Novel electric screen cabinet prewiring method for wind turbine generator

A wind turbine, pre-wiring technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., to achieve the effect of advanced operation, optimized design, and improved change efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

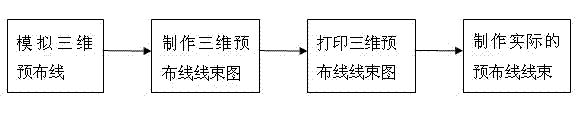

[0025] The present invention is a new pre-wiring method for the electric screen cabinet of a wind turbine. The schematic diagram of the electric screen cabinet, the layout diagram of the electric screen cabinet and the modeling of all components in the electric screen cabinet are drawn by computer software, and the computer is used according to the electrical schematic diagram. The software simulates the three-dimensional pre-wiring of the electrical screen cabinet; produces the required pre-wiring harness diagram; then prints the three-dimensional pre-wiring harness diagram; finally makes the actual pre-wiring harness and completes the production of pre-wiring, which is used to guide workers' operations, such as figure 1 shown. The specific steps are as follows:

[0026] (1) According to the design drawings or documents of the electrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com