Method and device for preparing regenerated sponges by polyurethane sponge wastes

A technology of polyurethane sponge and waste, which is applied in the field of polyurethane sponge waste prepared into regenerated sponge and devices, which can solve the problems of no treatment method, difficulty in reusing waste, and waste manpower and financial resources for sponge waste treatment, so as to reduce Production waste, energy saving, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This polyurethane sponge waste is prepared into the regenerated sponge method, it is characterized in that the preparation steps are as follows:

[0021] 1) The polyurethane sponge waste is crushed by a crushing machine into small particle sponge waste with a particle diameter of 1-20mm.

[0022] 2) Measure the small particle sponge waste in batches.

[0023] 3) Add glue batch by batch and mix evenly. The amount of glue added is 5-20% of the sponge waste by weight.

[0024] 4) Apply pressure and bond to form a recycled polyurethane sponge block.

Embodiment 2

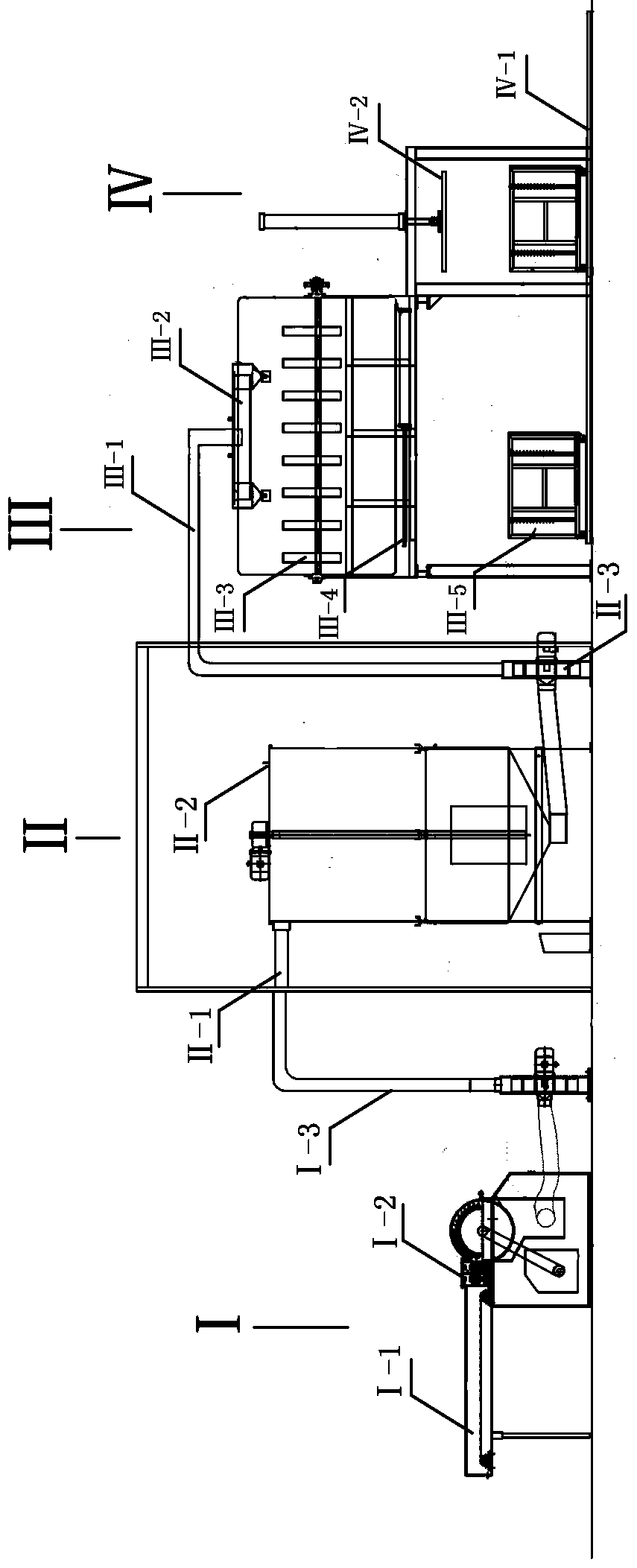

[0026] see figure 1 , the polyurethane sponge waste is prepared into a regenerated sponge device, which is used for the above method to prepare a regenerated sponge, and is characterized in that it includes the following process equipment:

[0027] 1) Polyurethane sponge crushing process equipment (I): a crushing machine (I-2) with conveying and unloading equipment (I-1) and a powerful discharge device A (I-3) to realize the crushing of polyurethane sponge waste into granules Small particle sponge waste with a diameter of 1~20mm.

[0028] 2) Batch metering process equipment (II): intermittent storage batch metering device (II-2) with small particle sponge waste feed pipe (II-1) and powerful discharge equipment B (II-3). Realize intermittent storage and metering of small particle sponge waste in batches.

[0029] 3) Adding glue batch by batch and mixing process equipment (III): Stirring device (III-3) with upper feeding pipe (III-1) and glue adding mechanism (III-2), and a sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com