Monitoring device and monitoring method of photoresist surplus, and chip manufacturing device

A monitoring device and photoresist technology are applied in the field of chip manufacturing devices and monitoring devices for the remaining amount of photoresist, which can solve the problem that the remaining amount of photoresist cannot be monitored.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the application will be described in detail below with reference to the accompanying drawings, but the application can be implemented in many different ways defined and covered by the claims.

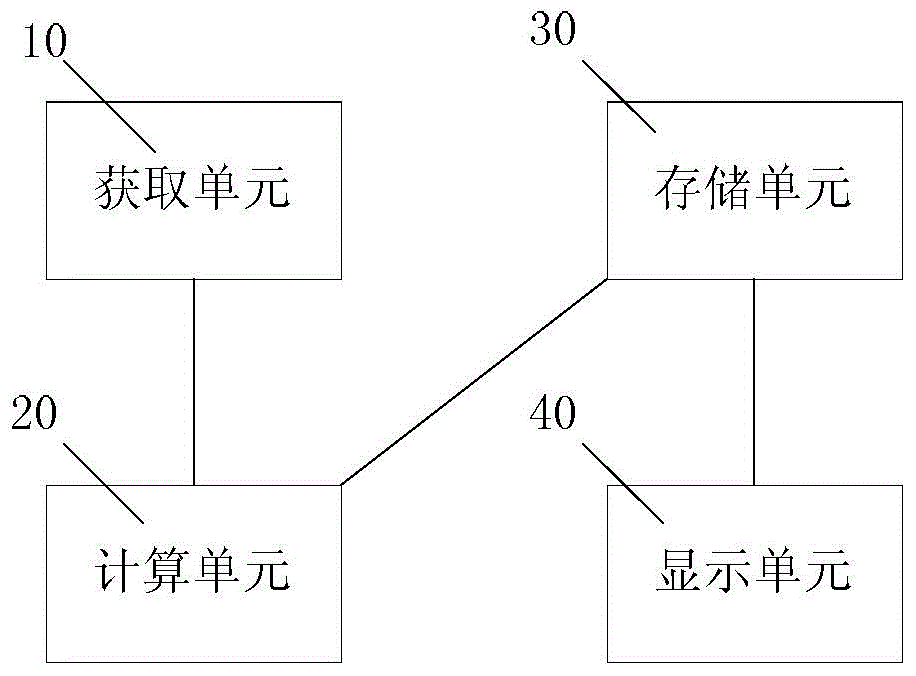

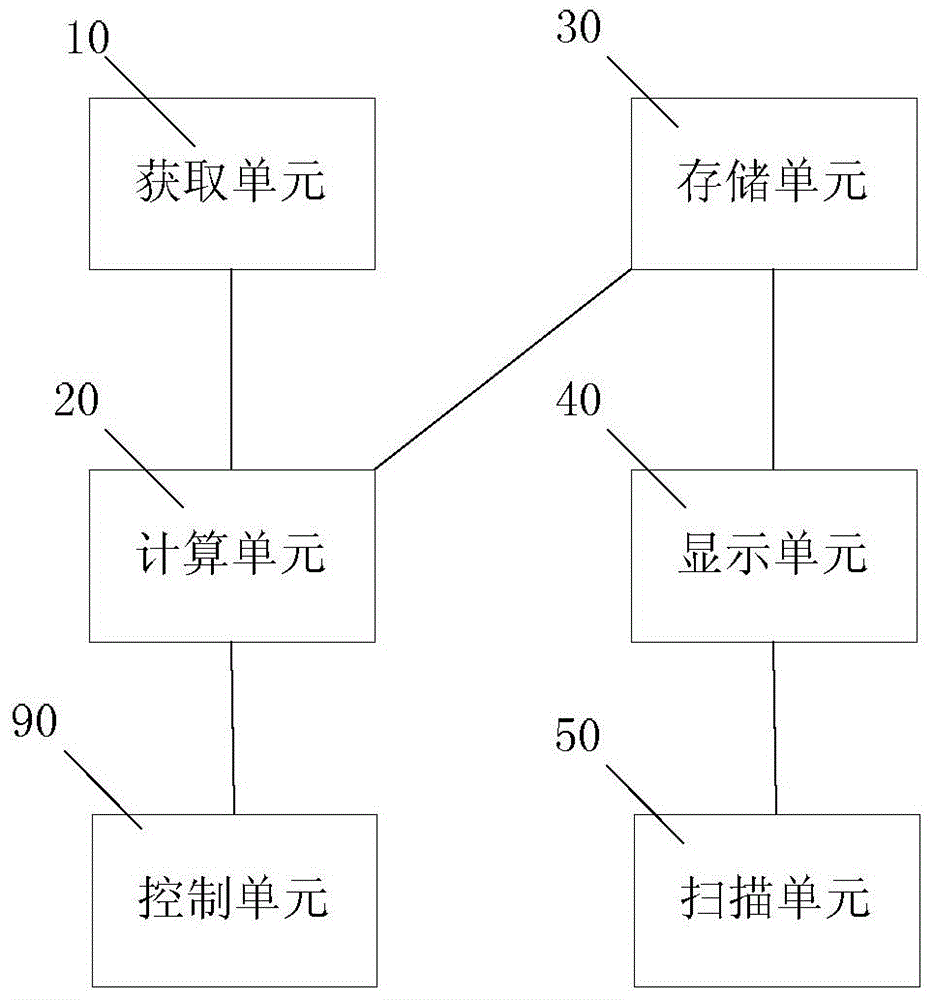

[0034] In order to solve the problem that the remaining amount of photoresist cannot be monitored as pointed out in the background art, a device for monitoring the remaining amount of photoresist is proposed in this application. like figure 1 As shown, the monitoring device includes: an acquisition unit 10, to acquire the shipment quantity of various types of products; a calculation unit 20, connected to the acquisition unit 10, to obtain the quantity according to the shipment quantity of various types of products and the usage of various types of products The unit product photoresist dosage of photoresist and the photoresist initial quantity of every kind of photoresist determine the photoresist residual quantity of every kind of photoresist; Storage unit 30 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com