Panel receiving equipment

A technology of plates and equipment, which is applied in the field of forming and cutting steel doors and leaves, can solve the problems of uneven stacking of plates, low production efficiency, and low transfer efficiency, and achieve the effects of ensuring product quality, saving production, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

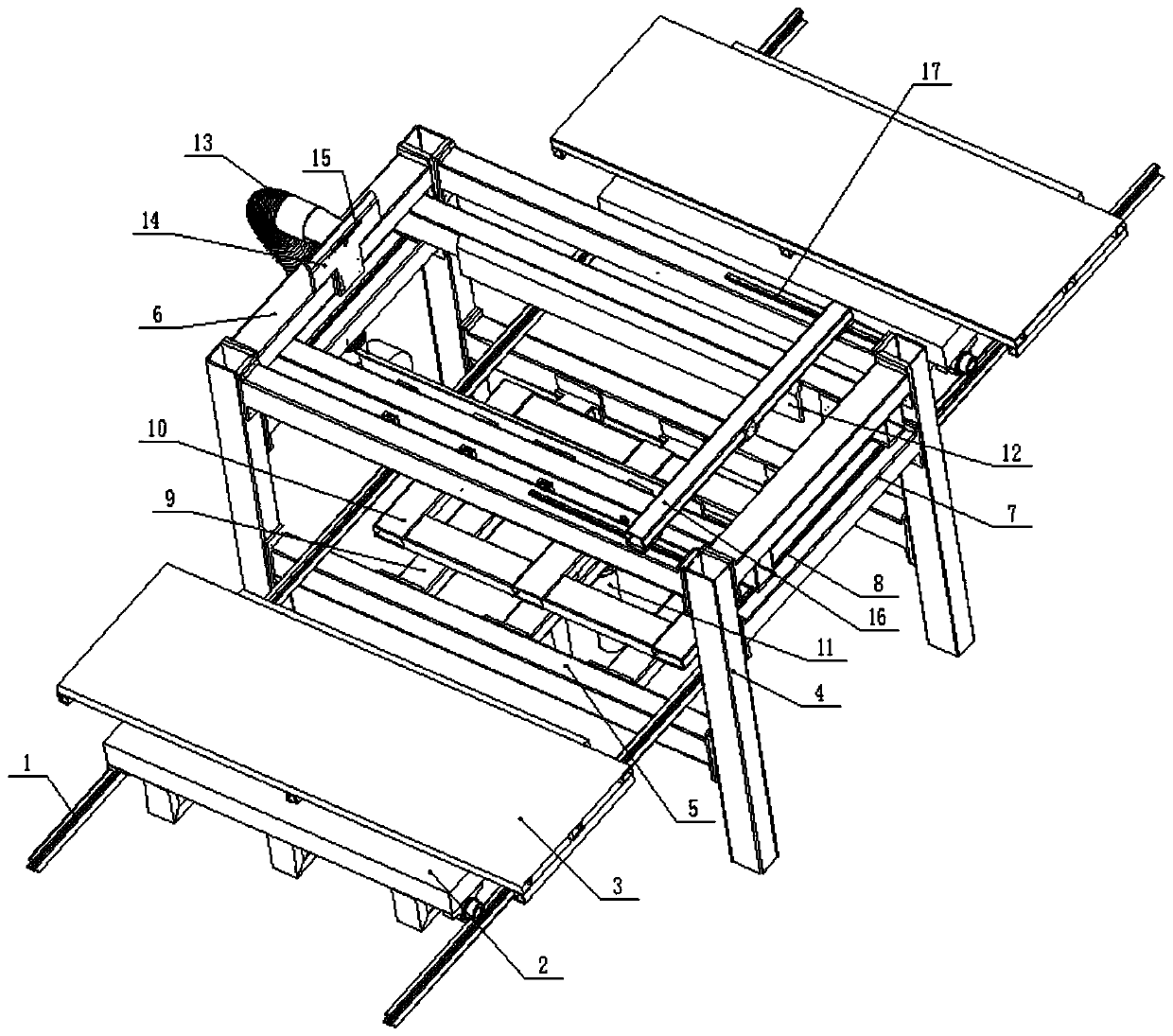

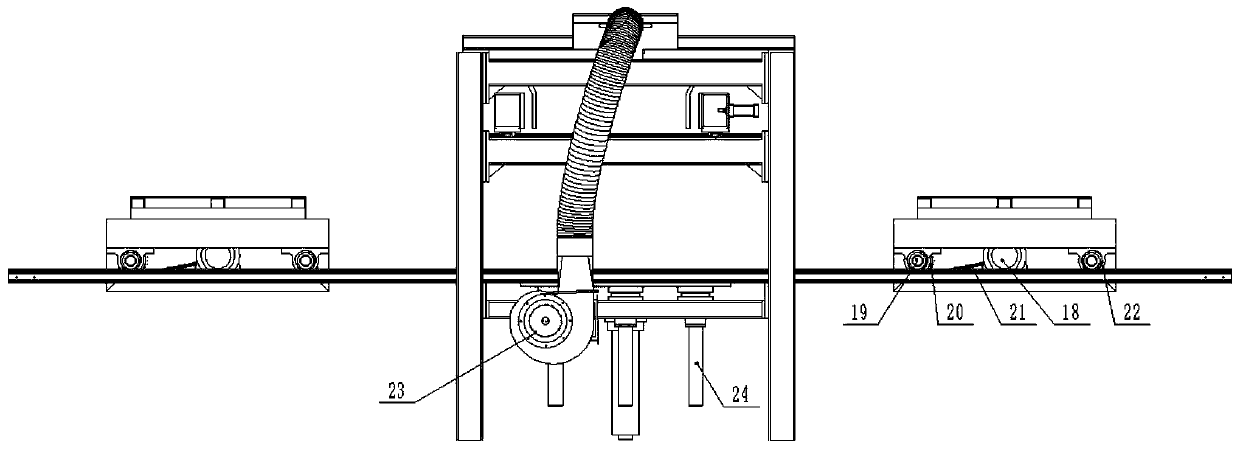

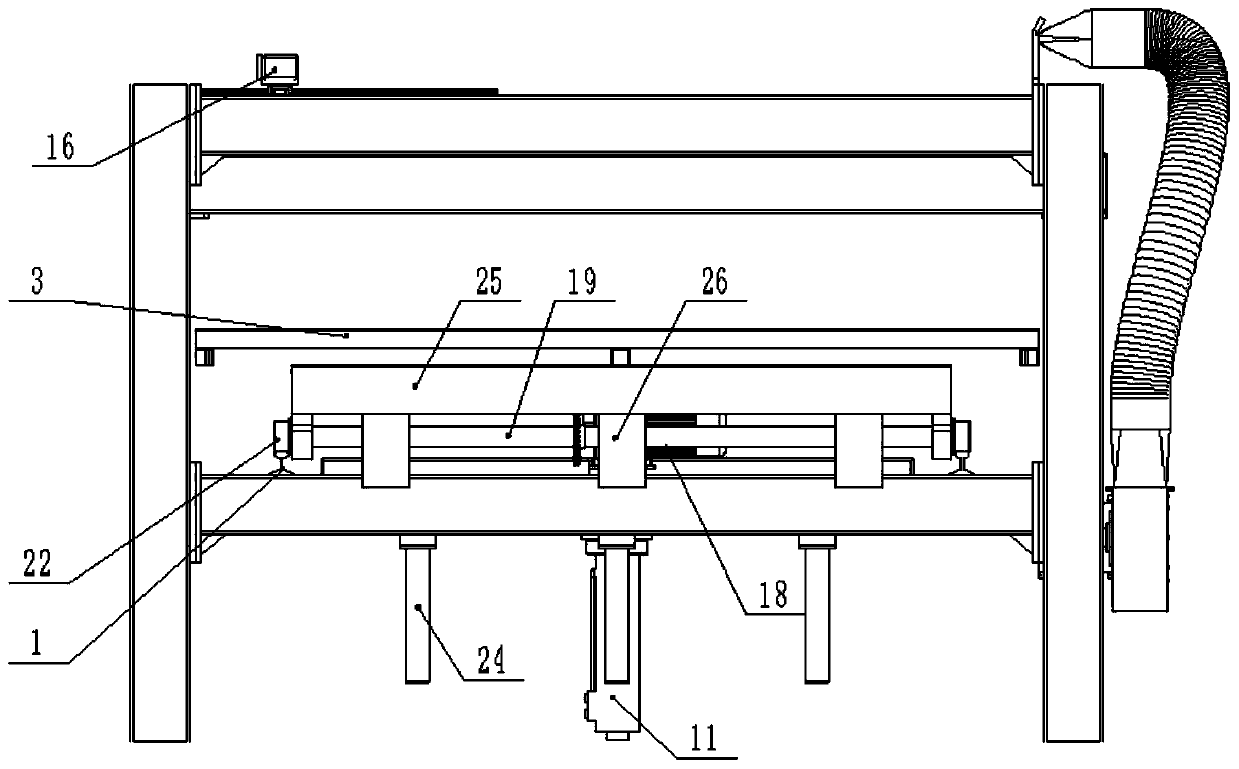

[0031] like figure 1 Shown, a kind of sheet material receiving equipment comprises material receiving frame, moving track 1, receiving car 2, material receiving tray 3, support frame 10 and power unit, and described moving track 1 is installed on the inside of receiving frame Below, the material receiving vehicle 2 is slidingly installed on the moving track 1, the material receiving tray 3 is installed on the material receiving vehicle 2, and the lifting frame is installed directly below the material receiving frame, which is used to control the power device for lifting or falling the lifting frame It is installed below the lifting frame. In this embodiment, the power device is a lifting cylinder 11 . The inside of the material receiving frame is provided with a material receiving cavity that runs through from top to bottom. The material receiving vehicle 2 and the material receiving tray 3 move up and down in the material receiving cavity under the drive of the support frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com