Expansion/shrinkage mechanism for steel plate winding shaft

A technology of expansion and contraction mechanism and steel plate coil, which is applied in the field of expansion and contraction mechanism, which can solve the problems of steel coil inner diameter deformation damage, indentation, inflexible taper blocks and grooves, etc., so as to improve the yield rate and reduce production waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

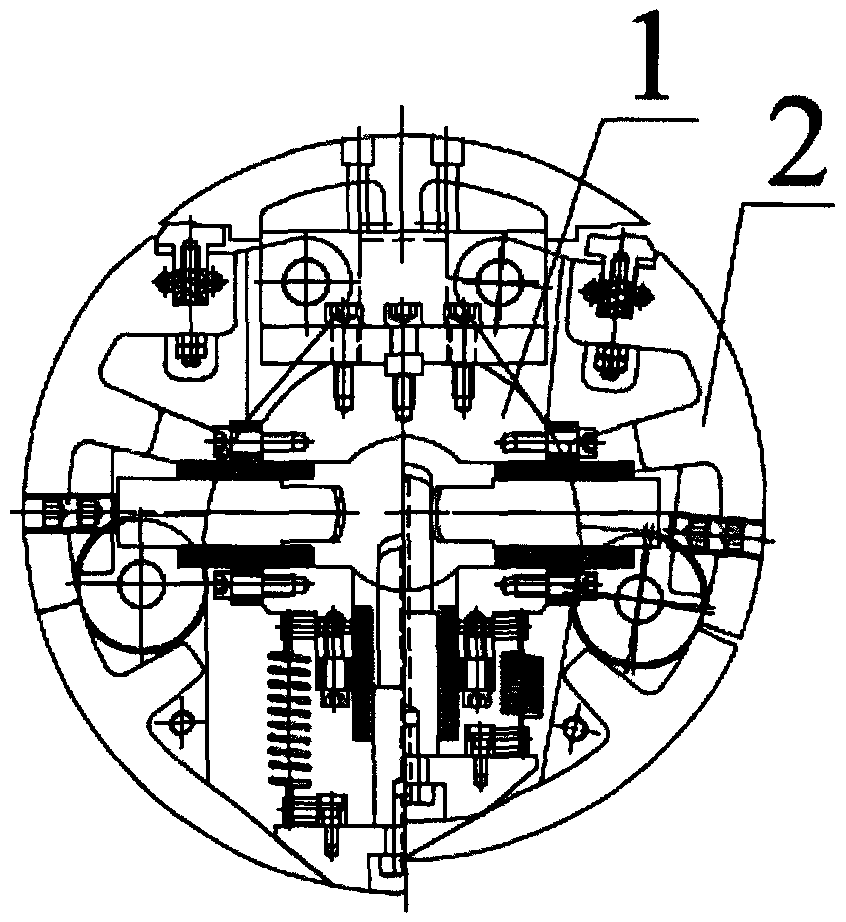

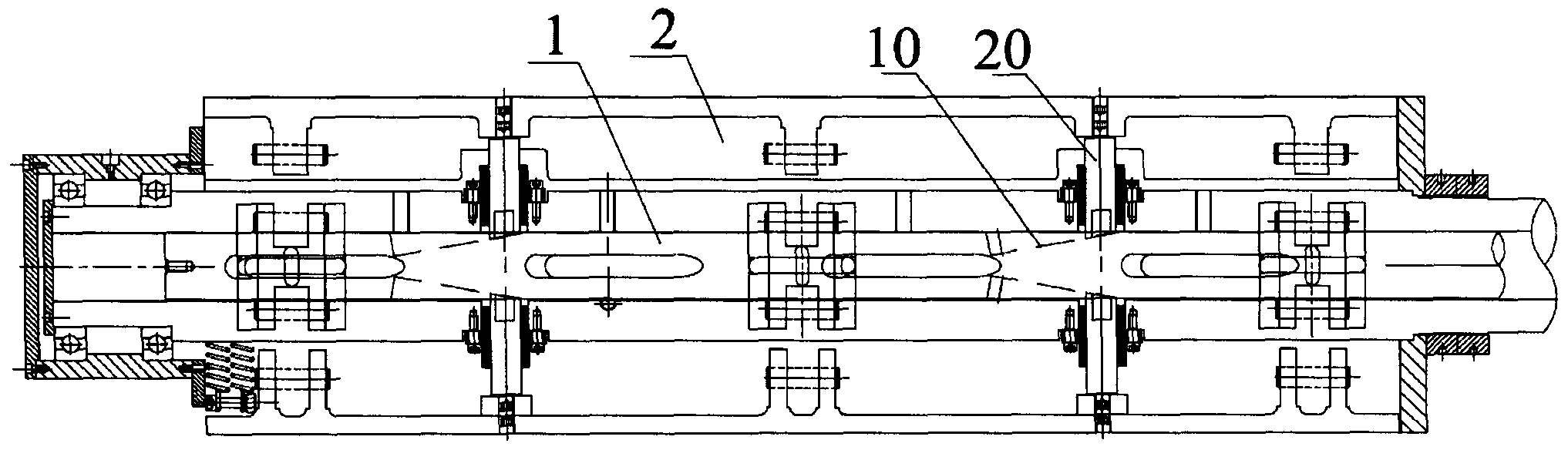

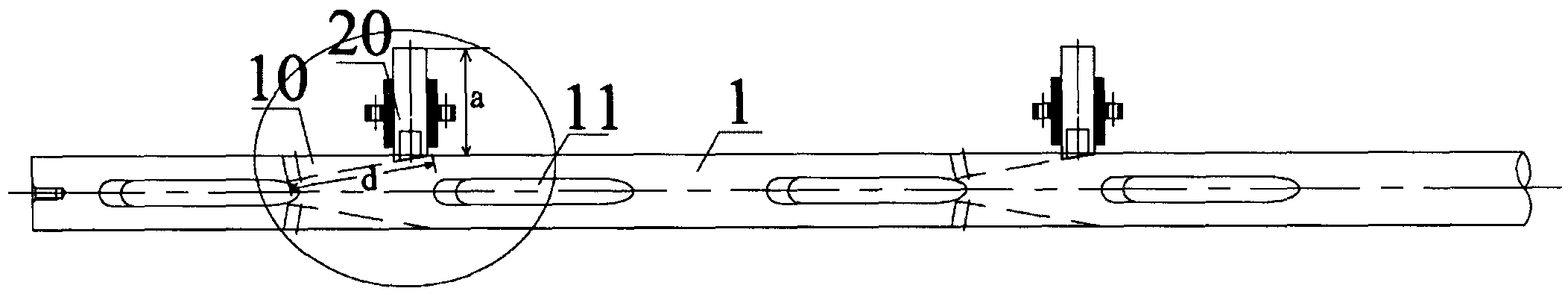

[0019] see Figure 1 to Figure 5 , Embodiment 1 of the present invention: an expansion and contraction mechanism for a steel plate coiling shaft, the steel plate coiling shaft is a long cylindrical structure composed of four blades 2, and the expansion and contraction mechanism includes an expansion and contraction main shaft 1 and a plurality of expansion and contraction oblique tips 20, the expansion and contraction main shaft 1 is arranged at the central position of the cylindrical mechanism, and a plurality of expansion and contraction oblique tips 20 are arranged on four blades 2 in equal quantity; on the expansion and contraction main shaft 1 A groove 10 is provided at a position corresponding to each expansion-contraction oblique tip bar 20 , and each expansion-contraction oblique tip bar 20 can be inserted into the corresponding groove 10 on the expansion-contraction main shaft 1 .

[0020] In this embodiment, the bottom of the groove 10 is a slope, and the bottom of t...

Embodiment 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the length of the slope at the bottom of the groove 10 of the expansion-contraction spindle 1 is 120 mm. The length of the surface of the protruding blade 2 of the expanding and shrinking oblique tip bar 20 is 200 mm.

Embodiment 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the length of the slope at the bottom of the groove 10 of the expansion-contraction spindle 1 is 120 mm. The length of the surface of the protruding blade 2 of the expanding and shrinking oblique tip bar 20 is 150mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com