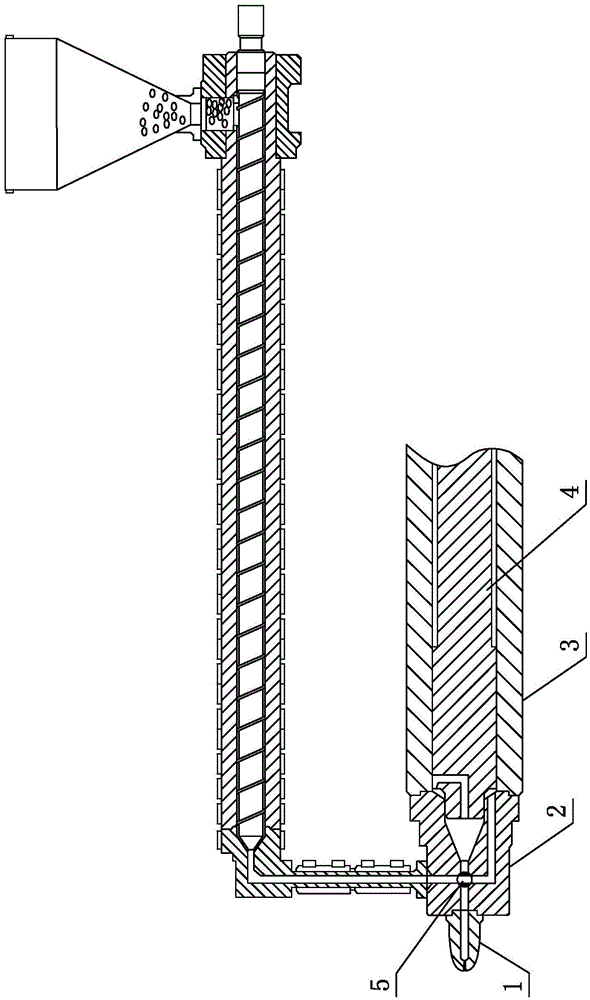

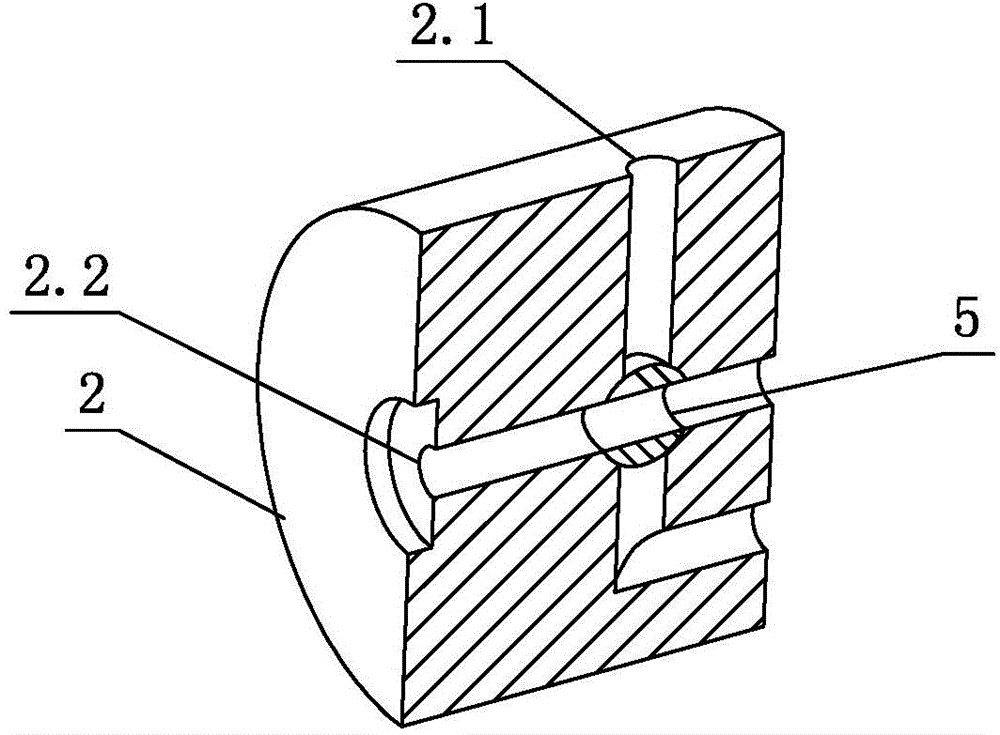

Non-retention plunger injection storage cylinder structure of injection moulding machine

ActiveCN104057574AAvoid a series of problems caused by detentionSolve a series of problems caused by detentionSpray nozzleInjection moulding

The invention relates to a non-retention plunger injection storage cylinder structure of an injection moulding machine. The non-retention plunger injection storage cylinder structure comprises a spray nozzle, a front-end flange, a storage cylinder and a plunger, wherein the spray nozzle, the front-end flange and the storage cylinder are sequentially assembled hermetically; the plunger is inserted into the storage cylinder in a left-right moving way. The non-retention plunger injection storage cylinder structure is characterized in that a shuttle valve is embedded into the front-end flange; a central channel is arranged in the plunger; a storage cavity and an annular storage channel are formed between the front-end flange and the plunger after adhesive injection; a first-in first-out principle in a fused plastic storage process is realized by using an inner channel to transfer raw material; and residual material is pushed to the end opening of the front-end flange and injected into a mould in a storage process every time. According to the non-retention plunger injection storage cylinder structure, a series of problems caused by the retention of material at the front end of the plunger are completely prevented, the problems of difficult raw material replacement, plastic degradation and the like in a production process are ingeniously solved, so that the product waste is greatly reduced, the working efficiency and the finished product ratio are increased, and the difficulty of equipment maintenance work is lowered; residual adhesive material is conveyed into the storage cavity to participate in the adhesive injection, so that the purpose of removal of the residual material is reached.

Owner:广东伊之密精密注压科技有限公司

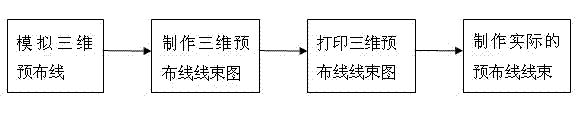

Novel electric screen cabinet prewiring method for wind turbine generator

ActiveCN102930092AAdapt to production needsEasy to manufactureSpecial data processing applicationsProcess engineeringComputer software

The invention discloses an electric screen cabinet prewiring method and provides a novel electric screen cabinet prewiring method for a wind turbine generator. According to the method, three-dimensional prewiring is simulated by utilizing computer software, and prewiring can be efficiently and intuitively realized according to an electrical schematic diagram and can be immediately changed along with the electrical schematic diagram. The novel electric screen cabinet prewiring method for the wind turbine generator comprises the following steps of: simulating three-dimensional prewiring; manufacturing a three-dimensional prewiring wiring harness diagram; printing the three-dimensional prewiring wiring harness diagram; and manufacturing an actual prewiring wiring harness. The simulated three-dimensional prewiring of an electric screen cabinet can immediately and correspondingly change with an electric screen cabinet design drawing or file. The method is mainly applied to guiding wiring in the electric screen cabinet of the wind turbine generator and can be used for guiding wiring in other electric screen cabinets. By the method, prewiring can be efficiently and intuitively realized according to the electrical schematic diagram, the production waste is reduced, and large-scale diversified production requirements are met.

Owner:ZHUZHOU CSR ELECTROMECHANICAL TECH

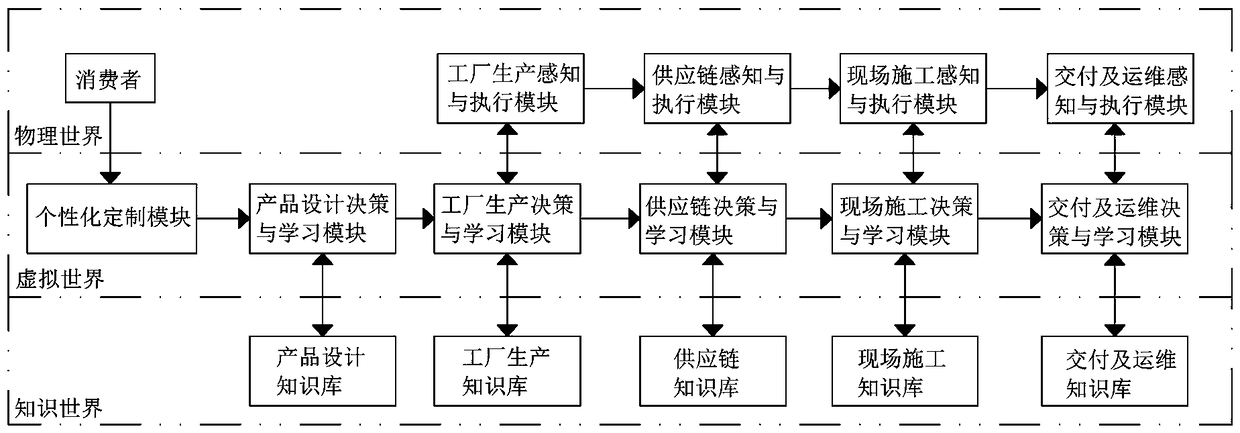

Intelligent constructing system based on CPS

ActiveCN108198093AImprove design efficiencyImprove process design efficiencyData processing applicationsComputer moduleVirtual world

The invention discloses an intelligent constructing system based on CPS (Cyber-Physical Systems). The intelligent constructing system comprises a consumer personalized customization module, a productdesign decision-making and learning module, a factory production decision-making and learning module, a supply chain decision-making and learning module, a site construction decision-making and learning module, a delivery-and-operation-and-maintenance decision-making and learning module, a factory production perceiving and executing module, a supply chain perceiving and executing module, a site assembly perceiving and executing module, a delivery-and-operation-and-maintenance perceiving and executing module, a product design knowledge base, a factory production knowledge base, a supply chain knowledge base, a site construction knowledge base and a delivery-and-operation-and-maintenance knowledge base, wherein the consumer personalized customization module, the product design decision-making and learning module, the factory production decision-making and learning module, the supply chain decision-making and learning module, the site construction decision-making and learning module and the delivery-and-operation-and-maintenance decision-making and learning module belong to the virtual world; the factory production perceiving and executing module, the supply chain perceiving and executing module, the site assembly perceiving and executing module and the delivery-and-operation-and-maintenance perceiving and executing module belong to the physical world; the product design knowledgebase, the factory production knowledge base, the supply chain knowledge base, the site construction knowledge base and the delivery-and-operation-and-maintenance knowledge base belong to the knowledge world. According to the intelligent constructing system based on the CPS, the intelligent computation and analysis capacity of a computer is used for replacing manual empirical judgment or decision,full industry chain designing is achieved, decision-making mistakes in the building construction process are reduced, unnecessary production waste is reduced, the construction period is shortened, the invest is reduced, and the real-time efficiency of building construction engineering is improved.

Owner:墨点狗智能科技(东莞)有限公司

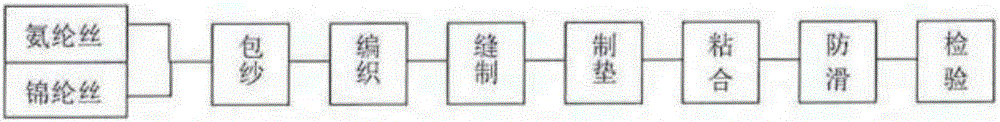

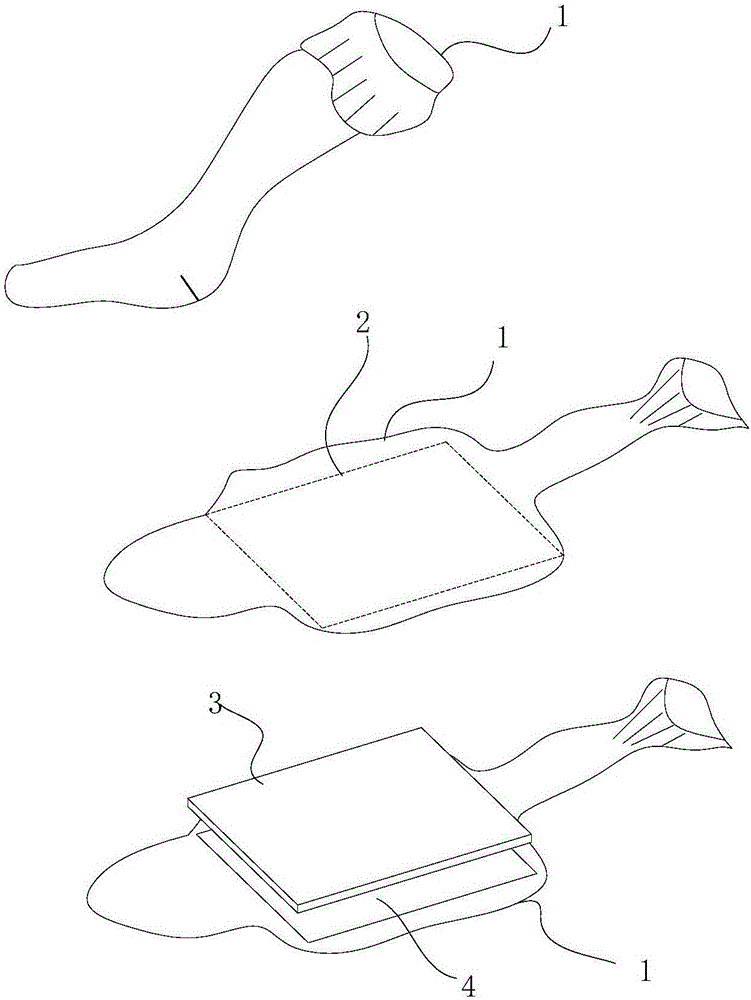

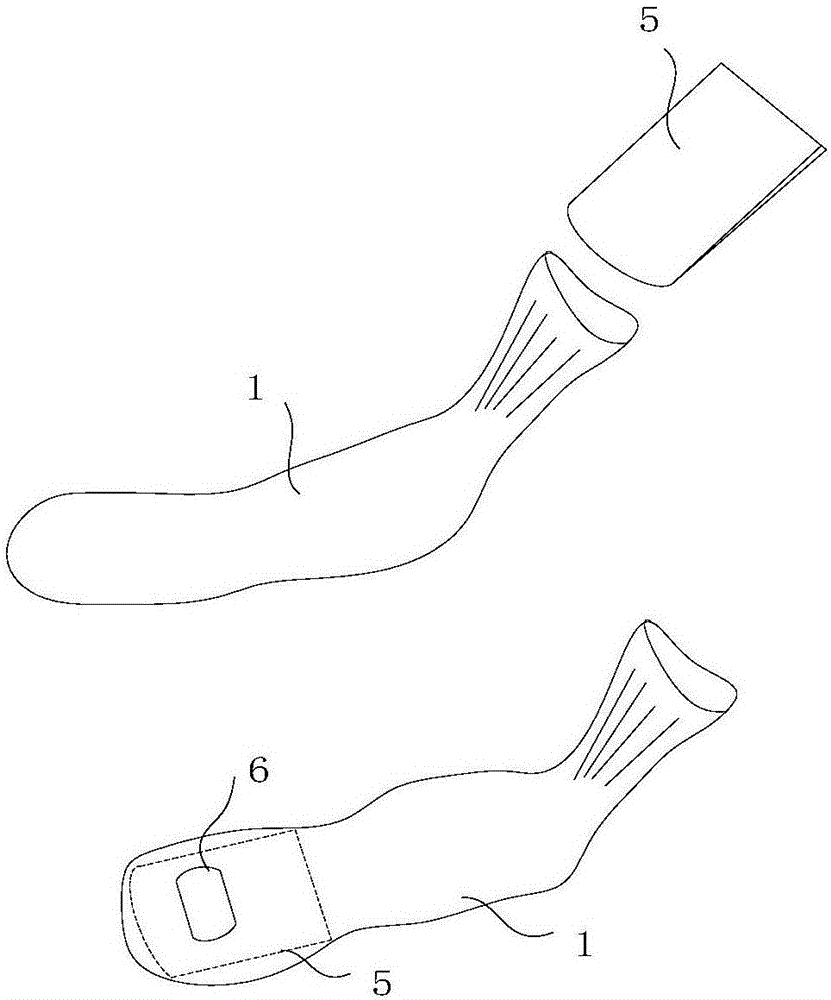

Sports socks produced by virtue of bonding technology and having effect of cushioning heels and production process of sports socks

ActiveCN106510011APlay a supporting rolePlay a bufferWeft knittingSynthetic resin layered productsSOCKSYarn

The invention provides a production process of sports socks having an effect of cushioning heels. The production process comprises the following steps: (1) covering yarns; (2) conducting knitting; (3) conducting sewing; (5) conducting bonding; (6) applying non-slip tapes; and (7) conducting inspection: inspecting bonded positions and an effect. According to the production process provided by the invention, under the precondition of not increasing the investment of novel equipment, socks, which are produced by virtue of a normal cylindrical weaving machine, are locally bonded with shape pads through the novel bonding technology, so that effects of supporting, cushioning and protecting are achieve. In accordance with users' demands, the heel pads (the shape pads) can be made into different shapes, and inner pads, made from various materials, can be selected. In addition, the invention also provides the sports socks produced by the production process.

Owner:LUSHAN HUAMEI COVERED YARN CO LTD

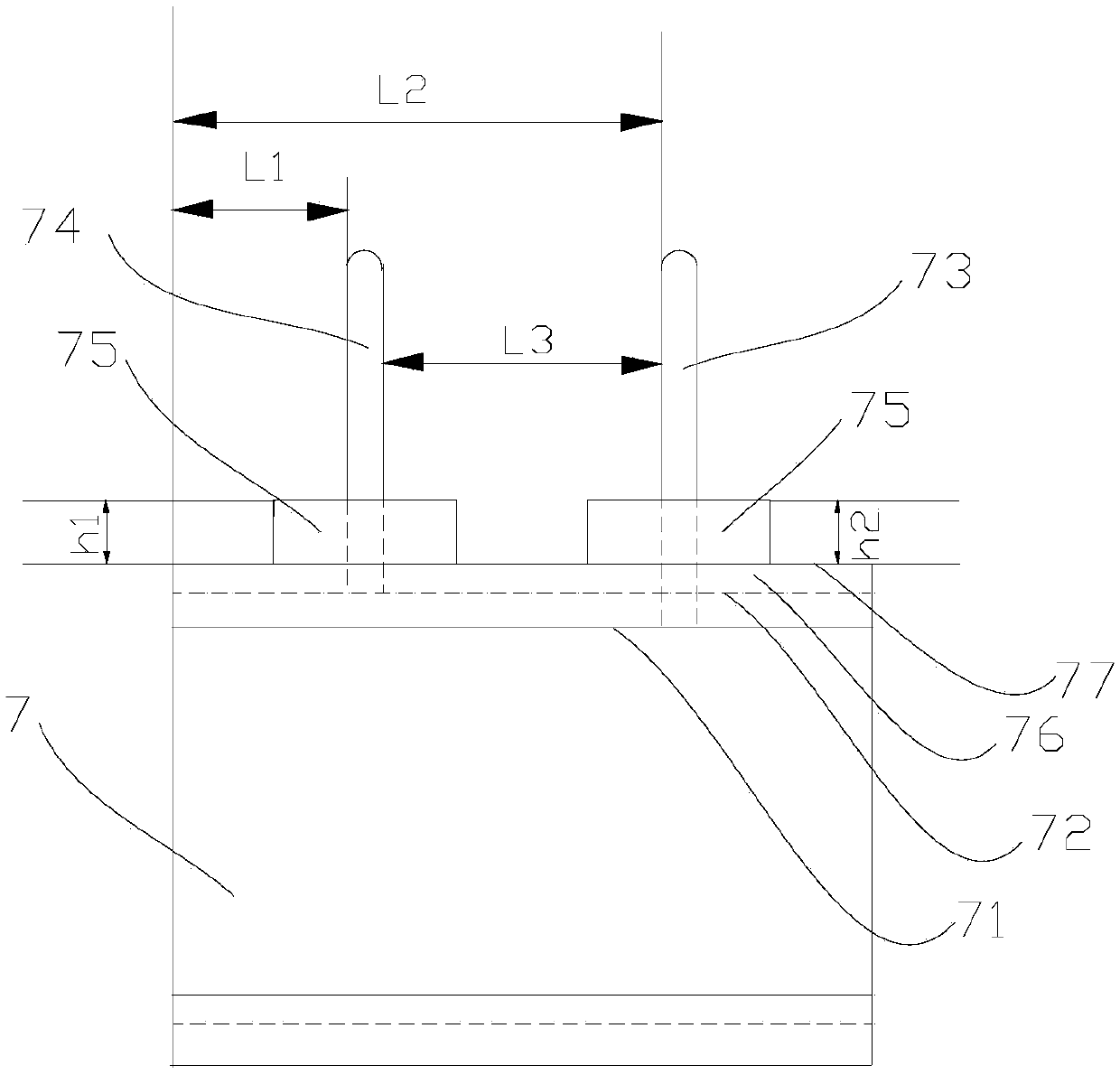

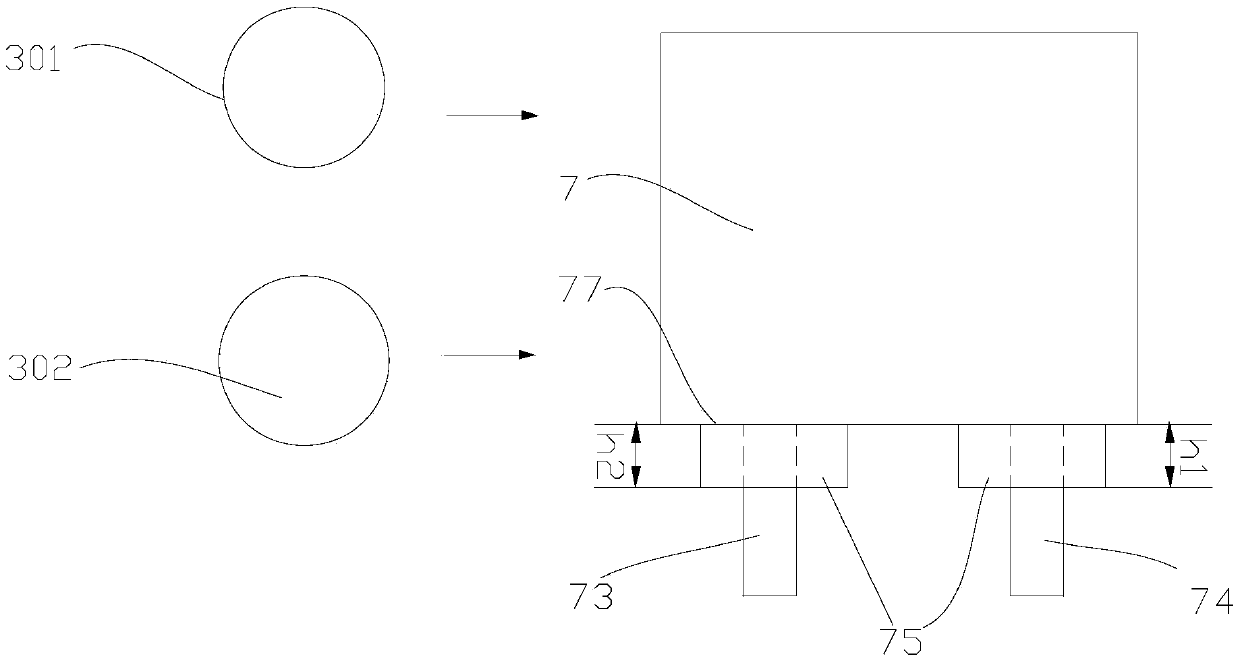

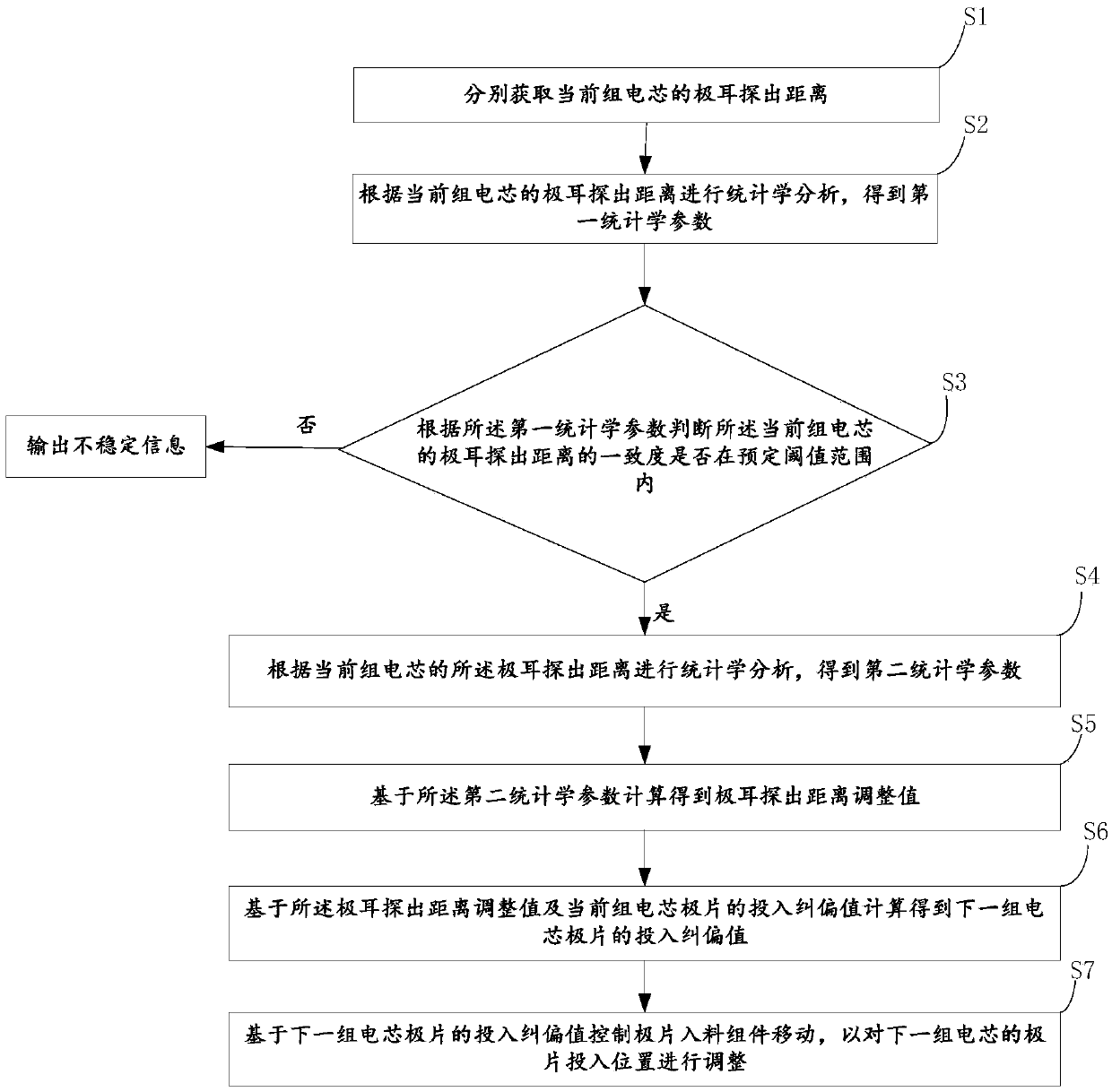

Tab checking and correcting method and device

ActiveCN111193072AInput position is accurateImprove consistencyFinal product manufactureElectrolyte accumulators manufactureWinding machineSimulation

The invention relates to the technical field of winding machine automation, and discloses a tab checking and correcting method and device. According to the tab checking and correcting method, consistency analysis is carried out on the tab extending distances of the current group of battery cells, and when the consistency of the tab extending distances of the current group of battery cells exceedsa preset threshold range, unstable information is output to prompt an operator to check reasons; when the consistency of the extending distances of the tabs of the current group of battery cells conforms to a preset threshold range, the input deviation rectifying value of the current group of battery cell pole pieces is matched with the tab extending distance adjusting value of the current group of battery cells, and the input deviation rectifying value of the next group of battery cell pieces is obtained, so that a more reliable deviation correction value is provided for the next group of pole pieces, and the more accurate input position of the pole pieces is ensured, so that the consistency of the tab extending distance is improved, and the quality of the battery cell is ensured.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

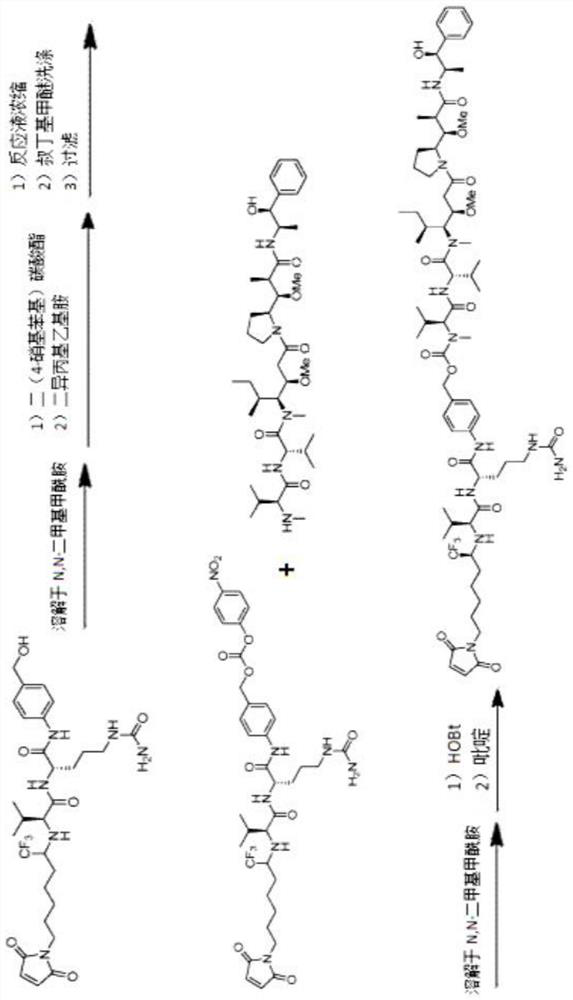

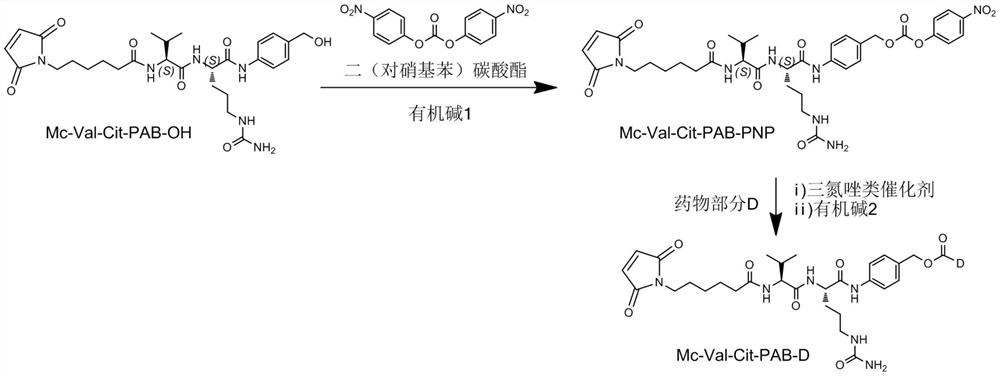

Preparation technology of antibody drug conjugate intermediate by one-pot method

ActiveCN111620927ALow costReduce lossOrganic active ingredientsPeptide preparation methodsDrug conjugationAntiendomysial antibodies

The invention relates to a method for preparing an antibody drug conjugate intermediate by a one-pot method. A preparation technology comprises the steps of enabling MC-Val-Cit-PAB-OH and bis(4-nitrophenyl) carbonate (NPC) to be in contact for a reaction under the condition of existence of organic alkali, after the reaction is completed, supplementing and adding the organic alkali, 1-hydroxybenzotriazole and a part of drugs D in a reaction system, and performing a reaction to obtain the antibody drug conjugate intermediate. In the whole reaction system, separation and purification treatment isonly performed once, steps of concentration and washing of intermediate reaction liquid, treatment of organic waste liquid, packaging and storage of intermediates, and the like are not needed, and higher yield can be achieved.

Owner:MABPLEX INT LTD

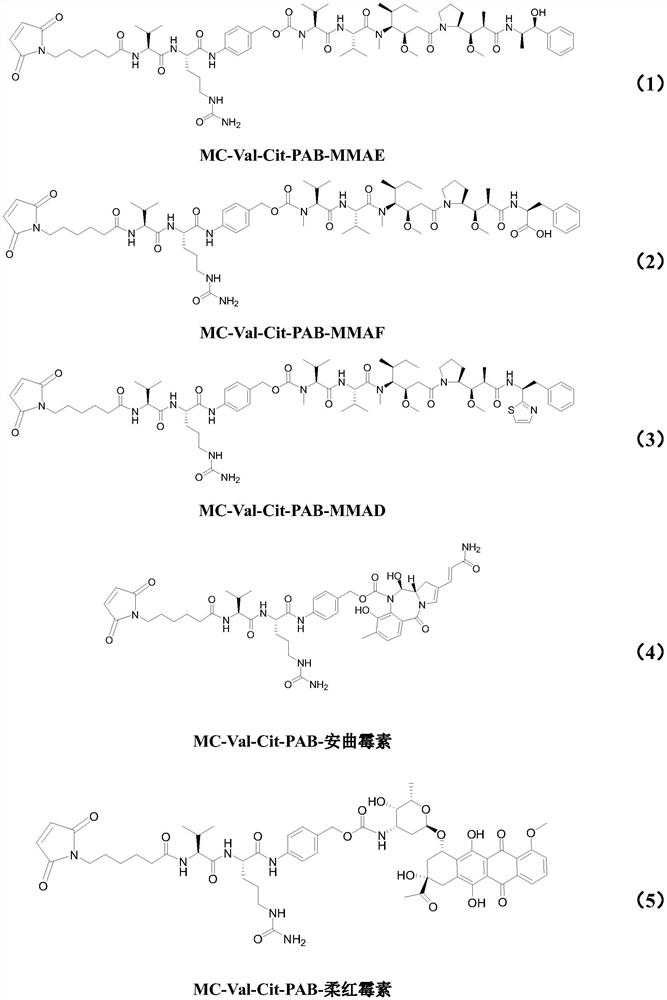

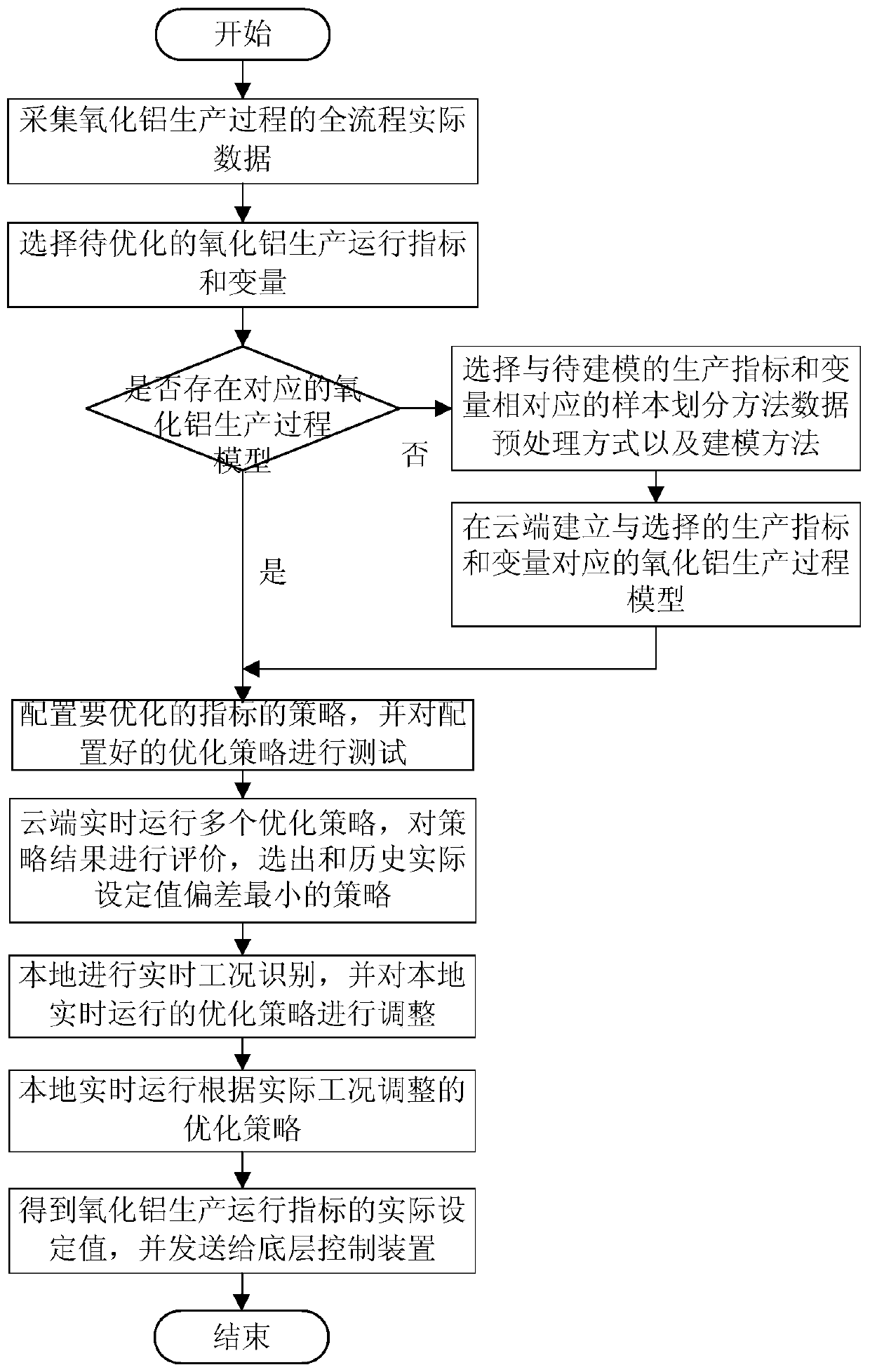

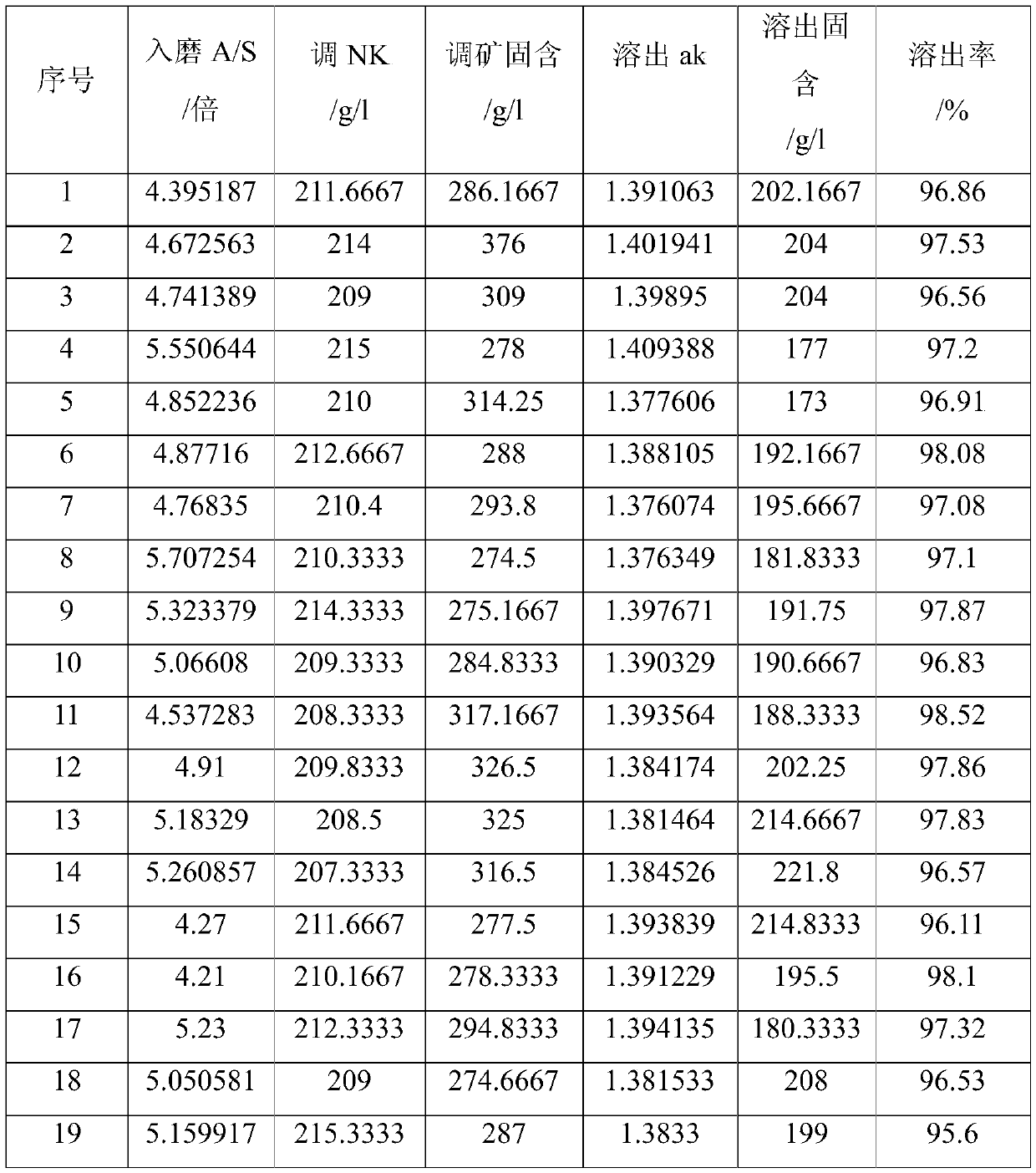

Aluminum oxide production operation optimization system and method based on cloud edge collaboration

ActiveCN110263494ALow costShorten the timeDesign optimisation/simulationTotal factory controlMinimum deviationPre treatment

The invention provides an aluminum oxide production operation optimization system and method based on cloud edge coordination, and relates to the technical field of aluminum oxide production operation optimization. The system and the method comprise the following steps: firstly, full-process data of an alumina production process is collected; the data are preprocessed and then transmitted to a local collaborative production operation optimization unit, the local collaborative production operation optimization unit judges the working condition of the current aluminum oxide production process firstly, an optimization strategy needing to be operated currently is automatically switched according to the working condition, and the local operation optimization strategy obtains the actual set value of the aluminum oxide production operation index. For the situation that an aluminum oxide production process model does not exist in the local collaborative production operation optimization unit, the local collaborative production operation optimization control unit sends modeling information to the cloud storage and collaborative optimization calculation unit, and modeling and testing are conducted on the cloud. And the cloud establishes a test and operates a plurality of optimization strategies, and recommends the strategy with the minimum deviation from the historical actual set value to the local collaborative production operation optimization unit.

Owner:NORTHEASTERN UNIV LIAONING

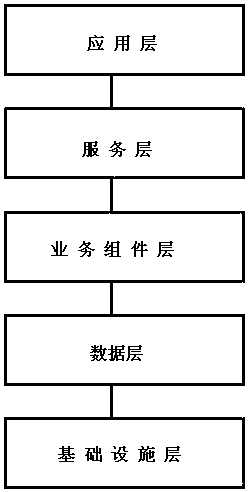

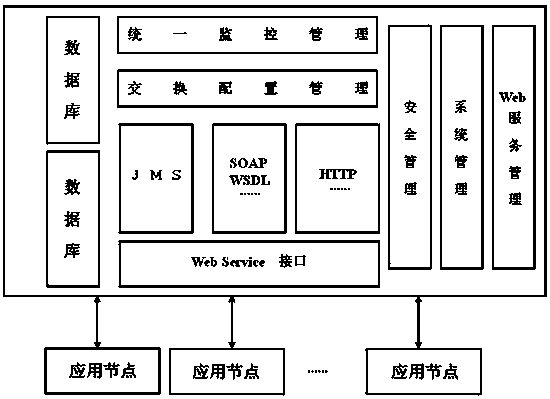

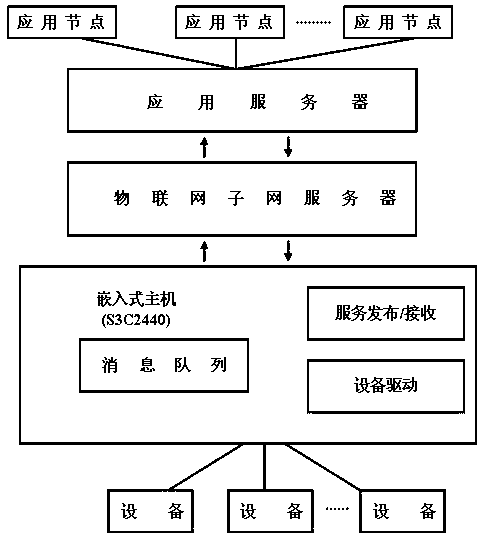

Intelligent IOT data exchange platform scheme system based on field of electronic commerce

The invention relates to an intelligent IOT data exchange platform scheme system based on the field of electronic commerce. The intelligent IOT data exchange platform scheme system based on the fieldof electronic commerce comprises three parts including an IOT-based application integration platform, a service management platform and an integrated monitoring platform; the platform is composed of an infrastructure layer, a data layer, a service component layer, a service layer and an application layer; the overall architecture of an IOT data exchange platform based on the field of electronic commerce is a B / S system architecture; on one hand, the data source of the system collects information data of related electronic commerce products and articles from an underlying sensor network; on theother hand, the data source of the system comes from data of other application systems in an IOT system; the platform system further comprises three functional modules including an electronic commerce product and article data acquisition, underlying service publishing and Web service calling; therefore, electronic merchants in the platform system can realize instant data sharing and exchange; unified management can be conveniently carried out; commodity information in inventory and circulation links can be accurately known; the inventory can be effectively reduced; and the fund utilization rate is increased.

Owner:DALIAN XINCHENG CREDIT MANAGEMENT CONSULTING

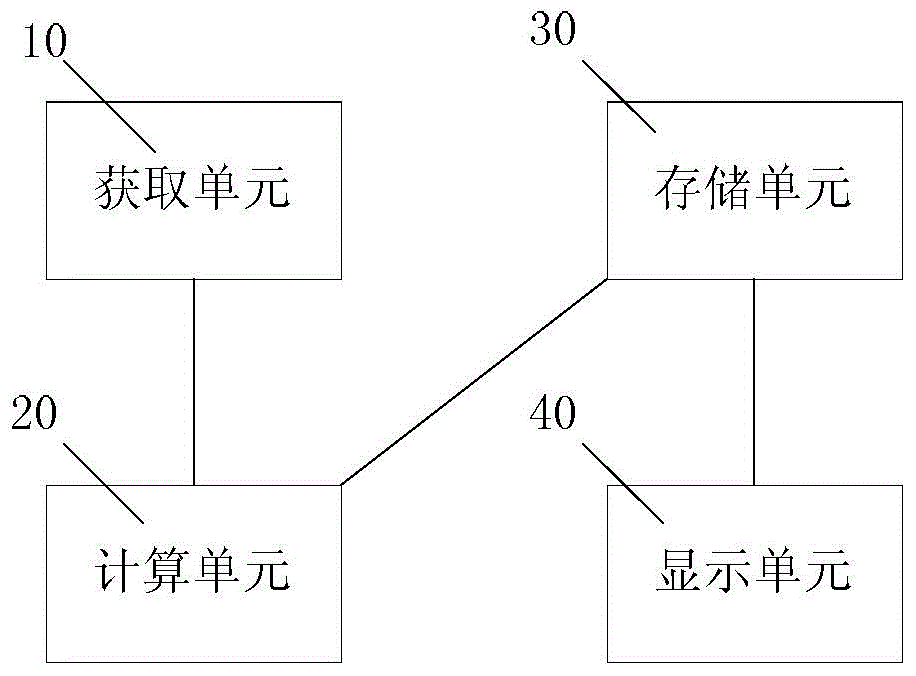

Monitoring device and monitoring method of photoresist surplus, and chip manufacturing device

ActiveCN104658934AIncrease usageReliable referenceSemiconductor/solid-state device testing/measurementProduction scheduleEngineering

The invention provides a monitoring device and a monitoring method of photoresist surplus, and a chip manufacturing device. The monitoring device comprises an acquisition unit, a computing unit and a storage unit, wherein the acquisition unit is used for acquiring the shipping quantity of various products; the computing unit is connected with the acquisition unit, and used for determining the photoresist surplus of each photoresist according to the shipping quantity of the various products, the unit photoresist dosage of the different photoresists used by the various products, and the initial quantity of each photoresist; and the storage unit is connected with the computing unit, and used for storing the photoresist surplus of each photoresist and updating the initial quantity of each photoresist. The photoresist surplus of each photoresist can be determined according to the information, so that working personnel can monitor the photoresist surplus in real time, a reliable reference base is provided for the working personnel for reasonable arrangement of a production schedule, use rates of the photoresists are increased, production waste is reduced, and the production efficiency is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for detecting whether stainless steel is foggy or not after polishing

ActiveCN108036993AReduce the risk of material outageImprove satisfactionPreparing sample for investigationScattering properties measurementsClockwiseSteel belt

The invention relates to a method for detecting whether stainless steel is foggy or not after polishing. The method includes: taking samples with multiple lengths, and selecting three positions of left, middle and right on the samples for sampling; shearing the samples into square samples and placing the same into the bottom of a cold insetting mold horizontally; respectively taking 5mL and 10mL of two kinds of matching liquids, namely a curing agent and resin according to the proportion of 1:2, mixing the liquids, stirring slowly for 2 minutes in the clockwise direction, pouring the liquids into the cold insetting mold, allowing standing for 1 hour, and taking out an inset sample after a to-be-inset sample is hardened; opening a full-automatic grinding and polishing machine, performing flushing without loading the sample, slightly brushing a polishing cloth with a plastic brush, and cleaning the polishing cloth; taking out gold phase; detecting the surface of the gold surface.

Owner:SHANGHAI STAL PRECISION STAINLESS STEEL

Method for preparing feed-grade xylo-oligosaccharide through viscose squeezed alkali liquid

InactiveCN105420313AEliminate the purification processImprove conversion rateFermentationEnzymatic hydrolysisHydrolysate

The invention discloses a membrane concentration process for preparing feed-grade xylo-oligosaccharide through squeezed liquid from viscose production. The membrane concentration process comprises the following specific operation steps: A, filtering squeezed liquid from viscose production through a membrane, taking a concentrated solution and adding acid into the concentrated solution for neutralizing so as to obtain a xylan solution; B, carrying out enzymatic hydrolysis reaction on the xylan solution and compound enzymes so as to obtain an enzymatic hydrolysate and residues of enzymatic hydrolysis, adding water for diluting residues of enzymatic hydrolysis, preheating, carrying out centrifugal separation, taking supernatant namely the xylan solution and obtaining a secondary enzymatic hydrolysate under the effects of compound enzymes; C, mixing the enzymatic hydrolysates obtained in the step B, enabling the mixed solution to enter a nanofiltration membrane for desalting, so as to obtain a concentrated solution which is purification liquid of xylo-oligosaccharide, evaporating and drying so as to obtain the feed-grade xylo-oligosaccharide. The utilization ratio of xylan is high, production waste is reduced and the production cost is reduced.

Owner:YIBIN YATAI BIOTECH

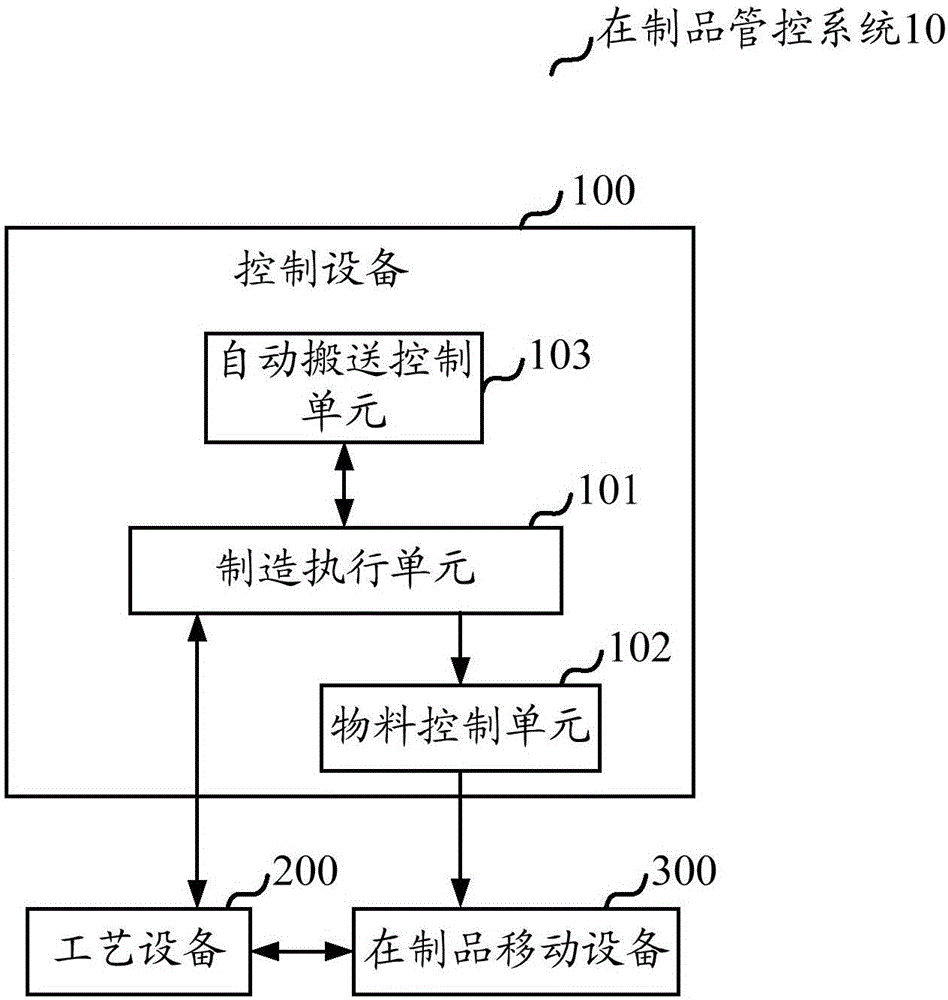

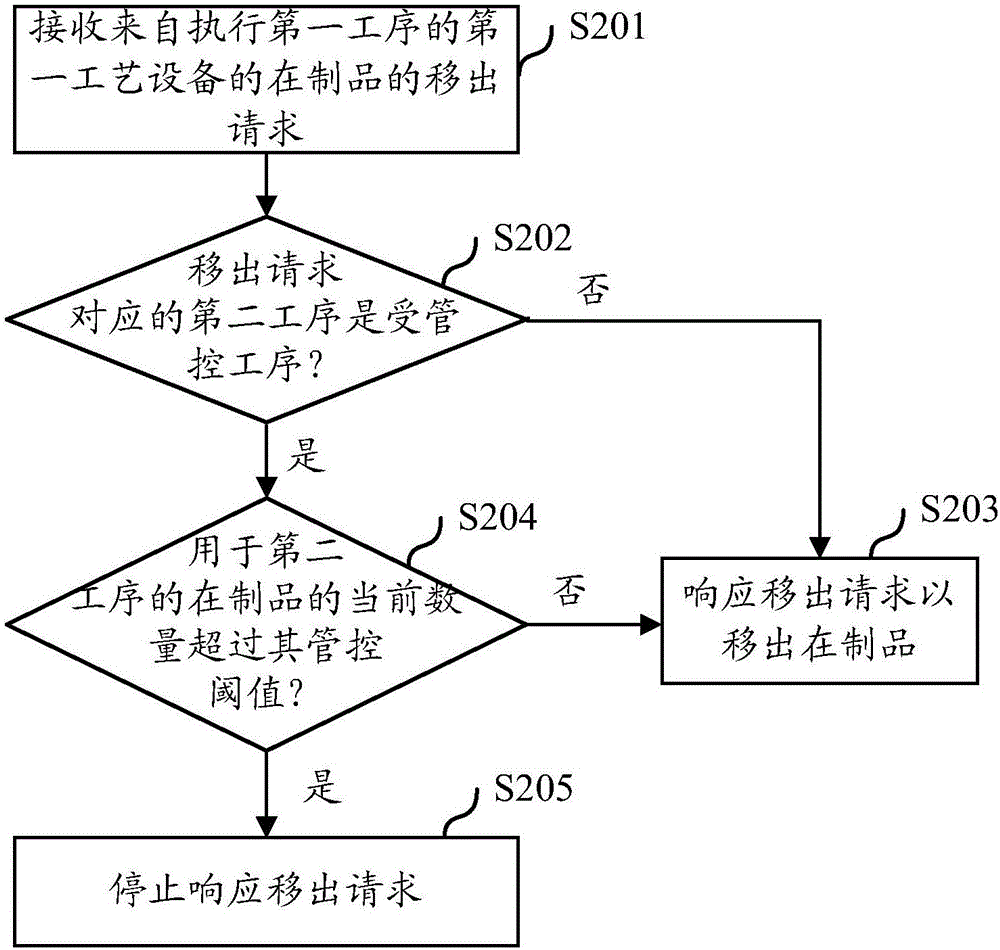

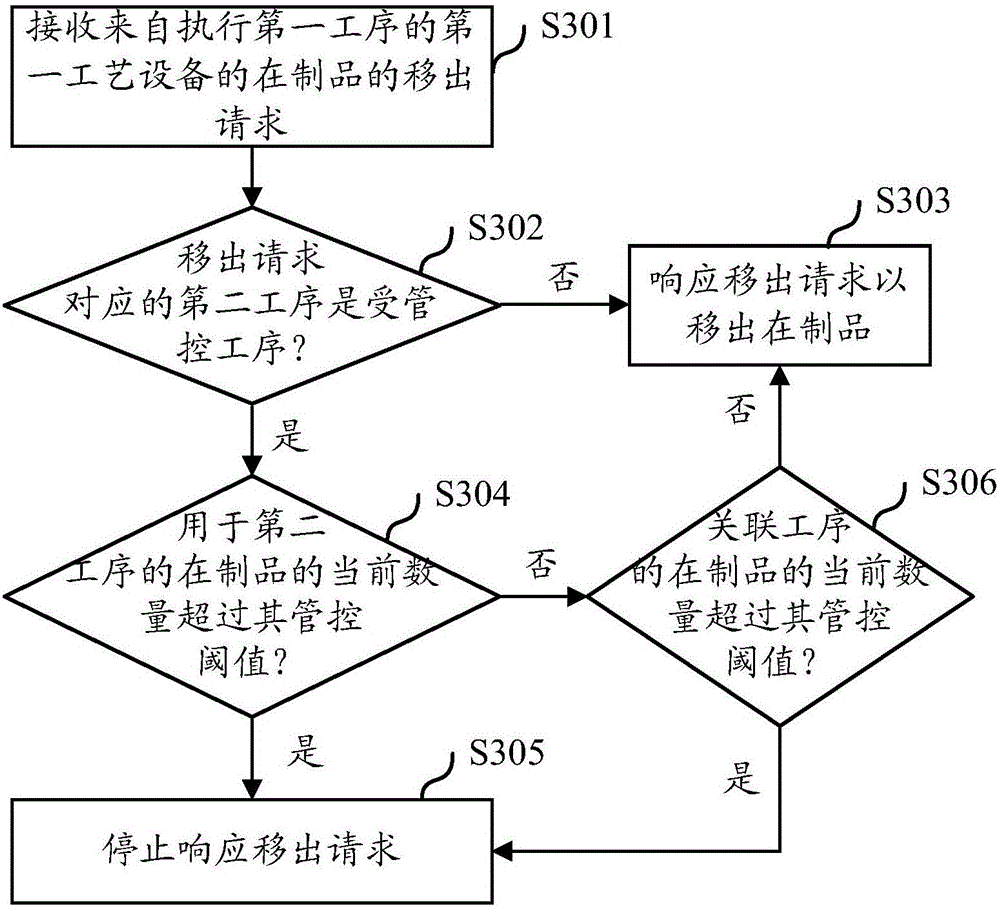

Method and system for management and control of articles being processed

ActiveCN106774196AReduce turnaround timeImprove transfer efficiencyTotal factory controlProgramme total factory controlProcess equipmentProcess engineering

The present invention relates to a method and system for management and control of articles being processed in an automatic production manufacture environment. The method comprises: receiving a shift-out request of articles being processed from a first process unit of a first working procedure; determining whether a second working procedure corresponding to the shift-out request is a managed and controlled working procedure or not; in the condition that the second working procedure is not the managed and controlled working procedure, responding to the shift-out request to shift out the articles being processed, and in the condition that the second working procedure is the managed and controlled working procedure, determining the current number of the articles being processed used in the second working procedure exceeds a management and control threshold or not; and in the condition that the current number of the articles being processed used in the second working procedure exceeds a management and control threshold, stopping responding to the shift-out request.

Owner:BOE TECH GRP CO LTD +1

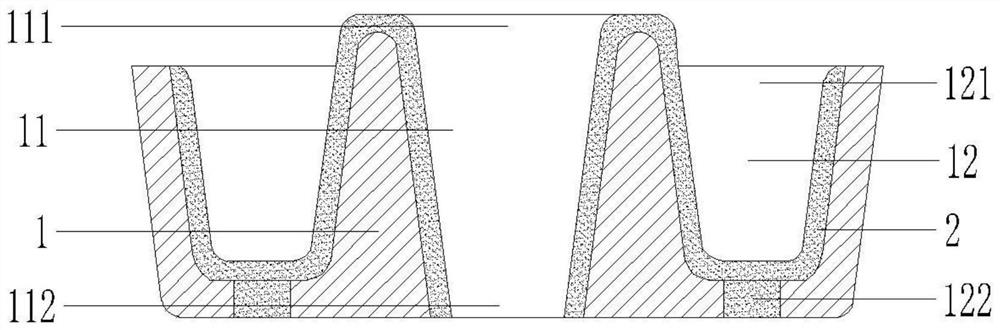

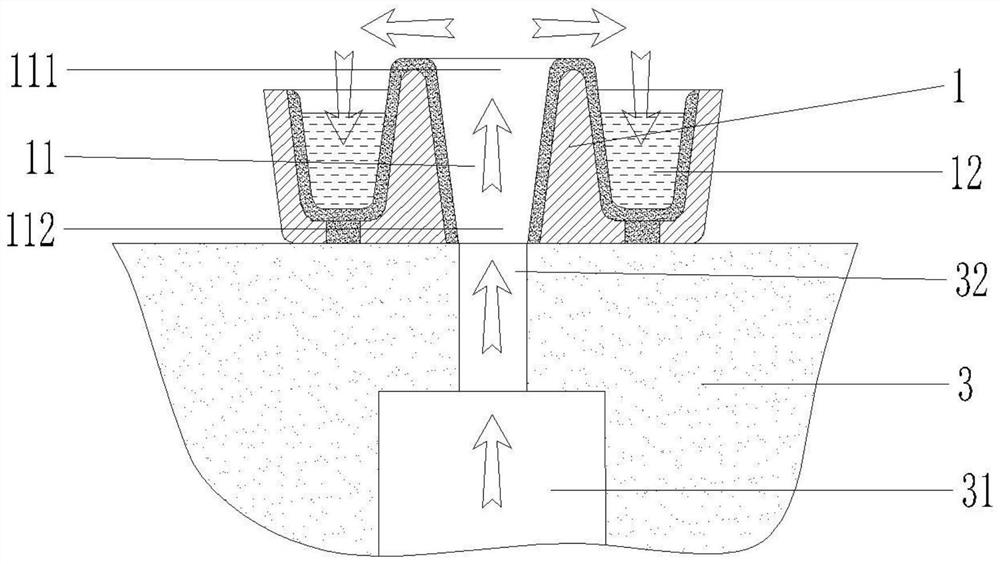

Method and device for preparing regenerated sponges by polyurethane sponge wastes

PendingCN110576546AReduce pollutionReduce production wastePlastic recyclingDomestic articlesEngineeringPollution

The invention relates to a method and device for preparing regenerated sponges by polyurethane sponge wastes. The method comprises the following operation steps: 1) sponge wastes are crushed to smallparticles; 2) the small particles of the sponge wastes are metered in batches; 3) glue is fed gradually for uniform mixing; and 4) regenerated sponge blocks are bonded through pressing. The device comprises equipment of four procedures. The method can prepare sponge leftover wastes generated in the sponge product production process to the regenerated sponge blocks for such products as sponge spring mattresses and cushions, so that the production waste is reduced, the cost is reduced, meanwhile, the environment pollution possibly caused by the sponge wastes is reduced, production enterprises are more environment-friendly, and more energy is saved.

Owner:赛诺(浙江)聚氨酯新材料有限公司

Material separation type dryer

InactiveCN106288698AEasy to separatePrevent side leakageDrying machines with non-progressive movementsGrain treatmentsEngineeringSeparation pattern

The invention discloses a material separation type dryer which comprises a base, wherein a limiting groove is formed in the upper surface of the base; a first support column mounting block and a second support column mounting block are fixedly connected to the limiting groove through bolts and nuts; a first support column is mounted on the inner side surface of the first support column mounting block through a hexagonal nut; a second support column is mounted on the inner side surface of the second support column mounting block through a hexagonal nut; end openings of the first support columns and the second support columns are fixedly connected with a drying cylinder; a separation cylinder support base is mounted at the bottom of an inner cavity of the drying cylinder; a separation cylinder is mounted on the separation cylinder support base. According to the material separation type dryer, a plurality of small holes are formed in the surface of the separation cylinder; wire meshes for filtering small particles are mounted in the small holes; in the material stirring, crushing and separating process, small particles are conveyed into the drying cylinder through the wire meshes in the small holes, so as to facilitate the separation in the next step; the drying cylinder and the separation cylinder are arranged separately, so that the separation effect is improved.

Owner:成都君华睿道科技有限公司

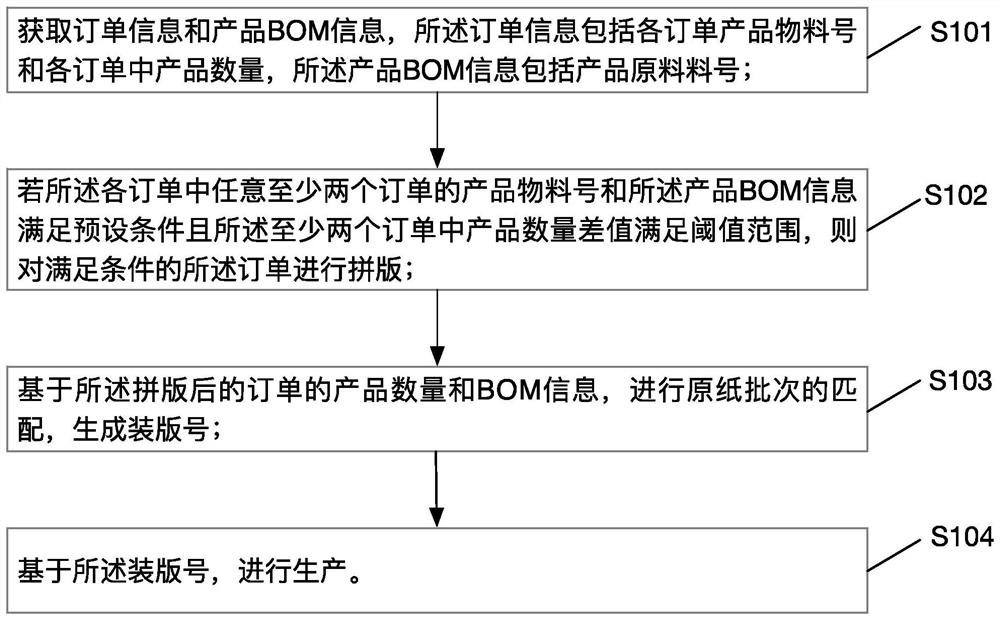

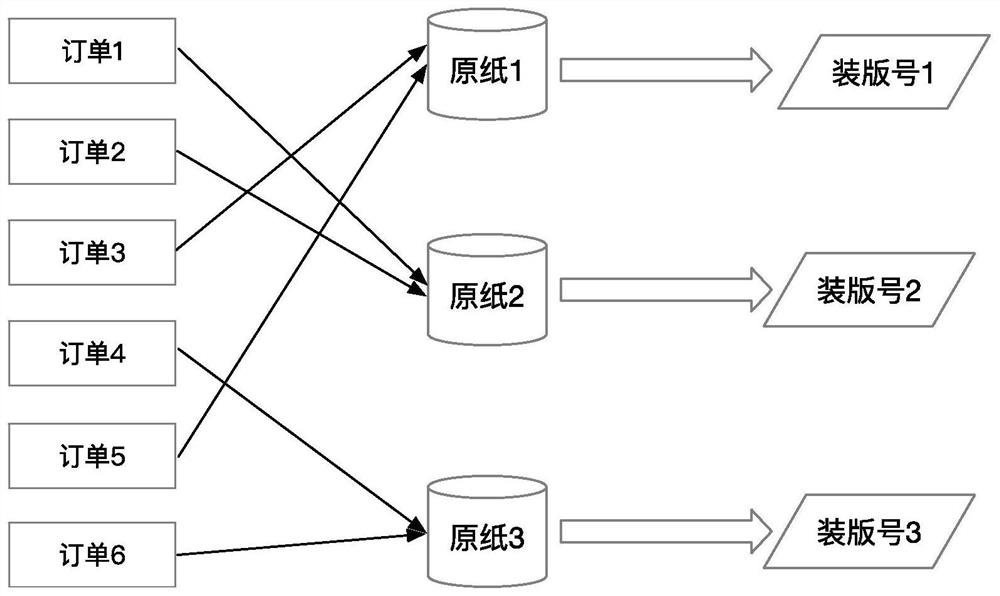

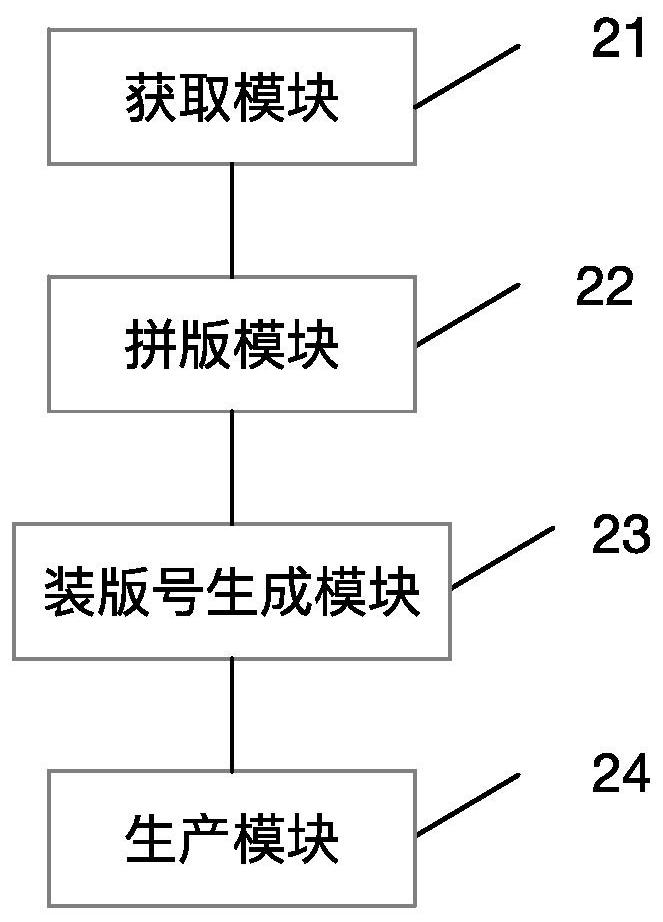

Printing industry makeup production method, device, system and storage medium

PendingCN113377300AReduce production wasteFacilitate unified traceabilityForecastingResourcesEngineeringProcess engineering

The invention discloses a printing industry makeup production method, a device, a system and a storage medium. The method comprises the following steps: obtaining order information and product BOM information, the order information comprises the product material number of each order and the product number in each order, and the product BOM information comprises the product raw material number; if the product material numbers of any at least two orders in the orders and the product BOM information meet a preset condition and the difference value of the product numbers in the at least two orders meets a threshold range, carrying out makeup on the orders meeting the condition; on the basis of the product quantity and BOM information of the makeup order, matching body paper batches, and generating a loading number; and carrying out production based on the plate loading number. According to the makeup production method, device and system in the printing industry and the storage medium, the raw paper breadth is utilized to the maximum extent, and unnecessary production waste is reduced.

Owner:青岛奥利普奇智智能工业技术有限公司

Quantitative casting overflow device

PendingCN111745131AReduce production wasteHigh densityFoundry mouldsFoundry coresLiquid pressureEngineering

The invention provides a quantitative casting overflow device. The quantitative casting overflow device comprises a cup holder, an overflow channel, an overflow cup and a stripping opening, wherein the overflow channel penetrates through the cup holder in the vertical direction and is arranged at the center position of the cup holder; the overflow cup is located on the cup holder, is an annular groove formed by the overflow channel through surrounding and is of a basin-like structure; an upper opening of the overflow cup is lower than an upper opening of the overflow channel; and the strippingopening is formed in the bottom of the overflow cup and penetrates through the cup holder. According to the quantitative casting overflow device, an overflow solution is collected to enable the production to be safe and clean, due to the existence of the overflow channel, the liquid pressure of a gas port and a riser is increased, the density of the casting is improved, the risk of shrinkage porosity of the casting is reduced, the height of box feeding is reduced, the air permeability of a sand mold is improved, and the modeling efficiency is improved; and by observing the overflow of a metalsolution, the overflow weight of the metal solution is set through the process calculation, a quantitative overflow cup suitable for the casting process is designed, and the operating standards of the casting process is formulated and implemented, so that the process is standardized, and the process is visualized.

Owner:龙岩市龙象机械设备制造有限公司

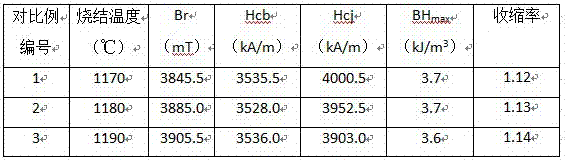

Production technique of high-performance permanent magnetic ferrite pre-sintered material

The invention discloses a production technique of a high-performance permanent magnetic ferrite pre-sintered material. The technique comprises steps as follows: a mixture of iron oxide red and strontium carbonate as raw materials of permanent magnetic ferrite is put in a mixing tower, water is added, grinding is performed, composition correction of iron oxide red and strontium carbonate is executed by an X-ray fluorescence analyzer, and a ratio of iron oxide red to strontium carbonate is 5.95-6.55 in percentage by mass; a mixed material obtained after the composition correction is conveyed toa centrifugal dehydrator agitating tower for dehydrating; high-concentration slurry is conveyed to a rotary kiln for pre-sintering and conveyed to a cooling kiln for cooling, finally, a product entersa ball mill for smashing, and the pre-sintered material is obtained; water content of the mixed slurry is controlled in a range of 35%-45%; in the pre-sintering stage, the feed quantity of sinteringis controlled to be 1.5T-2.5T / h, and kiln temperature of the feeding end is controlled to be 320-360 DEG C; in the ball milling stage, the granularity of the finished product is controlled to be 3-8 mu m. According to the method, batch production of the high-performance permanent magnetic ferrite pre-sintered material is realized, bottleneck of outsourcing of the pre-sintered material for a long time is solved, and stability of follow-up industry chains of the company is guaranteed.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

Automatic assembly line of LED street lamp

InactiveCN104191241AEasy to assembleEasy to transportAssembly machinesWork benchesAssembly lineSurface plate

The invention provides an automatic assembly line of an LED street lamp. The automatic assembly line comprises a base. Base plates are arranged on two sides of the base. A first conveying belt is arranged in the middle of the base. Turnplates are arranged on the base plates. Rotary shafts are arranged on joints between the turnplates and the base plates. A second conveying belt is arranged upon the first conveying belt. A frame is arranged on the base. Operation panels and lighting lamps are arranged on the upper portion of the frame. A storage plate is arranged on the frame. Drawers are arranged at two ends of the base. The first and the second conveying belts are used for input and output of the street lamp, respectively, thus conveying of workpiece is facilitated, and working efficiency is improved. Through the base plates and the rotational turnplates, street lamp assembly is facilitated; through a clamping groove, processing station is set according to the actual requirement by the factory; through switches, the lighting lamps are controlled, and corresponding lighting lamps can be closed in case that the station does not run.

Owner:SUZHOU CHENGTENG ELECTRONICS TECH

Method for rejuvenating dendrobium officinale tissue culture thin and weak seedlings

InactiveCN104472360AImprove stoutnessImprove effective utilizationHorticulture methodsPlant tissue cultureSeedlingCulture mediums

The invention discloses a method for rejuvenating dendrobium officinale tissue culture thin and weak seedlings. The method is suitable for enabling dendrobium officinale tissue culture seedlings to be strong and rejuvenating thin and weak seedlings after planting culture, belonging to the field of plant biotechnology. According to the invention, strong seedlings and thin and weak seedlings which do not meet the requirement in planting culture for tissue culture seedlings are taken as objects; the transfer or germination standard can be reached by implanting a culture medium provided by the invention, so that the phenomenon that a great amount of thin and weak seedlings are discarded due to nonuniform growth and nutrient element absorption differences in the seedling tissue culture process is reduced effectively, and the production cost is reduced. By the tissue culture rapid propagation method provided by the invention and the rejuvenation culture for 65 days, the diameter can be thickened by about 40%, so that the effective seedling rate in the tissue culture seedlings is improved greatly, and the loss cost for the production of dendrobium officinale tissue culture seedlings is reduced.

Owner:云南红河州巨丰生物科技股份有限公司

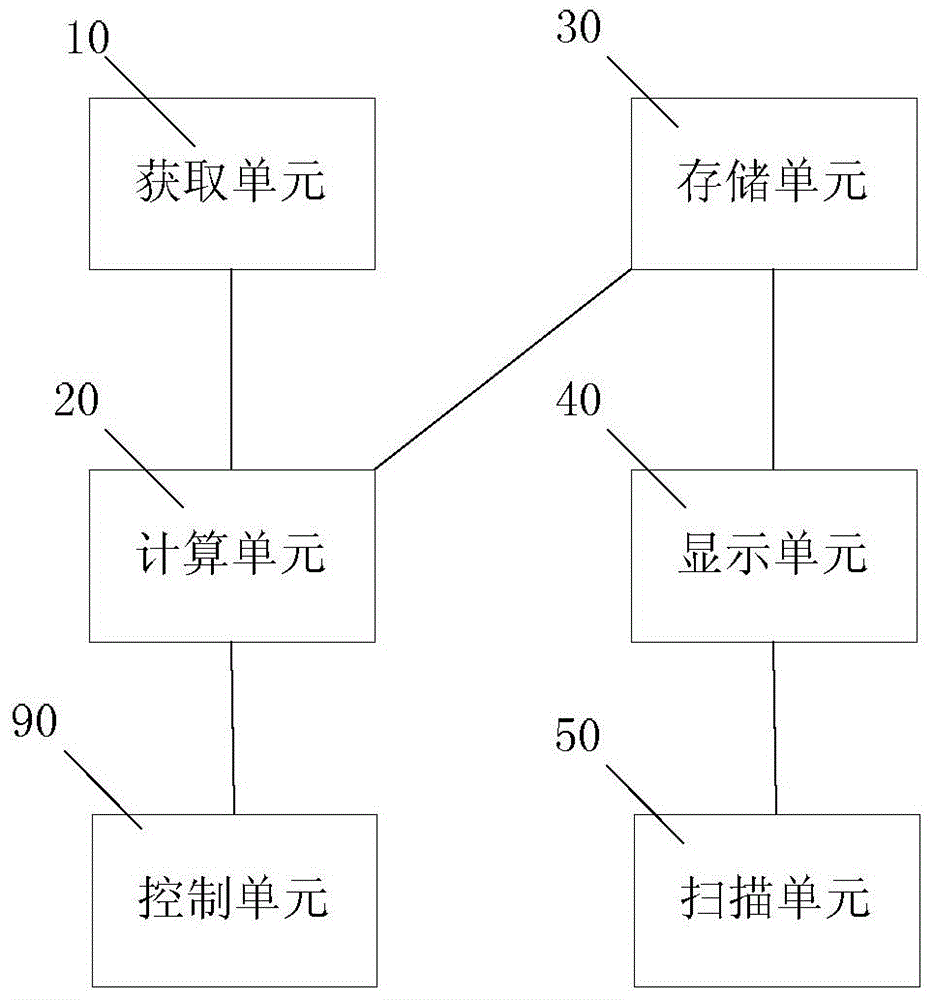

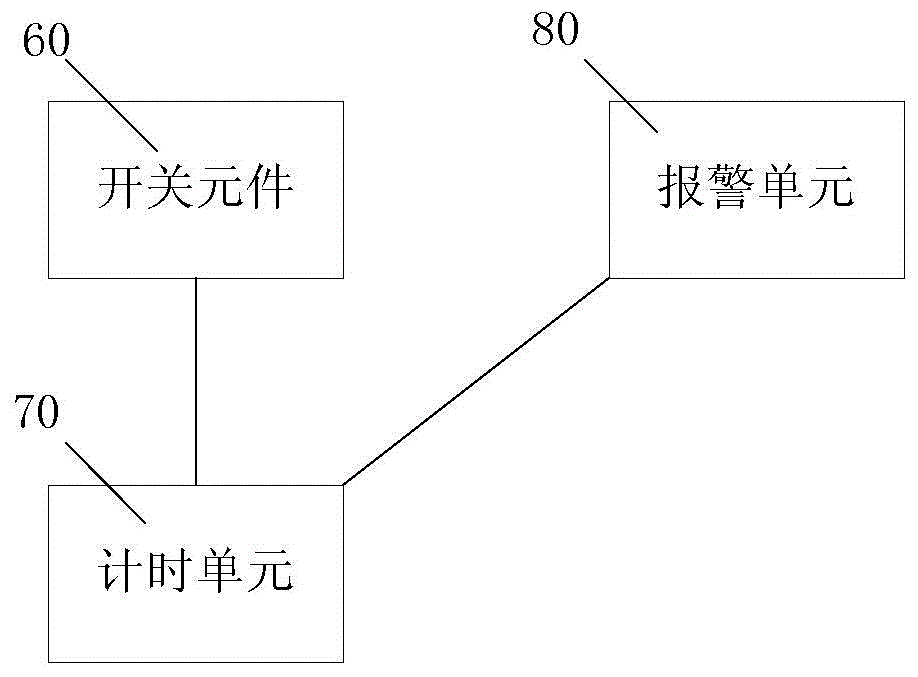

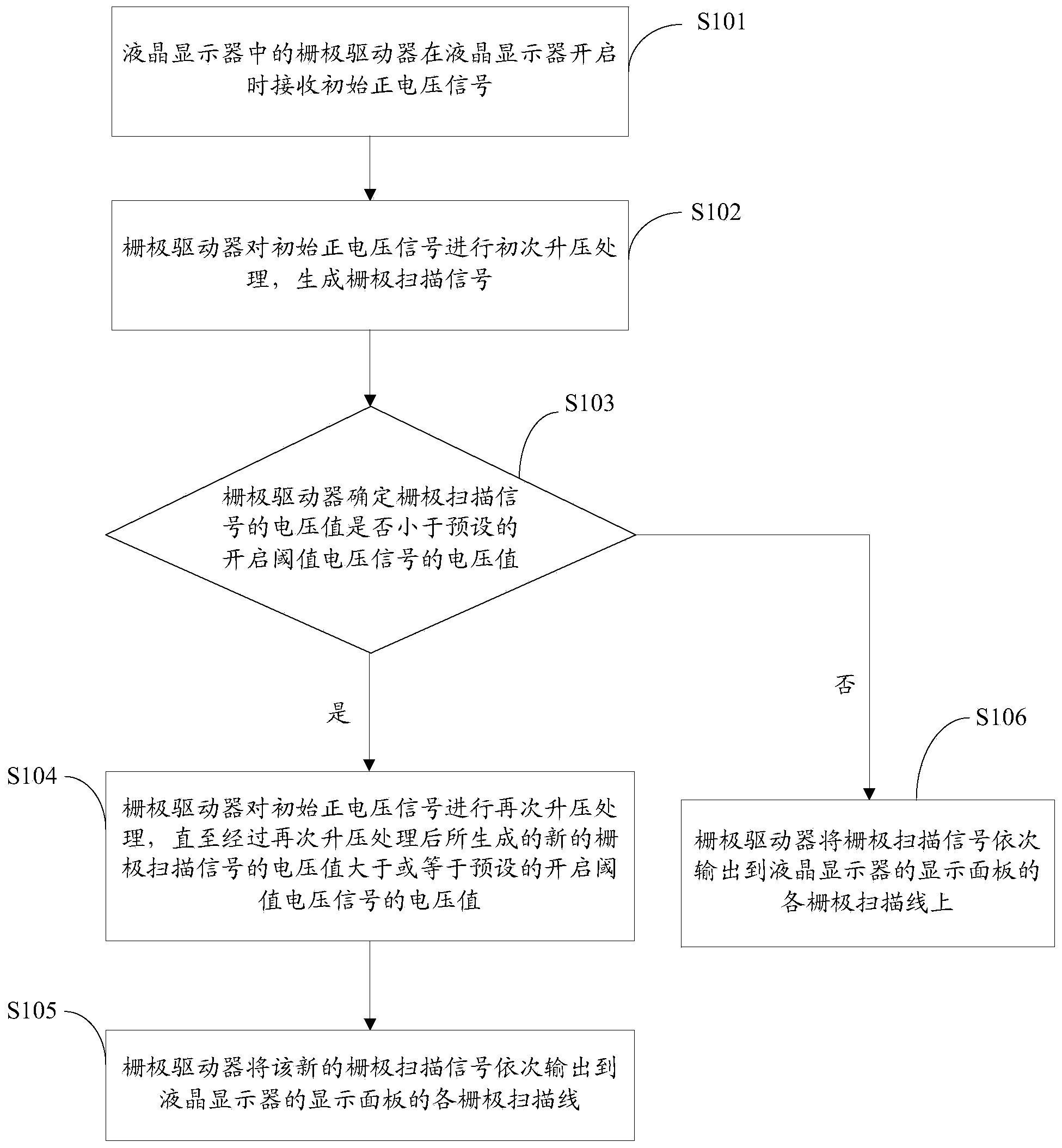

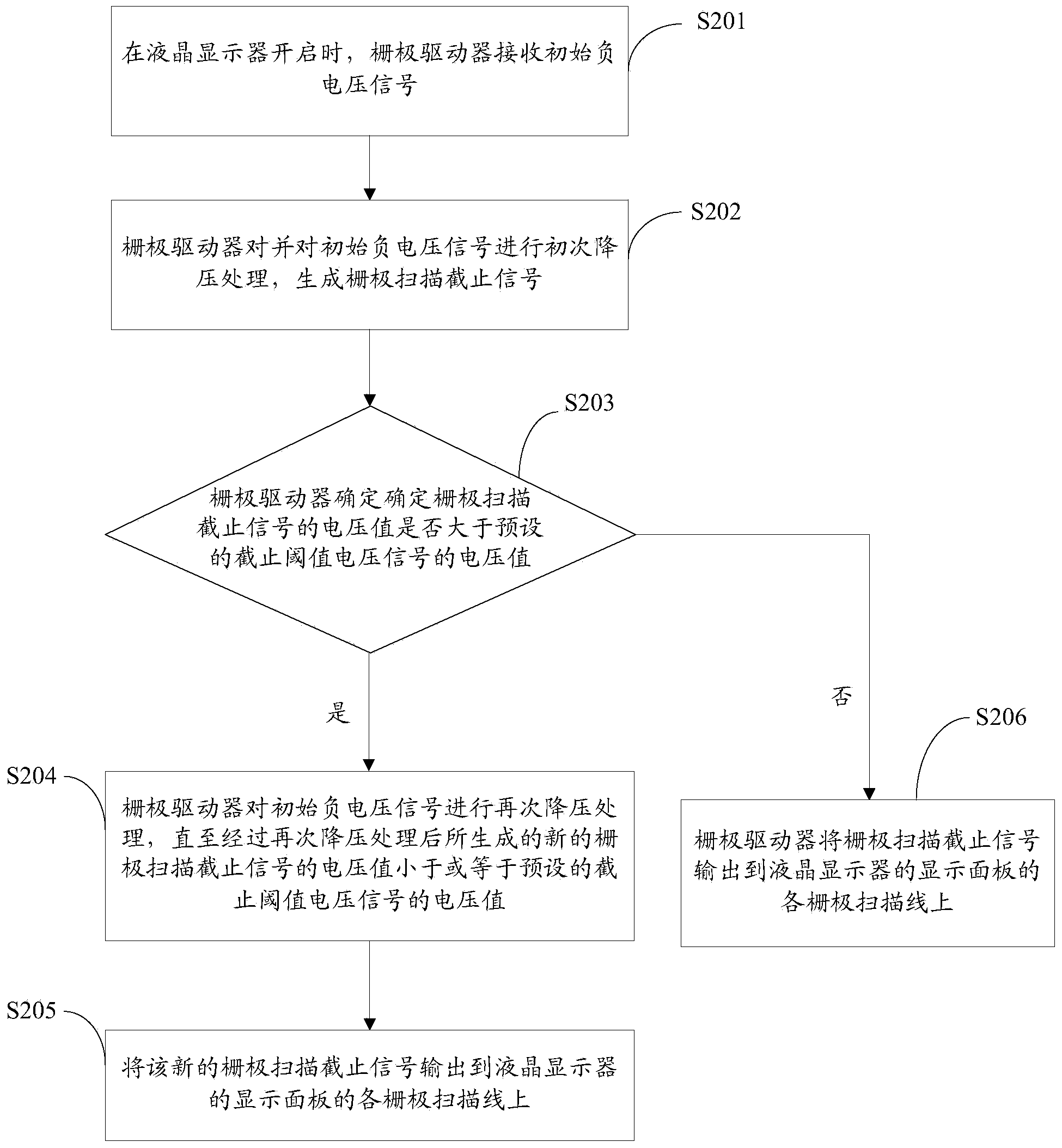

Control method for grid electrode scanning signal and liquid crystal displayer

InactiveCN103886846AReduce production wasteAvoid display effectsStatic indicating devicesLiquid-crystal displayLiquid crystal

The invention discloses a control method for a grid electrode scanning signal and a liquid crystal displayer. Due to the fact that after initial boosting processing is carried out on a received initial positive voltage signal, the generated grid electrode scanning signal is compared with a preset opening threshold voltage signal, boosting processing is carried out on the initial positive voltage signal once again under the situation that the grid electrode scanning signal cannot reach the preset opening threshold voltage signal until the voltage value of the new grid electrode scanning signal generated after the once-more boosting processing is larger than or equal to the voltage value of the preset opening threshold voltage signal, and the new grid electrode scanning signal is sequentially output to grid electrode scanning lines of a display panel of the liquid crystal displayer. Therefore, it is ensured that thin film transistors connected with the grid electrode scanning lines can be normally switched on through the scanning signals input to the grid electrode scanning lines of the display panel, the problem that the liquid crystal displayer is scrapped due to the fact that an RC load of the liquid crystal displayer is large is solved, and unnecessary production waste is reduced.

Owner:BOE TECH GRP CO LTD +1

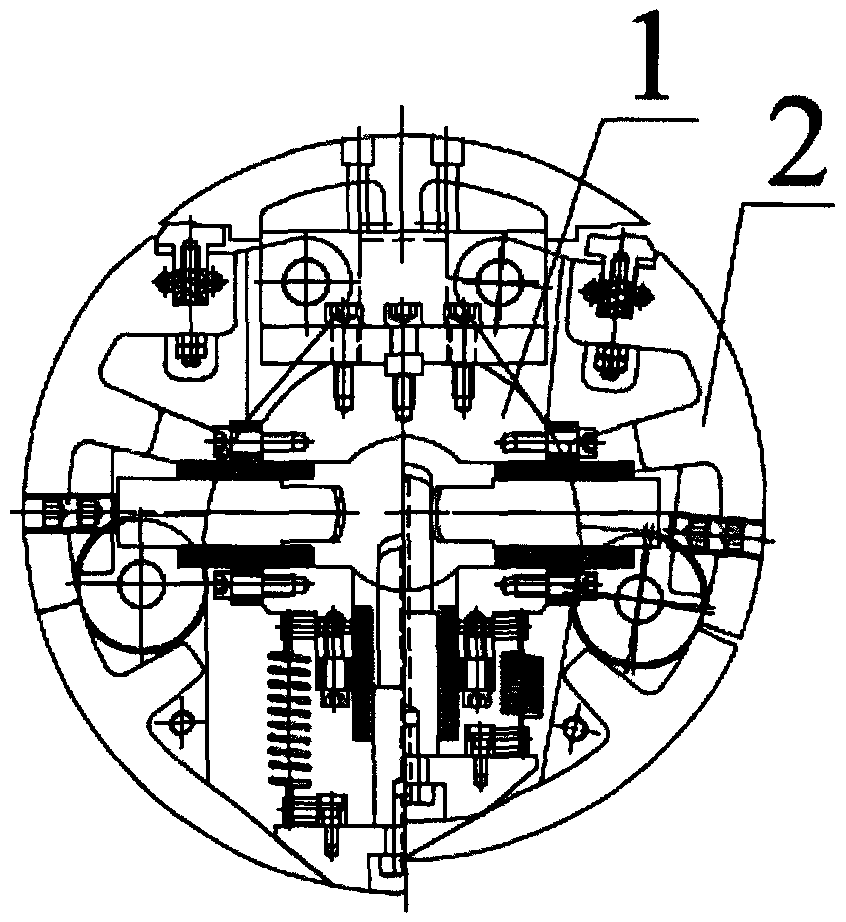

Expansion/shrinkage mechanism for steel plate winding shaft

Owner:KUNSHAN GUOZHI PRECISION MACHINERY

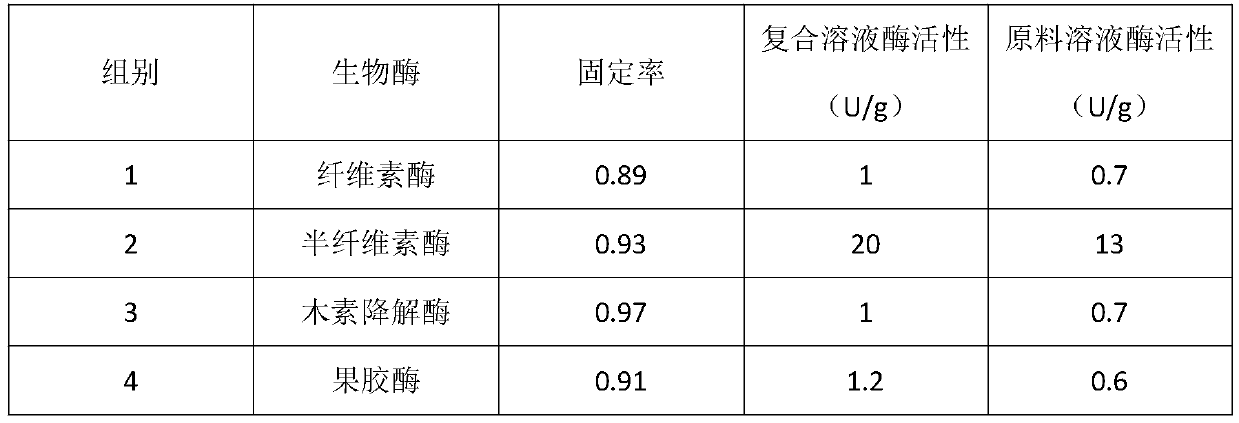

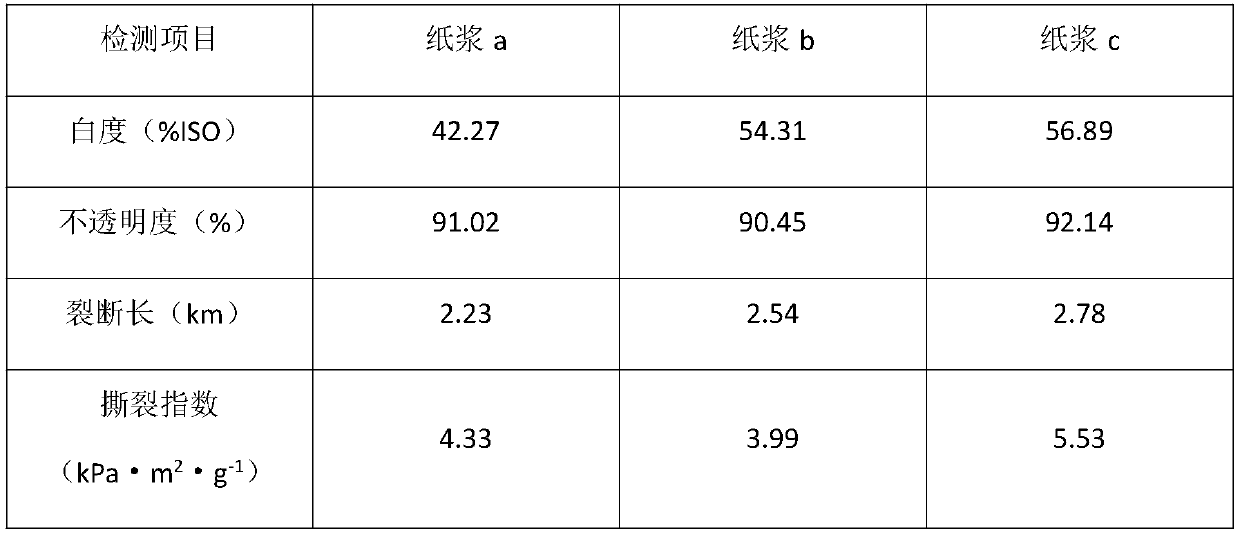

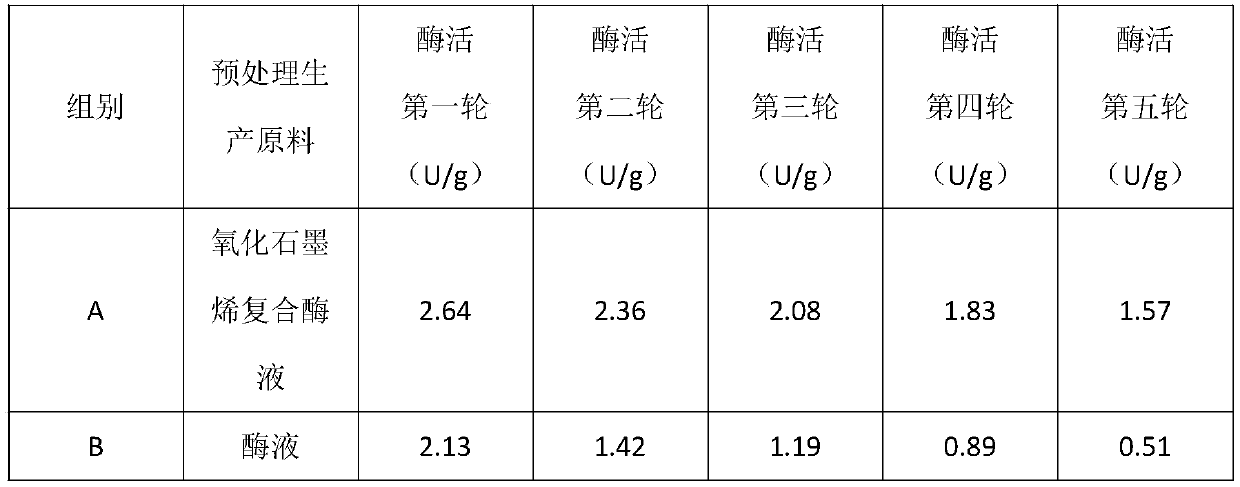

Compound enzyme for preparing pulp, and preparation method and use method of compound enzyme

ActiveCN109881520AEffectively fixedHigh activityPaper material treatmentPectinaseBiocompatibility Testing

The invention provides a compound enzyme for preparing pulp. The compound enzyme comprises an enzyme carrier and a bio-enzyme, the enzyme carrier is graphene oxide, the bio-enzyme is one or more of cellulase, hemicellulase, ligninase and pectinase, and the bio-enzyme is fixed to the enzyme carrier in an adhering mode. By adopting a method, the bio-enzyme can be effectively fixed to the graphene oxide carrier, the high-proportion surface area and good biocompatibility of the graphene oxide are fully utilized, functional groups rich on the surface of the graphene oxide also have the acidic chemical property, and the action of neutralizing alkaline ions in a solution can be achieved, so that the pH value of the local part around the graphene oxide is decreased, thus the bio-enzyme adhering to the surface of the graphene oxide exerts activity advantageously, the bio-enzyme is fixed by the graphene oxide, most of the bio-enzyme remains in a liquid environment so as to be secondarily utilized, the utilization efficiency of the bio-enzyme is improved, and production waste is reduced.

Owner:秾源科技(北京)有限公司

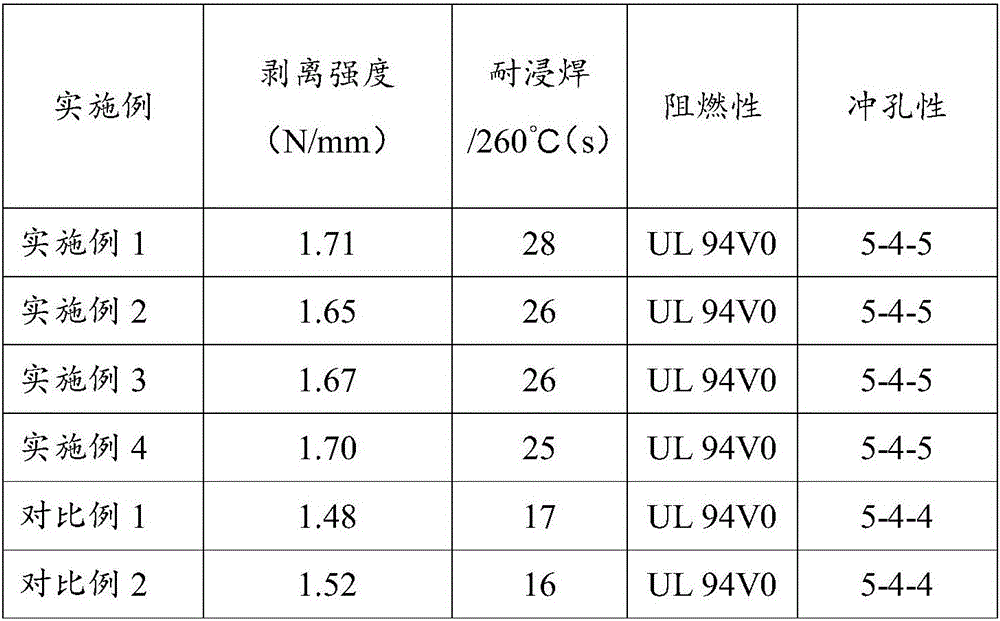

Glue liquor for flame-retardant paper-based copper-clad laminate, flame-retardant paper-based copper-clad laminate and preparation methods of glue liquor and flame-retardant paper-based copper-clad laminate

ActiveCN106433018AImprove performanceWide range of usesPaper/cardboard layered productsMetal layered productsSolventAlkaline catalyst

The invention provides glue liquor for a flame-retardant paper-based copper-clad laminate, the flame-retardant paper-based copper-clad laminate and preparation methods of the glue liquor and the flame-retardant paper-based copper-clad laminate. The glue liquor for the flame-retardant paper-based copper-clad laminate is prepared from, by weight, epoxidized soybean oil-modified phenolic resin, epoxy resin, a flame retardant and an organic solvent, wherein the epoxidized soybean oil-modified phenolic resin is prepared from, by weight, 1,200-1,600 parts of epoxidized soybean oil, 500-700 parts of phenol, 1,000-1,300 parts of bisphenol A, 5-10 parts of 2-methylimidazole, 800-1,200 parts of formaldehyde, 60-150 parts of a basic catalyst, 2,500-3,000 parts of a solvent, 5-60 parts of graphene and 5-40 parts of graphene oxide. The copper-clad laminate is simple in preparation process, capable of saving energy and low in cost and has the good punching property, soldering resistance, flame retardance and processability.

Owner:抚州市龙兴电子材料有限公司

Method for preparing food-grade xylo-oligosaccharide through viscose squeezed alkali liquid

The invention discloses a method for preparing a food-grade xylo-oligosaccharide through viscose squeezed liquid. The method is characterized by comprising the following specific operation steps: A, filtering squeezed liquid from viscose production through a membrane, taking a concentrated solution and adding hydrochloric acid into the concentrated solution for neutralizing so as to obtain a xylan solution; B, carrying out enzymatic hydrolysis on the xylan solution and compound enzymes so as to obtain an enzymatic hydrolysate and residues of enzymatic hydrolysis, adding water for diluting residues of enzymatic hydrolysis, preheating and carrying out centrifugal separation, taking supernatant namely the xylan solution and obtaining a secondary enzymatic hydrolysate under the effects of compound enzymes; C, mixing the enzymatic hydrolysates obtained in the step B, enabling the mixed solution to enter a nanofiltration membrane for desalting, carrying out activated carbon decoloration on the obtained concentrated solution, carrying out resin ion exchange so as to obtain purification liquid of xylo-oligosaccharide, evaporating and drying so as to obtain the food-grade xylo-oligosaccharide. The utilization ratio of xylan is high, production waste is reduced and the production cost is reduced.

Owner:YIBIN YATAI BIOTECH

New sealing method of acid-proof flame-proof battery casing

InactiveCN101096127AHigh strengthCorrosion resistance is not lowCell component detailsHeat sealerHeating time

The invention relates to a new sealing method for anti-acid flameproof battery shell. Battery upper cover and groove made of ABS plastic and AS plastic are sealed in thermal melting. At first, electric heating formwork corresponding to battery structure is manufactured and installed on the thermal sealing machine. Then half-finished battery with sealing shell is set on the thermal sealing machine and electric heating plate inserts between the battery upper cover and the battery groove. The sealing position is heated. Heating temperature is controlled in 270deg.C-280deg.C and heating time is in 6-13 seconds. Finally the electric heating plate is drawn out. The battery upper cover and the battery groove are pressed to the proper position so as to accomplish sealing. The invention is used for sealing of battery shell and makes two different plastic melted thermally and bonded. The invention is provided with high producing efficiency and good sealing quality. The invention is favor of circumstance protection.

Owner:JIANGSU SHUANGDENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com