Method for automatically searching optical assemble path of components of products with subordinate relations

A technology for automatically finding the best path, applied in special data processing applications, instruments, and electrical digital data processing, etc., can solve problems such as lagging production plans, large randomness in production arrangements, and many uncertain factors in production schedules. The effect of eliminating overproduction, realizing quick response, and shortening the product manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

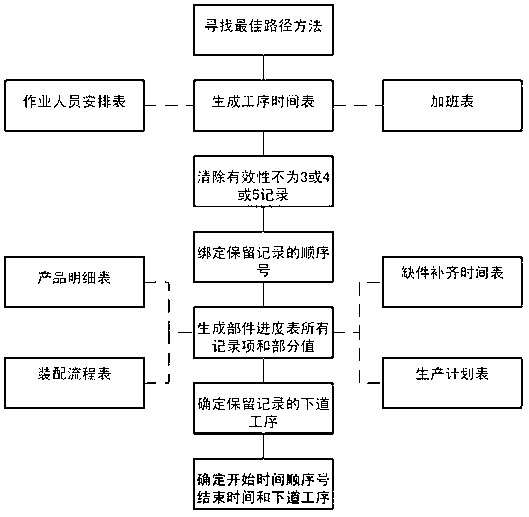

[0243] One, in figure 1 A method structure diagram for automatically finding the best path for component assembly of products with affiliation;

[0244] Enter or import product details, assembly flow charts, production schedules, missing parts supplement schedule data;

[0245] Adjust the product priority, the number of workers in each process during normal working hours and the number of workers in each process during overtime;

[0246] According to product affiliation, product assembly process, production planning time, product matching time, missing parts replenishment time, abnormal delay time, actual completion time, product priority, normal working hours, the number of workers in each process and overtime hours for each process The number of operators and other factors can automatically complete the calculation of the component schedule;

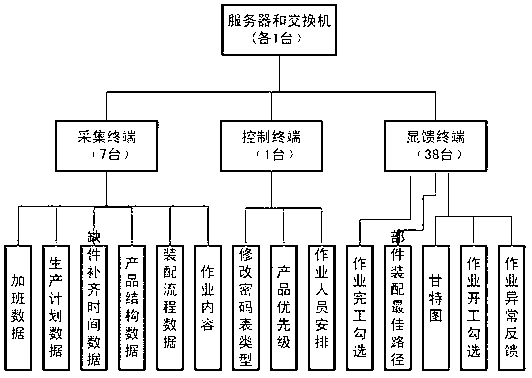

[0247] Two, in figure 2 The method of automatically finding the best path for component assembly of products with affiliation rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com