Glue liquor for flame-retardant paper-based copper-clad laminate, flame-retardant paper-based copper-clad laminate and preparation methods of glue liquor and flame-retardant paper-based copper-clad laminate

A copper clad laminate and flame retardant technology, which is applied in the field of copper clad laminate production, can solve the problems such as the inability to meet the heat resistance and thermal stability of printed circuit copper clad laminates, poor flame retardant performance, and poor heat resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

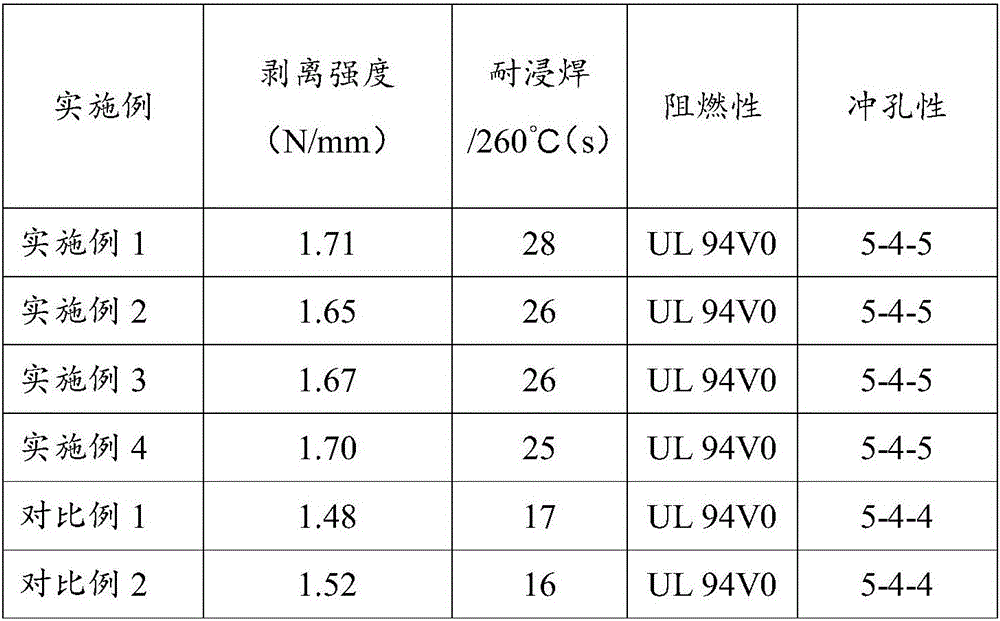

Examples

Embodiment 1

[0061] An embodiment of the present invention provides a method for manufacturing a flame-retardant paper-based copper-clad laminate, including the following steps:

[0062] (1) Get the raw material of the described epoxidized soybean oil modified phenolic resin of following parts by weight: 1400 parts of epoxidized soybean oil, 565 parts of phenol, 1100 parts of bisphenol A, 8 parts of 2-methylimidazoles, 945 parts of formaldehyde , 80 parts of triethylamine, 27 parts of ammonia water, 2800 parts of methanol, 30 parts of graphene, 25 parts of graphene oxide;

[0063] Add epoxidized soybean oil, phenol, and bisphenol A to the reaction kettle in turn, stir for 10 minutes to mix, then add 2-methylimidazole, and react at 180°C for 5 hours. After the temperature in the reaction kettle is naturally cooled to 165°C, Slowly enter water and cool to 85°C, add formaldehyde and stir for 10 minutes, then add triethylamine and ammonia water, and react at 100°C for 60 minutes, take samples ...

Embodiment 2

[0068] An embodiment of the present invention provides a method for manufacturing a flame-retardant paper-based copper-clad laminate, including the following steps:

[0069] (1) Get the raw material of the described epoxidized soybean oil modified phenolic resin of following parts by weight: 1200 parts of epoxidized soybean oil, 500 parts of phenol, 1000 parts of bisphenol A, 5 parts of 2-methylimidazoles, 800 parts of formaldehyde , 90 parts of triethylamine, 45 parts of ammonia water, 2500 parts of methanol, 25 parts of graphene, and 20 parts of graphene oxide;

[0070] Add epoxidized soybean oil, phenol, and bisphenol A to the reaction kettle in turn, stir for 10 minutes to mix, then add 2-methylimidazole, and react at 180°C for 6 hours. After the temperature in the reaction kettle is naturally cooled to 165°C, Slowly enter water and cool to 85°C, add formaldehyde and stir for 10 minutes, then add triethylamine and ammonia water, and react at 105°C for 45 minutes, then take...

Embodiment 3

[0074] An embodiment of the present invention provides a method for manufacturing a flame-retardant paper-based copper-clad laminate, including the following steps:

[0075] (1) Get the raw material of the described epoxidized soybean oil modified phenolic resin of following parts by weight: 1450 parts of epoxidized soybean oil, 700 parts of phenol, 1100 parts of bisphenol A, 8 parts of 2-methylimidazoles, 1200 parts of formaldehyde , 70 parts of triethylamine, 30 parts of ammonia water, 2800 parts of methanol, 35 parts of graphene, 22 parts of graphene oxide;

[0076] Add epoxidized soybean oil, phenol, and bisphenol A to the reaction kettle in turn, stir for 10 minutes to mix, then add 2-methylimidazole, and react at 150°C for 6 hours. After the temperature in the reaction kettle is naturally cooled to 165°C, Slowly enter water to cool to 85°C, add formaldehyde and stir for 10 minutes, then add triethylamine and ammonia water, and react at 95°C for 60 minutes, take samples to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com