High-speed carton identification device

A marking device and high-speed technology, applied in the field of mechanical equipment, can solve problems such as poor recognition, low production efficiency, and unintelligent mechanical operation, and achieve the effects of convenient operation, simple structure, and high market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

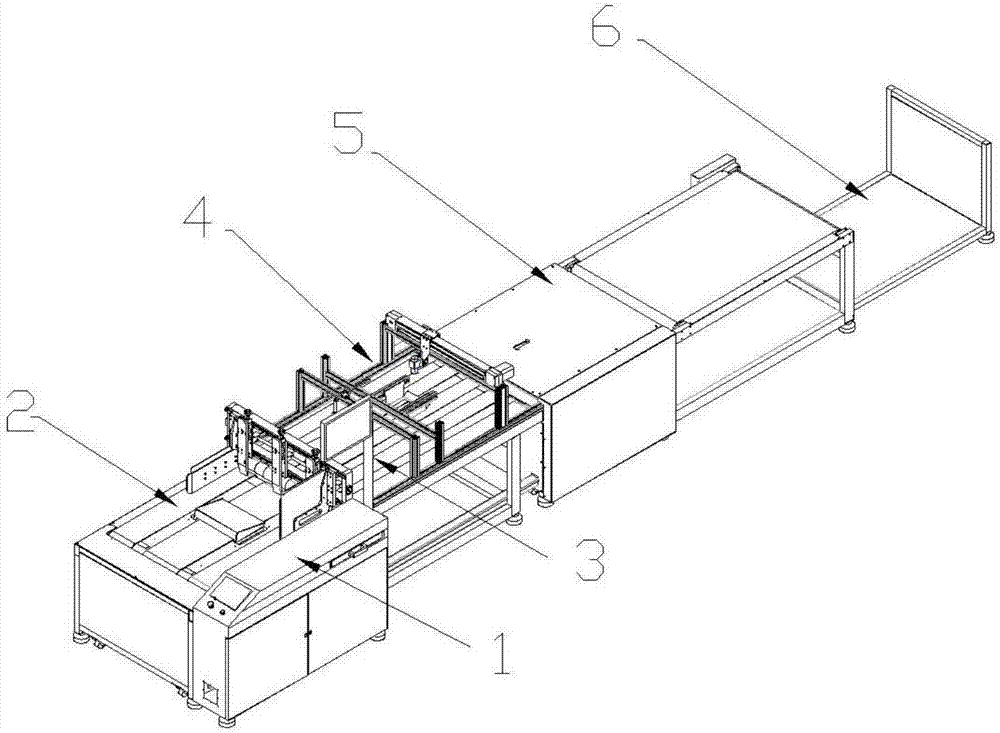

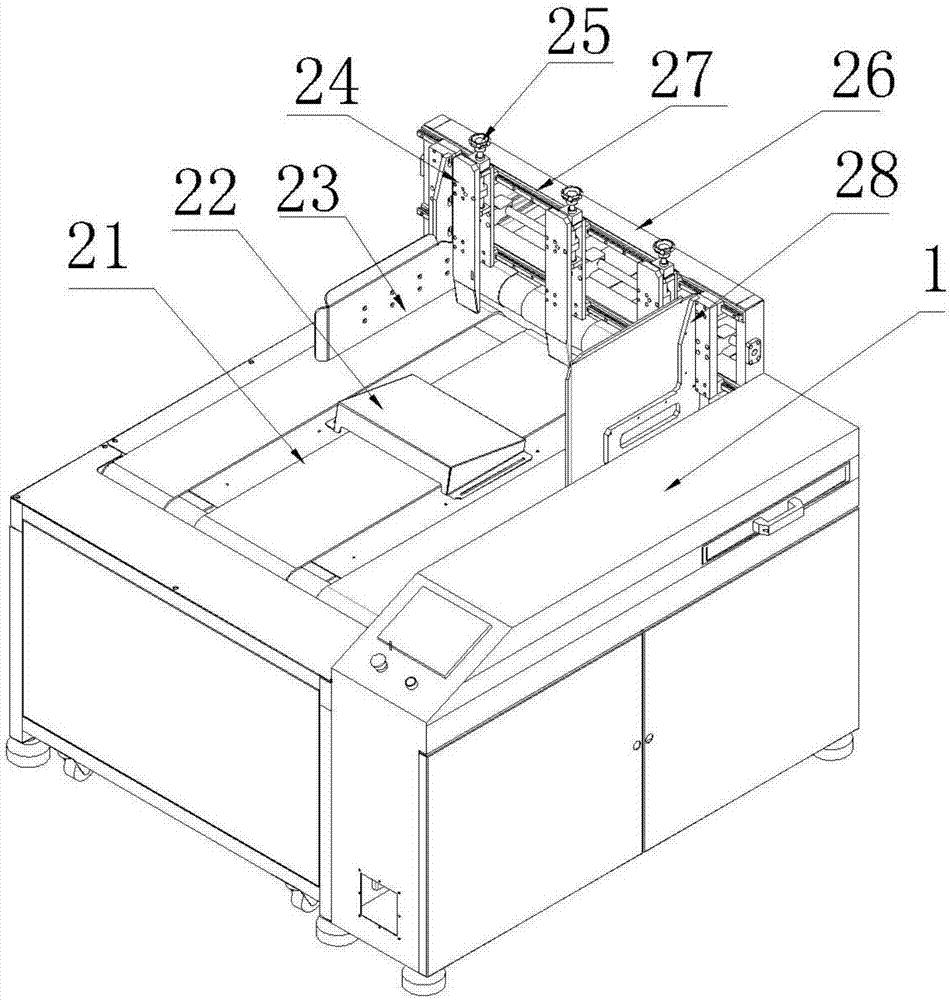

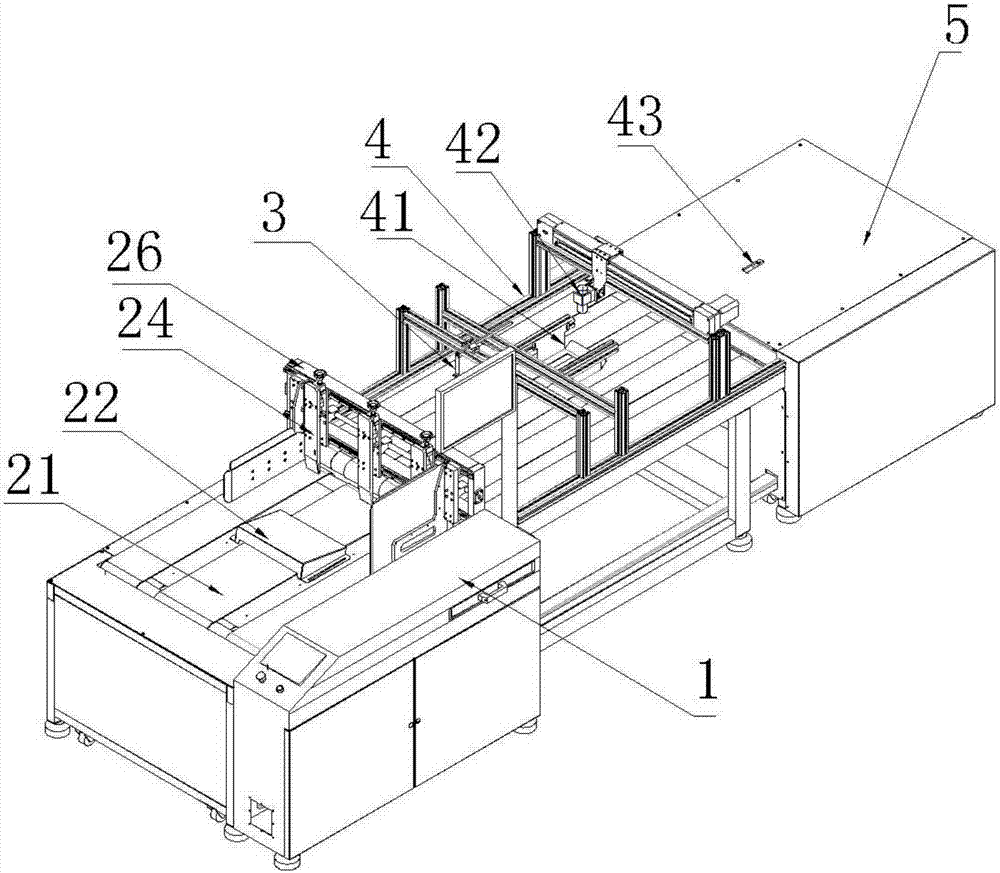

[0033] Embodiment 1 discloses a carton high-speed marking device, such as figure 1 and image 3 As shown, it includes control box 1, paging device 2, coding device 3, detection device 4, rejecting device 5 and receiving device 6, paging device 2 is located at the head end of carton high-speed marking device, and coding device 3 is located at paging device 2 In the middle of the detection device 4, the receiving device 6 is located at the tail end of the carton high-speed marking device, and the material transmission is carried out between each device through the conveyor belt; the rejecting device 5 is located between the detection device 4 and the receiving device 6, for better application For a variety of large, medium and small packaging carton sizes, such as figure 2As shown, the control box 1 is fixedly installed on the side of the sorting device 2, and the sorting device 2 includes a sorting conveyor belt 21, a support plate 22, a left sorting baffle 23, a right sortin...

Embodiment 2

[0038] Embodiment 2 discloses that Embodiment 1 discloses a carton high-speed marking device, including a control box 1, a paging device 2, a coding device 3, a detection device 4, a rejecting device 5, and a receiving device 6. The paging device 2 is located at the carton high-speed At the head end of the marking device, the coding device 3 is located in the middle of the paging device 2 and the detection device 4, and the receiving device 6 is located at the tail end of the carton high-speed marking device, and the material transmission is carried out between each device through the conveyor belt; the rejecting device 5 is located in the detection device 4 and the receiving device 6, in order to be better applicable to various sizes of large, medium and small packaging cartons, the control box 1 is fixedly installed on the side of the paging device 2, and the paging device 2 includes a paging conveyor belt 21 and a supporting plate 22 , left pagination baffle 23, right pagina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com