Sports socks produced by virtue of bonding technology and having effect of cushioning heels and production process of sports socks

A production process and technology for sports socks, applied in the field of sports socks, can solve problems such as local thickness limitation and heel damage, and achieve the effects of reducing production waste, protecting the environment and having a long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

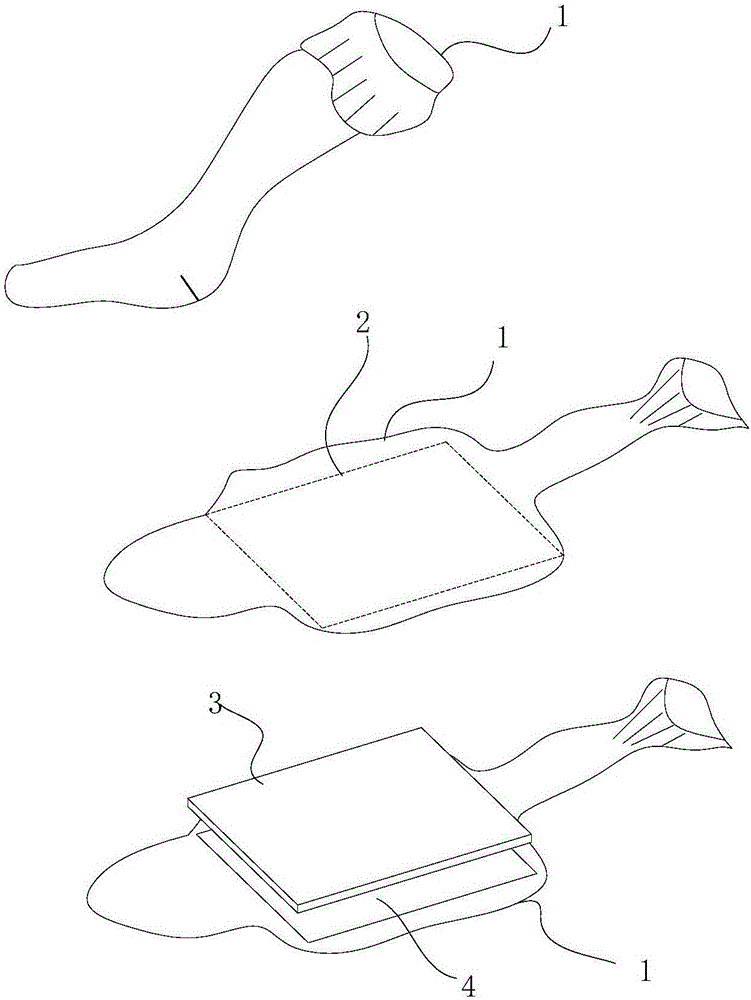

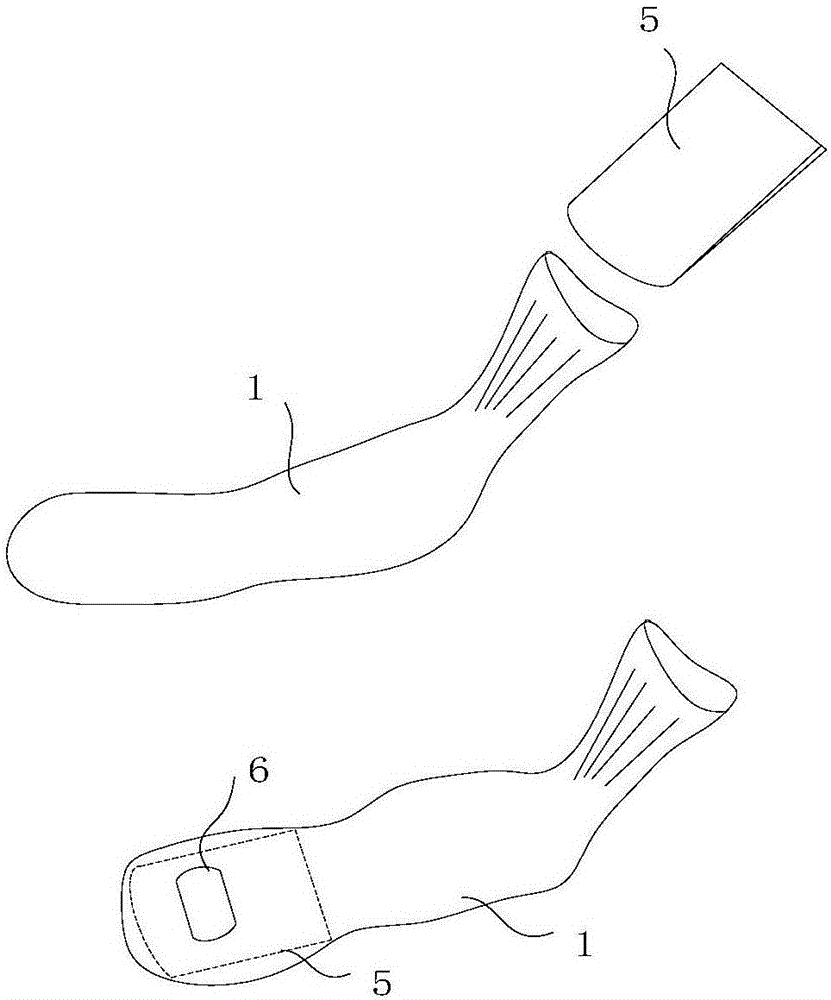

[0037] This embodiment proposes a kind of sports socks production process and sports socks with cushioning heel effect

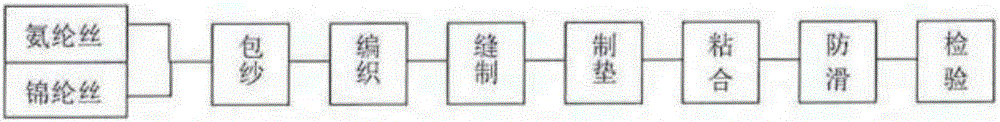

[0038] The process includes the following steps,

[0039] (1) Wrapped yarn: use spandex as the inner wrapping yarn, and nylon as the outer wrapping yarn to wrap to obtain wrapping yarn; in this embodiment, the special spandex of model 15D is selected, and the nylon of model DTY / FDY 8D is selected (other types can also be selected according to needs). model); the twist is 800T / M, the draft ratio is 3.0, and the overfeed rate is 94%.

[0040] (2) Weaving: use a cylindrical loom to weave the above-mentioned wrapped yarn with cotton yarn to obtain a stocking blank; this embodiment uses a cotton yarn with a model number of 100s.

[0041] (3) Sewing: Sew the toe part of the sock to facilitate subsequent dyeing.

[0042] (4) Mat making: the heel pad in the present embodiment includes a sponge inner pad and a cloth coat covered in the inner pad. In this embodiment...

Embodiment 2

[0053] This embodiment proposes a kind of sports socks production process with buffer heel effect,

[0054] The process includes the following steps,

[0055] (1) Wrapped yarn: use spandex as the inner wrapping yarn and polyester as the outer wrapping yarn to wrap to obtain wrapping yarn; this embodiment selects the special spandex of model 20D, the draft ratio is 3.0, the twist is 800T / M, and the overfeed is 94 %.

[0056] (2) Weaving: use a cylinder loom to weave the above-mentioned wrapped yarn and cotton yarn to obtain a stocking blank; this embodiment uses a blended yarn with a model number of 20s.

[0057] (3) Sewing: Sew the toe part of the sock to facilitate subsequent dyeing.

[0058] (4) Mat making: the heel pad in the present embodiment includes a slow-rebound inner pad and a cloth overcoat covered in the inner pad. In the present embodiment, the cloth is elastic cloth, which contains bamboo fiber material, and the slow-rebound material has anti- Bacteria, anti-m...

Embodiment 3

[0069] This embodiment proposes a kind of sports socks production process with buffer heel effect,

[0070] The process includes the following steps,

[0071] Wrapped yarn: use spandex as the inner wrapping yarn, and nylon as the outer wrapping yarn to wrap to obtain wrapping yarn; this embodiment selects the special spandex of model 60D, and selects the nylon of model DTY / FDY 70D (other models can also be selected according to needs) ); the twist is 800T / M, and the overfeed is 94%.

[0072] (2) Weaving: use a cylindrical loom to weave the above-mentioned wrapping yarn with cotton yarn to obtain a stocking blank; this embodiment selects cotton yarn with a model number of 80s.

[0073] (3) Sewing: Sew the toe part of the sock to facilitate subsequent dyeing.

[0074] (4) Mat making: the heel pad in this embodiment includes a resin gel inner pad and a cloth coat covering the inner pad, and the material of the cloth coat in this embodiment is bamboo fiber. The resin gel in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com